Method for preparation of silver antimony telluride thermoelectric material by combining low temperature solid phase reaction with hot pressing process

A silver telluride antimony, solid-phase reaction technology, applied in the direction of thermoelectric device junction lead wire materials, etc., can solve the problems of long-term high-temperature smelting, unfavorable mass production, etc., and achieves low reaction temperature and simple and controllable hot pressing process. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a silver antimony telluride thermoelectric material in combination with a low-temperature solid-state reaction combined with a hot-pressing process, comprising the following steps:

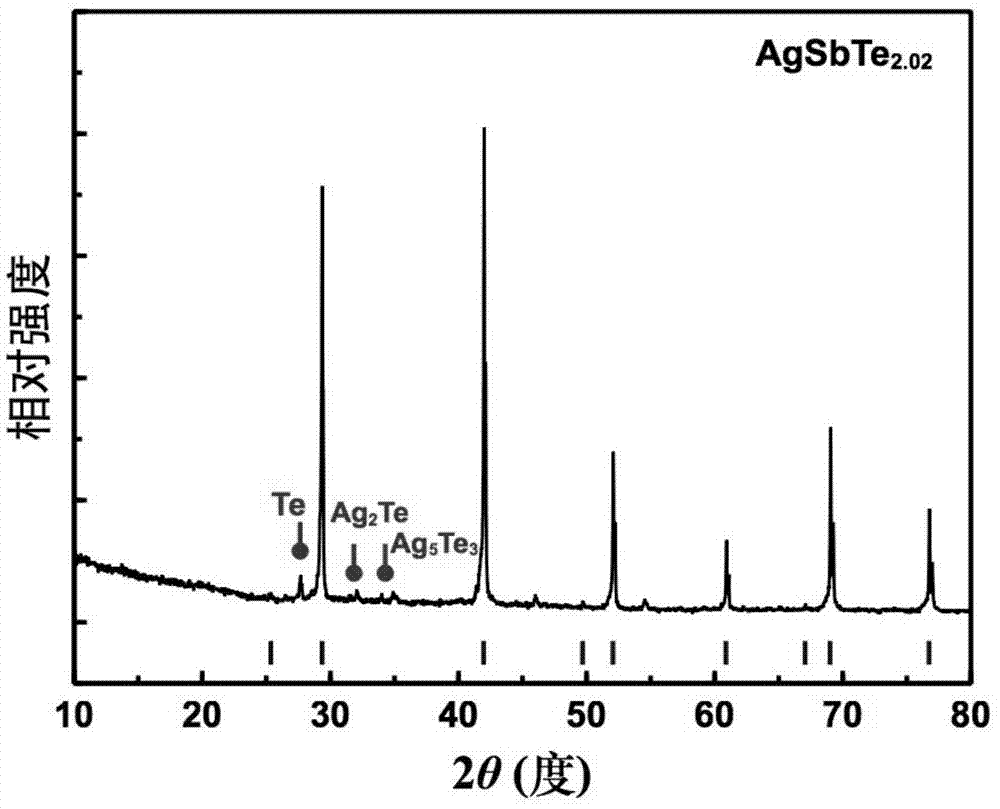

[0031] 1) Ingredients: According to the chemical formula AgSbTe 2.02 (i.e. x is 0.02, Te excess 1%) stoichiometric ratio of each element 1:1:2.02 Weigh powdered elemental silver, antimony and tellurium as raw materials, the amount of raw material is 4.5g, wherein elemental silver, tellurium and antimony The particle sizes are 325 mesh, 200 mesh and 200 mesh respectively;

[0032] 2) Briquetting seal: put the raw materials in step 1) into an agate mortar, fully grind them for 30 minutes, and then press them into a cylindrical block with a diameter of 15 mm and a height of 4 mm on a tablet press, and the density of the obtained block is about 89% of the density of silver antimony telluride; put the resulting block into a quartz tube with a diameter of 20 mm and a lengt...

Embodiment 2

[0040] A method for preparing a silver antimony telluride thermoelectric material in combination with a low-temperature solid-state reaction combined with a hot-pressing process, comprising the following steps:

[0041] 1) Ingredients: According to the chemical formula AgSbTe 2 (i.e. x is 0) stoichiometric ratio of each element 1:1:2 Weigh powdery elemental silver, antimony and tellurium as raw material, the quality of raw material is 4.35g;

[0042] 2) Briquetting seal: put the raw materials in step 1) into an agate mortar, fully grind them for 60 minutes, and then press them into a cylindrical block with a diameter of 15 mm and a height of 4 mm on a tablet press, and the obtained block has a density of about 86% of the density of silver antimony telluride; the obtained block is put into a quartz tube with a diameter of 20mm and a length of 12cm, and the -3 Sealed under Pa conditions;

[0043] 3) Solid-state reaction: place the vacuum-sealed quartz tube obtained in step 2) ...

Embodiment 3

[0047] A method for preparing a silver antimony telluride thermoelectric material in combination with a low-temperature solid-state reaction combined with a hot-pressing process, comprising the following steps:

[0048] 1) Ingredients: According to the chemical formula AgSbTe 2.02 (i.e. x is 0.02) the stoichiometric ratio of each element is 1:1:2.02 Weigh powdery elemental silver, antimony and tellurium as raw material, raw material quality is 4.55g;

[0049] 2) Briquetting seal: put the raw materials in step 1) into an agate mortar, fully grind them for 30 minutes, and then press them into a cylindrical block with a diameter of 15 mm and a height of 4 mm on a tablet press, and the density of the obtained block is about 90% of the density of silver antimony telluride; put the resulting block into a quartz tube with a diameter of 20 mm and a length of 12 cm, and vacuum 10 -3 Sealed under Pa conditions;

[0050] 3) The first solid phase reaction: place the vacuum-sealed quartz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com