Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "High fixation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

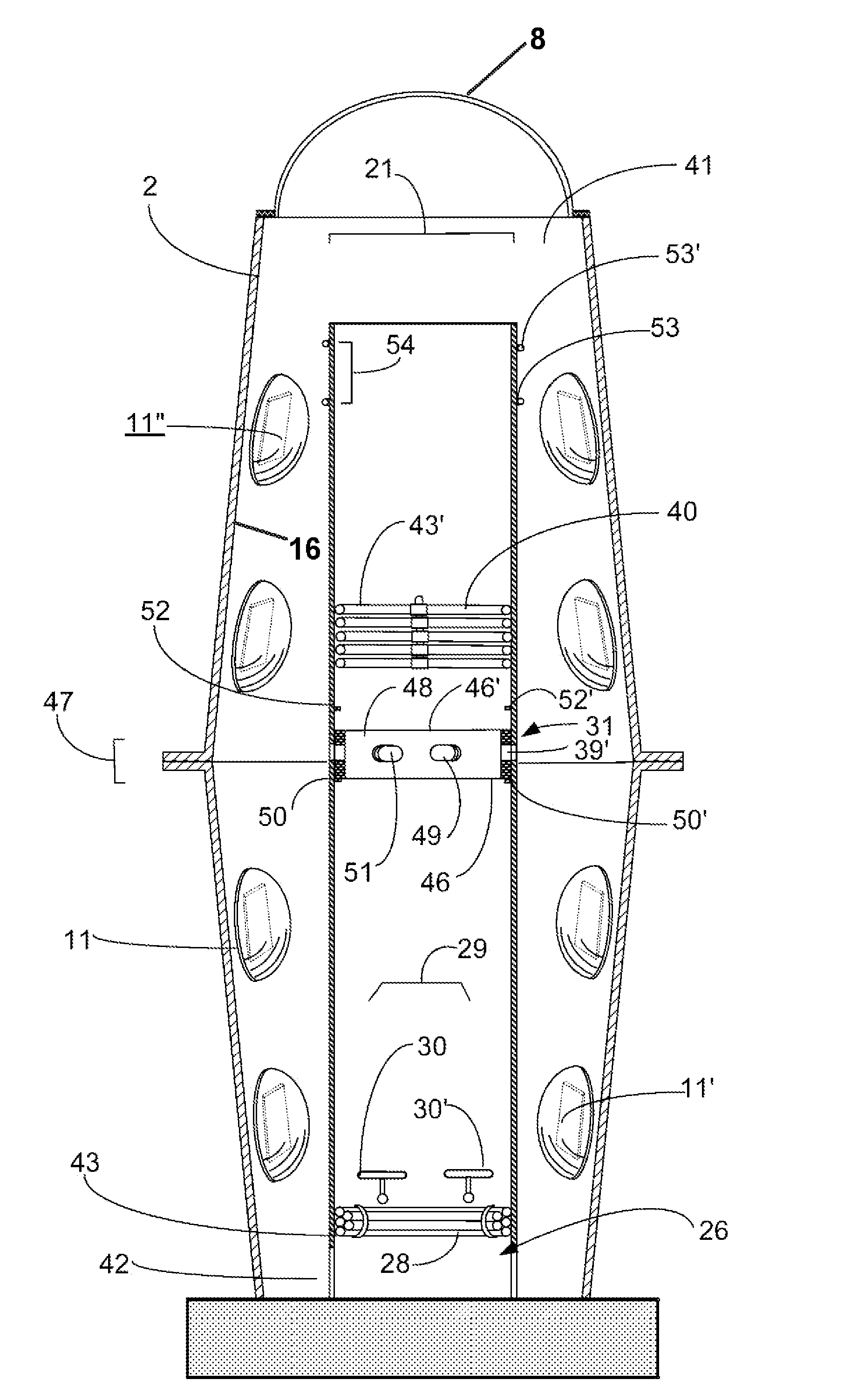

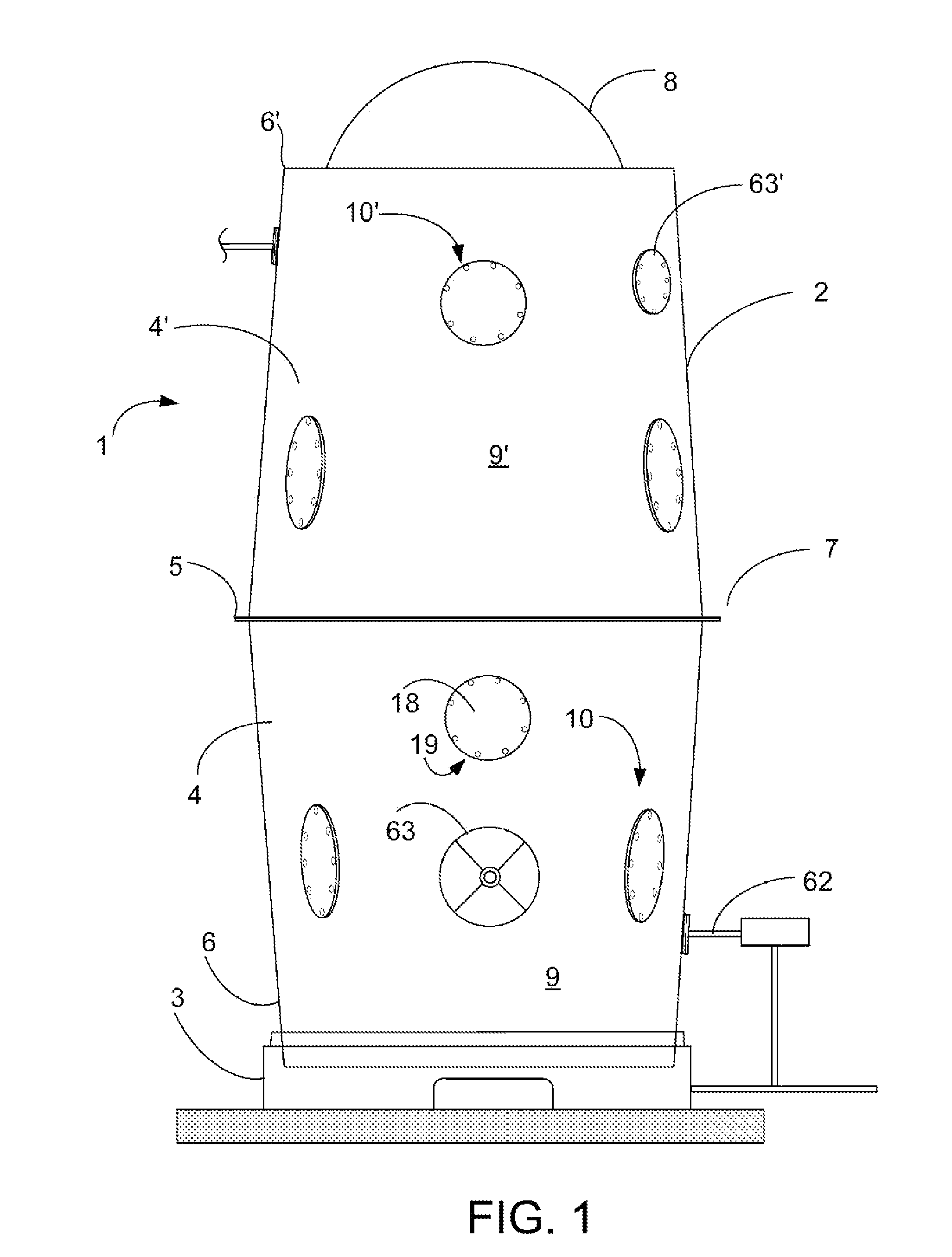

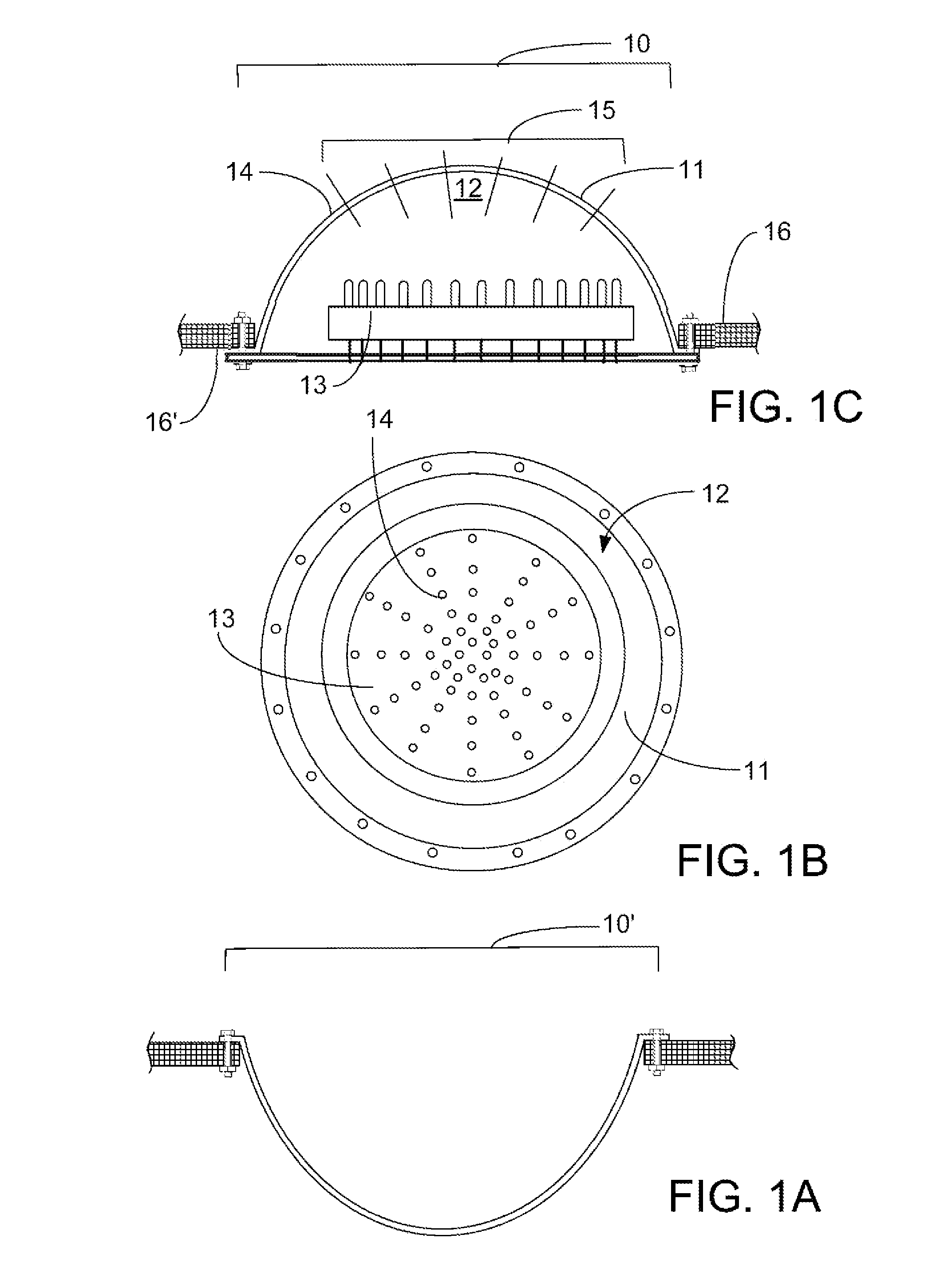

Enclosed bioreactor system and methods associated therewith

ActiveUS8569050B1Minimal power generationMinimize CO emissionBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateBiological body

A bioreactor production system for growing commercial volumes of algae or other biomass in a uniquely configured, enclosed, biosecure, photo-type reactor vessel, having internal artificial growth light production as well as exterior solar energy capturing devices or the like designed to facilitate enhanced sunlight exposure for photosynthesis organism production. A unique electromagnetic field generation system is integrated with the bioreactor and its operation to substantially enhance growth rate and overall productivity.

