Method for separating and recycling valuable metal in tungsten slag

A technology for the separation and recovery of valuable metals, applied in the direction of improving process efficiency, can solve the problems of single recovery species and high energy consumption, and achieve the effects of high production efficiency, low energy consumption, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

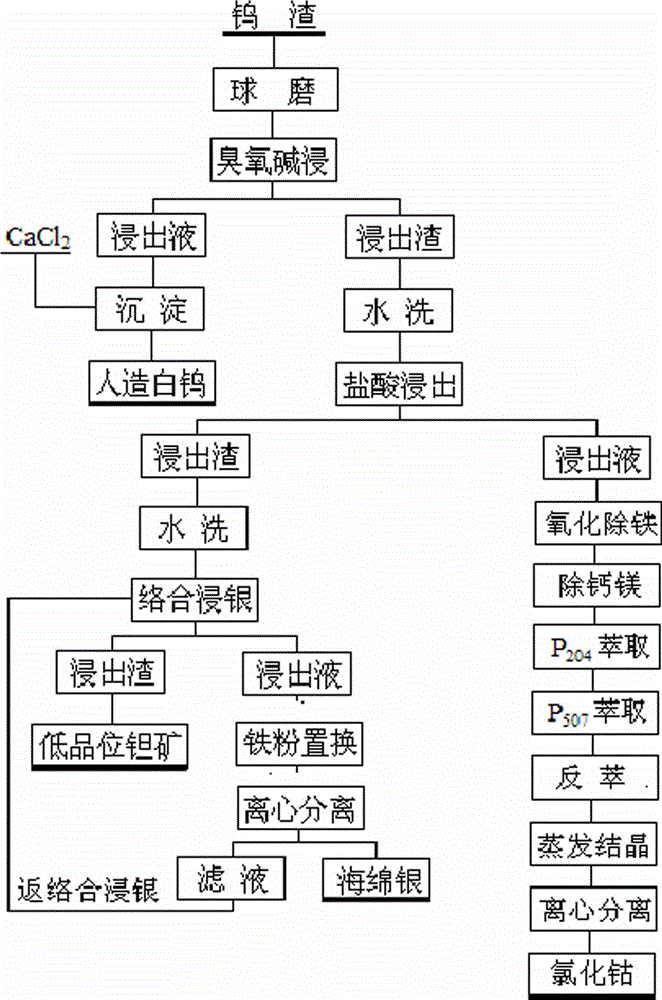

Image

Examples

Embodiment 1

[0037] A method for separating and recovering valuable metals in tungsten slag, comprising the following steps:

[0038] ⑴Put the tungsten slag through wet ball milling to produce fine powder slurry;

[0039] In step (1) of the present invention, the particle size of the fine powder pulp is -100 mesh.

[0040] (2) Add liquid caustic soda to the fine powder pulp prepared in step (1) to make 1N~3N alkaline pulp, start stirring, heat up to 80°C with steam, feed ozone, keep the temperature not lower than 80°C, and react for 1 hour~ 2 hours;

[0041] (3) Separating the solid-liquid of the ore pulp after the ozone alkali leaching reaction in step (2), adjusting the pH value of the filtrate to 8-9 with hydrochloric acid or sulfuric acid, filtering to remove silicon, and recovering artificial scheelite with calcium chloride precipitation;

[0042] In the process of using ozone alkali leaching, ozone acts as an oxidizing agent to oxidize metals in tungsten slag into oxides, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com