Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1206 results about "Motor Drive Unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

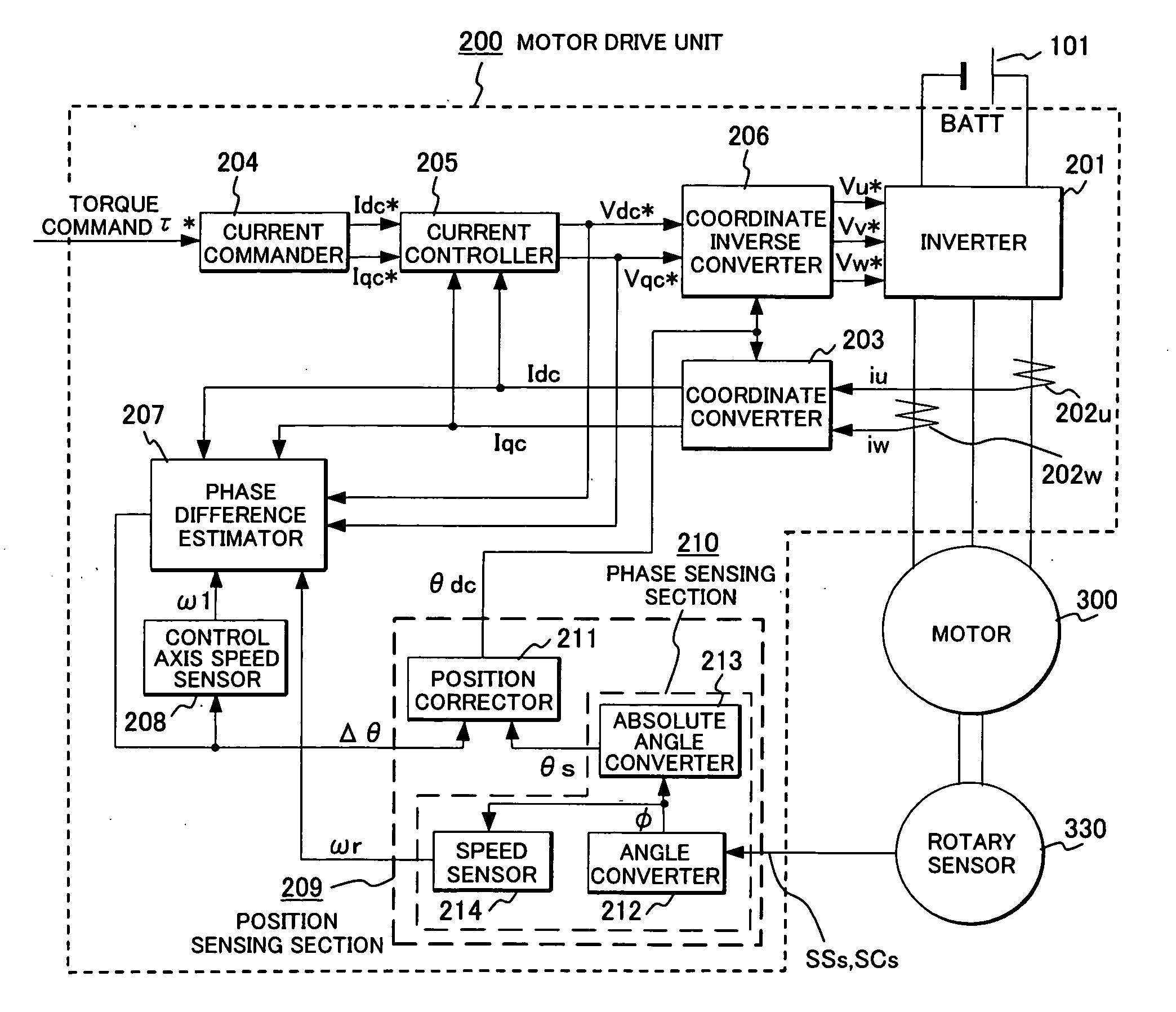

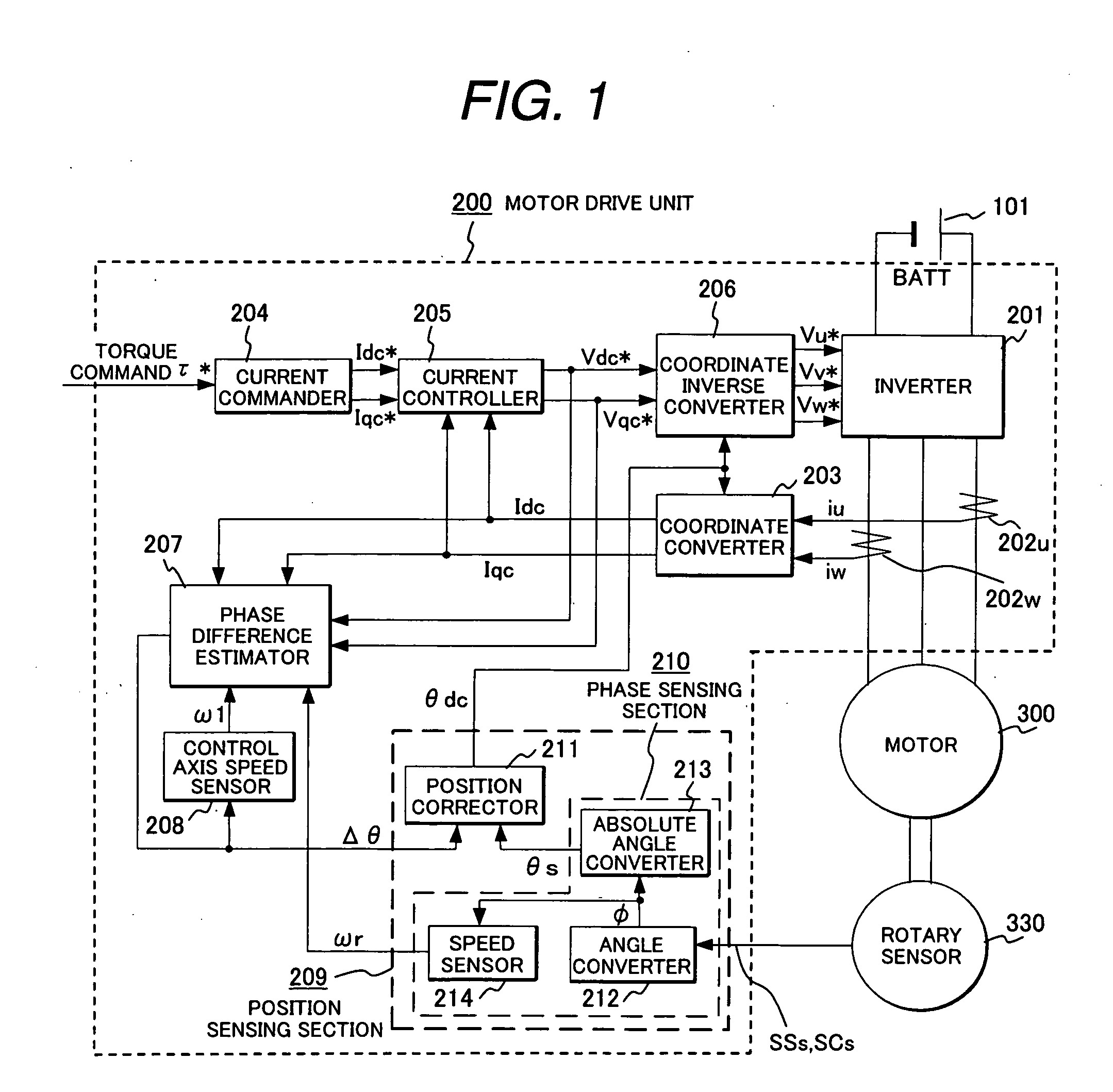

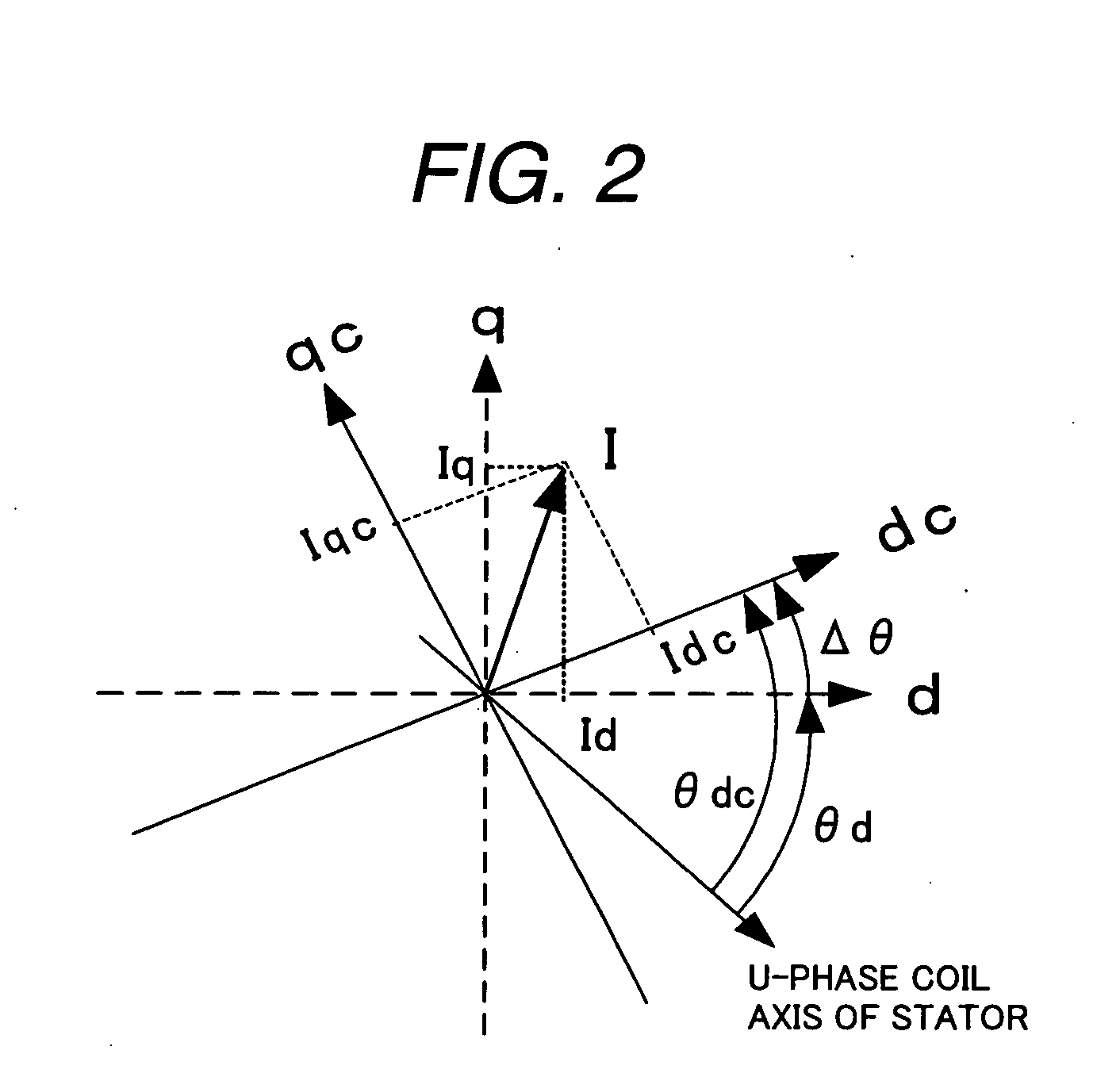

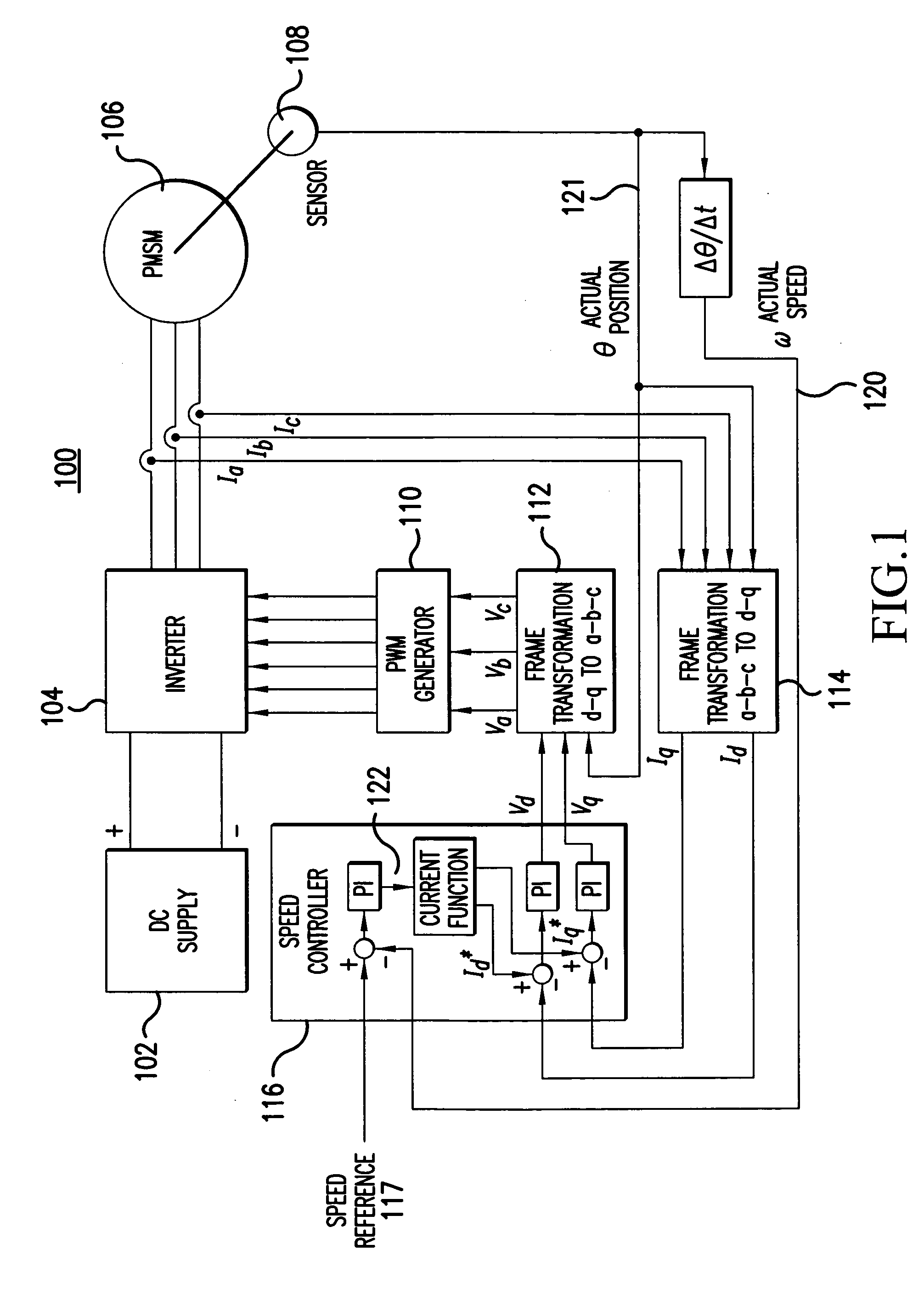

Synchronous motor drive unit and a driving method thereof

InactiveUS20060125439A1Efficient driveImprove maintainabilityAsynchronous induction motorsElectric energy vehiclesSynchronous motorPhase difference

A rotary sensor that outputs two analog signals, such as one sine wave and one cosine wave and has multiple periods within one period of the electrical angle of a motor is employed. The motor is energized at each position for a specified length of time upon its startup by using multiple electrical angles corresponding to the multiple candidate absolute angles obtained from the rotary sensor signal as the initial position of the motor, and the electrical angle at which the motor acceleration becomes maximum is determined as the absolute angle. While the motor drive is in operation, on the other hand, the phase difference Δθ between the phase of the motor at the counter electromotive voltage and the control phase is directly computed from the parameters of the motor, sensed current, voltage command and angle speed so as to correct the shifted position. A high-efficiency motor drive unit with improved maintainability of rotary sensor and improved accuracy of sensing the magnet pole position of a permanent magnet synchronous motor that accelerates and decelerates very quickly in a wide range of speed is realized.

