Moderate thermophilic enriched substance used for mineral leaching of copper pyrites

A moderately thermophilic and enrichment technology, applied in the direction of microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve problems such as slow progress, achieve faster reaction speed, increase bioleaching rate and leaching rate, The effect of shortening the leaching cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1 The collection, cultivation and domestication of the moderate thermophilic enrichment of the present invention

[0012] Prepare liquid medium (or claim B-type medium) to consist of: (NH 4 ) 2 SO 4 3.0g / L, Na 2 SO 4 2.1g / L, MgSO 4 ·7H 2 O 0.5g / L, K 2 HPO 4 0.05g / L, KCl 0.1g / L, Ca(NO 3 ) 2 0.01g / L, 0.1g / L yeast powder, the rest is water.

[0013] Pit water was collected from the Dexing copper mine in Jiangxi, China, the Dabaoshan mine in Guangdong, and the lead-zinc mine in Chenzhou, Hunan. Then these pit waters were mixed together, centrifuged for 2 minutes by a low-speed centrifuge (3000r / min) to remove impurities, and the supernatant was collected. Put the supernatant in a 3L shake flask, add B-type medium, 10g / L ferrous sulfate and 2g / L elemental sulfur, and culture in a shaker at 200r / min at 48°C. When the concentration of microorganisms in the solution reaches 10 8 cells / ml for subculture.

Embodiment 2

[0018] Embodiment 2 chalcopyrite ore leaching test 1

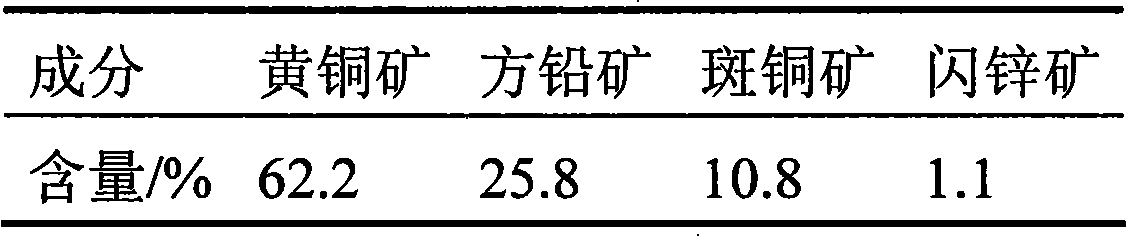

[0019] Taking the chalcopyrite produced in Meizhou, Guangdong as the ore sample, the particle size of the ore particles is less than 75 μm, and the composition of the ore sample is shown in Table 1.

[0020] Table 1 Mineral Phase Analysis of Chalcopyrite (Meizhou, Guangdong) Concentrate

[0021]

[0022] Acid leaching was carried out on the ore sample in a glass cylindrical reactor with a cover, and 1800mL of B-type medium was added to inoculate the moderately thermophilic enrichment, the inoculation amount was 10%, and the pulp concentration was 80g / L. The mechanical stirring speed is 500 rpm. The reactor was placed in a constant temperature bath at 48°C with an initial pH value of 2.0. The acid consumption in the leaching process is supplemented by 10mol / L sulfuric acid, and the water lost by evaporation is supplemented by continuous flow of distilled water through a peristaltic pump. After the leaching, the clarif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com