Owner:BARNES JANE A +1

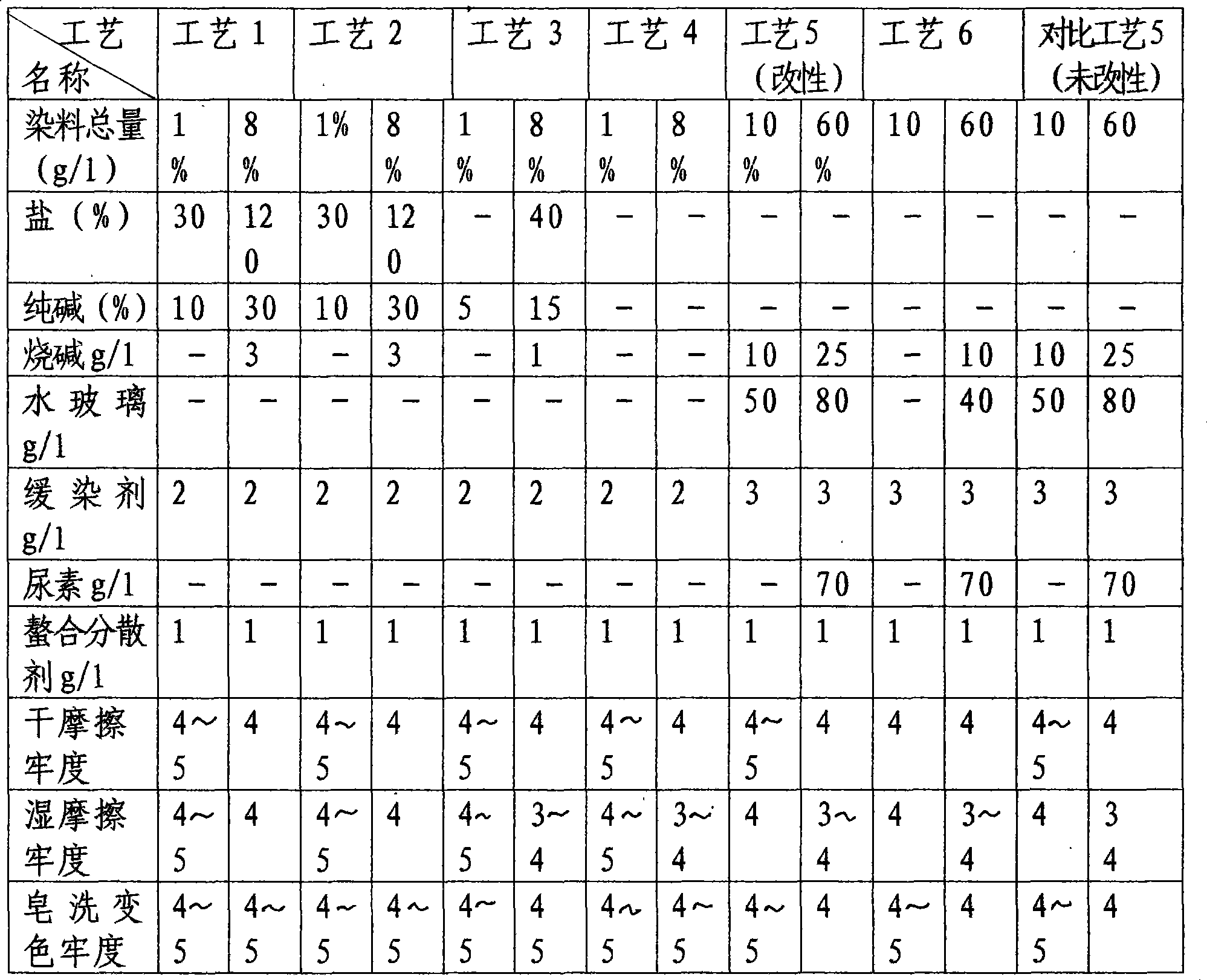

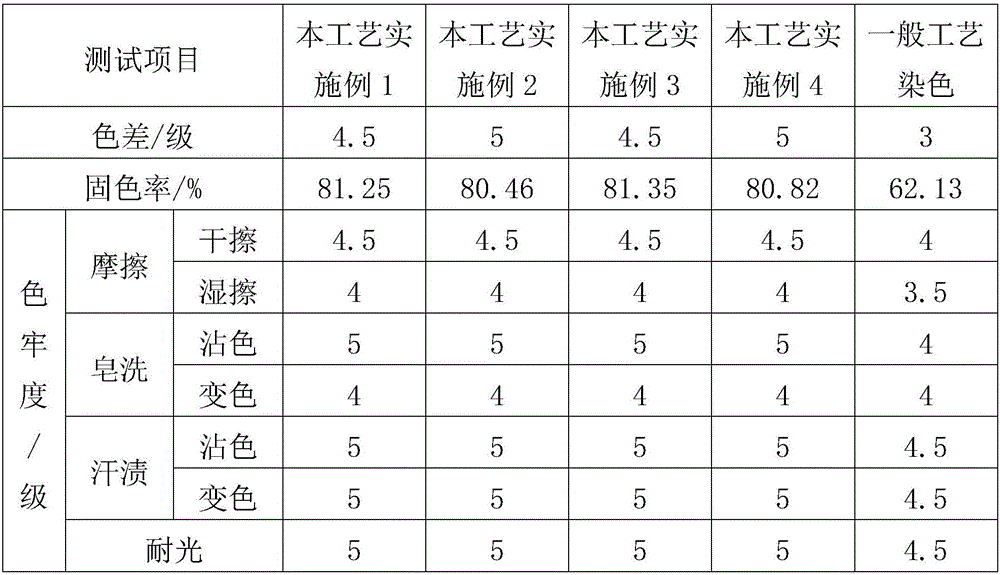

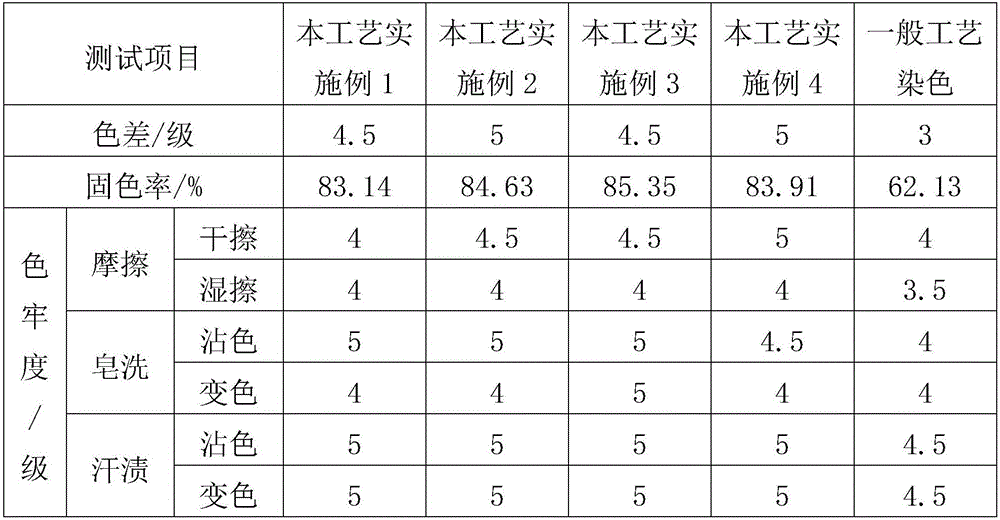

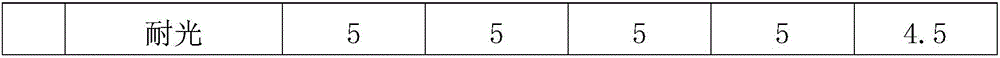

Salt free dyeing with reactive dye

The invention provides a reactive dye salt-free dyeing process for cotton fiber, which comprises the following steps of pre-treatment, modified treatment, dyeing, post-treatment and so on. The modified treatment is that a copolymer of poly epichlorohydrin and polyamine used for cotton fiber is pretreated and cleaned under high temperature and alkali conditions before a special reactive dye used for a leveling agent is added to dye the cotton fiber, and the dyeing process is completed under salt-free, alkali-free or low-alkali conditions, thereby improving dyeing and fixing rate of the dye. The reactive dye salt-free dyeing process simplifies the prior dyeing process, is simple and easy to understand for operators, reduces influences of human operation factors on dyeing process and dyeing quality, and lowers production cost and sewage treatment cost overall.

Owner:胡红湘

Dimensionality-stable regenerated cellulose fiber and preparation method thereof

ActiveCN102586919AImprove filtering effectImprove wet modulusArtificial filaments from viscoseViscoseWet strength

The invention relates to a preparation method of a dimensionality-stable regenerated cellulose fiber. The preparation method comprises the following steps: carrying out dipping, squeezing, crushing, ageing, yellowing, continuous dissolving, filtering, and deaeration operations on a cellulose raw material to prepare a spinning viscose glue; and spinning to prepare the dimensionality-stable regenerated cellulose fiber, wherein a mixture comprising one or more of a denaturant and a crosslinking agent is added in the continuous dissolving step of the spinning viscose glue operation or before the spinning step. The dimensionality, the dry strength, the wet strength and the dry extension of the dimensionality-stable regenerated cellulose fiber are 1.4-1.72dtex, 1.6-3.0CN / dtex, 1.2-2.8CN / dtex and 10-20% respectively. The dimensionality-stable regenerated cellulose fiber prepared by adopting the method of the invention overcomes disadvantages of low fabric preparation rate and bad dimensional stability caused by the overhigh hygroscopic expansion rate and large wet tensile elongation of common viscose fibers, and has the advantages of stable transverse section and vertical dimensionality, and strong weaving strength.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Method for dyeing modified cellulose fiber fabric on rhubarb and curcuma longa dyes

InactiveCN101349020AHigh fixation rateStable color fastnessDyeing processVegetal fibresHigh rateCellulose fiber

The invention provides a method for dyeing a modified cellulose fiber textile by a rhubarb and turmeric dye. The method comprises the following: 1. a step of modifying a quaternary ammonium group of the cellulose fiber textile, in which a modifying agent with a concentration of 50 to 60 g / l and sodium hydrate with a concentration of 12 to 18g / l react for 40 to 60 minutes at a temperature of between 64 and 75 DEG C, the bath ratio is 1:30; in the post treatment after the modification, the fiber textile is washed by hot water at a temperature of between 40 and 50 DEG C for 10 minutes, is washed by cold water, is prickled by HAC with a concentration of 2 to 3g / l for 2 minutes, is washed by water to be neutral and is dried; 2. a step of preparing the dye solution by the sodium hydrate extracting agent with a concentration of 15 to 45g / l; and 3. a step in which the modified cellulose fiber textile is dyed, washed by water and dried directly by the dyeing technique and is washed by soap, washed by water and dried. The technique is simple and easy to implement, does not need the mordanting and the fixation processes and the like, has high rate of dye-uptake, good dye quality and the friction resisting color fastness and the colorfastness to washing up to more than three grades, is nontoxic, does not pollute the environment, and has low cost, and remarkable economic benefits and environmental benefits.