Owner:HITACHI LTD

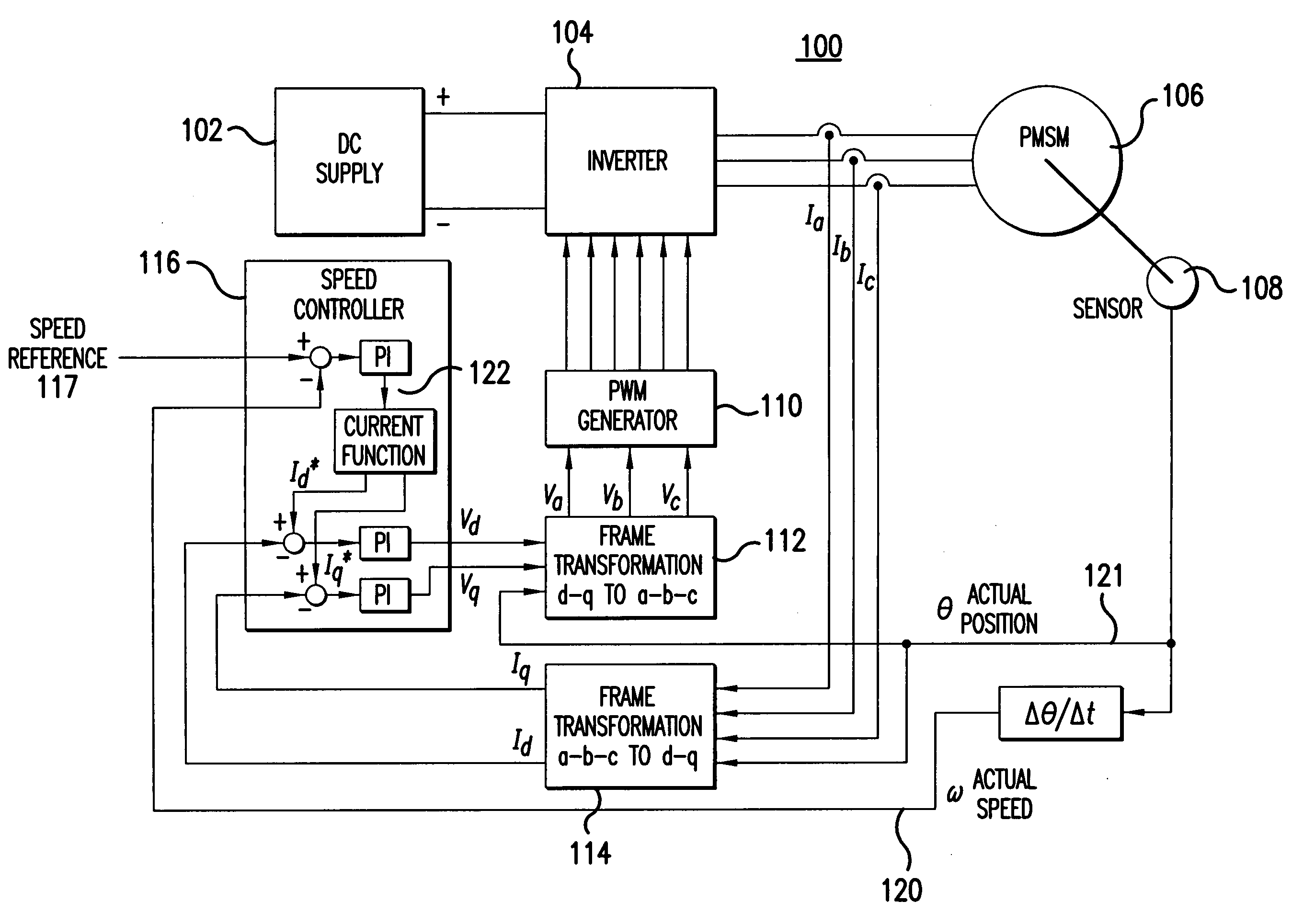

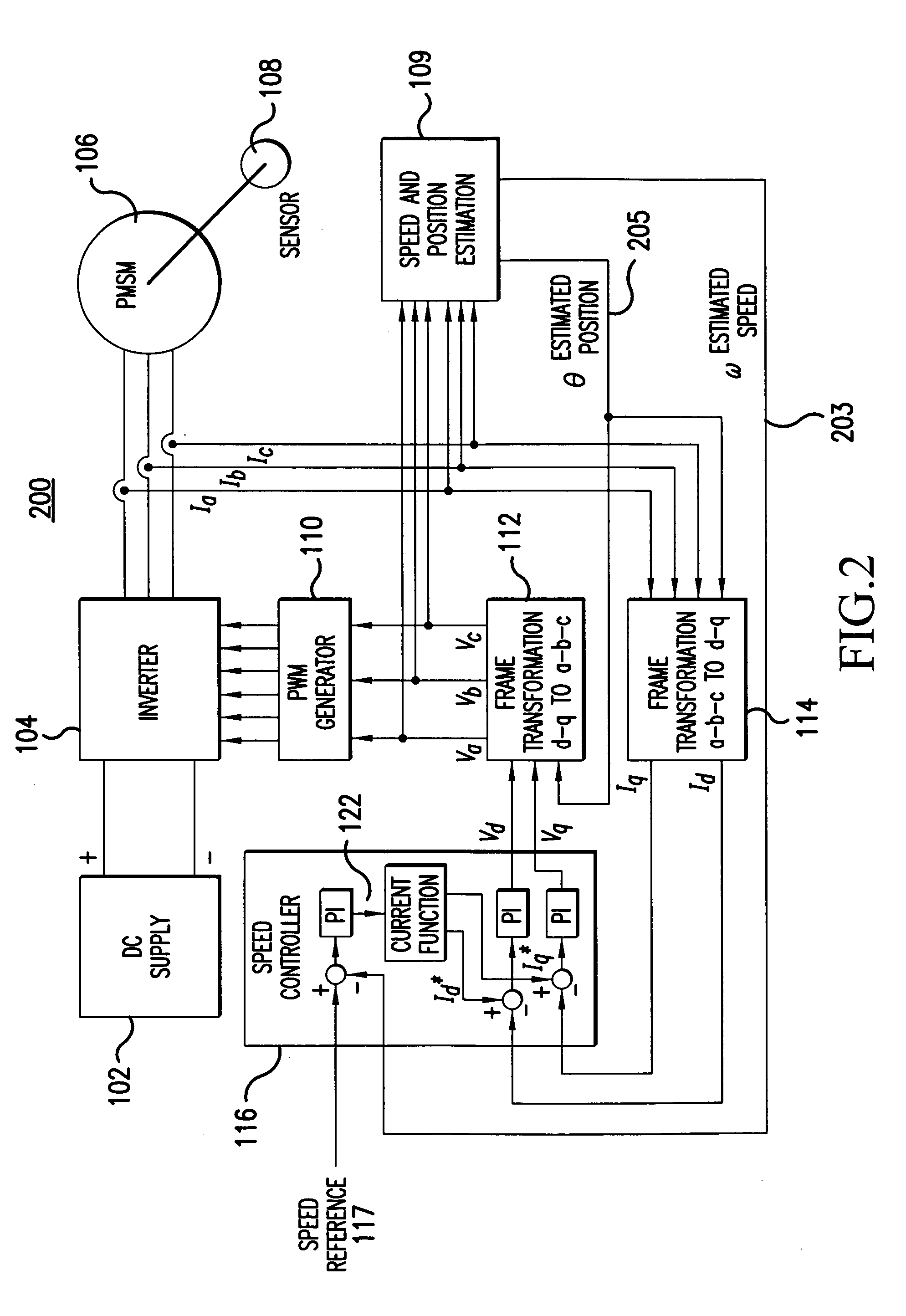

Sensorless control method and apparatus for a motor drive system

InactiveUS20050007044A1Quick calculationAccurate predictionDC motor speed/torque controlAC motor controlKaiman filterControl power

A method and apparatus provide a state observer control system 600 for a motor 106 that uses an extended Kalman filter 330 to predict initial rotor position and afterwards accurately predict rotor position and / or speed under variable types of loading conditions. A control system model 300 is generated that allows variable setting of an initial rotor position to generate estimated rotor position and speed as outputs. The control system model 300 includes an EKF (extended Kalman filter) estimator 330, speed controller 322, a current controller 324, and a variable load component 310. During operation, EKF estimator 330 estimates rotor speed 327 and position 333 based on reference voltages 402, 404 and currents 1325 generated by speed and current controllers 322, 324 and input from frame transformers 326, 328. Additionally, the reference currents and voltages 402, 404, 1325 are frame-transformed to be used as feedback signals 418, 346 in the system 600 and as drive signals to control power to be applied to a motor load 602.

