Multi-color roller gravure printing production method of textile dye

A gravure printing and textile technology, which is applied in the field of multi-color roller gravure printing for textile dyes, can solve the high technical requirements of dyes and supporting auxiliaries, reduce the quality of printed textile products, and print textiles. Reduced staining of white ground and other issues, to achieve the effect of reducing staining of white ground, rich color gradation of printed patterns, and less floating color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] New production method of multi-color roller gravure printing with reactive dyes on cotton cloth (1)

[0021] Production materials: mercerized cotton dyeing chemicals: reactive dye gravure printing ink, sodium hydroxide, sodium carbonate, potassium carbonate, sodium chloride, soaping liquid (2g / L soap flakes, 2g / L soda ash).

[0022] Production equipment: multi-color roller gravure printing machine with adjustable thickness of printed matter, lengthened door width, enhanced drying, etc., uniform padding machine, fast steaming machine, flat car washing machine.

[0023] 1. Gravure printing process

[0024] Gravure printing process and conditions

[0025] Mercerized cotton → multi-color roller gravure printing (speed 30 m / min) → drying → printed cotton

[0026] 2. Soda rolling and steaming process

[0027] 2.1 Alkaline solution prescription

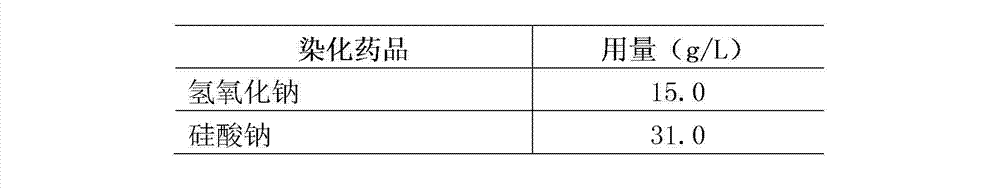

[0028] Table-1 Prescription of Reactive Dye Printing Alkali Solution

[0029]

[0030] 2.2 Soda rolling and steaming process...

Embodiment 2

[0037] New production method of multi-color roller gravure printing with reactive dyes on cotton cloth (2)

[0038] Production material: mercerized cotton cloth

[0039] Dyeing chemicals: sodium hydroxide, sodium silicate, reactive dye gravure printing printing ink, soaping liquid (2g / L soap flakes, 2g / L soda ash).

[0040] Production equipment: Uniform padding machine, infrared drying machine, drying drum drying machine, multi-color roller gravure printing machine improved by adjusting the thickness of printed matter, lengthening the width of the door, strengthening drying, etc., steaming machine, flat car washing machine.

[0041] 1. Soda padding process

[0042] 1.1 Alkaline solution prescription

[0043] Table-2 Prescription of Reactive Dye Printing Alkali Solution

[0044]

[0045] 1.2 Alkali Padding Process and Conditions

[0046] Mercerized cotton cloth → even padding with alkali agent solution (one dipping and one padding, liquid rolling rate 70%, speed 30 m / min...

Embodiment 3

[0057] A New Production Method of Cotton Vat Dye Multi-Color Roller Gravure Printing

[0058] Production material: mercerized cotton cloth

[0059] Dyeing chemicals: Special ink for vat dye gravure printing, sodium hydroxide, sodium dithionite, soaping liquid (2g / L soap flakes, 2g / L soda ash).

[0060] Production equipment: multi-color roller gravure printing machine with adjustable thickness of printed matter, lengthened door width, enhanced drying, etc., uniform padding machine, fast steaming machine, flat car washing machine.

[0061] 1. Gravure printing process

[0062] Gravure printing process and conditions

[0063] Mercerized cotton → multi-color roller gravure printing (speed 30 m / min) → drying → printed cotton

[0064] 2. Alkali rolling and reduction steaming process

[0065] 2.1 Alkaline solution prescription

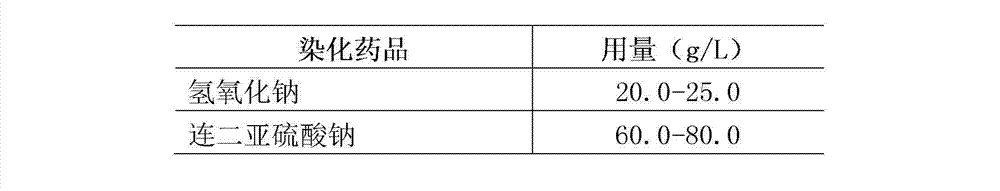

[0066] Table-3 Prescription of vat dye printing alkali solution

[0067]

[0068] 2.2 Soda reduction steaming process and conditions

[0069] Printe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com