Owner:DALIAN POLYTECHNIC UNIVERSITY

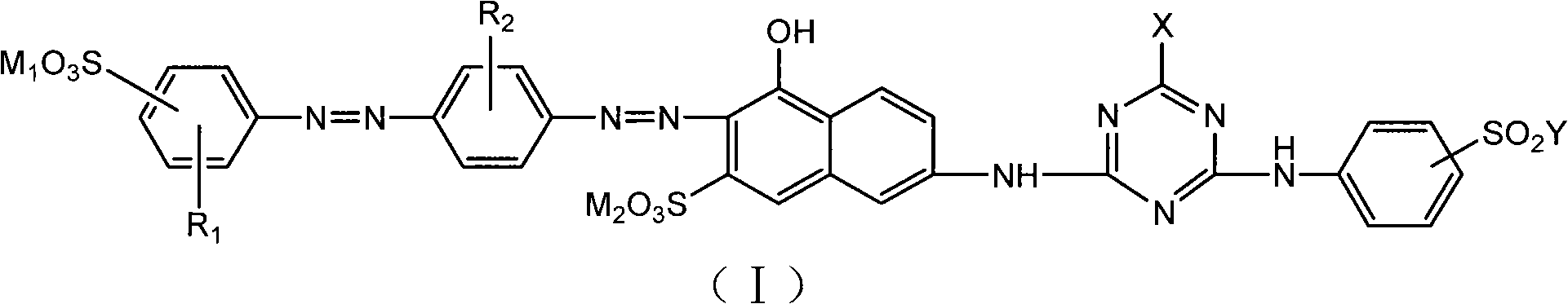

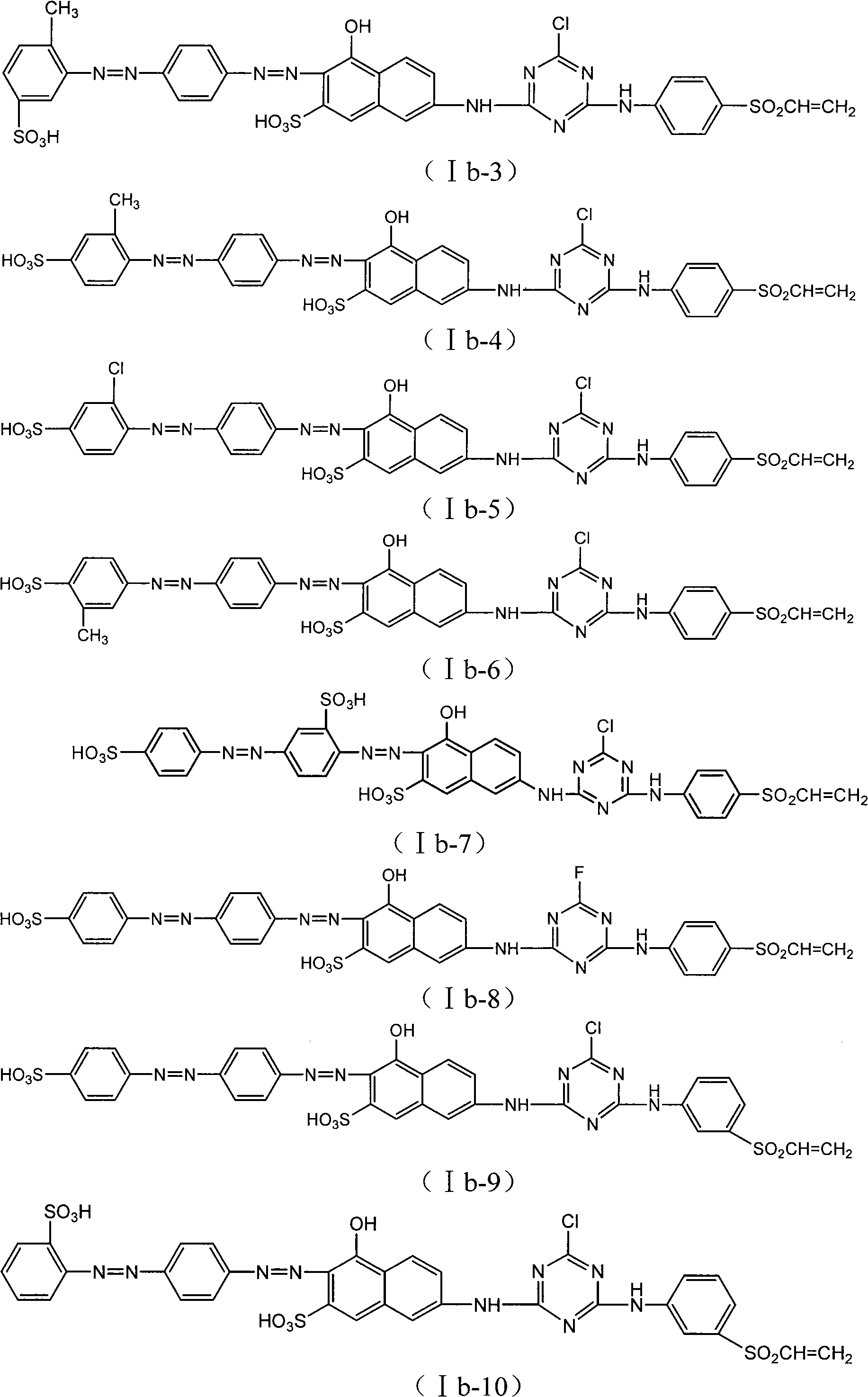

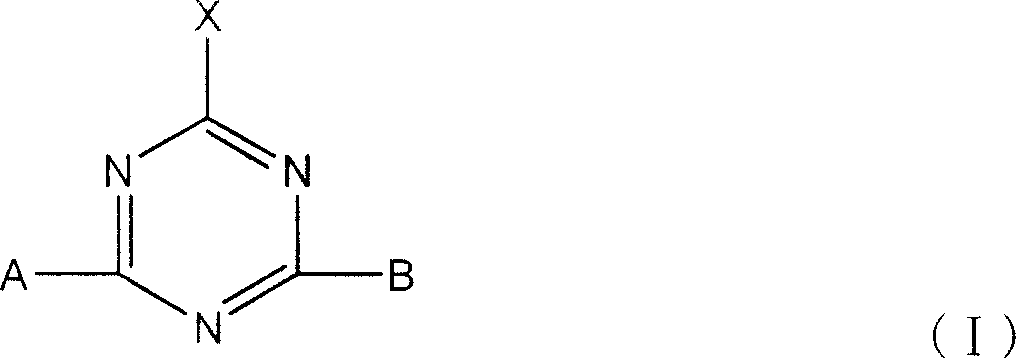

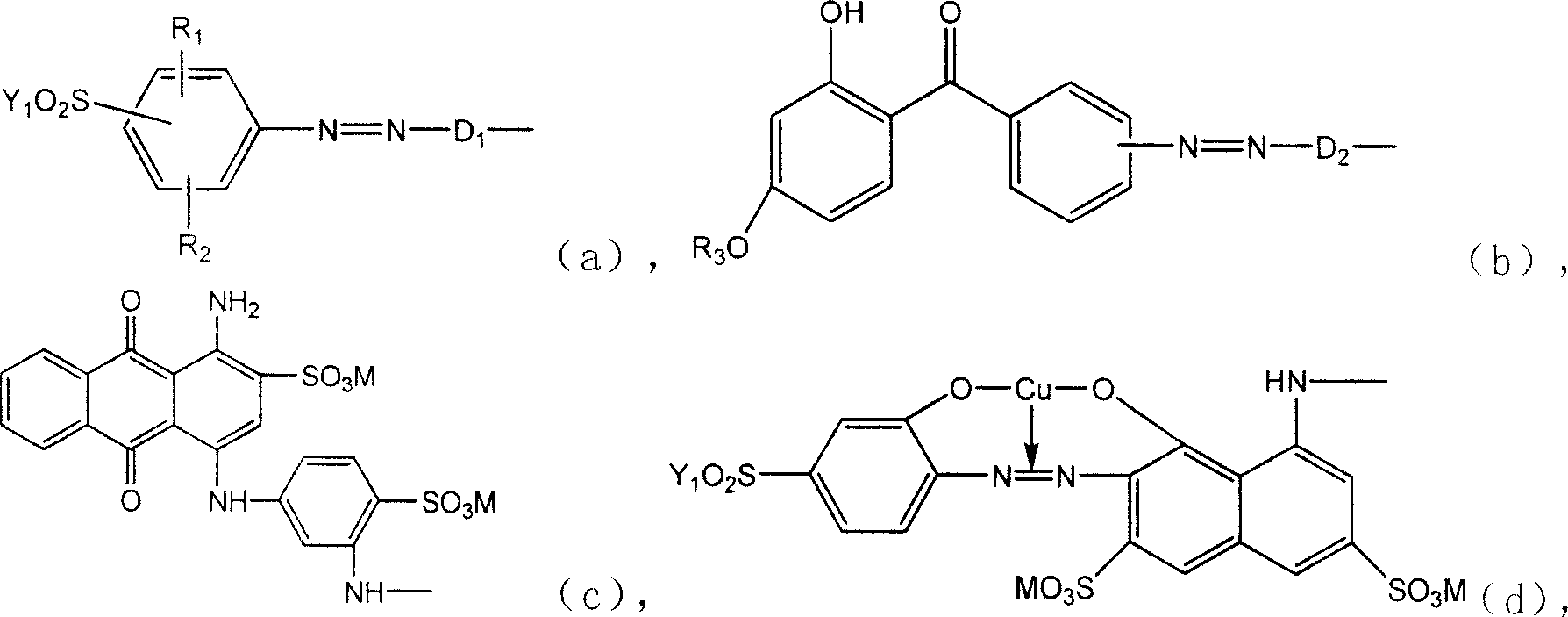

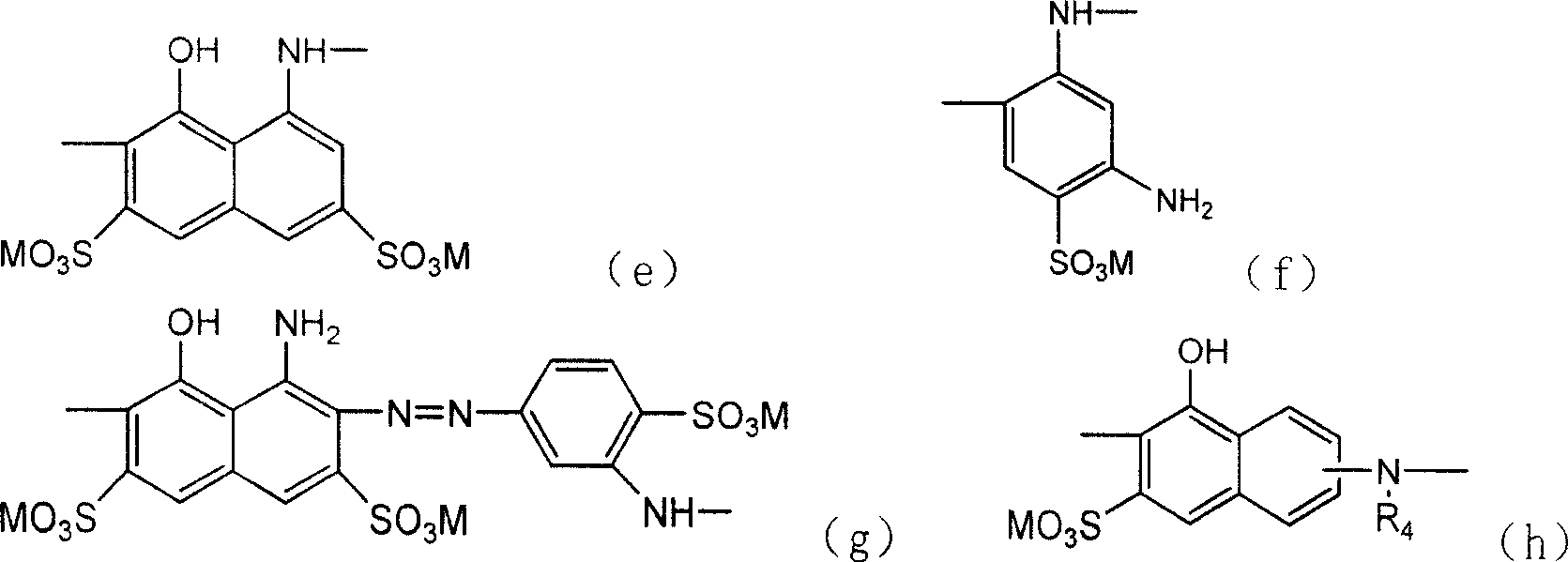

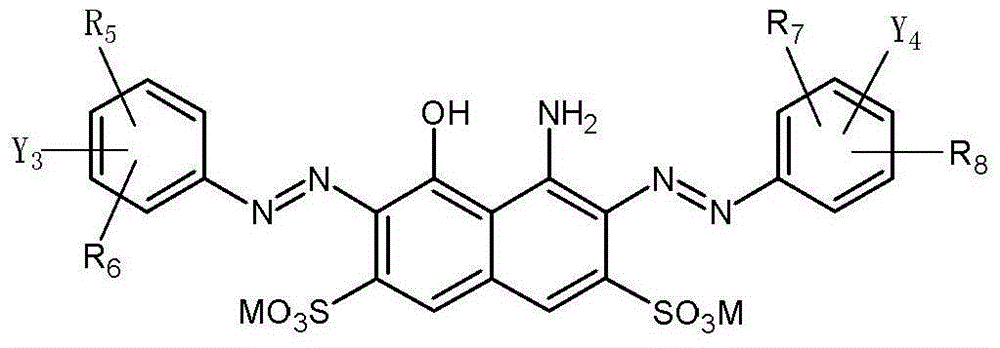

Red disazo dye compound, preparation method and composition thereof

InactiveCN101307186AHigh fixation rateExcellent wet fastnessAzo dyesDyeing processReactive dyeAcid dye

The invention provides a red bisazo-based dye compound (I) and a method for preparing the same, relating to a red bisazo-based dye composition. The red bisazo-based dye compound of the invention, after being commercialize, can used for dyeing in liquid and paste states after micronization or in powdery and granular states after being dried by spray drying. The dye is a novel product combining acid dry and reactive dye. The dye has excellent light fastness and remarkable wet fastness and is particularly applicable to nylon dyeing which has high requirements on color fastness to washing, rubbing and sweat as well as dyeing of wood fibers and cotton fibers. The cloth dyed with the dye has stability of heat sensitivity, and excellent sunproof, washable and water resistant performances.