Owner:HONEYWELL INT INC

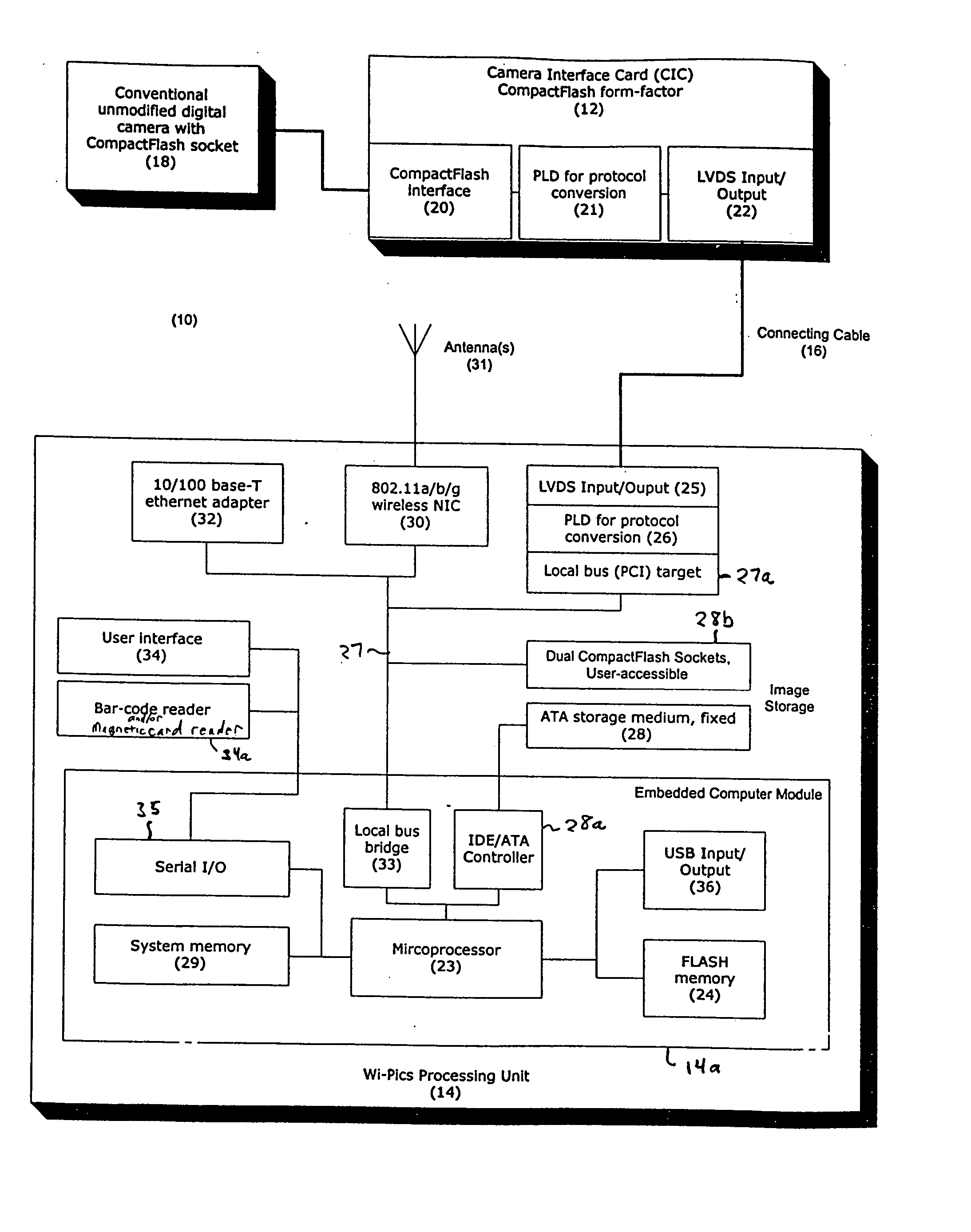

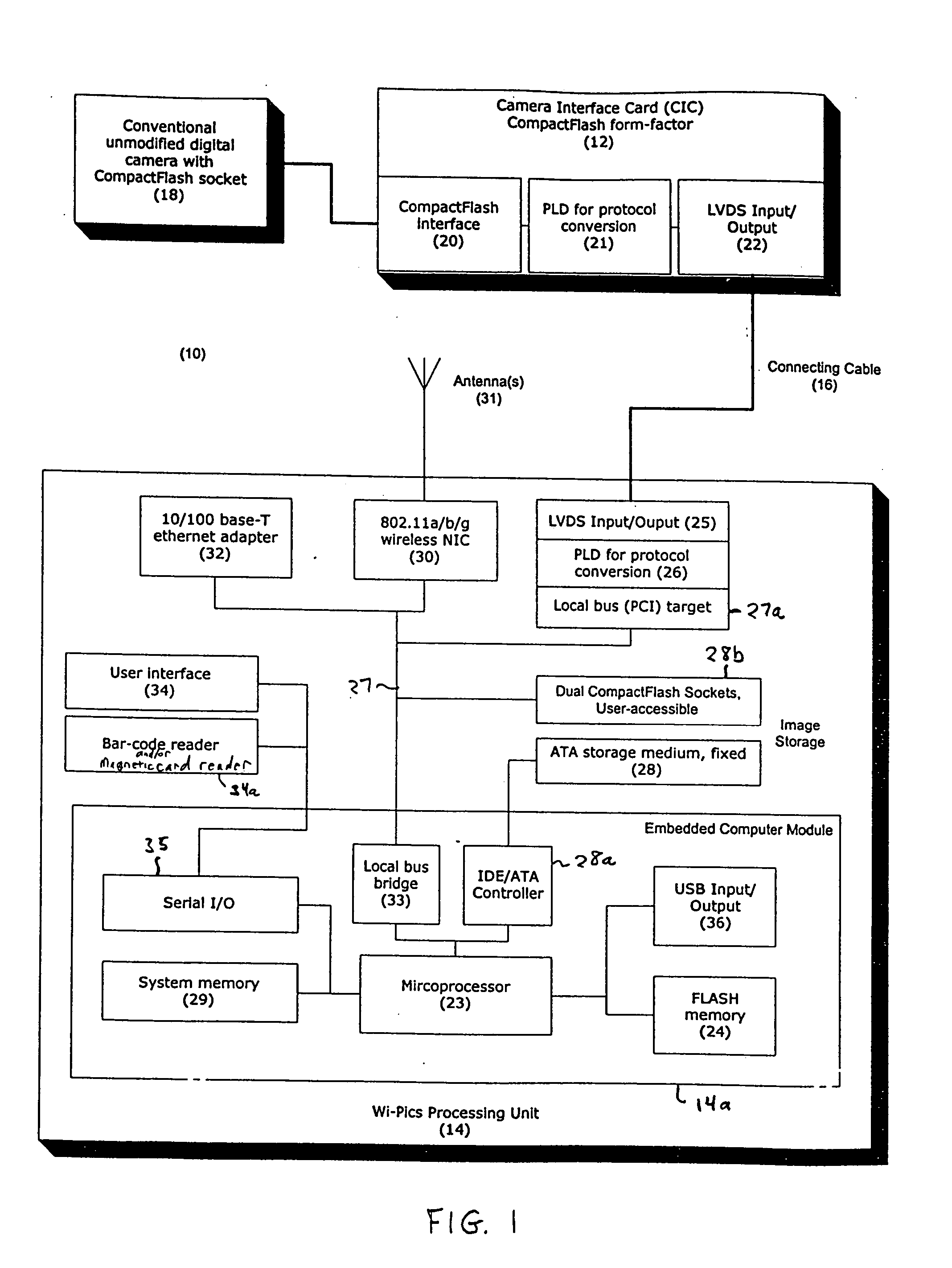

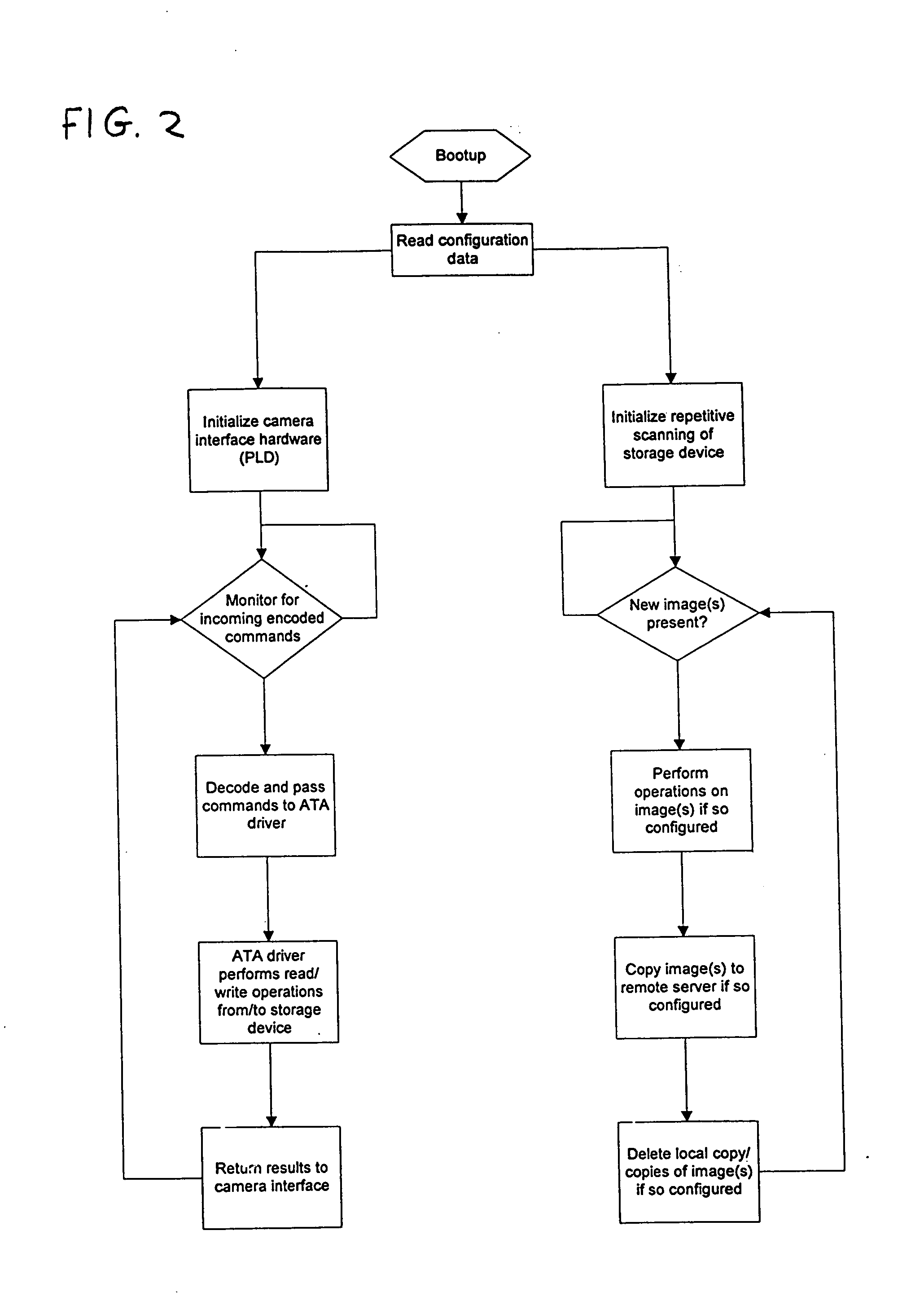

Apparatus for communicating over a network images captured by a digital camera

InactiveUS20050036034A1Data augmentationTelevision system detailsColor television detailsCable transmissionWireless data

An apparatus is provided for communicating over a network images captured by a digital camera, such as a digital camera without an on-board network interface. The apparatus includes a housing separate from the digital camera having a processing unit with memory for storage of images, a camera interface card received in a memory card slot of the digital camera, and a cable or wireless connection coupling the camera interface card to the processing unit for data communication. The apparatus emulates a memory card to the digital camera, such that the digital camera's electronics operate with the memory of the processing unit through the camera interface card, as if such memory was on a memory card located in slot of the digital camera. Images captured by the digital camera are transferred, via the camera interface card and cable, to memory of the processing unit, and the digital camera can access images stored in memory of the processing unit. The processing unit has a wireless data network interface and Ethernet communication interface, whereby captured images stored in memory of the processing unit are queued in real-time for network transfer, and subsequently transferred via one of the network communication interfaces, to a computer system, such as an web site or file server, at a network destination address configurable in the processing unit. Data may be inputted by the user before and / or after image capture for association with images prior to their network transfer. The housing for the processing unit may be shaped like a motor drive unit and attached to the bottom of the camera, or worn by the user of the camera in the form of a belt pack or backpack.

