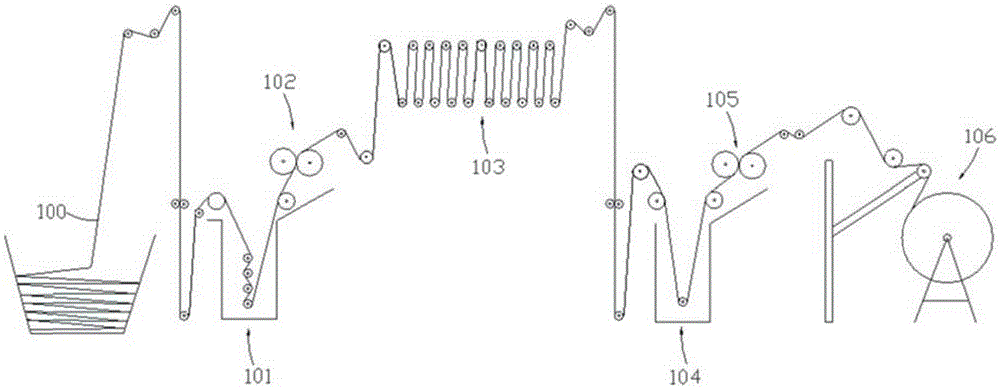

Reactive dye cold pad-batch dyeing equipment and dyeing method

A technology for cold pad dyeing and reactive dyes, applied in the field of reactive dye cold pad dyeing equipment, can solve the problems of low utilization rate of reactive dyes, inconsistent cloth surface temperature, poor penetration and diffusion, etc. The effect of uniform color and avoiding alkali resistance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The fabric is pure cotton mercerized semi-finished product, which is dyed according to the following method.

[0064] A reactive dye cold pad-batch dyeing method, comprising the following steps:

[0065] (1) One padding: the fabric passes through the first dipping tank and the first padding car in turn;

[0066] Wherein, the liquid carrying rate of the fabric after the first padder is 55%;

[0067] The composition in the first dipping tank is:

[0068] Active Bright Yellow BES (Shanghai Wonder Chemical Co., Ltd.), the concentration is 60g L -1 ;

[0069] Deoxygenase, the concentration is 3g L -1 ;

[0070] Penetrant, the concentration is 2g·L -1 ;

[0071] (2) Ventilation treatment for 2 minutes;

[0072] (3) Second padding: the fabric passes through the second dipping tank and the second padding car in turn;

[0073] Wherein, the liquid carrying rate of the fabric after the second padder is 85%;

[0074] The composition in the second dipping tank is:

[0075...

Embodiment 2

[0083] The fabric is pure cotton mercerized semi-finished product, which is dyed according to the following method.

[0084] A reactive dye cold pad-batch dyeing method, comprising the following steps:

[0085] (1) One padding: the fabric passes through the first dipping tank and the first padding car in turn;

[0086] Wherein, the liquid carrying rate of the fabric after the first padder is 60%;

[0087] The composition in the first dipping tank is:

[0088] Active Orange 122 (Shanghai Wonder Chemical Co., Ltd., Active Orange B-2RFN), the concentration is 40g L -1 ;

[0089] Reactive red 222 (Wujiang Taoyuan Dyestuff Co., Ltd., reactive scarlet BF-2GF), the concentration is 10g L -1 ;

[0090]Deoxygenase, the concentration is 3g L -1 ;

[0091] Penetrant, the concentration is 2g·L -1 ;

[0092] (2) Ventilation treatment for 3 minutes;

[0093] (3) Second padding: the fabric passes through the second dipping tank and the second padding car in turn;

[0094] Wherein,...

Embodiment 3

[0105] The fabric is a semi-finished product of Modal bleaching and bleaching, and it is dyed according to the following method.

[0106] A reactive dye cold pad-batch dyeing method, comprising the following steps:

[0107] (1) One padding: the fabric passes through the first dipping tank and the first padding car in turn;

[0108] Wherein, the liquid carrying rate of the fabric after the first padder is 60%;

[0109] The composition in the first dipping tank is:

[0110] Reactive blue 19 (Shanghai Wonder Chemical Co., Ltd., active brilliant blue B-RV), the concentration is 40g L -1 ;

[0111] Deoxygenase, the concentration is 3g L -1 ;

[0112] Penetrant, the concentration is 2g·L -1 ;

[0113] (2) Ventilation treatment for 4 minutes;

[0114] (3) Second padding: the fabric passes through the second dipping tank and the second padding car in turn;

[0115] Wherein, the liquid carrying rate of the fabric after the second padder is 75%;

[0116] The composition in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com