Bio-active carbon fibre and its preparing process

A technology of biological activated carbon and carbon fiber, which is applied in fiber treatment, fiber chemical characteristics, ultrasonic/sonic fiber treatment, etc. Excellent capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

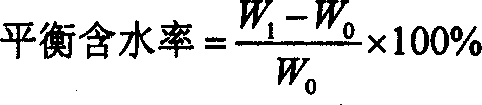

[0019]The polyacrylonitrile copolymer fiber (its single-filament hole number is 3000, denier 1.1 denier (1.22dtex)) that the commercially available British courtaulds company of election wet spinning is produced contains more than 90% acrylonitrile monomer component ( By weight) is: acrylonitrile 96, methylene succinic acid 1, methyl acrylate 3, equilibrium moisture content 0.67%. The non-melting treatment is carried out at 220-280 ° C, the heat treatment atmosphere is air, the treatment time is 60 minutes, and the heating rate 1.0°C / min. Fiber deformation +10%, to obtain polyacrylonitrile non-melting fibers with an equilibrium moisture content of 6.9% and a fiber oxygen content of 9.5%. Carbonize and activate the fibers at 300-800°C. Control the carbonization heating rate to 80 °C / min, activation temperature 800 °C, activation time 30 minutes, obtain equilibrium moisture content 29.7%, fiber oxygen content 20.4%, tensile strength 489Mpa, specific surface area 1326m 2 / g of ac...

Embodiment 2

[0021] Except that it does not melt and the heating rate, all the other operating conditions are the same as in Example 1. The non-melting heating rate is reduced by one time than that of Example 1, and the non-melting fiber with an equilibrium moisture content of 10.5% and a fiber oxygen content of 16.2% is obtained, and an equilibrium moisture content of 32.9%, a fiber oxygen content of 25.1%, a tensile strength of 365Mpa and a specific Surface area 1358m 2 / g of bioactive carbon fiber. Because the heating rate of the non-melting treatment of the polyacrylonitrile fiber is low and the time of the fiber non-melting is long, the biocompatibility of the activated carbon fiber is excellent.

Embodiment 3

[0023] Except that it does not melt and the heating rate, all the other operating conditions are the same as in Example 1. The non-melting heating rate was increased to 1.5°C / min to obtain non-melting fibers with an equilibrium moisture content of 5.4% and a fiber oxygen content of 7.4%, as well as an equilibrium moisture content of 24.3%, a fiber oxygen content of 21.1%, a tensile strength of 324Mpa and a specific surface area 1123m 2 / g of activated carbon fiber. The biocompatibility of activated carbon fibers decreased due to the rapid heating rate of polyacrylonitrile fibers in non-melting treatment. The biocompatibility of the bioactive carbon fiber still meets the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com