Owner:UNITED IMAGING SOLUTIONS

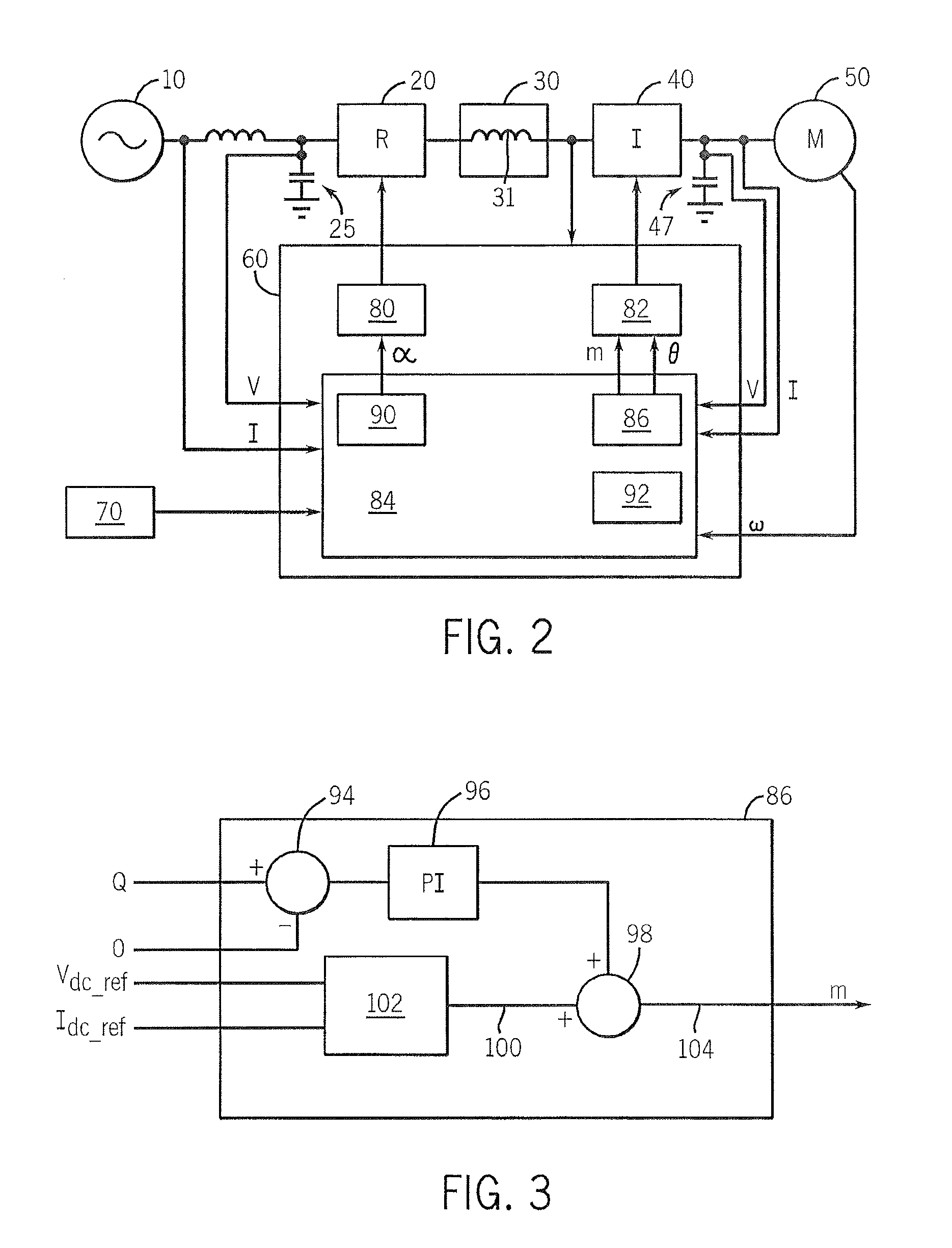

Motor drive using flux adjustment to control power factor

ActiveUS7683568B2Single-phase induction motor startersMotor/generator/converter stoppersMotor speedPower inverter

Owner:ROCKWELL AUTOMATION TECH

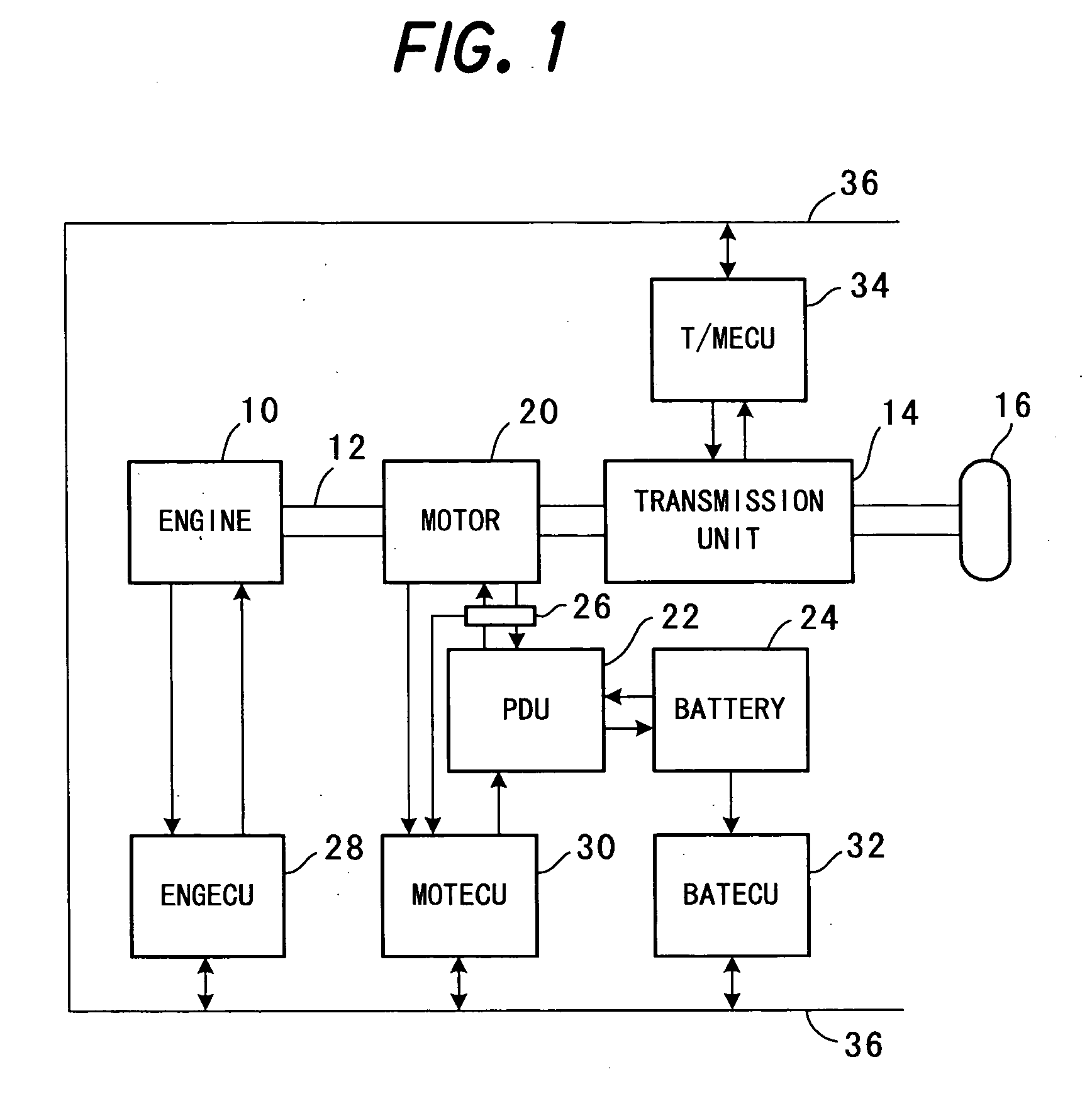

Power drive unit

InactiveUS20060052914A1Minimized in sizeHarsh environmentSpeed controllerElectric devicesComputer moduleCurrent sensor

In a power drive unit having power modules (three-phase inverter circuits) connected to a control circuit board, bus bars extending from the power modules and a current sensor each installed near the bus bars and including a sensing element that detects currents outputted from the bus bars, there are provided a sensor board on which the sensing element is mounted, and lead pins each connecting the sensor board to the control circuit board and having a bowed shape whose one end is connected to the sensor board and other end once extends away from the circuit board and then turns back toward the circuit board. With this, the circuit board and current sensors can be connected through the lead pins without increasing the distance therebetween and stress produced in the lead pins can be alleviated, thereby enabling the unit to be minimized in size and utilized in a harsh service environment.

