Flotation method for copper-containing nickel sulfide ore

A nickel sulfide ore roughing technology, which is applied in flotation, solid separation, etc., can solve the problems of reducing the nickel recovery rate and the buoyancy of nickel minerals, and achieve the improvement of nickel recovery rate, copper recovery rate, and prevention of oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

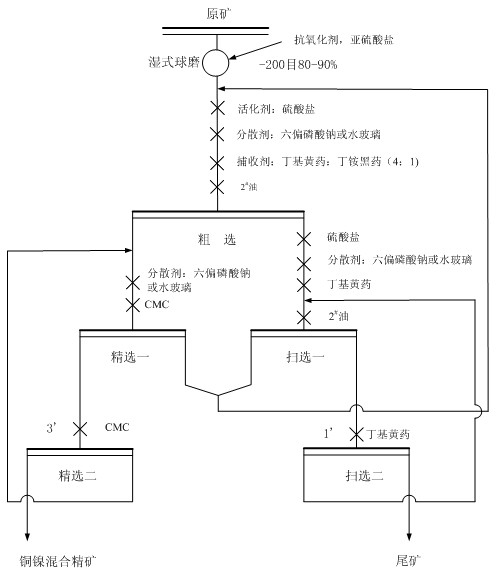

Method used

Image

Examples

Embodiment 1

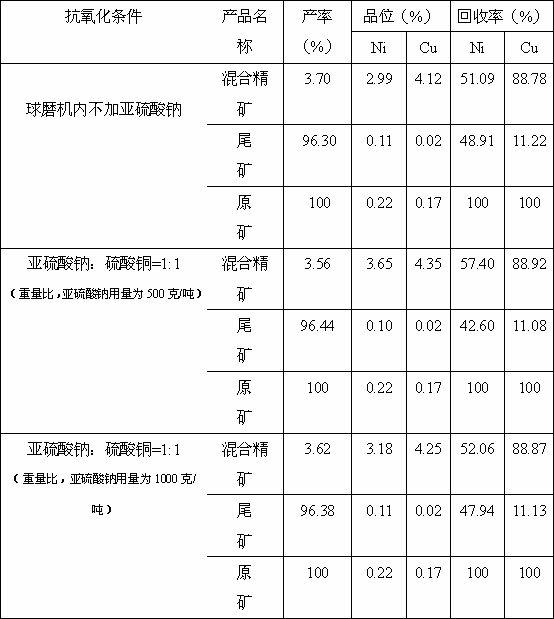

[0025] Embodiment 1: this copper-containing nickel sulfide ore flotation method, the specific operation steps are as follows:

[0026] The properties of copper-containing nickel sulfide ore raw samples are as follows: Cu 0.17% (mass percentage, the same below), oxidation rate 8.96%; Ni 0.22%, oxidation rate 25%; CaO 2.57%; MgO 30.90%; Al 2 o 3 2.16%; SiO 2 35.93%; Fe 2 o 3 6.63%; Pt 1.7 g / t, Pd 2.32 g / t.

[0027] The first group of tests is to wet-grind the copper-containing nickel sulfide ore to -200 mesh weight ratio accounting for 90%, and add 500 g / ton of sodium sulfite during the grinding process, and add it when stirring and slurrying before roughing and sweeping. The total amount of sodium silicate is 1500 g / ton, and the total amount of copper sulfate is 500 g / ton, and the collector combined with conventional butyl xanthate and butyl ammonium black drug (butyl xanthate: butyl ammonium black drug=4:1 ) with a total amount of 200 g / ton and foaming agent No. 2 ...

Embodiment 2

[0033] Embodiment 2: this copper-containing nickel sulfide ore flotation method, the specific operation steps are as follows:

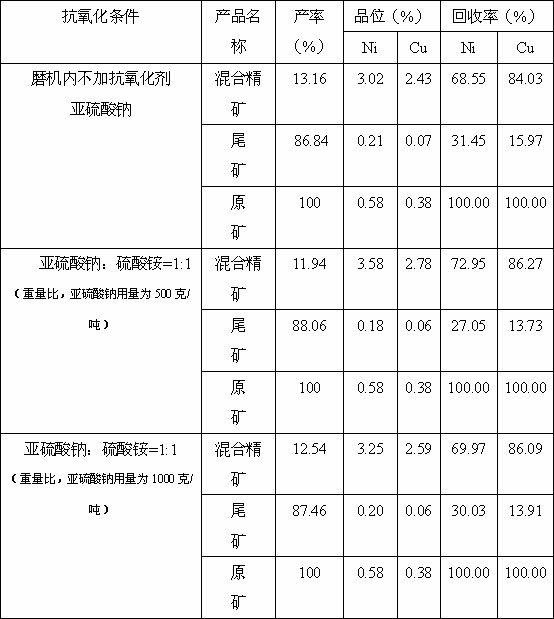

[0034] The properties of copper-containing nickel sulfide ore raw samples are as follows: Cu 0.38% (mass percentage, the same below), oxidation rate 15.12%; Ni 0.58%, oxidation rate 12%; CaO 9.15%; MgO 12.39%; Al 2 o 3 8.69%; SiO 2 43%; Fe 2 o 3 6.63%; Pt 2.13g / t, Pd 2.39g / t.

[0035]The first group of tests is to wet-grind the above-mentioned copper-containing nickel sulfide ore to -200 mesh weight ratio accounting for 80%, and add 500 g / ton of sodium sulfite during the grinding process, and add it when stirring and slurrying before roughing and sweeping The total amount of sodium silicate is 1200 g / ton, and the total amount of activator ammonium sulfate is 500 g / ton, and the collector of conventional butyl xanthate and butyl ammonium black drug (butyl xanthate: butyl ammonium black drug=4 : 1) Flotation with a total amount of 150 g / ton a...

Embodiment 3

[0040] Embodiment 3: this copper-containing nickel sulfide ore flotation method, the specific operation steps are as follows:

[0041] The properties of copper-containing nickel sulfide ore raw samples are as follows: Cu 0.25% (mass percentage, the same below), oxidation rate 10.21%; Ni 0.35%, oxidation rate 20%; CaO 5.57%; MgO 21.90%; Al 2 o 3 4.16%; SiO 2 39.93%; Fe 2 o 3 6.63%; Pt 2.1 g / t, Pd 2.34 g / t.

[0042] The first group of tests is to wet-grind the above-mentioned copper-containing nickel sulfide ore to -200 mesh, accounting for 85% by weight, and add 750 g / ton of sodium metasulfite during the grinding process. Add a total of 1000 g / ton of sodium hexametaphosphate, then add an equal weight of activator copper sulfate 750 g / ton, a collector combined with conventional butylxanthate and butylammonium black medicine (butylxanthate: butylammonium black Drug = 4: 1) The total amount is 180 g / ton, and the total amount of foaming agent No. 2 oil is 60 g / ton for flota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com