Cadmium telluride thin-film solar cell back contact layer production method and vertical coater

A technology for solar cells and manufacturing methods, applied in coatings, circuits, electrical components, etc., can solve the problems of low coating efficiency, high transportation cost, pinhole phenomenon, etc., to improve coating efficiency, high material utilization, and increase effective effect of interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the methods and devices provided by the present invention will be described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

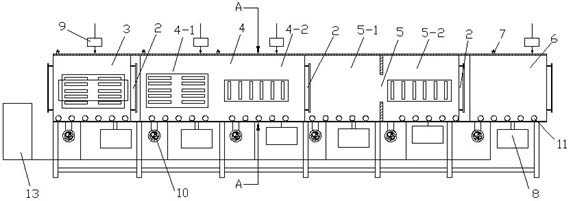

[0021] Such as Figure 1 to Figure 3 As shown, a method for manufacturing the back contact layer of a cadmium telluride thin-film solar cell is carried out in a vacuum environment. The steps are as follows: first, preheat the substrate 1, and evacuate while heating. When the vacuum degree reaches 1Pa And when the temperature of the substrate 1 reaches any value between 160°C and 220°C, the vacuum valve 2 is opened, and the substrate 1 enters the heating zone 4-1 of the thermal insulation antimony telluride deposition chamber 4 for heating, and stays in the heating zone 4-1 In 5 to 10 minutes, the temperature of the substrate 1 can reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com