Owner:KEIHIN CORP +1

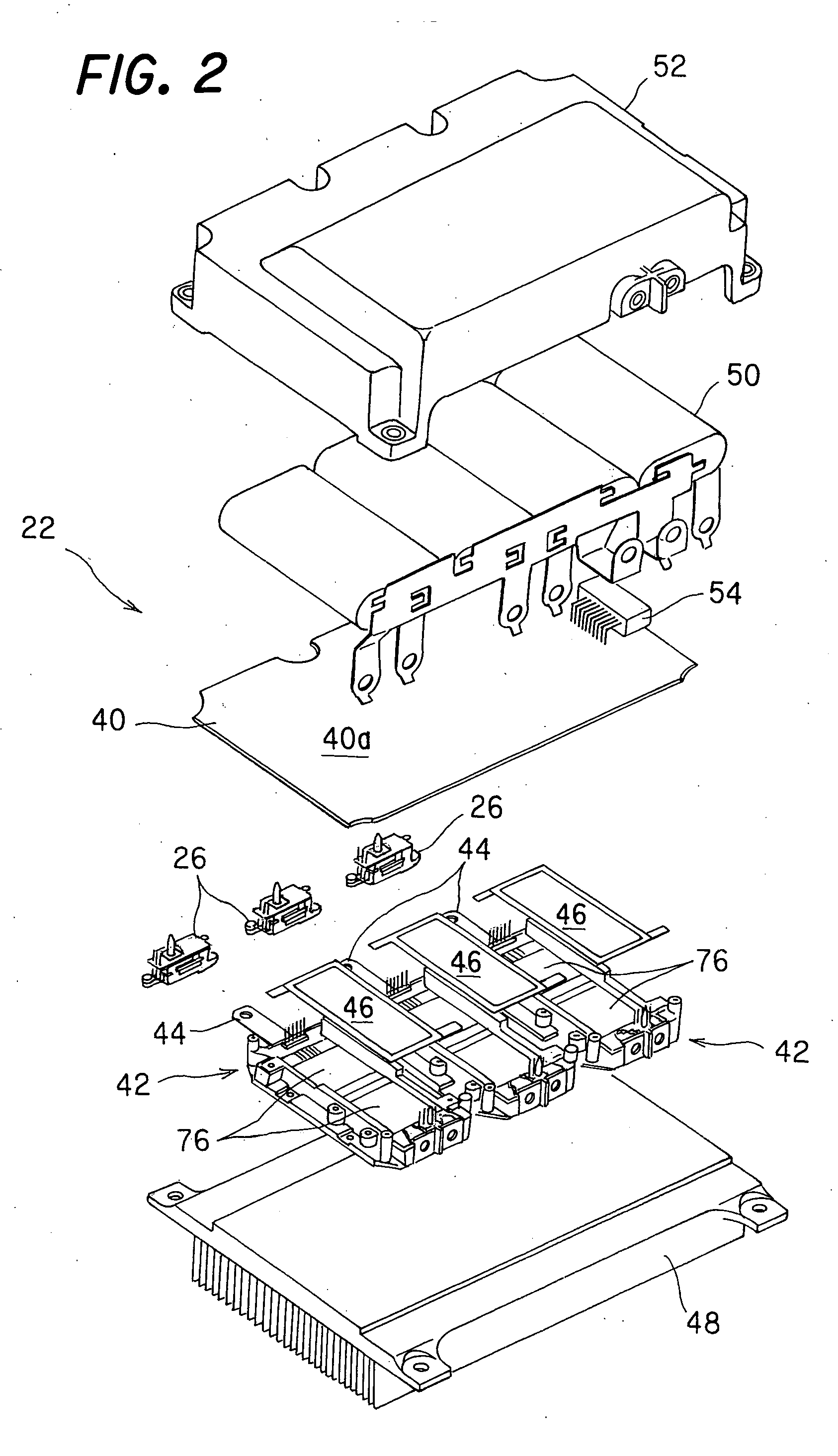

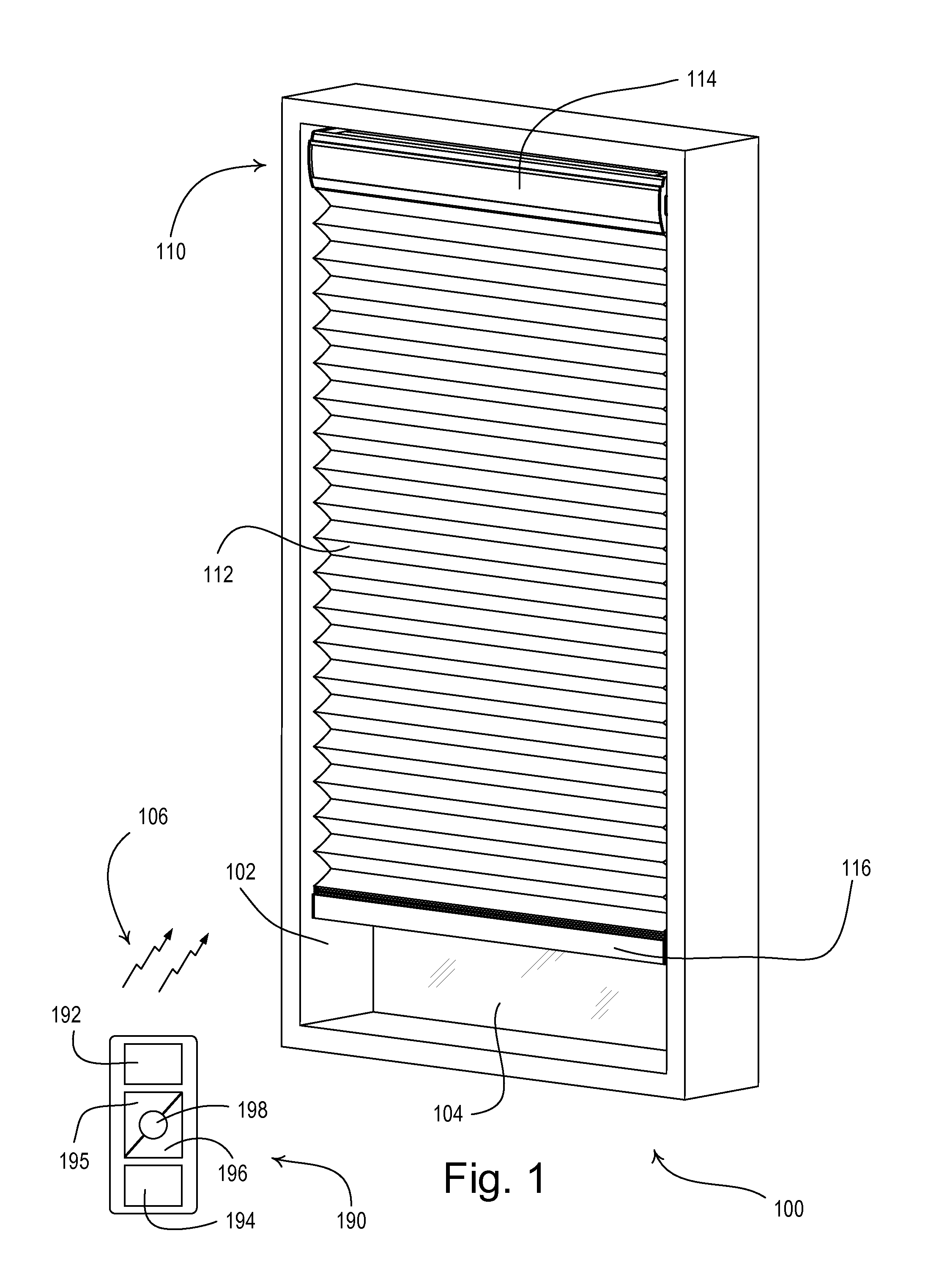

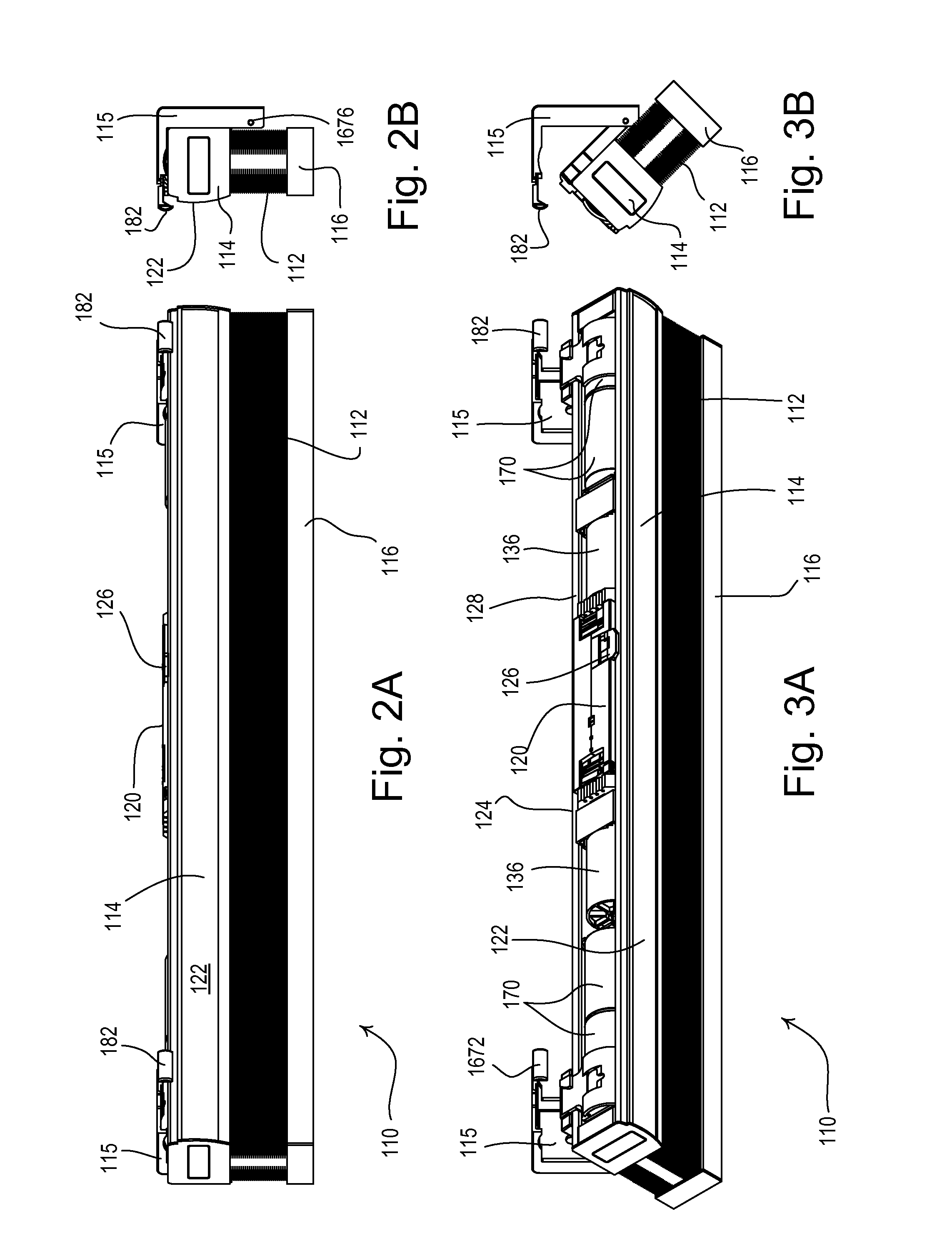

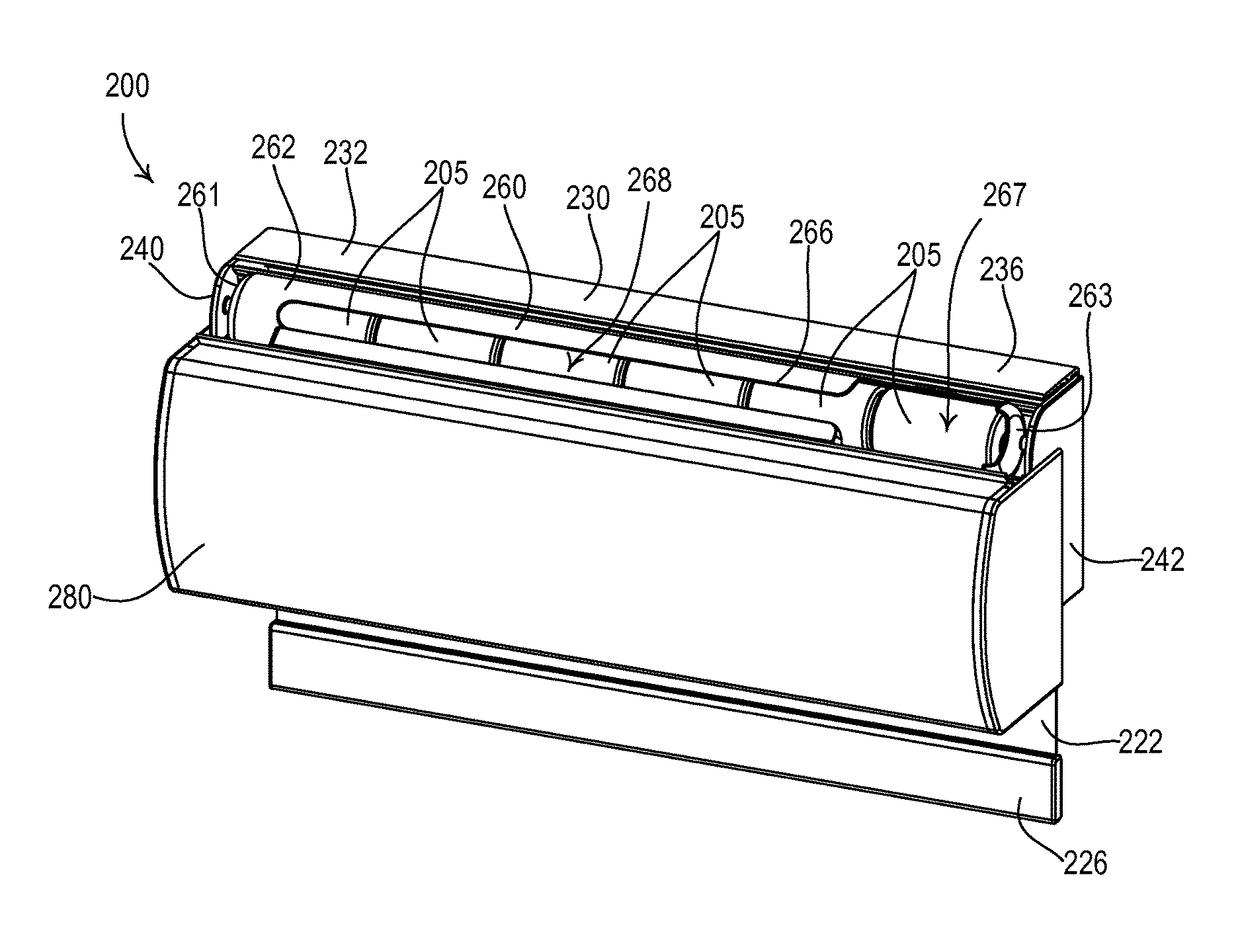

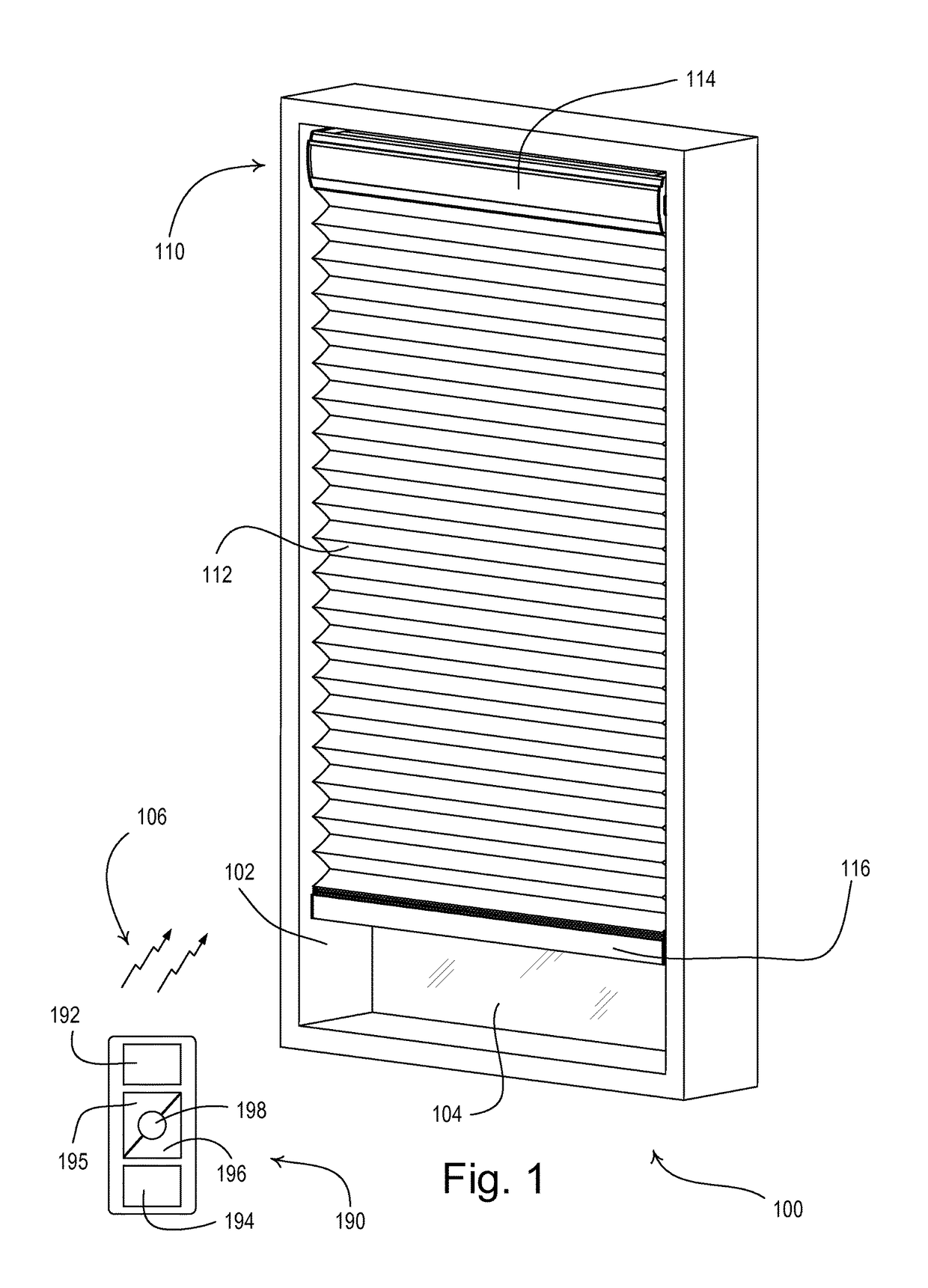

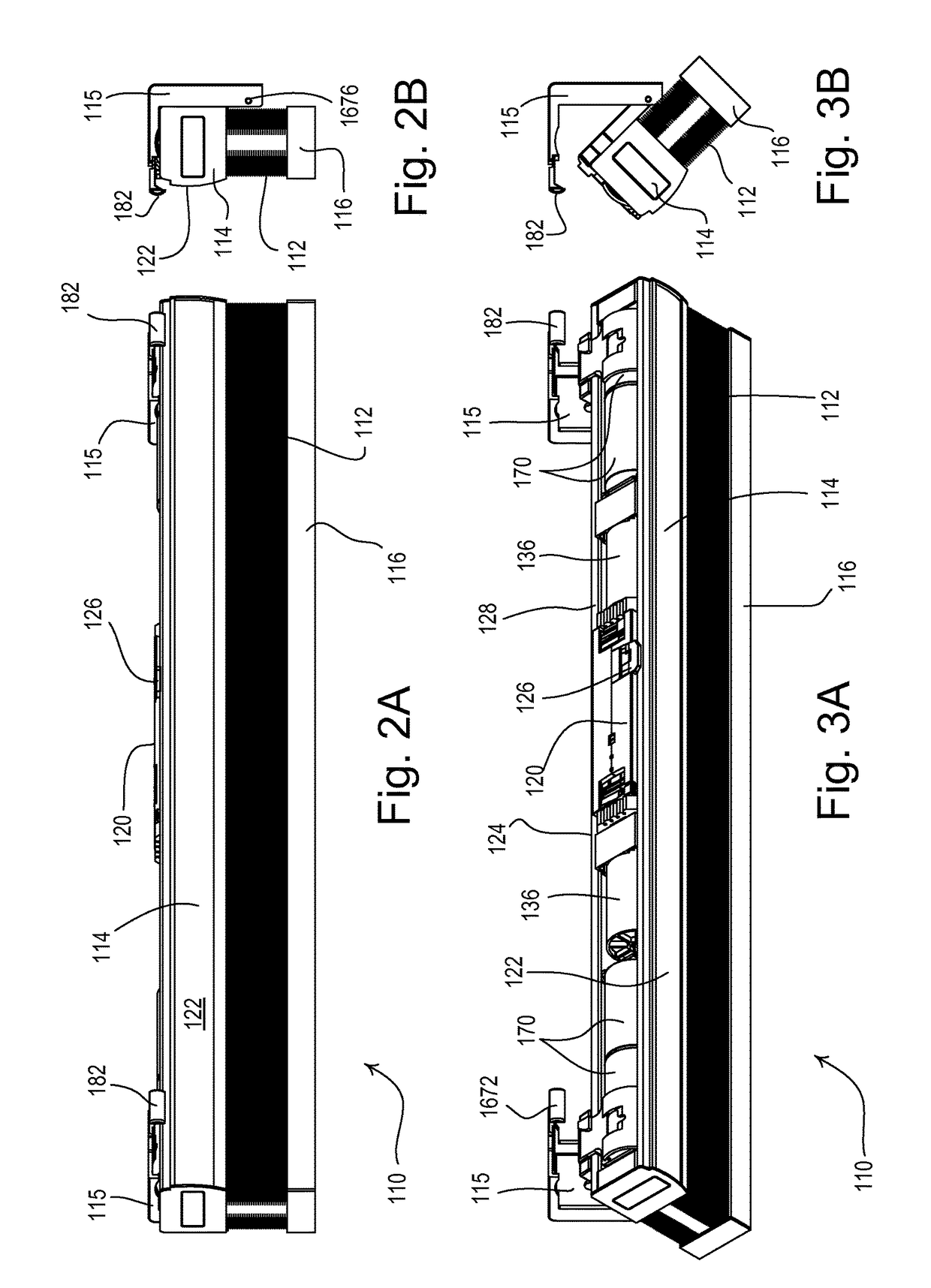

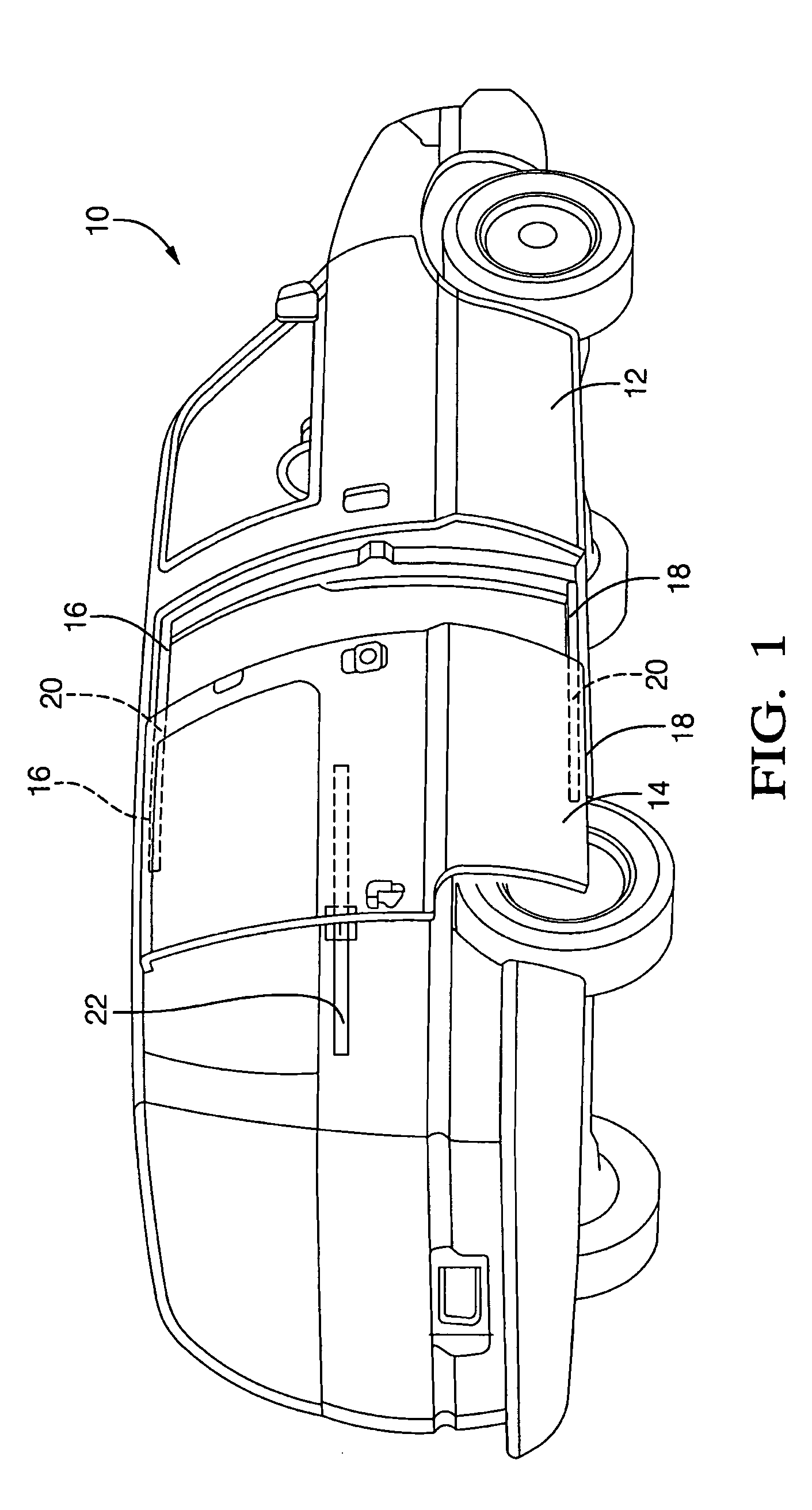

Motorized window treatment

ActiveUS20150226001A1Long lastingPrevent movementExtensible doors/windowsPower managementMotor speedElectrical battery

A motorized window treatment may provide a low-cost solution for controlling the amount of daylight entering a space through a window. The window treatment may include a covering material (e.g., a cellular shade fabric or a roller shade fabric), a drive assembly for raising and lowering the covering material, and a motor drive unit including a motor configured to drive the drive assembly to raise and lower the covering material. The motorized window treatment may comprise one or more battery packs configured to receive batteries for powering the motor drive unit. The batteries may be located out of view of a user of the motorized window treatment (e.g., in a headrail or in a battery compartment). The motorized window treatment may use various power-saving methods to lengthen the lifetime of the batteries, e.g., to reduce the motor speed to conserve additional battery power and extend the lifetime of the batteries.

Owner:LUTRON TECH CO LLC

System and method for determining stator winding resistance in an ac motor using motor drives

ActiveUS20100194329A1Improved motor control performanceImprove controlSingle-phase induction motor startersDC motor speed/torque controlMotor driveTerminal voltage

A system and method for determining the stator winding resistance of AC motors is provided. The system includes an AC motor drive having an input connectable to an AC source and an output connectable to an input terminal of an AC motor, a pulse width modulation (PWM) converter having switches therein to control current flow and terminal voltages in the AC motor, and a control system connected to the PWM converter. The control system generates a command signal to cause the PWM converter to control an output of the AC motor drive corresponding to an input to the AC motor, selectively generates a modified command signal to cause the PWM converter to inject a DC signal into the output of the AC motor drive, and determines a stator winding resistance of the AC motor based on the DC signal of at least one of the voltage and current.

