Polyester-cotton disperse dye, and reactive dye one-bath process dyeing method

A technology of disperse dyes and reactive dyes, applied in the field of dyeing, can solve the problem of no disperse dye capsules/reactive dyes, etc., and achieve the effects of excellent light fastness, reduced interference and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

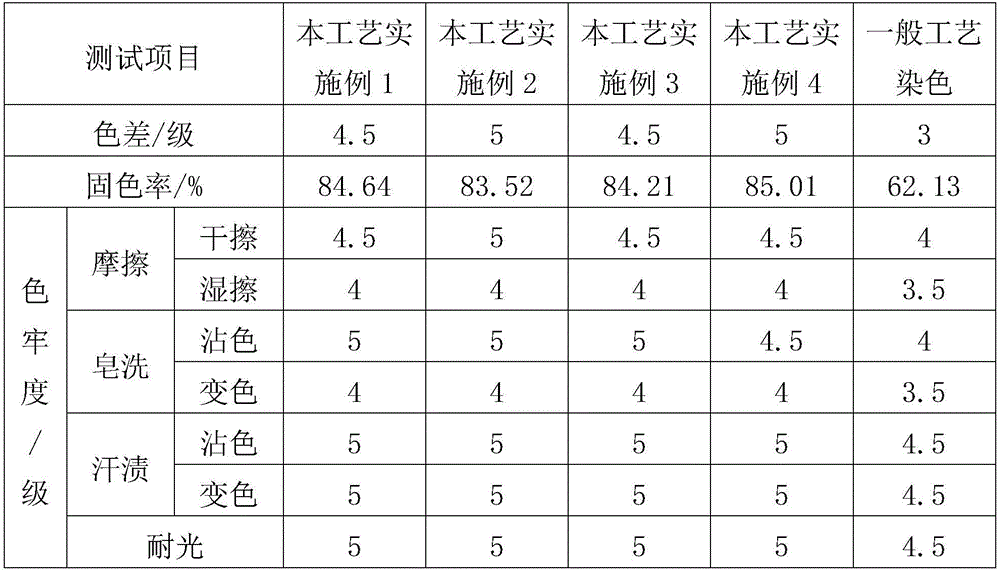

Examples

Embodiment 1

[0019] In this embodiment, a polyester-cotton disperse dye and reactive dye one-bath dyeing process includes: preparing a dye solution at room temperature, adjusting the pH of the dye solution to 4, immersing the polyester cotton in accordance with the bath ratio of 1:40, and using 2°C / min The temperature was raised to 105°C at a rate of 10 minutes, and then the temperature was raised to 130°C at a rate of 2°C / min, and kept at a temperature of 45 minutes. ℃, wash at 25℃ for 5 minutes, use 3g / L NP-10 and 1g / L soda ash to wash at 100℃ for 5 minutes, then wash at 80℃ for 5 minutes, and dry;

[0020] Wherein, the dyeing solution includes: reactive black G 0.5% owf, anhydrous sodium sulfate 40g / L, pH buffer 1.5g / L, disperse dye microcapsules 5% owf, dyeing auxiliary 0.1g / L; The preparation method of the dye microcapsules comprises: adding disperse yellow brown XF and chitosan to the acetic acid solution with a concentration of 0.5wt%, stirring evenly, adding liquid paraffin and Twe...

Embodiment 2

[0022] In this embodiment, a polyester-cotton disperse dye and reactive dye one-bath dyeing process includes: preparing a dye solution at room temperature, adjusting the pH of the dye solution to 6, immersing the polyester cotton in accordance with the bath ratio of 1:10, and using 3°C / min Raise the temperature to 95°C at a rate of 15 minutes, then raise the temperature to 150°C at a rate of 1°C / min, keep it at a temperature of 35 minutes, then filter the dye solution to isolate the disperse dye microcapsules and continue dyeing for 25 minutes, then cool down to 95°C at a rate of 1.5°C / min. ℃, wash at 15℃ for 15min, use 1g / L NP-10 and 3g / L soda ash to wash at 95℃ for 15min, then wash at 60℃ for 20min, and dry;

[0023] Wherein, the dye solution includes: reactive red C-XDR 1.5% owf, anhydrous sodium sulfate 30g / L, pH buffer 3.5g / L, disperse dye microcapsules 0.5% owf, dyeing auxiliary 3g / L; The preparation method of disperse dye microcapsules comprises: adding disperse crimson...

Embodiment 3

[0025] In this embodiment, a polyester-cotton disperse dye and reactive dye one-bath dyeing process includes: preparing a dye solution at room temperature, adjusting the pH of the dye solution to 5, immersing the polyester cotton in accordance with the bath ratio of 1:25, and using 2.5°C / min Raise the temperature to 100°C at a rate of 12 minutes, then raise the temperature to 140°C at a rate of 1.5°C / min, keep it at a temperature of 40 minutes, then filter the dye solution to isolate the disperse dye microcapsules and continue dyeing for 20 minutes, then cool down to 90 at a rate of 2°C / min. ℃, wash at 20℃ for 10min, use 2g / L NP-10 and 2g / L soda ash to wash at 98℃ for 10min, then wash at 70℃ for 10min, and dry;

[0026] Wherein, the dyeing solution includes: active orange C-3R 1% owf, anhydrous sodium sulfate 35g / L, pH buffer 2.5g / L, disperse dye microcapsules 2% owf, dyeing auxiliary 1g / L, the The preparation method of disperse dye microcapsules comprises: adding disperse blu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com