Owner:SHANGYU XINSHENG CHEM IND +1

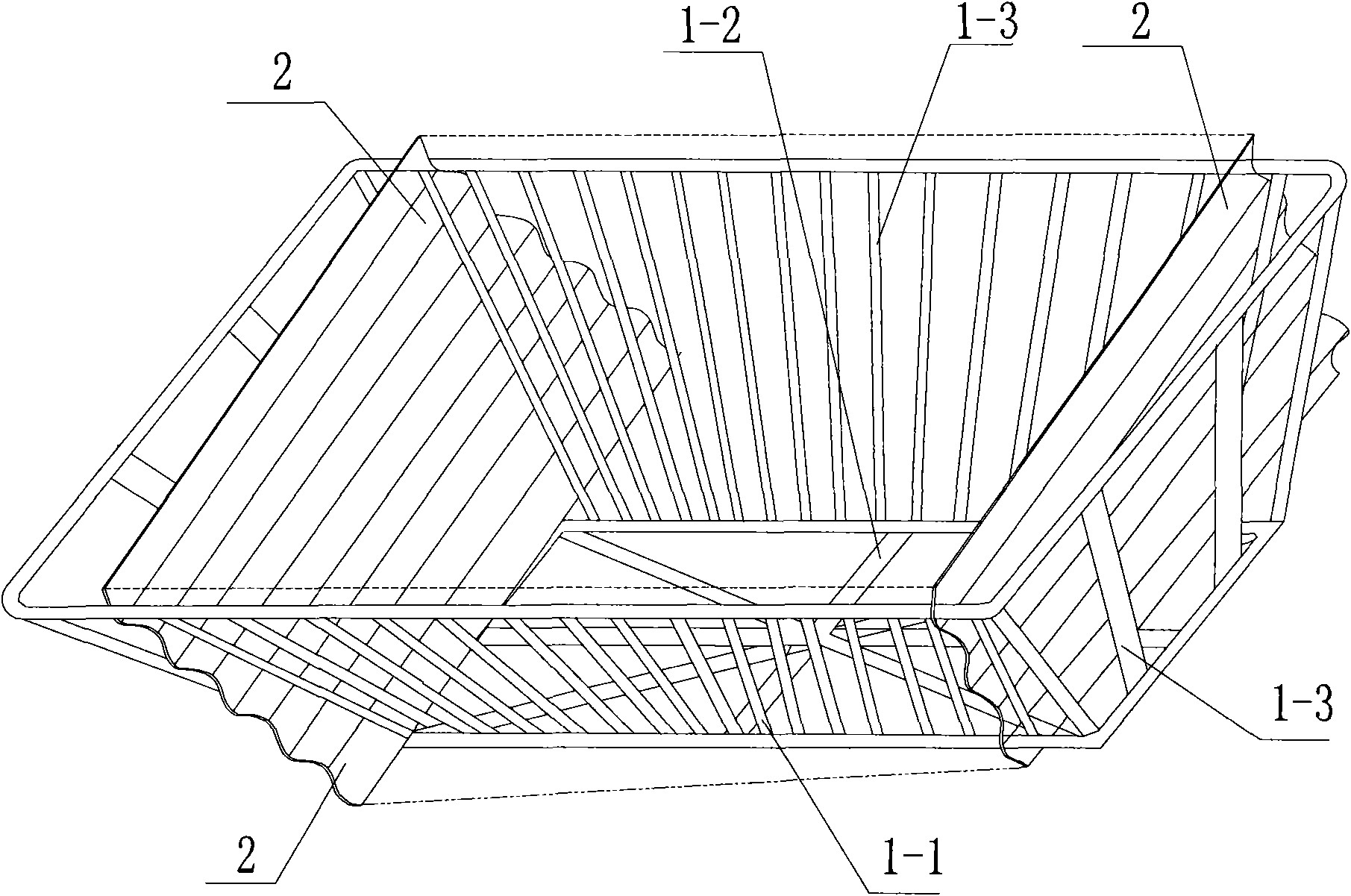

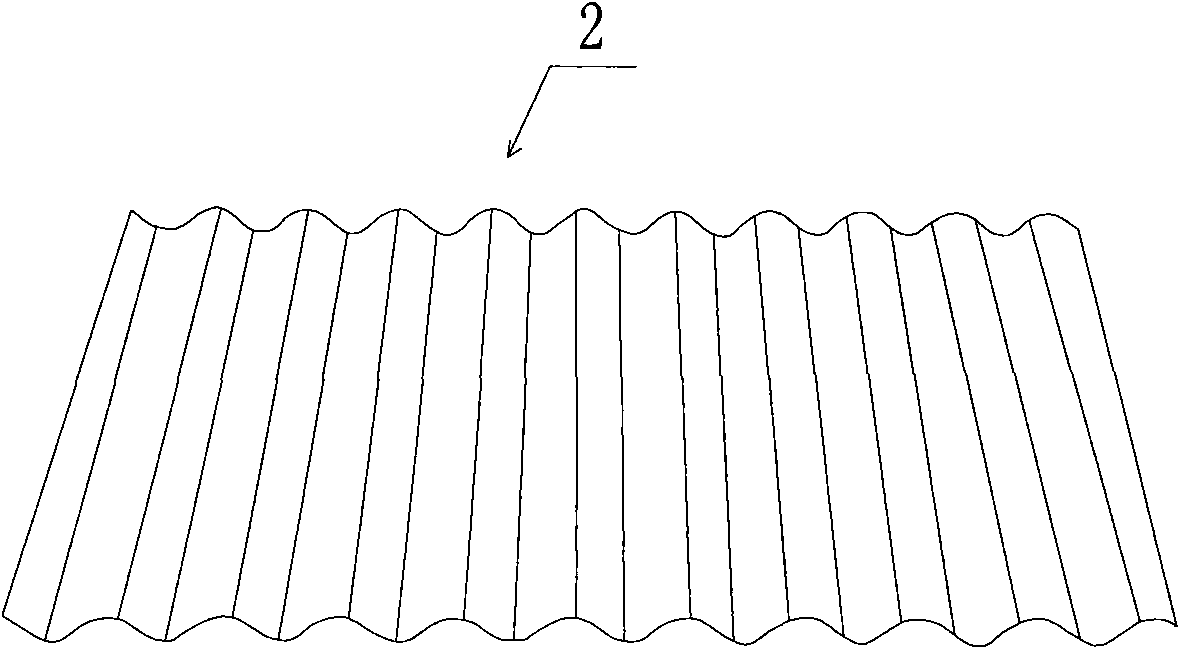

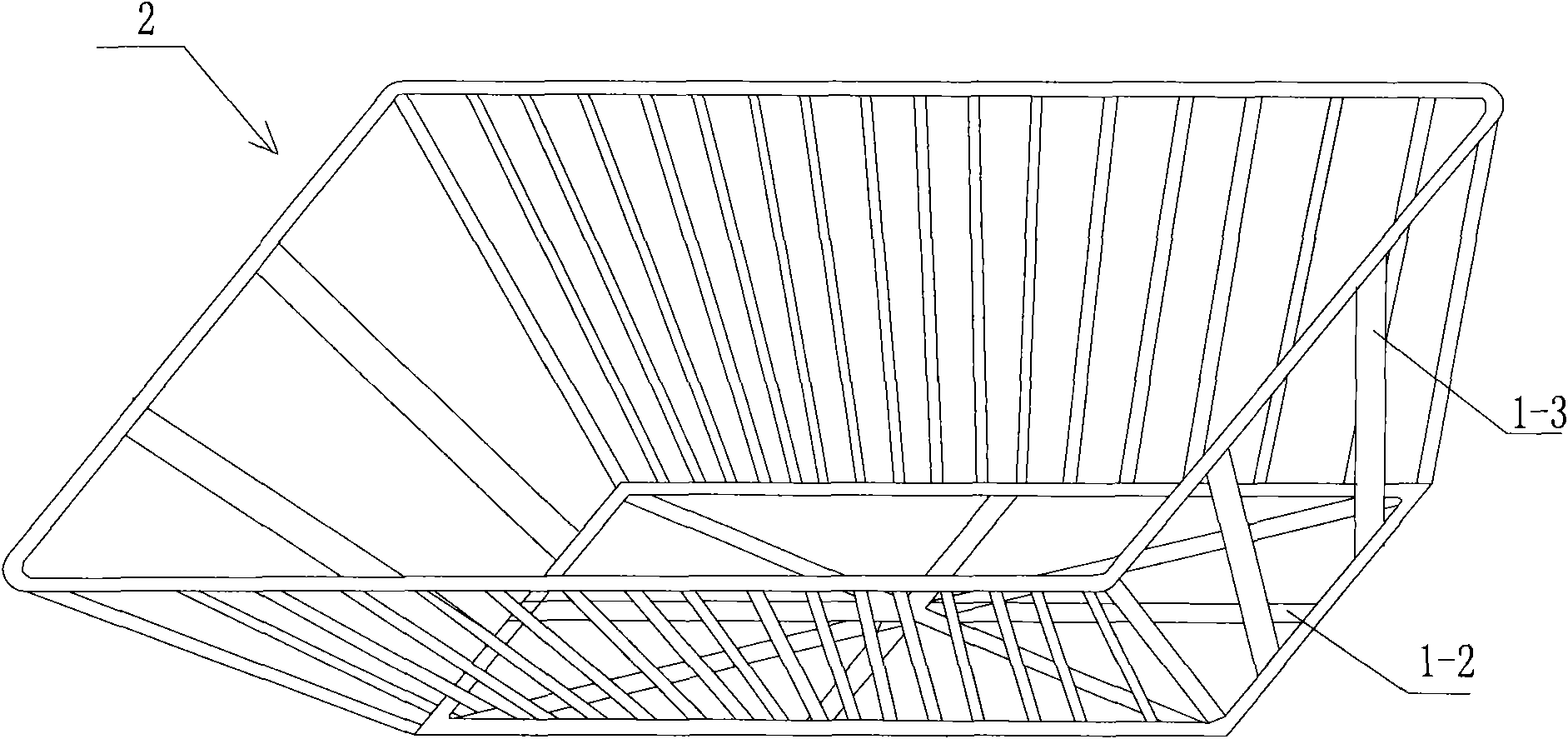

Method for culturing monomeric oyster seeds and seed collector

InactiveCN101773079AEasy to useExcellent adhesionClimate change adaptationPisciculture and aquariaOysterMonomer