Owner:EATON CORP

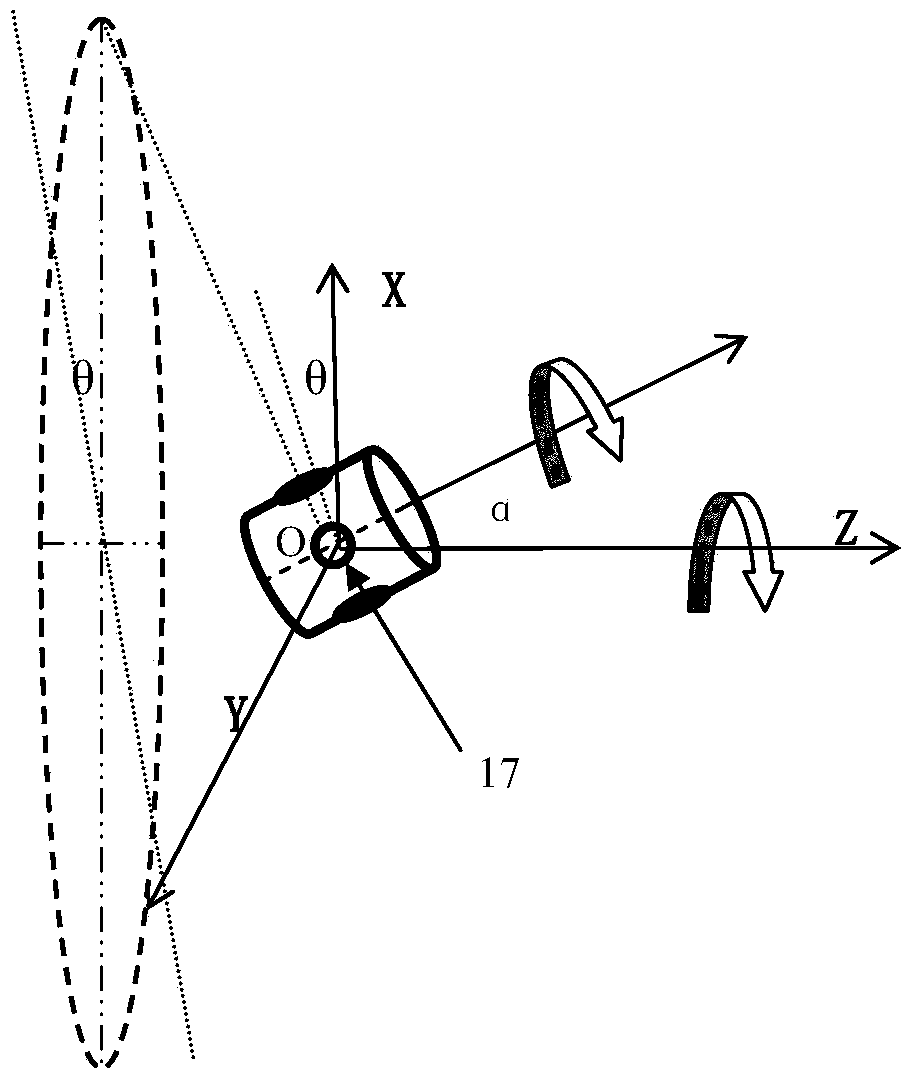

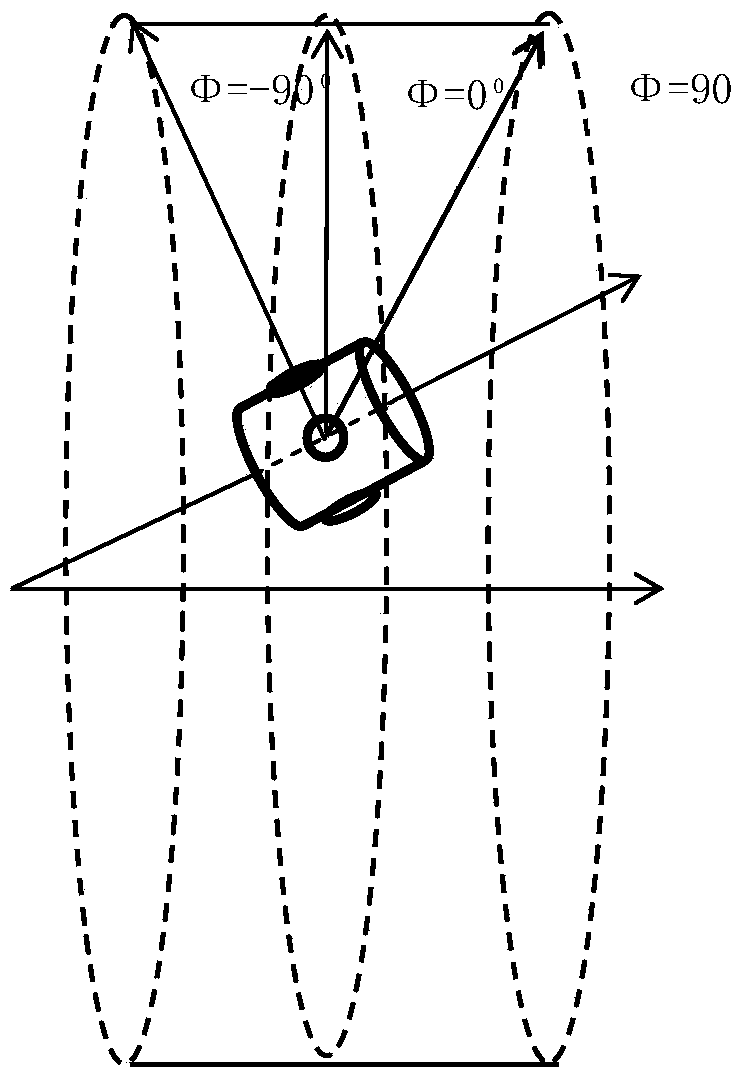

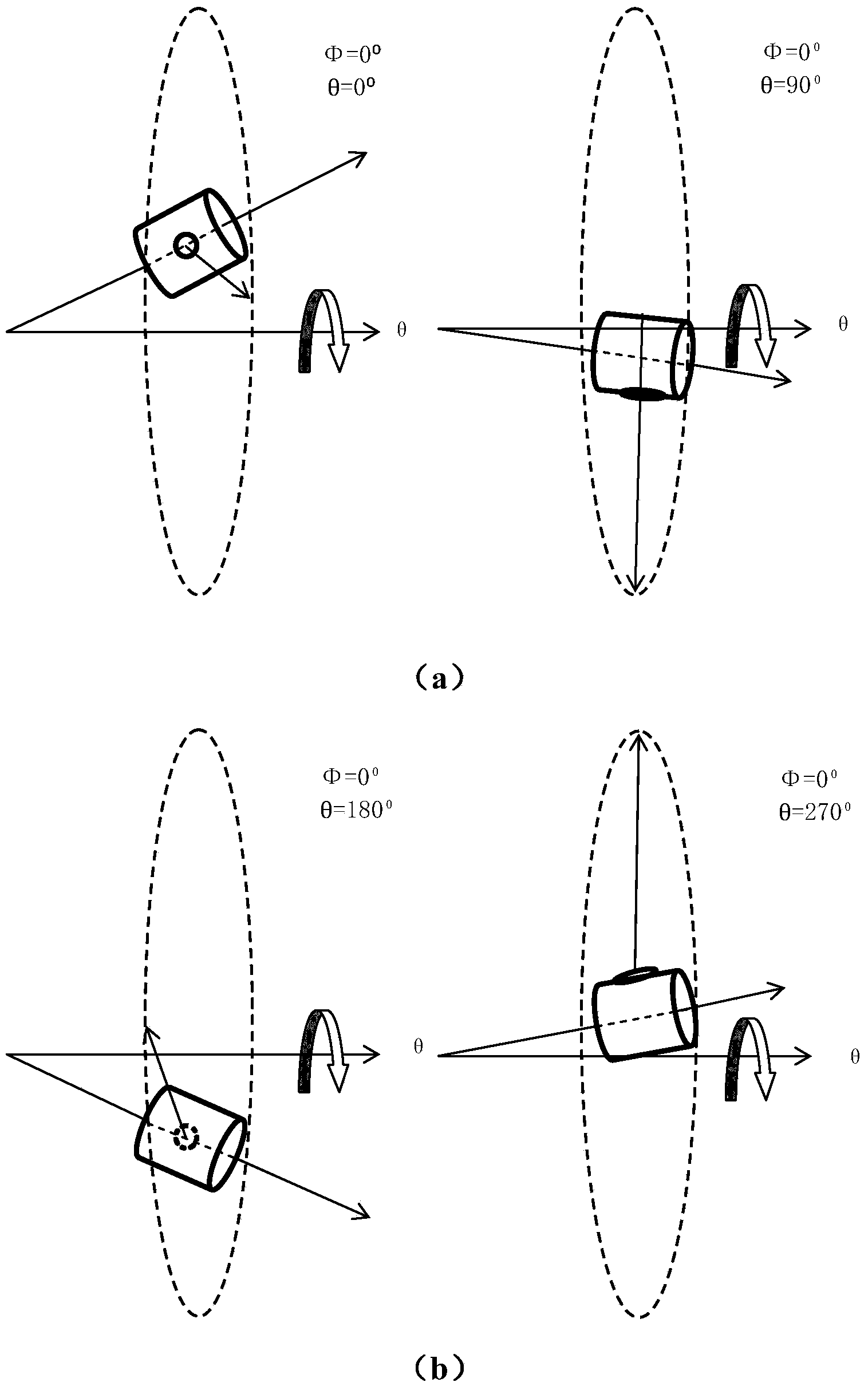

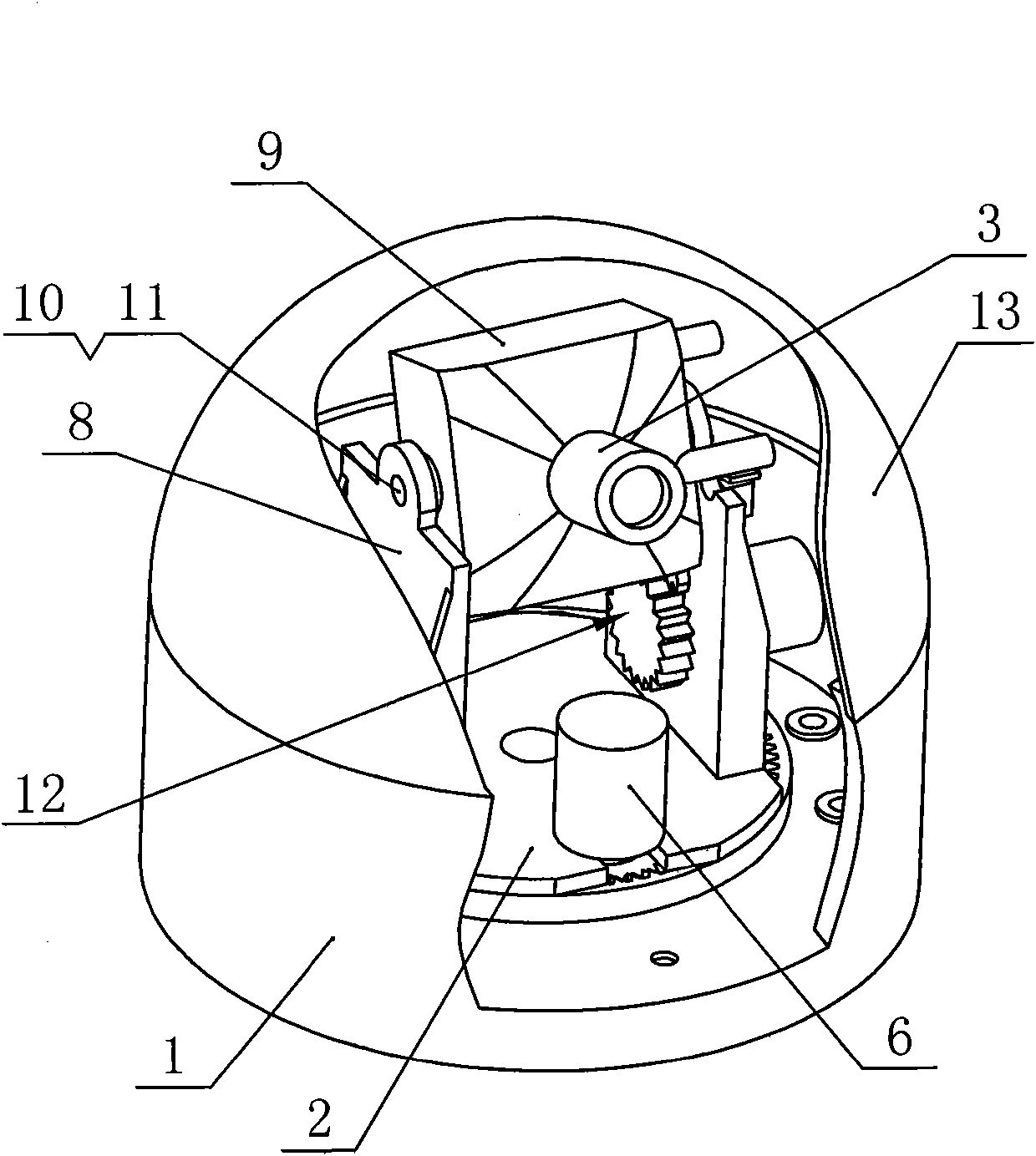

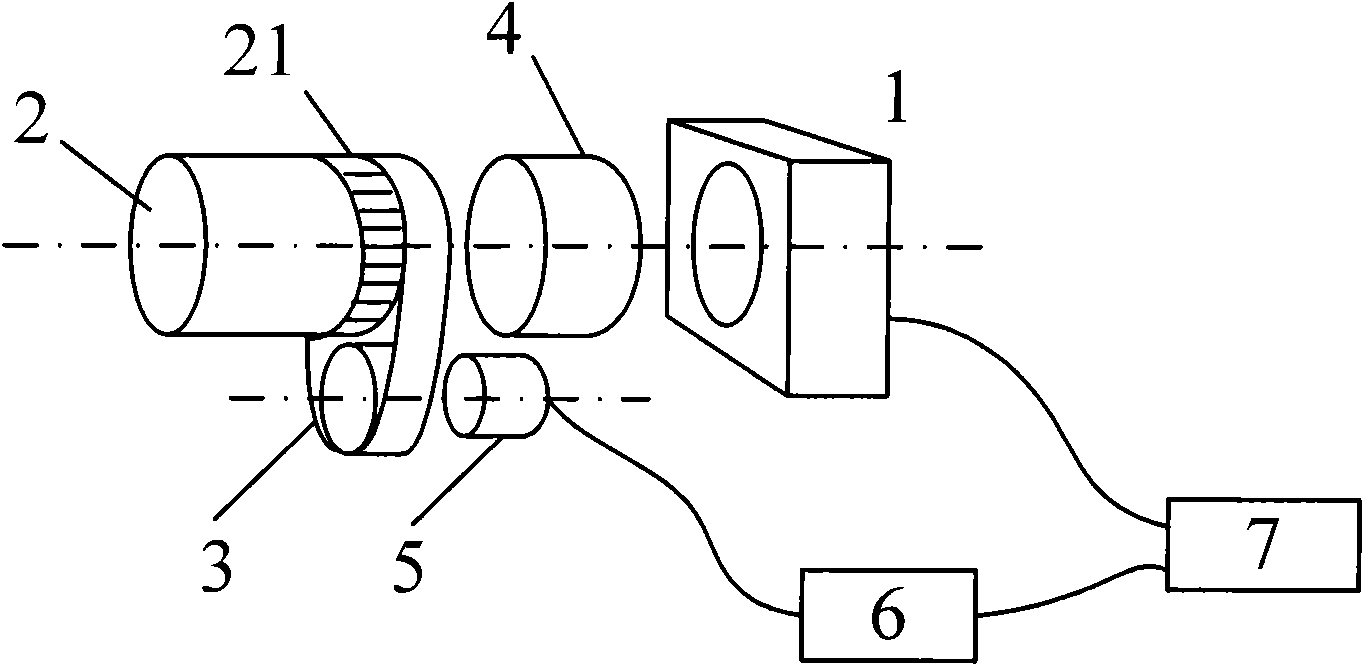

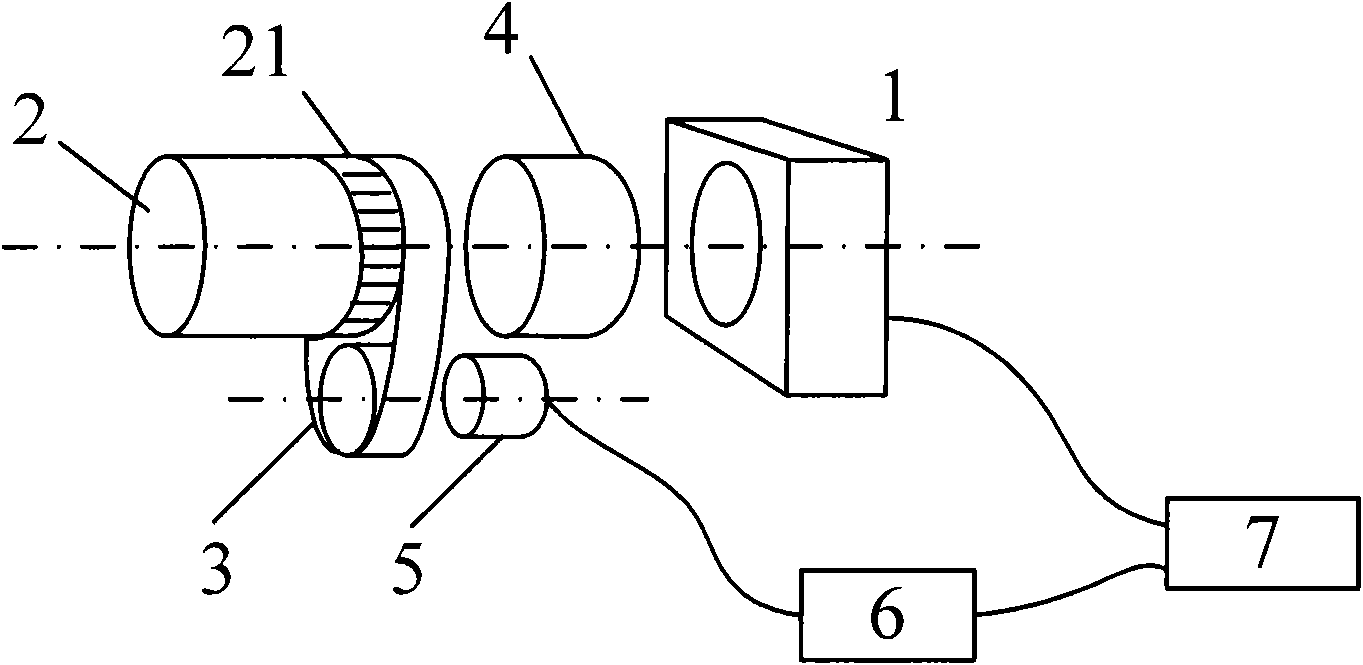

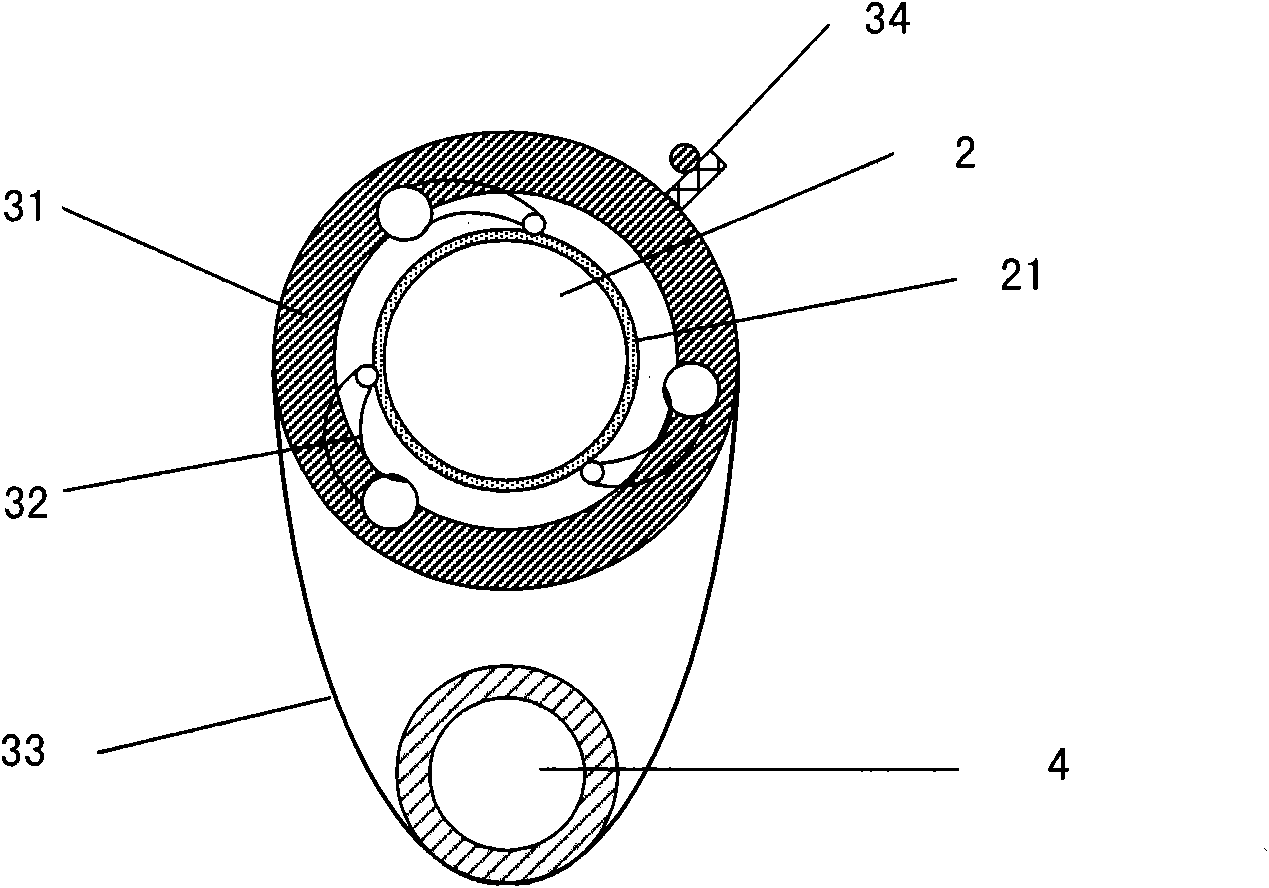

Three-dimensional laser scanning method and device

InactiveCN103837095AEasy to controlImprove the accuracy of 3D scanning measurementUsing optical meansElectromagnetic wave reradiationLaser rangingGrating

The invention discloses a three-dimensional laser scanning method and device. The method comprises the following steps that a three-dimensional coordinate system is generated with the central point of laser transmitting in a scanning head as the scanning origin in a vertical scanning surface, azimuth Theta and apex angle Phi of a laser beam transmitted by a ranging sensor are worked out according to azimuth Theta and pitch angle Beta of the scanning head when laser ranging is acquired every time, and a