Liquid making technique for manganese oxide ore

A manganese oxide ore and process technology, applied in the field of manganese smelting, can solve problems such as failure to reach the technical level of electrolytic metal manganese, and achieve the effects of reduced quantity, reduced labor intensity, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

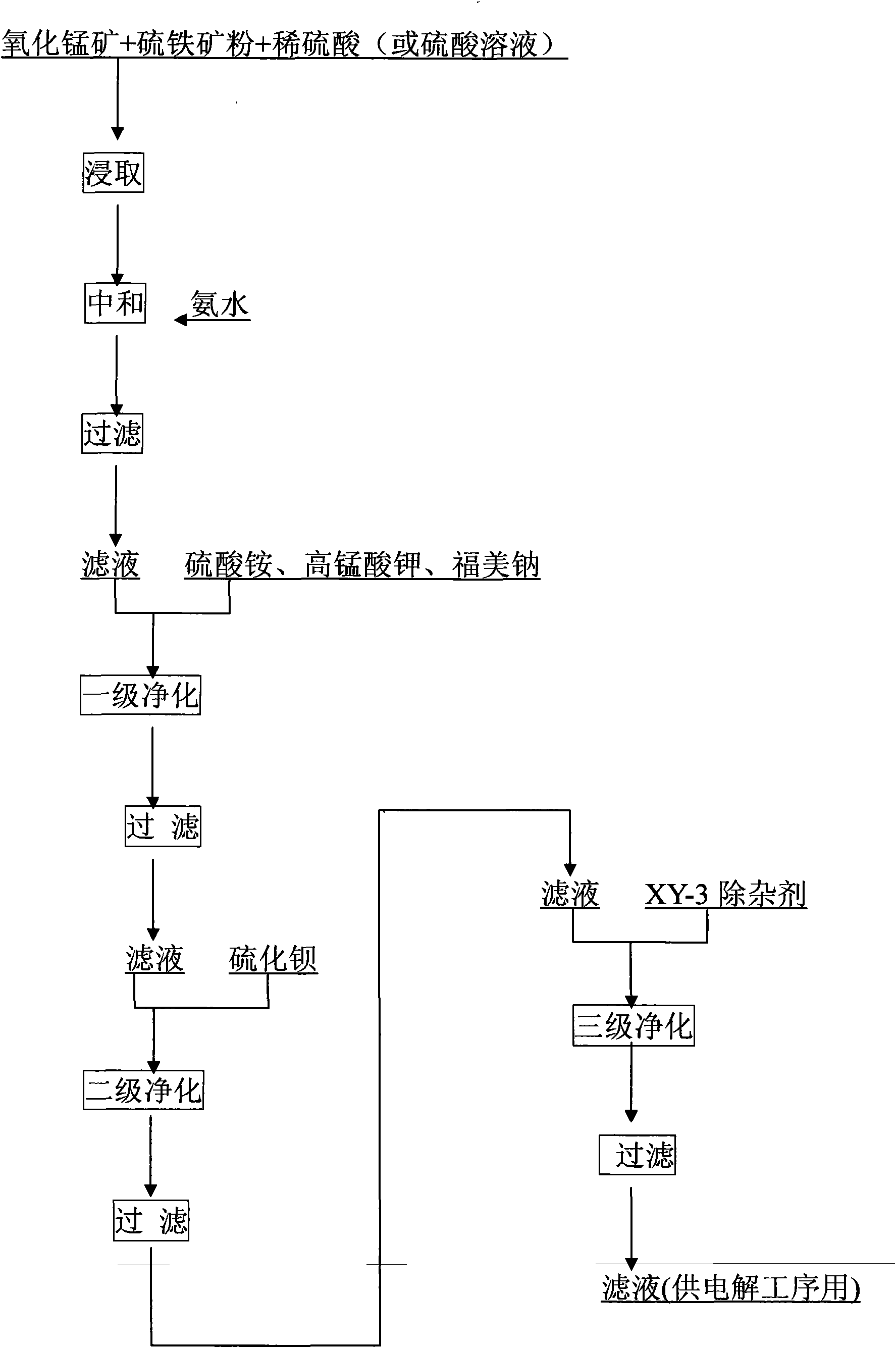

Method used

Image

Examples

Embodiment 1

[0015] The weight ratio of manganese oxide powder, pyrite powder and sulfuric acid is 1:0.213:0.36

[0016] 1) Pour about one-third of the volume of anolyte into the leaching tank and stir at the same time. The effective volume of the leaching tank is 180m 3 , the anolyte contains 12.6g / l of manganese and 32.68g / l of sulfuric acid. It has been preheated to about 80°C, and then 6.072 tons of sulfuric acid is injected, and then 31 tons of manganese oxide ore powder with a grade of 17% is injected, and part of the anode is injected at the same time. liquid and start to heat up, and then put in 6.613 tons of pyrite powder with a sulfur content of 32%. Sulfuric acid 3g / l, stop heating, and cool the bath to about 75-80°C.

[0017] 2), add 10% ammoniacal liquor to the above-mentioned solution that has reached the end of the reaction for neutralization, the process temperature is controlled at 80°C, react until the pH value is 6.03, filter and discard the filter residue, and obtain a...

Embodiment 2

[0022] This embodiment is basically the same as Example 1, the difference is that step 3) is changed to: put the crude manganese sulfate solution obtained in step 2) into the next-stage purification tank with the same volume as the leaching tank, and stir simultaneously, and add Ammonium sulfate to 130g / l, pH value at 6.0, after fully dissolving, add 120kg of barium sulfide, process temperature is controlled at 75-80°C, reaction time is 2 hours, pH value is at 6.3, after filtering, add potassium permanganate 10kg, After 1 hour, add sodium thiram until the nickel removal is qualified, and then filter to obtain a coarse-step purified manganese sulfate solution.

Embodiment 3

[0024] Present embodiment and embodiment 1 technological conditions are the same, but a kind of liquid preparation of continuous leaching, purification, the leaching tank that uses is to be 180m by five effective volumes 3 Each leaching tank is connected in series to form a three-stage continuous leaching. The last two purification tanks are used for neutralization. The qualified neutralization liquid enters the first purification tank continuously after being filtered. The purification tank used is composed of seven effective volumes 180m 3 Each purification tank is connected in series to form a seven-level continuous purification, in which there is a filtration facility between the third purification tank and the fourth purification tank, and there is also a filter between the fifth purification tank and the sixth purification tank After the solution slips out of the last tank, it is filtered and sent to the electrolysis process.

[0025] Manganese oxide ore powder contains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com