The invention provides a method for culturing monomeric oyster seeds and a seed collector. The problems such as poor seed fixation effect, difficult substrate removal and the like in the prior art can be solved. By using a plastic corrugated plate as the fixation substrate of the monomeric oyster seeds in the invention, the problems such as unsatisfactory seed collection effect, difficult substrate removal, easy breakage of the oyster seeds, mutual conglomeration and attachment of oysters and the like in the prior art are solved.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

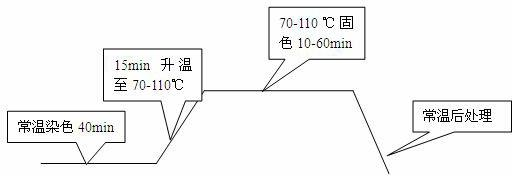

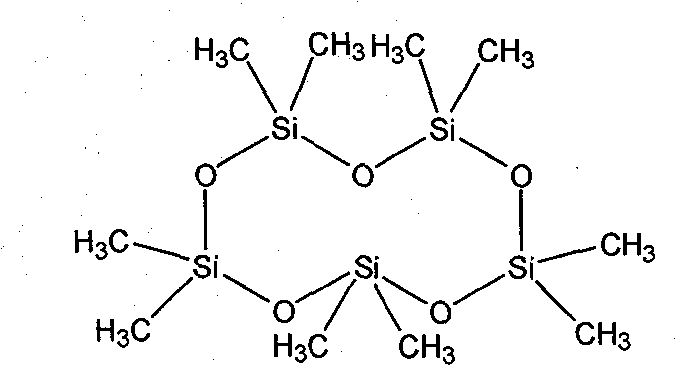

Dyeing process of pure cotton fabric

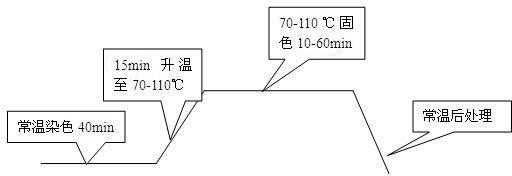

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

Efficient and continuous dyeing process method for textile fabric through wet-state steaming

InactiveCN101858019AShort processIncrease productivitySucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersVapor pressureAir volume

The invention provides an efficient and continuous dyeing process method for textile fabric through wet-state steaming, which belongs to the fabric dyeing method. The process method comprises the following steps in sequence: fabric soaking in dyeing solution, bake-steaming for color fixation, water washing and drying and feeding. During the drying and feeding procedure, the humidity of mixed gas in the reaction steam box is 25-35 percent, the temperature of the mixed gas is 120-130 DEG C, the air volume of the mixed gas is 4m3 / s, and the processing time is 2-3 minutes; the saturated vapor pressure is 0.15-0.2MPa; and during the water washing procedure, the content of the water softener B in lotion is 2-3g / L, and the rest is water. The dyeing process method shortens the process flow, thereby not only improving the production efficiency, but also saving the energy. In addition, compared with the traditional dyeing process, the dyeing process method has the advantages of high color fixing speed, high color fixing rate, bright color, no dye transfer, low alkali consumption, good reproducibility, good levelness, good penetration and the like. Therefore, the invention can be used for obtaining good washing-resistant and friction-resistant fastness.

Owner:YUYUE HOME TEXTILE

Preparation method of fibroin blending regenerated cellulose fiber

ActiveCN102851777AImprove stabilityHigh chemical activityConjugated cellulose/protein artificial filamentsArtificial filaments from viscoseCross-linkAdhesive

The invention discloses a preparation method of fibroin blending regenerated cellulose fiber, comprising the steps of (1) degumming, swelling, drying and smashing the silk offcuts to obtain a fibroin powder with grain size of 0.1-0.5 micrometers; (2) dispersing the fibroin powder with sodium hydroxide solution, adding the dispersing agent and the cross-linking agent aliphatic acid alkylolamides to obtain the fibroin dispersion mother solution; and (3) blending the fibroin dispersion mother solution with the cellulose adhesive to obtain the blended adhesive, and carrying out spinning molding and post processing to obtain the fibroin blending regenerated cellulose fiber. According to the preparation method provided by the invention, the loss amount of the protein in the preparation process is low, the content of protein in the produced fibroin blending regenerated cellulose fiber is high, the production cost is low, the strength of the fibroin blending regenerated cellulose fiber is high; and the preparation method is easy for industrial production, improves the textile processing performance of the fibroin blending regenerated cellulose fiber and broadens the application range of the fibroin blending regenerated cellulose fiber.

Owner:湖州珠力纳米材料科技开发有限公司

Reactive dye ecological dyeing method of silk fabrics

InactiveCN102767099ASave water for dyeingEasy to operateDyeing processSodium bicarbonateSodium Bicarbonate Solution

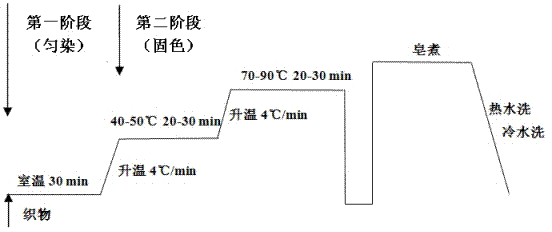

The invention provides a reactive dye ecological dyeing method of silk fabrics, which comprises the following steps of: (1) even dyeing: using reactive dye and decamethyl cyclopenta siloxane (D5) according to the mass ratio of 1:10 to 50 to prepare a reactive dye / D5 suspending dispersed liquid; padding the silk fabrics in 30 to 90 g / l of sodium bicarbonate solution; and dyeing the silk fabrics in the reactive dye / D5 suspending dispersed liquid with the rolling liquid rate of 160 to 200% at room temperature for 25 to 35 minutes, wherein the rolling liquid rate is used for ensuring even dyeing of the silk fabrics; and (2) color fixing: heating a mixture system obtained from the step (1) to 40 to 50 DEG C, and keeping the temperature for 20 to 30 minutes; then heating to 70 to 90 DEG C, and keeping the temperature for 20 to 30 minutes; and taking the silk fabrics out, and performing soap boiling. In the process of dyeing provided by the invention, an electrolyte is not added for dyeing acceleration, the dyeing rate of the dye is close to 100%, the fixing rate is higher than that of traditional bath dyeing, and the fastness of the fabrics is good after dyeing. Because the electrolyte is not needed for dyeing acceleration, the burden of treating dyeing waste water is effectively reduced, and the ecological environment is protected.

Owner:ZHEJIANG SCI-TECH UNIV

Knitted fabric printing and dyeing process with special effect

ActiveCN101649560AHas a hazy three-dimensional printing effectGood fixation ratePattern makingHeating/cooling textile fabricsEngineeringAdditional values

The invention relates to a knitted fabric printing and dyeing process with a special effect. A conventional CVC knitted fabric has the hazy three-dimensional printing effect by organically combining various processes together, such as active printing, dispersive printing, three-cedar sheet two-phase color fixation, and the like. The process is concretely divided into six steps of preprocessing blank fabric, burning-out printing, disperse / reactive printing in one paste, steaming, washing by water and molding, and the process is simple and is easy to operate; favorable physical and chemical indexes and color light reproducing performance are obtained through the two-phase color fixation process, thereby lower-end CVC burnt-out fabric becomes special style fabric with a high additional value. Accordingly, the invention has the characteristics of simple operation, high dye fixing rate, less pollution to environment, hazy three-dimensional special effect and favorable color light reproducing performance. The printing and dyeing process can be also used for a T / R product and a T / C product extended from the traditional CVC knitted fabric.

Owner:ZHEJIANG FURUN DYEING & PRINTING

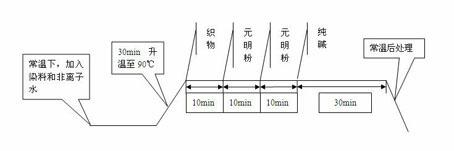

Reactive dye dyeing method for cotton fabric

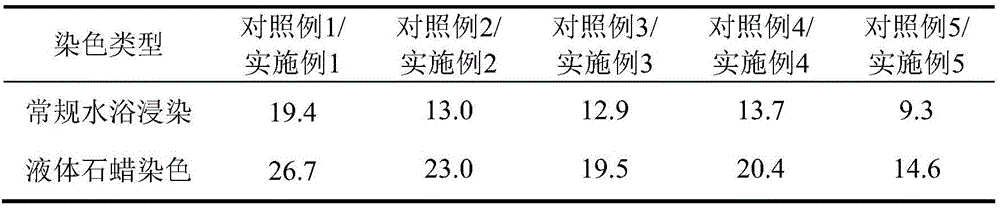

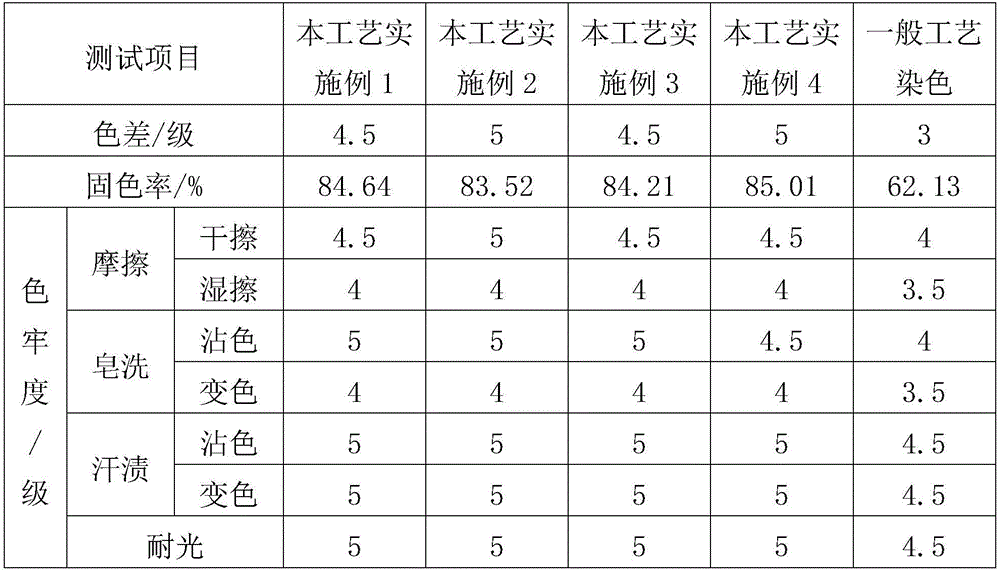

ActiveCN106337303AHigh dyeing rateSolve the large amount of saltDyeing processParaffin waxRoom temperature

The invention discloses a reactive dye dyeing method for a cotton fabric. The reactive dye dyeing method comprises the following steps of 1 pretreating of the cotton fabric, wherein the cotton fabric is padded in a sodium carbonate solution with the concentration of 10-100 g / L, the pickup rate is controlled to be 100%-200%, and dyeing is prepared; 2 dyeing, wherein dye liquor is prepared by utilizing liquid paraffin as a continuous phase medium for dyeing, and the cotton fabric obtained in the step 1 is placed into reactive dye / a liquid paraffin bath (dye liquor) at room temperature to be dyed for 20-60 min; 3 fixation, wherein the mixture system obtained in the step 2 is heated to 50 DEG C to 100 DEG C, and heat preservation is conducted for 20-50 min; 4 soap boiling, wherein the cotton fabric is taken out, and soaping is conducted to remove the unfixed dye on the surface of the cotton fabric. According to the reactive dye dyeing method for the cotton fabric, the liquid paraffin is selected to replace water to serve as the reactive dye dyeing medium, neutral salt is not needed for accelerating dyeing in the dyeing process, the dyeing rate of the dye is high, and the fixation rate is high.

