Vibrating screen for flour processing

A vibrating screen and flour technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of large damage to ground infrastructure, large vibration noise of the whole machine, large energy consumption per ton of powder, etc., and achieve better screening effect. The effect of reducing vibration and noise and reducing energy consumption per ton of powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

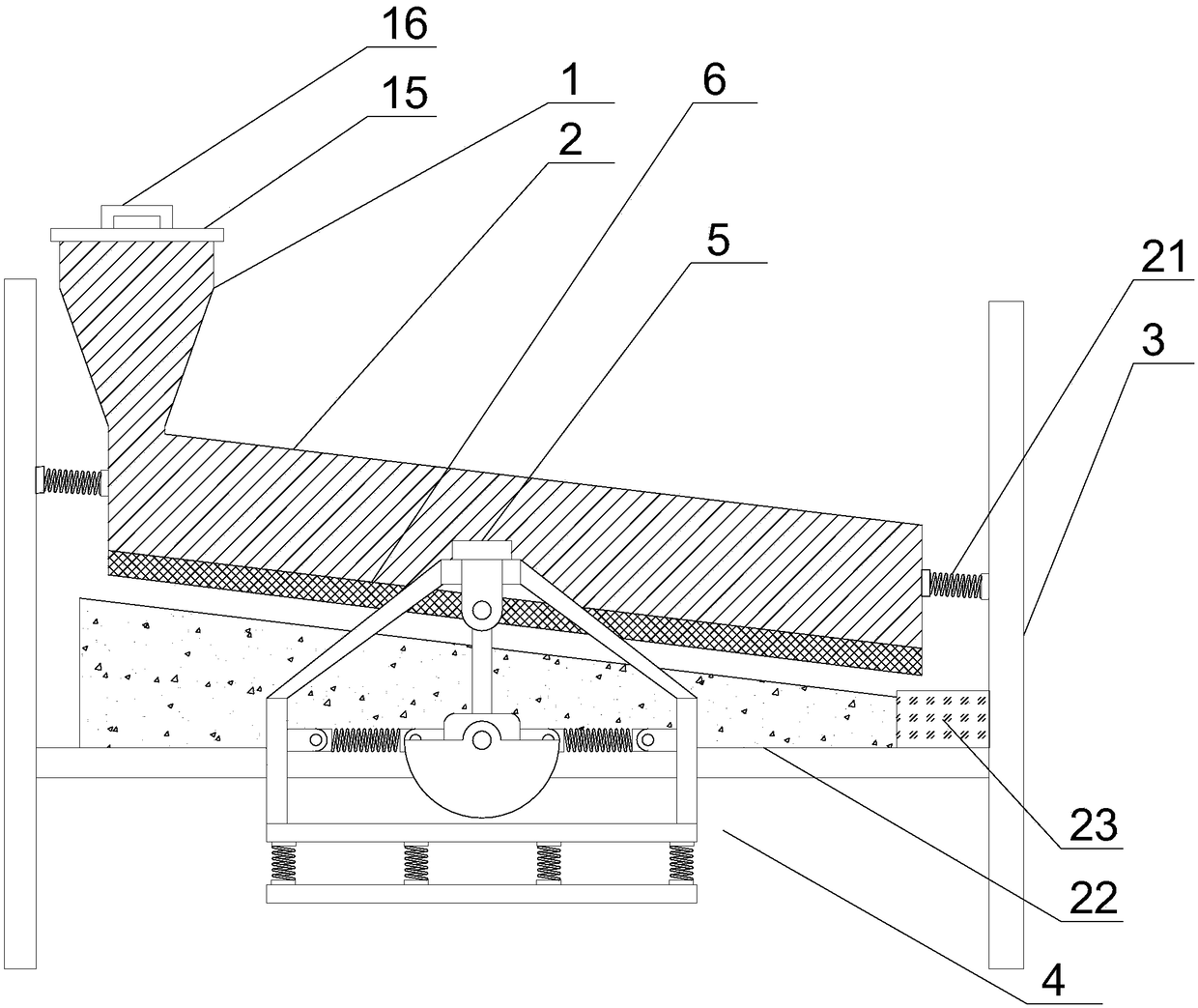

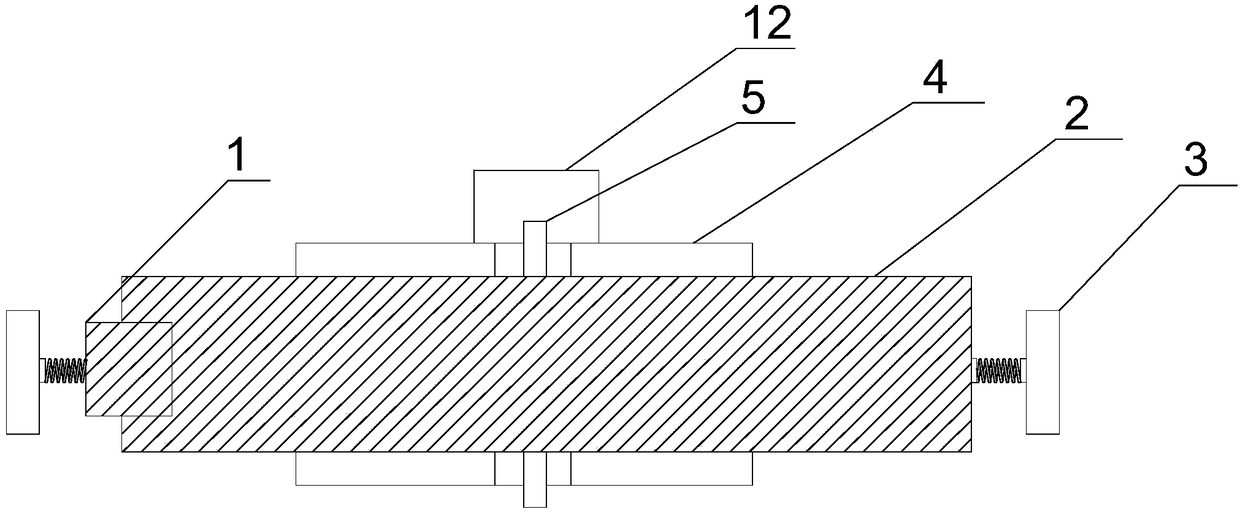

[0030] A vibrating sieve for flour processing, comprising a feed hopper 1, a sieve box 2, a fixed frame 3 and a vibrating device 4, characterized in that the feed hopper 1 and the sieve box 2 are integrally formed, and the sieve box 2 For oblique setting and the bottom is provided with screen 6, the left and right ends are connected with fixed frame 3 by spring one 21, and described vibrating device 4 is symmetrically arranged on both sides of screen box 2, and described vibrating device 4 comprises mounting frame 7, fan-shaped eccentric Block 8 and fixed plate 9, described fan-shaped eccentric block 8 is connected with motor 12 output ends by eccentric shaft 10, is connected with movable block 11 in rotation on described eccentric shaft 10, and described movable block 11 left and right ends are all connected with mounting frame 7 Connected by spring two 13, the top of the movable block 11 is hinged with the connector 14 arranged on the top of the mounting frame 7 through a con...

Embodiment 2

