Method of preparing low iron-containing quartz sand for photovoltaic glass from pyrite type quartzite and pickling purification apparatus

A photovoltaic glass and iron ore type technology is applied in the field of pyrite type quartzite to prepare low-iron quartz sand for photovoltaic glass, and the field of acid washing and purification devices, which can solve the problem that affects the overall benefit of enterprises in the deep processing value of ore and the purity of quartz sand is not up to the standard. , difficult to remove and other problems, to achieve the effect of scientific and reasonable device design, low production cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

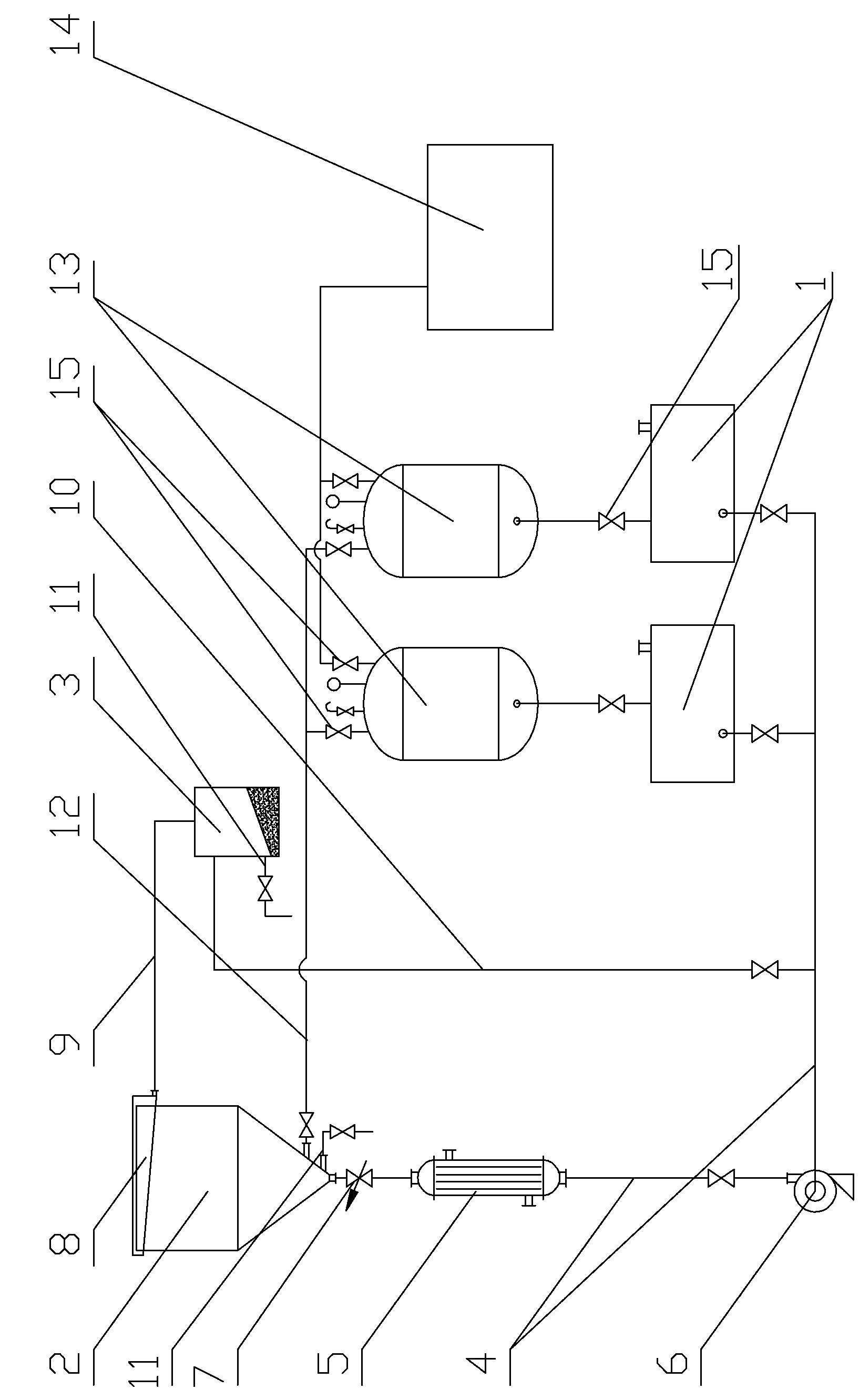

Image

Examples

Embodiment 1

[0024] This embodiment selects the No. 5 silica mine of Tangshan Jinxin Shida Silicon Industry Co., Ltd., which is a white or light white pyrite-containing quartzite mine, wherein SiO 2 The content is 99.0%, Fe 2 o 3 The content is 0.15%.

[0025] (1) After cleaning the surface sediment of the pyrite-containing quartzite ore selected in the mine, send it to the crusher for primary, medium and fine crushing to particles with a particle size of ≤25mm, and then send it to the rod mill for wet crushing. The method of making sand is to send the prepared mortar into a magnetic separator with a magnetic field strength of 3000 gauss for magnetic separation to remove the magnetic iron after the steel rod is worn out, and then sieve it with a cylindrical water sieve to remove the 24 mesh sieve and 120 Under the mesh sieve, most of the sulfur-iron minerals with a particle size of less than 120 mesh enter the tailings, collect the mortar in the range of 24-120 mesh for fine washing, and...

Embodiment 2

[0031] This embodiment selects the No. 6 silica mine of Tangshan Jinxin Shida Silicon Industry Co., Ltd., which is a light gray pyrite-containing quartzite mine, in which SiO 2 The content is 99.3%, Fe 2 o 3 The content is 0.10%.

[0032] (1) After cleaning the surface sediment of the pyrite-containing quartzite ore selected in the mine, send it to the crusher for primary, medium and fine crushing to particles with a particle size of ≤25mm, and then send it to the rod mill for wet crushing. The method of making sand is to send the prepared mortar into a magnetic separator with a magnetic field strength of 5000 gauss for magnetic separation to remove the magnetic iron after the steel rod is worn out, and then sieve it with a cylindrical water sieve to remove the 24-mesh sieve and 120 Under the mesh sieve, most of the pyrite minerals with a particle size of less than 120 mesh enter the tailings, collect the mortar in the range of 24 to 120 mesh for fine washing, and then use t...

Embodiment 3

[0037] In this embodiment, the No. 7 silica mine of Tangshan Jinxin Shida Silicon Industry Co., Ltd. is selected from the pale yellow pyrite-containing quartzite mine, wherein SiO 2 The content is 99.6%, Fe 2 o 3 The content is 0.13%.

[0038] (1) After the ore selected in the mine is cleaned of the surface sediment, it is sent to the crusher for primary, medium and fine crushing to particles with a particle size of ≤25mm, and then sent to the rod mill for wet sand making. The mortar is first sent to a magnetic separator with a magnetic field strength of 5000 Gauss for magnetic separation to remove the magnetic iron after the steel rod is worn out, and then sieved with a cylindrical water sieve to remove the 24-mesh sieve and 120-mesh sieve. Most of the pyrite minerals less than 120 mesh enter the tailings, collect the mortar in the range of 24 to 120 mesh for fine washing, and then use two series of spiral chutes to separate the dense pyrite minerals in the mortar, and fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com