Beneficiation method for copper sulfide ore containing easily-sliming gangue minerals

A technology of gangue minerals and beneficiation methods, applied in flotation, solid separation, etc., can solve the problems of gangue ore slime interference, low copper beneficiation index, etc., to enhance floatability, improve copper mineral surface characteristics, and copper beneficiation The effect of high technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

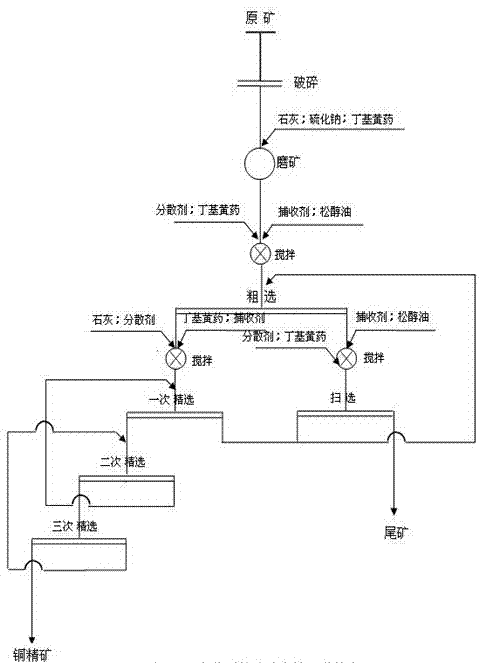

Method used

Image

Examples

Embodiment 1

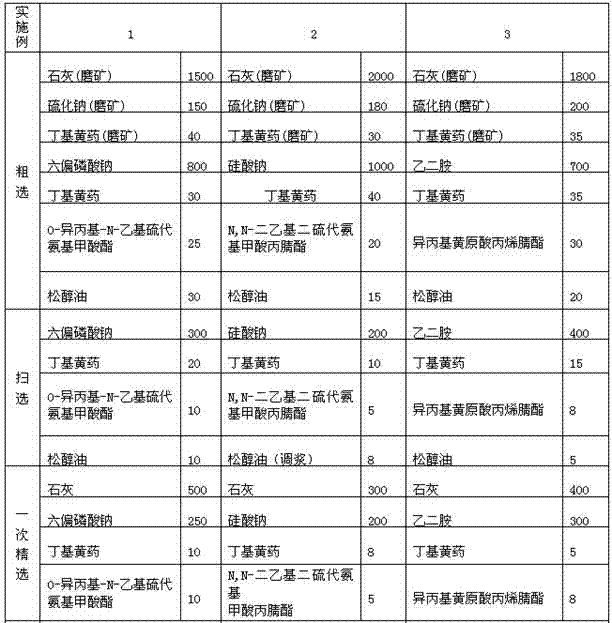

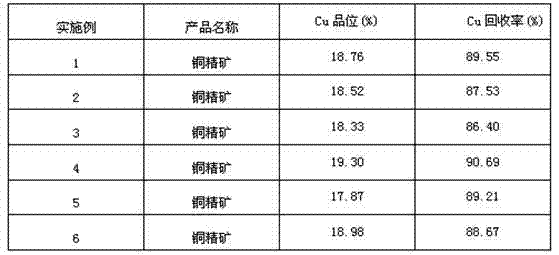

[0029] Table 1.1 Dosage of Examples 1-3 / (g / t raw ore)

[0030]

Embodiment 4-6

[0031] Table 1.2 Dosage of Examples 4-6 / (g / t raw ore)

[0032]

[0033] A method for beneficiating copper sulfide ore containing easily muddy gangue minerals, comprising the following steps:

[0034] A. Grinding process: crush the raw ore, and grind the ore until the ore particle size is less than 0.074mm, accounting for 78%, so that the copper sulfide minerals are fully dissociated. For each ton of raw ore, add lime 1500g / t, sodium sulfide 150g / t, butyl xanthate 40g / t, add water to adjust the slurry to a weight concentration of 33%, and the pH value of the slurry is 7.5-8.

[0035] B. Rough separation and pulping and rough separation operation: Add 800g / t of slime dispersant sodium hexametaphosphate, 30g / t of butyl xanthate, O-isopropyl-N-ethyl Thiocarbamate 25g / t, pine oil 30g / t, stirring for 20min, stirring speed controlled at 2000 / min, roughing flotation operation, flotation time 5min, roughing concentrate and roughing tailings .

[0036] C. Sweeping and pulping and ...

Embodiment 2

[0042] The raw ore grade of this embodiment is copper 0.51%, sulfur 4.95%, and its material composition is the same as embodiment 1.

[0043] A method for beneficiating copper sulfide ore containing easily muddy gangue minerals, comprising the following steps:

[0044] Grinding process: crush the raw ore, and grind the ore until the ore particle size is less than 0.074mm, accounting for 76%, so that the copper sulfide mineral is fully dissociated from the monomer. In terms of raw ore, add lime 2000g / t, sodium sulfide 180g / t, butyl xanthate 30g / t, add water to adjust the slurry to a weight concentration of 35%, and the pH value of the slurry is 7.5-8.

[0045] B. Rough separation and pulping and rough separation operation: Add 1000g / t of slime dispersant sodium hexametaphosphate, 40g / t of butyl xanthate, N,N-diethyl dithio Propionitrile carbamate 20g / t, pine alcohol oil 15g / t, stirring for 20min, stirring speed controlled at 2200 / min, roughing flotation operation, flotation ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com