Thermoelectric film material and production process

A thermoelectric thin film and manufacturing process technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

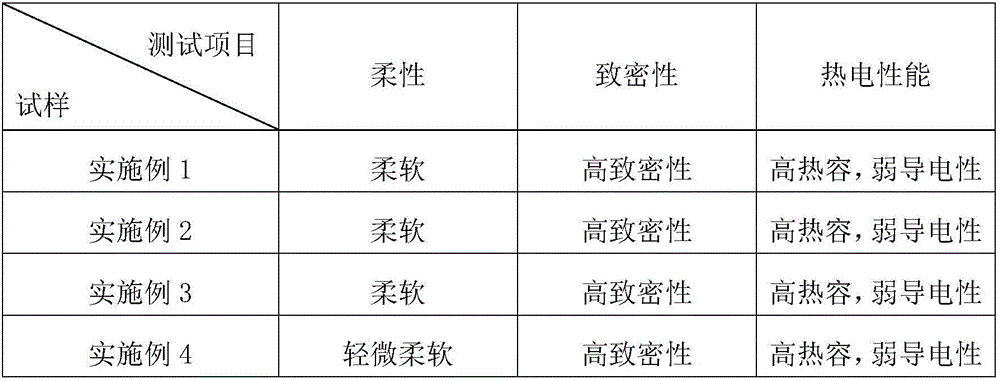

Examples

Embodiment 1

[0048] (1) Synthesis of base materials for thermoelectric materials: (1a) Bismuth telluride (Bi 2 Te 3 ) and antimony telluride (Sb 2 Te 3 ) according to the weight ratio of 1:1 to uniformly mix to obtain the main material, and then add an appropriate amount of sodium dodecylbenzene sulfonate (SDBS) in the main material obtained, the main material and sodium dodecylbenzene sulfonate ( SDBS) with a weight ratio of 100:1.5, mixed evenly to obtain a mixture; (1b) Put the obtained mixture into a reaction kettle, and hot-press sintering at a pressure of 0.29-0.3MPa and a temperature of 200°C for 16h , to obtain a sintered body of thermoelectric material. In addition, continuous stirring is required during the hot-pressing sintering process, and the stirring speed is controlled at 100r / min; (1c) Due to the difference in specific gravity between the sintered body of thermoelectric material and impurities, first use a centrifuge to The obtained thermoelectric material sintered body...

Embodiment 2

[0054] (1) Synthesis of base materials for thermoelectric materials: (1a) Bismuth telluride (Bi 2 Te 3 ) and antimony telluride (Sb 2 Te 3 ) uniformly mixed according to the weight ratio of 0.9:1.1 to obtain the main ingredient, and then add an appropriate amount of polyvinylpyrrolidone (PVP) to the obtained main ingredient, the weight ratio of the main ingredient to polyvinylpyrrolidone (PVP) is 110:1.3, Mix evenly to obtain a mixture; (1b) Put the obtained mixture into a reaction kettle, and hot press and sinter under the conditions of a pressure of 0.29-0.3MPa and a temperature of 210°C for 14 hours to synthesize a thermoelectric material sintered body, and in addition During the hot pressing sintering process, continuous stirring is required, and the stirring speed is controlled at 100r / min; (1c) Due to the difference in specific gravity between the thermoelectric material sintered body and impurities, the obtained thermoelectric material sintered body is first centrifug...

Embodiment 3

[0060] (1) Synthesis of base materials for thermoelectric materials: (1a) Bismuth telluride (Bi 2 Te 3 ) and antimony telluride (Sb 2 Te 3 ) uniformly mixed according to the weight ratio of 1.1:0.9 to obtain the main ingredient, and then add an appropriate amount of polyvinylpyrrolidone (PVP) to the obtained main ingredient, the weight ratio of the main ingredient to polyvinylpyrrolidone (PVP) is 90:0.9, Mix evenly to obtain a mixture; (1b) Put the obtained mixture into a reaction kettle, and hot press and sinter under the conditions of a pressure of 0.29-0.3MPa and a temperature of 210°C for 14 hours to synthesize a thermoelectric material sintered body, and in addition During the hot pressing sintering process, continuous stirring is required, and the stirring speed is controlled at 100r / min; (1c) Due to the difference in specific gravity between the thermoelectric material sintered body and impurities, the obtained thermoelectric material sintered body is first centrifuga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com