Owner:ZHEJIANG SCI-TECH UNIV

Compound preservative for wood or wood products and preparation method and processing method thereof

InactiveCN102069520AEasy to prepareHigh fixation ratePressure impregnationWood impregnation detailsChemistryChemical compound

The invention discloses a compound preservative for wood materials, which is prepared by the following raw materials by weight percent: 60-90% of nano-carrier, 5-25% of boron type compound and 5-15% of quaternary ammonium salt; the preparation method comprises the following steps: preparing the nano-sol carrier, preparing water solution of the boron type compound and the quaternary ammonium salt and preparing a finished product; when in use, wood or a wood product is placed in a treatment tank for vacuum pumping, the compound preservative is injected at normal temperature, then the vacuum pumping is further performed on the treatment tank, the vacuum is finally removed, and the treatment is performed once to three times for getting the antiseptic wood or the wood product. The preparation method of the preservative for the wood materials is simple, and the operation is easy; furthermore, the preservative is harmless to people and animals, does not pollute the environment during the production process and the using process, is strong in fixation and anti-loss performance, does not affect the appearance, the mechanical properties and the processing performance of the wood material to be processed, and can be used for antiseptic and anti-insect protection of the wood and building wood structures for indoor and outdoor decoration.

Owner:ZHEJIANG UNIV

Polyester-cotton disperse dye, and reactive dye one-bath process dyeing method

ActiveCN106245368AHigh color fixing rateAvoid hydrolysisDry-cleaning apparatus for textilesDyeing processDisperse dyePh buffering

The invention discloses a polyester-cotton disperse dye, and a reactive dye one-bath process dyeing method. The reactive dye one-bath process dyeing method comprise following steps: a dyeing solution is prepared at normal temperature; pH value of the dyeing solution is adjusted to 4 to 6; polyester-cotton fabric is immersed; the temperature is increased to 95 to 105 DEG C at a rate of 2 to 3 DEG C / min, and then is increased to 130 to 150 DEG C at a rate of 1 to 2 DEG C / min; suction filtration of the dyeing solution and isolation of disperse dye microcapsules are carried out, and continuous dyeing is carried out for 15 to 25min; the temperature is reduced to 85 to 95 DEG C at a rate of 1.5 to 2.5 DEG C / min; and primary water washing, soaping, afterwashing, and drying are carried out. The dyeing solution comprise, 0.5 to 1.5%owf of a reactive dye, 30 to 40g / L of anhydrous sodium sulfate, 1.5 to 3.5g / L of a pH buffering agent, 0.5 to 5%owf of disperse dye microcapsule, and 0.1 to 3g / L of a dyeing auxiliary. The reactive dye one-bath process dyeing method is simple; period is short; fixation rate is high; and levelling properties are excellent.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Cold pad-batch dyeing process for pure cotton fabric

InactiveCN102535201ALower average tensionLow frictionTextile storage in superimposed formTextile storage in wounded formRoom temperaturePlastic film

The invention discloses a cold pad-batch dyeing process for pure cotton fabric. The process flow comprises the steps of: padding and rolling a mixed liquor of a dye and an alkaline agent, coiling and plastic film coating, rotating stacking, primary water washing, soaping, secondary water washing and drying. In the padding and rolling process, an active dye at a concentration of 10g / l is adopted, 10-15 g / l of water glass is adopted as the alkaline agent, a concentration of urea is 3 to 5g / l and a concentration of sodium sulfate is 10g / l. The rotating stacking process is performed for 16h at a room temperature of 10-15 DEG C. By the adoption of the process of the invention, energy can be saved, consumption can be reduced, the fixation ratio of the dye is increased, the grade of the product is improved, and the process cost is low. Besides, the conditions of the cold pad-batch dyeing process are moderate, the fabric is subjected to low tension and small friction, and the apparent effects and hand-feel of the fabric are improved to a great extent.

Owner:CHANGSHU KAIDA PRINTING & DYEING

Polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology

ActiveCN106245352AImprove adsorption capacityImprove dyeing uniformityDyeing processMicroballoon preparationDisperse dyeOrganic solvent

The invention discloses a polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology. The technology comprises the steps of: S1, polyester dyeing: dipping a to-be-dyed polyester-cotton fabric in a dye solution containing microcapsule disperse dye, conducting heat preservation at 65-75DEG C, then performing heat preservation at 110-130DEG C, and carrying out cooling to 30-40DEG C, using chitosan to serve as the carrier of the disperse dye, and then conducting crosslinking curing; S2. cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, carrying out stirring reaction, then adding a reactive dye, performing heat preservation at 55-65DEG C, adding an organic solvent, conducting heat preservation at 70-90DEG C, then adding organic amine and sodium carbonate, and performing heat preservation at 60-100DEG C; and S3, aftertreatment: performing cooling to room temperature, and then carrying out primary washing, soaping and after-washing. The polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology provided by the invention has the advantages of simple process, little pollution, wide dye applicability, uniform coloring, high color fixation rate and good level-dyeing properties.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Bio-active carbon fibre and its preparing process

InactiveCN1328178AHigh fixation rateGood biocompatibilityUltrasonic/sonic fibre treatmentFibre chemical featuresFiberCarbon fibers

A biologic activated carbon fibre for attaching microbes to it is prepared through fusion-free treatment of raw material at heating speed of 0.5-2 deg.C per min to obtain fusion-free fibre, charring at 300-1100 deg.C and heating speed of 80-160 deg.C / min, and activating at 800-950 deg.C for 5-60 min, wheere fatty acid is used as activation promoter and the ultrasonic waves are used while dipping.Its advantages include no metal compound, more than 20% of water content, 150 MPa of tension strength, 2.8-25 % of oxygen content, and excellent biologic compatibility.

Owner:BEIJING UNIV OF CHEM TECH

Disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric

ActiveCN106223076APreserve surface hydrophilic propertiesGood dyeing rateDyeing processDisperse dyePre treatment

The invention discloses a disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric. The method comprises the following steps: S1, pretreatment: padding a polyester cotton fabric to be dyed in a finishing liquid, conducting two dipping and two rolling, pre-drying at 60-80 DEG C, baking at 120-140 DEG C, washing with cold water and drying; S2, polyester dyeing: immersing the polyester in a disperse dye, insulating at 65-75 C, and insulating at 110-130 DEG C; S3, cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, stirring for reaction, adding a reactive dye, insulating at 70-80 DEG C, adding a dyeing auxiliary, insulating, adding soda ash, and insulating at 60-100 DEG C; and S4, posttreatment: conducting an initial washing, soaping and post washing. The disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric has the advantages of simple process, easy industrial implementation, wide dye application, uniform coloration, high fixation rate and good levelness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

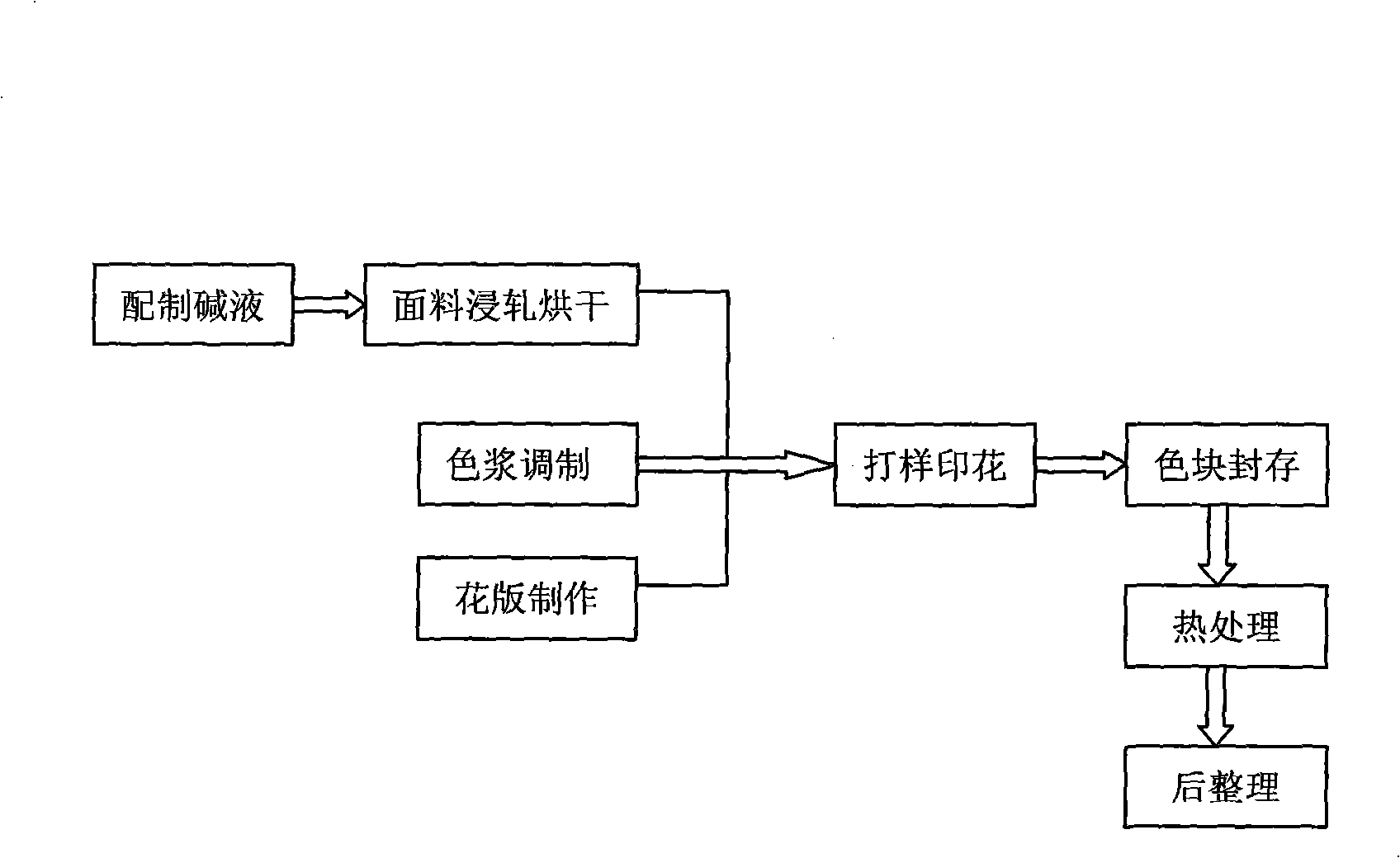

Printing and proofing method for silk reactive dye cold dome

InactiveCN101403201AHigh fixation rateRapid responseHeating/cooling textile fabricsDyeing processSmall sampleEngineering

The invention discloses a cold-stacking printing and proofing method of active silk dyes, which comprises the steps of preparation before printing; proofing and printing; the sealing of color blocks; heat treatment; and post treatment; the preparation before printing comprises three steps that need to be finished before the printing but the sequence of which is not restricted: the preparation of fabrics; the modulation of color paste; the making of a printing plate; the preparation of fabrics comprises two steps: lye is prepared; and the fabrics are padded in the lye and then dried. The method leads strong alkali on the fabrics to impel the active dye and the silk fibers to react quickly by padding the strong alkali on the fabrics, printing the color paste with the active dye after the drying and lifting the stacking temperature to 70 DEG C to 80 DEG C. Therefore, not only the color yield of small samples can be most close to the cold-stacking printing of 3 hours to 10 hours, but also the proofing time can be shortened to be within 10 minutes to 15 minutes after the method is used. The cold-stacking printing and proofing method of the active silk dyes solves the technical difficulties that compared with the mass production, the cold-stacking printing and proofing of the silk active dyes is large in difference and long in time, improves the fixation rate of the active dyes and shortens the proofing time.

