Preparation method of one-way wet conduction nano-fiber multilayer composite membrane with wettability gradient

A multi-layer composite membrane, nanofiber membrane technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problem of unidirectional water conductivity still needs to be improved, and achieve excellent unidirectional water conductivity, small diameter, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a unidirectional moisture-guiding nanofiber multilayer composite membrane with a wetting gradient, the specific steps are:

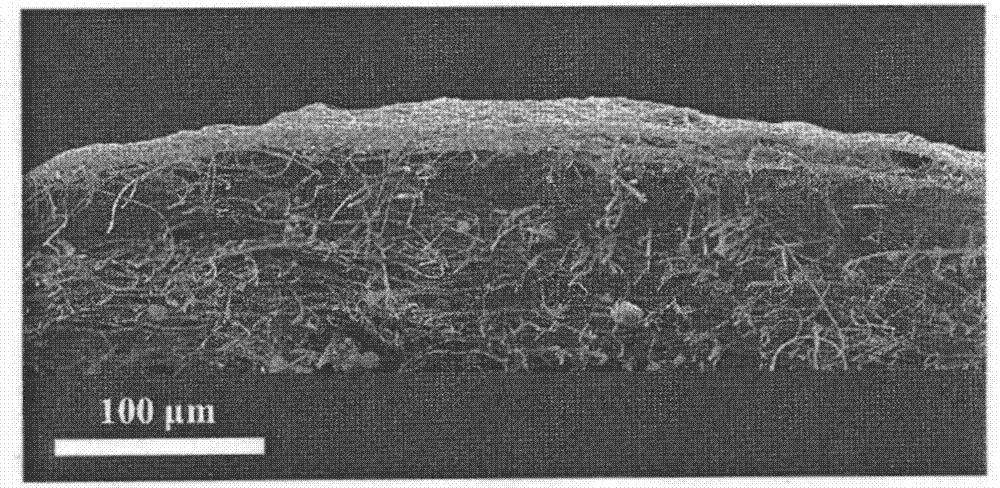

[0044] The first step: disperse the hydrophilic fumed silica nanoparticles in water, and ultrasonically disperse the nanoparticles uniformly to obtain a silica dispersion with a mass fraction of 2.5%; dissolve polyvinyl alcohol in the dispersion prepared above Prepare a polyvinyl alcohol electrospinning solution with a mass fraction of 12%, and add glutaraldehyde as a crosslinking agent. The mass fraction of glutaraldehyde in polyvinyl alcohol is 5%, and the spinning solution A1 is obtained by stirring evenly. The silk method deposits a layer of hydrophilic nanofiber film on the nonwoven fabric as the hydrophilic layer, the spinning voltage is 30kV, the receiving distance is 20em, the perfusion speed of the spinning solution is 2mL / h, the diameter of the obtained fiber is 350nm, and the obtained fiber The average pore diamet...

Embodiment 2

[0049] A method for preparing a unidirectional moisture-guiding nanofiber multilayer composite film with a wetting gradient, the preparation method comprising:

[0050] The first step: disperse the hydrophilic nano-calcium carbonate in acetic acid, ultrasonically disperse the nanoparticles evenly, and prepare a calcium carbonate dispersion with a mass fraction of 3%; dissolve chitosan in the above-mentioned dispersion to prepare mass The chitosan electrospinning solution A1 with a fraction of 20% was used to deposit a layer of hydrophilic nanofiber film on glossy paper as a hydrophilic layer by electrospinning. The spinning voltage was 30kV and the receiving distance was 25cm. The perfusion rate was 2 mL / h, the average pore diameter of the obtained fiber membrane was 4 μm, the obtained fiber diameter was 650 nm, and the thickness of the fiber membrane was 30 μm.

[0051] The second step: prepare two kinds of spinning solutions respectively, disperse the hydrophilic nano-calciu...

Embodiment 3

[0055] A method for preparing a unidirectional moisture-guiding nanofiber multilayer composite film with a wetting gradient, the preparation method comprising:

[0056] The first step: disperse the hydrophilic titanium dioxide nanoparticles in N-N dimethylformamide, ultrasonically disperse the nanoparticles uniformly, and prepare a titanium dioxide dispersion with a mass fraction of 0.5%; dissolve the polyimide in the above-mentioned Prepare the polyimide electrospinning solution A1 with a mass fraction of 18% in the prepared dispersion liquid, deposit a layer of hydrophilic nanofiber film on the glossy paper by electrospinning method as the hydrophilic layer, and the spinning voltage is 30kV. The distance is 20cm, the perfusion speed of the spinning solution is 1mL / h, the average pore diameter of the obtained fiber membrane is 1 μm, the obtained fiber diameter is 220nm, and the thickness of the fiber membrane is 25 μm.

[0057]The second step: prepare two kinds of spinning so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com