Active dye gravure printing ink and preparation method thereof, and method for applying active dye gravure printing ink for printing

A technology of reactive dyes and gravure printing inks, applied in the printing and dyeing industry, can solve the problems of expensive dye inks, high dye fixing rate, and slow printing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A kind of reactive dye gravure printing ink, this reactive dye gravure printing ink is made of reactive dye, cosolvent, resist salt, viscosity regulator and water, wherein cosolvent is urea, resist salt is sodium m-nitrobenzene sulfonate , the viscosity regulator is sodium carboxymethyl starch, and the mass percent of each component is as shown in Table 1, and described reactive dye is made up of following four kinds of reactive dye compounds, and the mass percent of each reactive dye compound is shown in Table 2;

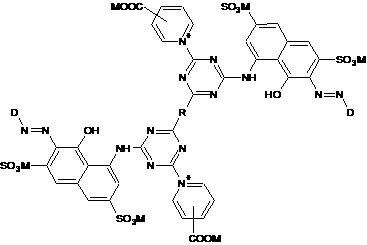

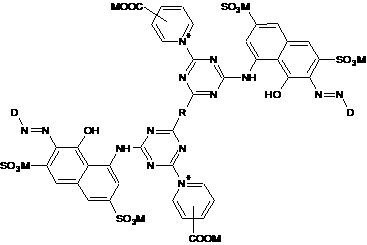

[0078] 1), red reactive dye compound, the structure is shown in formula (I):

[0079]

[0080] (I)

[0081] M in the formula (I) is hydrogen, and R is a bridging group, specifically:

[0082] , M in the bridging base is hydrogen, and D in formula (I) is , wherein M is hydrogen;

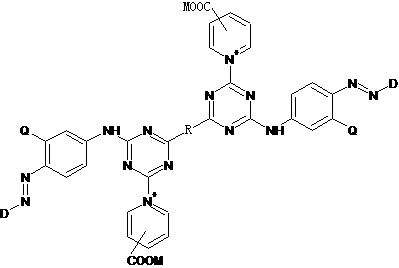

[0083] 2), yellow reactive dye compound, the structure is shown in formula (II):

[0084]

[0085] (II)

[0086] In formula (II), M is hydrogen, and Q is -NHCOCH 3 , ...

Embodiment 2

[0117] A kind of reactive dye gravure printing ink, this reactive dye gravure printing ink is made by reactive dye, cosolvent, resist salt, viscosity modifier and water, and wherein cosolvent is thiourea, and resist salt is m-nitrobenzenesulfonic acid Sodium, the viscosity modifier is sodium carboxymethyl cellulose fiber, the mass percent of each component is as shown in Table 1, and each reactive dye compound composition in described reactive dye is shown in Table 2, and wherein the composition of blue reactive dye compound is shown in Table 3, the basic structure of each reactive dye compound is the same as in Example 1, the difference is:

[0118] In the formula (II), M is Na, Q is -NHCONH 2 , R is the abutment, specifically:

[0119] , , M in the abutment is Na, formula (II) D is , where M is Na;

[0120] In the formula (III), M is Na, and R is a bridging group, specifically:

[0121] , where M is Na, D in formula (III) is , where M is Na;

[0122] In the formu...

Embodiment 3

[0138] A kind of reactive dye gravure printing ink, this reactive dye gravure printing ink is made of reactive dye, cosolvent, resist salt, viscosity modifier and water, wherein cosolvent is urea, resist salt is sodium m-nitrobenzene sulfonate , the viscosity modifier is sodium alginate, and the mass percent of each component is as shown in Table 1. The composition of each reactive dye compound in the reactive dye is shown in Table 2, and the composition of the blue reactive dye compound is shown in Table 3. Each reactive dye The basic structure of compound is the same as Example 1, and the difference is:

[0139] M in the formula (I) is hydrogen, and R is a bridging group, specifically:

[0140] , D in formula (I) is ;

[0141] In the formula (III), M is hydrogen, and R is a bridging group, specifically:

[0142] , D in formula (III) is Wherein M is hydrogen;

[0143] In formula (IV), M is hydrogen, and D is ;

[0144] In formula (V), M is hydrogen, D 1 for ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com