Plasma process for purifying coal-burning boiler smoke gas

A coal-fired boiler and flue gas purification technology, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high energy consumption and low removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

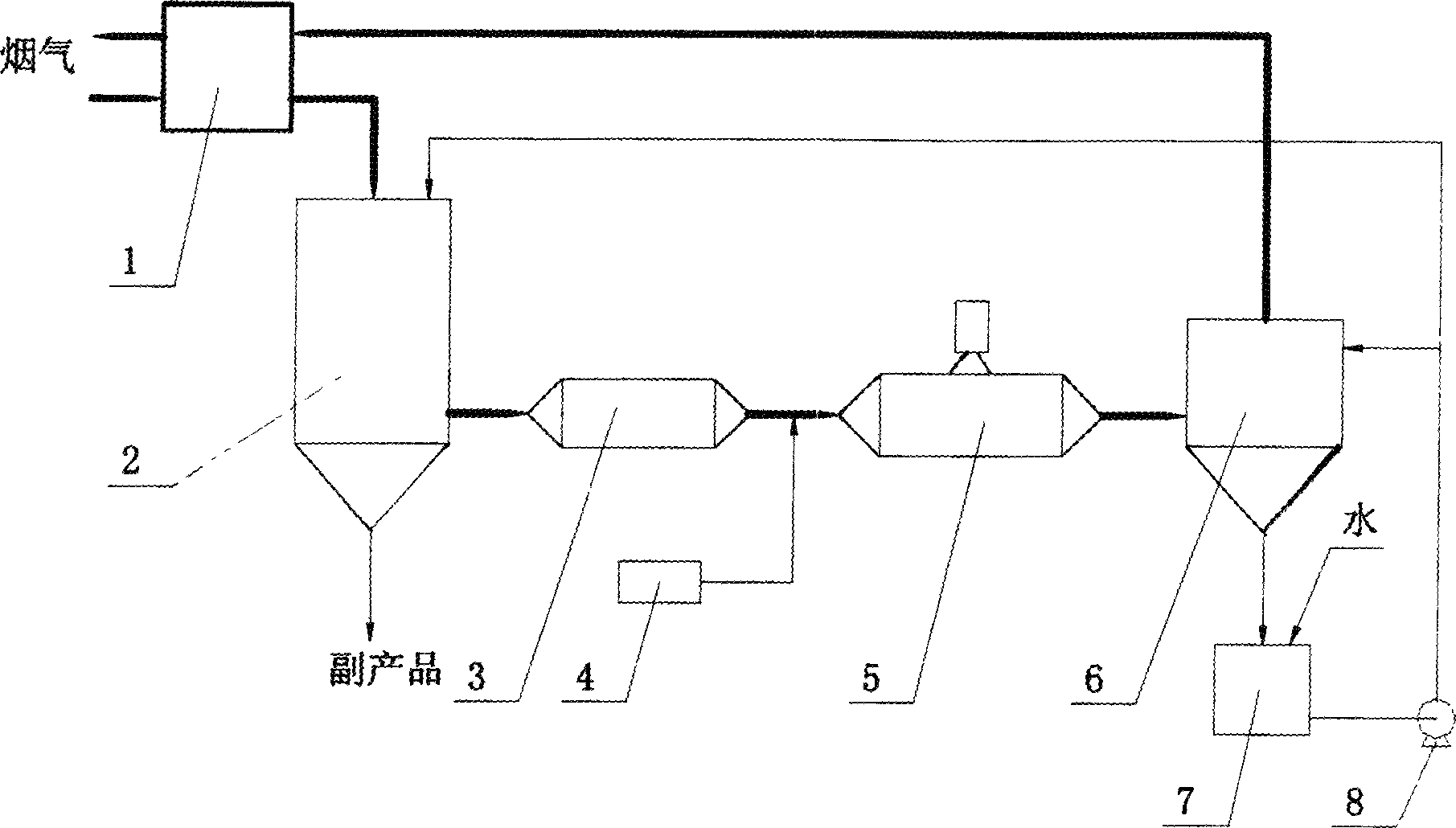

[0013] The original flue gas volume of a coal-fired boiler of a 100MW generating set is about 45×10 4 N m 3 / h, after the dust is removed by the dust collector, the temperature of the flue gas is about 150°C, containing SO 2 -2900mg / L, NO X -500mg / L, dust content≤200mg / Nm 3 , exchange heat with the purified flue gas (temperature ≥ 55°C) in the gas-gas heat exchanger (as shown in Figure 1), so that the temperature of the flue gas is reduced to 130-135°C; the flue gas from the top of the spray drying tower (2) The gas distributor enters evenly and mixes with the circulating solution rich in by-products in the subsequent process of atomization to make the flue gas humidify (9%-11%) and cool down (70°C-85°C) in the tower with a diameter of 9.5m and a height of 36m ), to meet the process requirements; at the same time, the by-products are granulated and dried, and the particles with a particle size of ≥50mm (about 70%) flow down the flow, settle in the cone of the tower, and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com