Method for manufacturing indium column

An indium column and positive adhesive technology, which is applied in the field of semiconductor device and circuit preparation technology, can solve the problems of uncontrollable and difficult to precisely control film thickness, etc., so as to improve welding accuracy, ensure verticality and uniformity, and shorten process time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

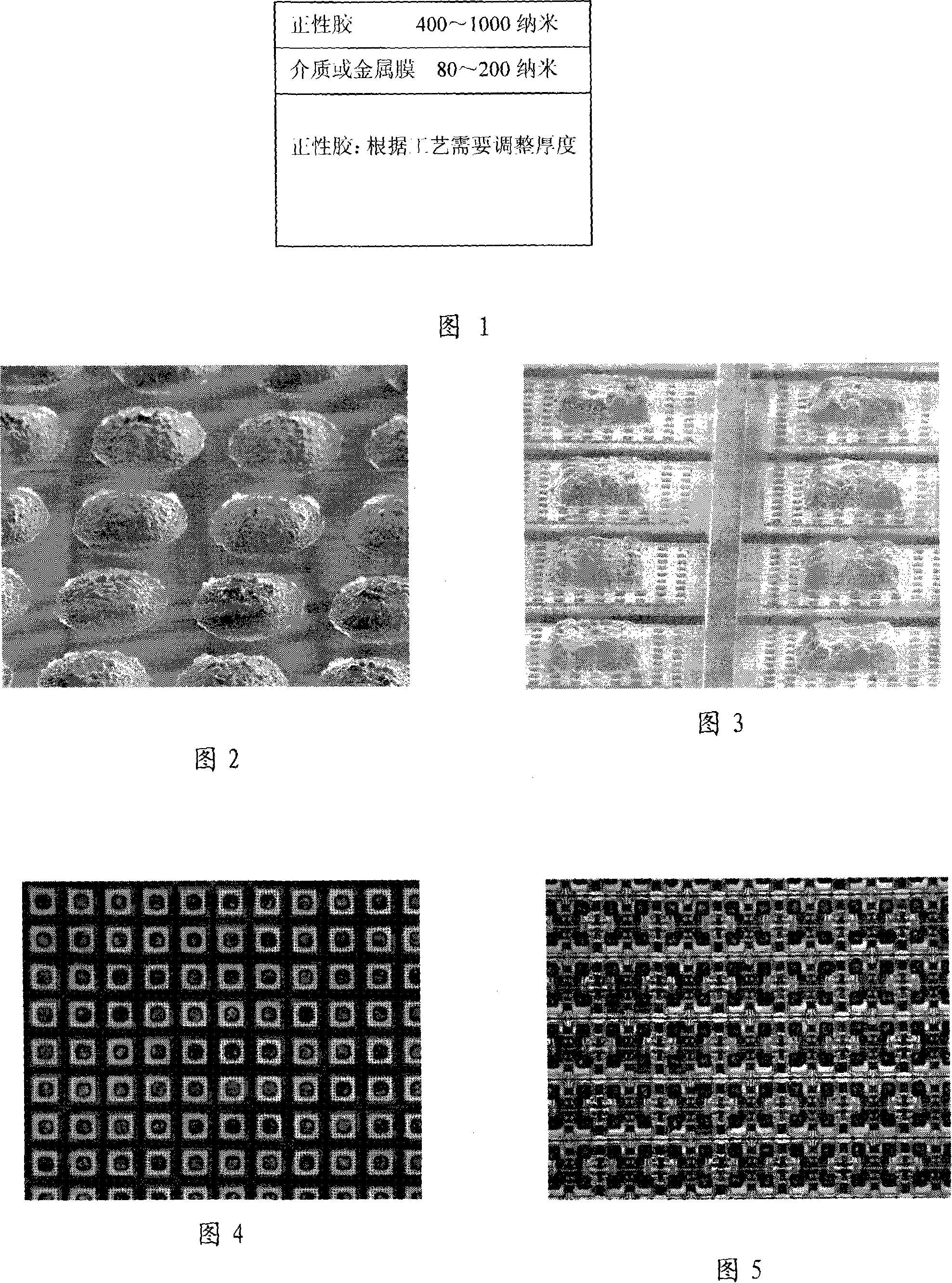

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is described in further detail:

[0029] The indium column we prepared has the following requirements:

[0030] 1) The height of the indium column is 7-8 microns, and the thickness of the photoresist film is not less than 10 microns;

[0031] 2) The photolithographic yield rate is not less than 95%, and the geometric size of the window is ±2 microns from the design value;

[0032] 3) The uniformity of indium film thickness distribution is ±10% of the design value, and the metal surface is smooth and not oxidized;

[0033] 4) The indium film has strong adhesion, and the yield of the indium column after peeling off is not less than 95%.

[0034] The process flow for preparing the above-mentioned indium column is as follows:

[0035] 1. Photolithography process

[0036] 1) Chip treatment: Soak in acetone-isopropanol for several minutes;

[0037] 2) Pre-baking: 100-180°C, 3 minutes;

[0038] 3) Apply the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com