Owner:浙江华泰丝绸有限公司

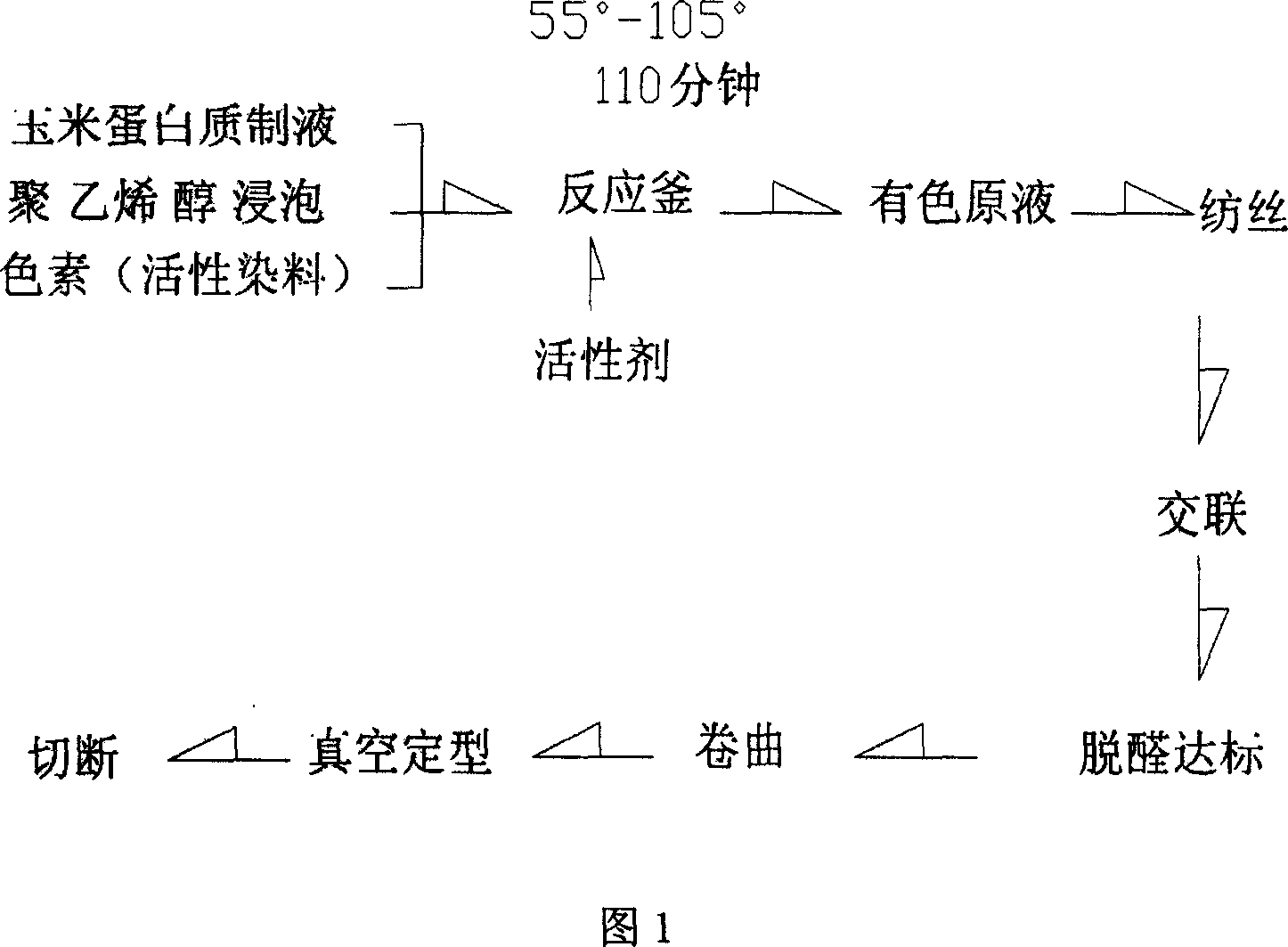

Maize protein colored textile fiber and method for producing same

InactiveCN1952225AHigh color fastnessNo pollution in the processMonocomponent protein artificial filamentDye addition to spinning solutionTextile fiberPhysical chemistry

The invention provides a colored fiber of corn protein and manufacture method. There is activated dye in corn protein. The manufacture method is that activated dye is added in the process for confecting spinning solution and plant protein colored fiber with the density of 0.7-3.0dtex is slubbed by wet spinning technology after ripening and polymerizing in reaction vessel. Because of activated dye added in confecting process, strike and fixation rates are improved. In detection method the cooler fiber has good fastness with five degree and enough light. There are no pollution and public disaster in the activated dye. The fiber is provided with good moisture conduction, light gravity, dry heat resistance and so on. It is knitted and tatted to various ultrathin or thickening apparel fabrics with high grade.

Owner:韩晓根 +1

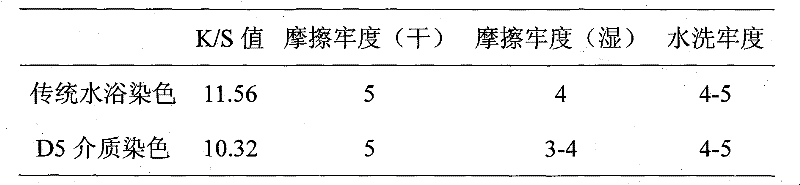

New dyeing method of active dye taking methylsiloxane as medium

The invention discloses a new dyeing method of an active dye taking methylsiloxane as a medium. In the invention, a non-aqueous medium is adopted, which can rapidly close to a fiber surface under the condition of not adding electrolyte for accelerating dye completely, thereby obviously improving adsorption rate and equilibrium adsorption capacity of the active dye, improving fixation rate of the dyeing, completely avoiding the problems of environment and zoology caused by using a large number of inorganic salts, and realizing salt-free dyeing of the active dye in a real meaning. The medium adopted by the invention can be used repeatedly, thereby reducing environmental pollution.

Owner:ZHEJIANG SCI-TECH UNIV +1

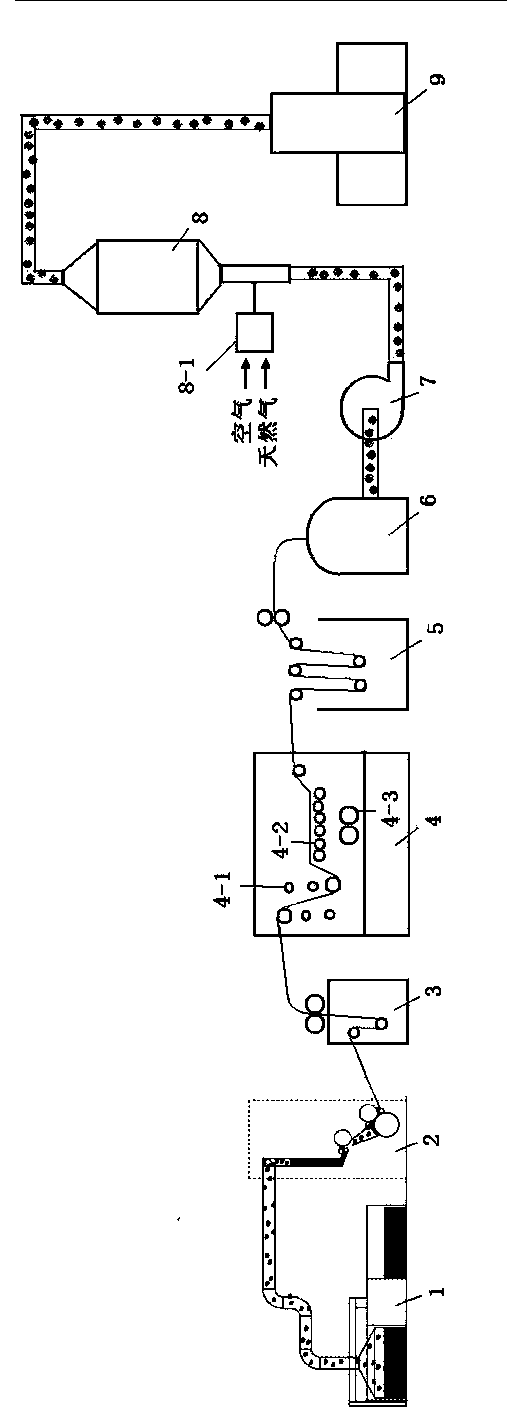

Method and system for shortened wet steaming dyeing of loose fibers

InactiveCN103726217ARealize continuous productionReduce manufacturing costSucessive textile treatmentsLiquid/gas/vapor removalFiberEngineering

The invention discloses a method and a system for shortened wet steaming dyeing of loose fibers. The method and the system have the advantages that continuous production of loose fiber dyeing is realized, so that production cost is lowered, production efficiency is improved, and labor intensity is lowered; shortened wet steaming technology which can save energy and reduce emission is applied to dyeing of the loose fibers, the dyeing process is simple, convenient, high in efficiency and energy saving, setting rate is high, dyeing effect is good, and dyestuff is high in utilization rate and environment friendly; automatic level of the dyeing system is increased.

Owner:JIANGSU BEILIN TEXTILE CO LTD

Active dye containing ultraviolet absorbing groups

The invention provides a dye compound containing an ultraviolet absorbing group, and also provides a preparation method and application of the dye compound. The dye compound of the present invention can be firmly combined with cellulose fibers and has excellent ultraviolet absorption performance.

Owner:DALIAN UNIV OF TECH

Process for cotton reactive dye applying in silk broadcloth dying

The invention relates to a technique for dyeing silk fabrics by a cotton reactive dye. The technical problem to be solved is that the technique needs to dye silk fabrics by the cotton reactive dye effectively, has the characteristics that the dye uptake is high, the fixation ratio is high, the color depth of the product is increased greatly, the coloring matter is saved and the dyeing quality is high; moreover, the residual liquid discharge concentration is decreased and the environment is protected. The technical proposal is to adopt the cotton reactive dye for dyeing silk fabrics and has the following steps that: 1) the silk broadcloth after the pre-treatment is placed into a dye vat, a dye solution is prepared and is added into the dye vat to dye, the dye solution has a pH value ranging from 6.5 to 7.5, the dye temperature ranges from 85 to 98 DEG C, the dye time lasts one to two hours; 2) the dye residual solution is discharge partially or completely, clear water is added, the temperature is adjusted to 50 to 60 DEG C; 3) certain amount of ammonium polycarylate is added to fix the color, the pH value is kept to be 9 to 10, the fixation time lasts one to two hours, the temperature of the clear water ranges from 4 to 20 DEG C.