[0033] In this embodiment, on the basis of Embodiment 1, further, the top of the feed hopper 1 is provided with a cover plate 15, the top of the cover plate 15 is provided with a handle 16, and the cover plate 15 is threaded with the top of the feed hopper 1. Connection, screw connection can facilitate the opening and closing of the cover plate 15, and cover the cover plate 15 in the working state. On the one hand, it can prevent the cover plate 15 from shaking off during the vibration process, and on the other hand, it can prevent the flour from being shaken out by the feeding hopper 1 It causes waste; setting the handle 16 can facilitate the operation of the staff, making the opening and closing of the cover plate 15 more time-saving and labor-saving.

Embodiment 3

[0035] In this embodiment, on the basis of Embodiment 1, further, the mounting frame 7 includes a fixed rod one 17, a fixed rod two 18, a base 19 and a connecting piece 14, and the left and right ends of the connecting piece 14 are fixedly connected with fixed Rod one 17, described fixed rod one 17 is inclined setting, and one end away from connector 14 is affixed to the top of fixed rod two 18, and the bottom of described fixed rod two 18 is all affixed with base 19, and the mode of fixed connection makes mounting frame 7. The connection state of each part is more stable, prevents falling off during the vibration process, and affects the normal operation of the equipment. The inclined setting of the fixed rod-17 can strengthen the stability of the mounting frame 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com