Owner:HIGH FASHION CHINA CO LTD

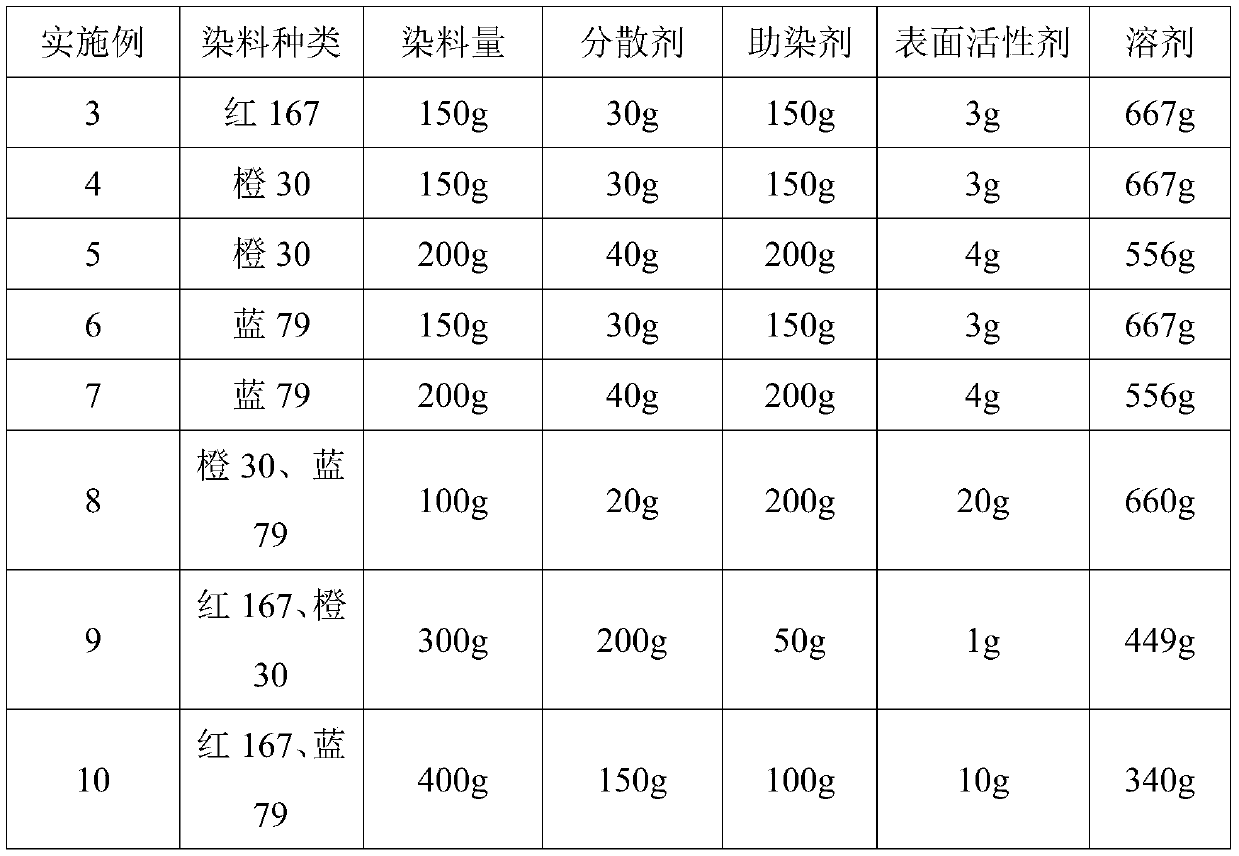

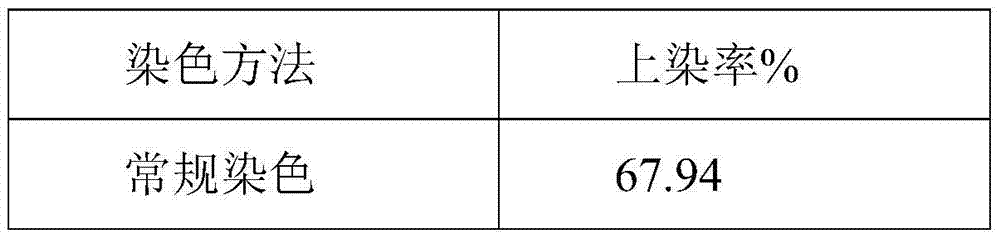

Waterless dyeing disperse dye color paste, preparation method and application thereof

ActiveCN110862699ASmall particle sizeEasy to transportOrganic dyesDyeing processDisperse dyeActive agent

The invention provides a waterless dyeing disperse dye color paste, which is composed of the following raw materials by weight: 10%-40% of a disperse dye filter cake, 2%-35% of a dispersing agent, 5%-20% of a dyeing assistant, 0.1%-0.5% of a surfactant and 20%-88% of a solvent. The waterless dyeing disperse dye color paste provided by the invention is small in particle size, and after waterless dyeing, textiles do not contain crackable carcinogenic aromatic amine azo dye, allergenic dye, forbidden aromatic amine or bioactive substance. The waterless dyeing disperse dye color paste disclosed bythe invention can be stored stably for 6-12 months, is beneficial to dye transportation and dyeing plant production management, and has a dyeing effect of high fixation rate after being applied to textiles.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

High-efficiency steaming production process by two-phase printing process

InactiveCN101608406AFast steam fixationEasy to operateDyeing processLiquid/gas/vapor textile treatmentFiberColour fastness

The invention discloses a high-efficiency steaming production process by a two-phase printing process. The process comprises the following steps: reactive dye is used as a first phase to be printed on a fiber; a second phase is rolled independent of a color fixing liquid alkaline agent, alkali can promote ionization of the fiber and the reaction velocity of the dye, and lead the dye and the fiber to be activated to form covalent bond, and to speed up the completion through a high efficiency steam box. The process comprises the following steps: pretreating openpore, printing and drying single pulp by the dye without fixing agents, such as alkali and the like, rolling the fixing chemical liquid in high efficiency and short steaming efficiently; and washing and drying. The process has the characteristics of high reaction speed, steam usage conservation, high production efficiency, good dye yield and color fastness and high production quality.

Owner:杨安心

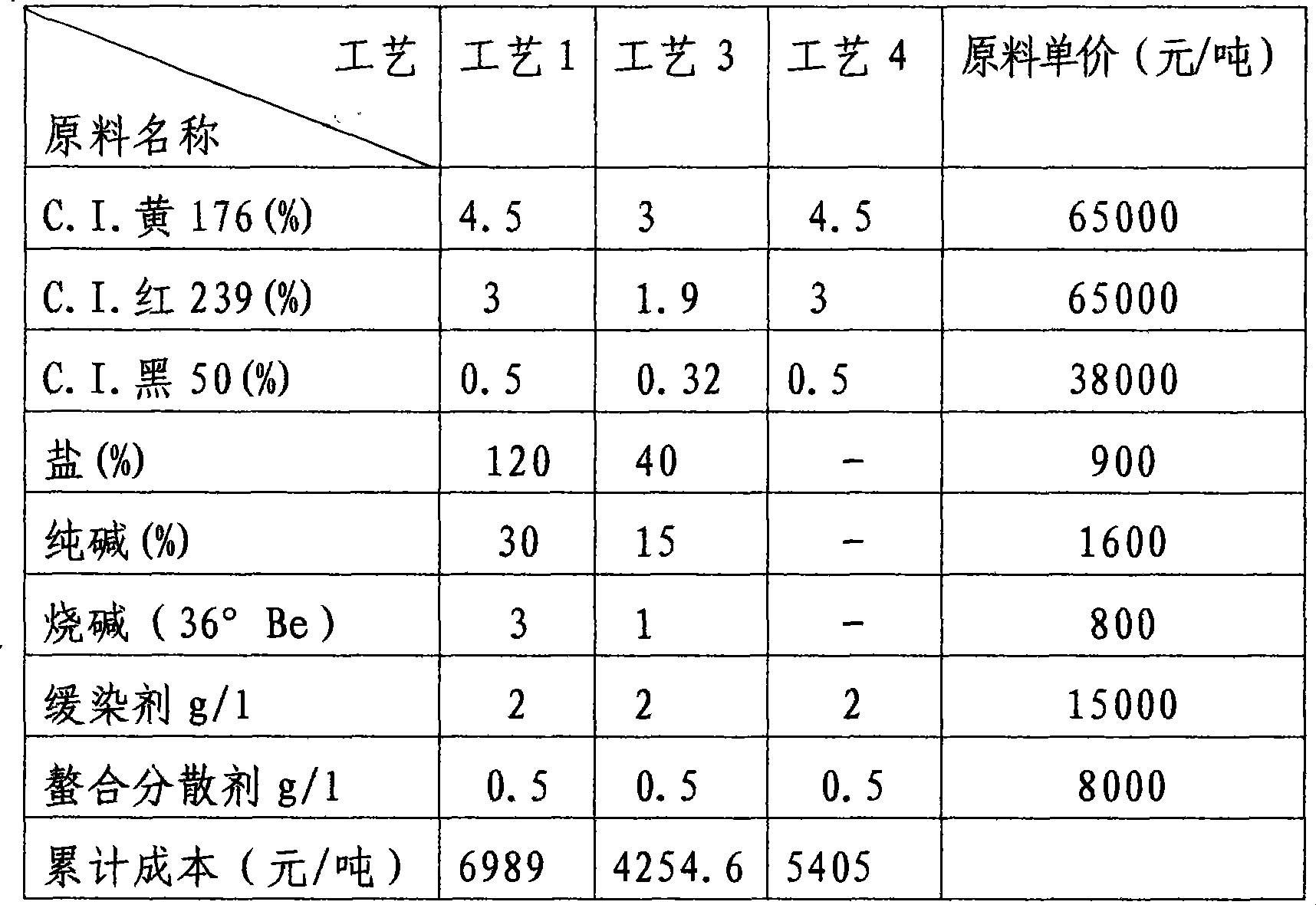

Composite active black dye

ActiveCN104530755AGood compatibilityEasy to washOrganic dyesDyeing processPhotochemistryMaterial technology

The invention relates to the field of active dye in a novel material technology, and particularly relates to composite active black dye. The composite active black dye is formed by mixing active dye A, active dye B, active dye C and active dye D, wherein the weight percent of the four active dye is as follows: the dye A accounts for 5 to 70 percent; the dye B accounts for 5 to 70 percent; the dye C accounts for 5 to 20 percent; the dye D accounts for 5 to 30 percent. The dye provided by the invention is not only good in compatibility and easy to wash, but also relatively high in fixation rate; the absolute fixation rate of the composite active black dye reaches up to 80 to 85 percent; the dying residual liquid can be reduced by 30 to 40 percent under the same condition.

Owner:ZHEJIANG YIDE CHEM

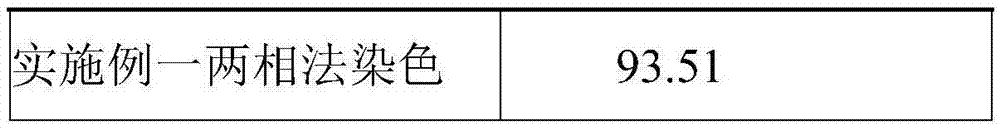

All-cotton fabric dyeing method adopting two-phase medium

The invention discloses an all-cotton fabric dyeing method adopting a two-phase medium based on a dyeing system consisting of an oil phase medium and a water phase medium which are not incompatible. The oil phase medium consists of a cyclic polymer of dimethyl siloxane and a lipophilic nonionic surfactant; the lipophilic nonionic surfactant is low in turbidity point, so that the oil phase medium and the water phase medium can be mixed under lower temperature to form one phase; with the increase of the temperature, the phase can be divided into two phases to ensure successful dyeing and facilitate recycling of the oil phase medium. The method comprises the following steps: weighing a textile with a certain weight, preparing the oil phase medium and the water phase medium, adding a fiber textile, performing dyeing curing treatment, soaping and drying the product. According to the all-cotton fabric dyeing method adopting the two-phase medium, the steps are simple, convenient and feasible; water consumption is greatly reduced; meanwhile, dyeing wastewater emission is relieved, the dyeing rate and the curing rate are greatly improved, and energy consumption is reduced.

Owner:ZHEJIANG SILK TECH

Printing and dyeing process of knitted fabric

InactiveCN103741508AHigh fixation rateReduce pollutionFibre treatmentDyeing processStencil printingScreen printing

The invention discloses a printing and dyeing process of a knitted fabric. The printing and dyeing process comprises the following steps: 1) taking 6-7 parts by mass of a refining agent, 3-5 parts by mass of hydrogen peroxide, 8-9 parts by mass of an alkali, 4-7 parts by mass of a brightening agent for treating a grey fabric, dewatering and shaping; 2) preparing stencil printing paste, using a rotary screen printing machine for printing and completing burnout printing; 4) well preparing pattern forming paste; and using the rotary screen printing machine for printing with the temperature of a drying room of 125 DEG C to complete the dispersion activity same-paste printing; 5) baking at 165-170 DEG C for 4 to 6 minutes; 6) adopting a wet shortened steaming device for surface rolling of a color fixing solution containing 7g / L of borax, 17g / L of caustic soda and 35g / L of sodium silicate, with the mangle expression being 75%, the steaming temperature being 135 DEG C and the ageing time being 4 to 5 minutes; 7) performing water washing by selecting of a continuous rope-like water washing machine, and using a centrifuge for dehydrating; and 8) softening and shaping. The printing and dyeing process disclosed by the invention has the characteristics of high fixation rate of dyes, simplicity in operation and small environmental pollution.

Owner:CHANGSHU FUYI PRINTING & DYEING

Soybean protein colored spinning fiber and its production method

InactiveCN1928169AHigh color fastnessNo pollution in the processMonocomponent globulin artificial filamentDye addition to spinning solutionFiberSoybean protein

The invention provides a soybean protein colored fiber and production method. There is activated dye in soybean protein colored fiber. The production method is described as: during the process of making up filature original fluid, activated dye is put in, then colored fiber of plant protein whose density is 0.7-3.0dtex is ripened, get together and slubbed through technology of wet method filature in reactor. Because activated dye is put in during making up fluid coloring and sessile rates are increased. Coloring firming degree of the colored fiber can reach five grades after measuring.

Owner:韩晓根 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com