calculation formula of the three-dimensional laser corner coordinate is acquired. The device comprises the scanning head, a shaft driving unit, a ranging unit, a motor driving unit and an embedded control unit. The scanning head comprises a reflector, a bearing, a laser hole and a mechanical bracket. The mechanical bracket comprises a transverse bracket, a longitudinal bracket and a bearing support. The shaft driving unit comprises a bearing direct drive motor, an apex direct drive motor, a bearing driving shaft, an apex driving shaft, a bearing round grating and an apex round grating. The laser ranging unit comprises a one-dimensional laser ranging sensor, an adjustable bracket and a connecting piece. By means of the three-dimensional laser scanning method and device, the measurement accuracy of the three-dimensional scanning is improved, volume of the scanning device is reduced, and the small, exquisite and portable device is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

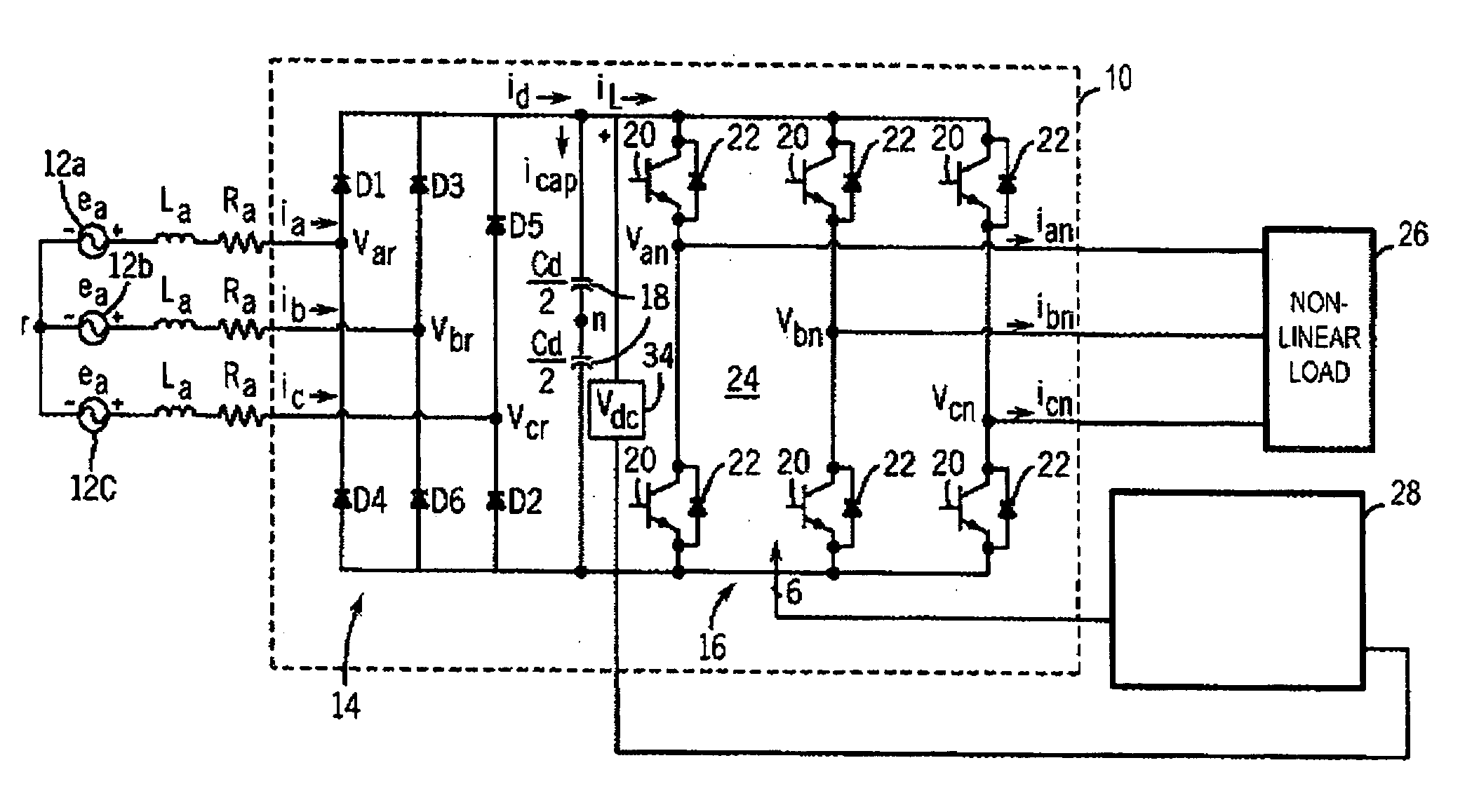

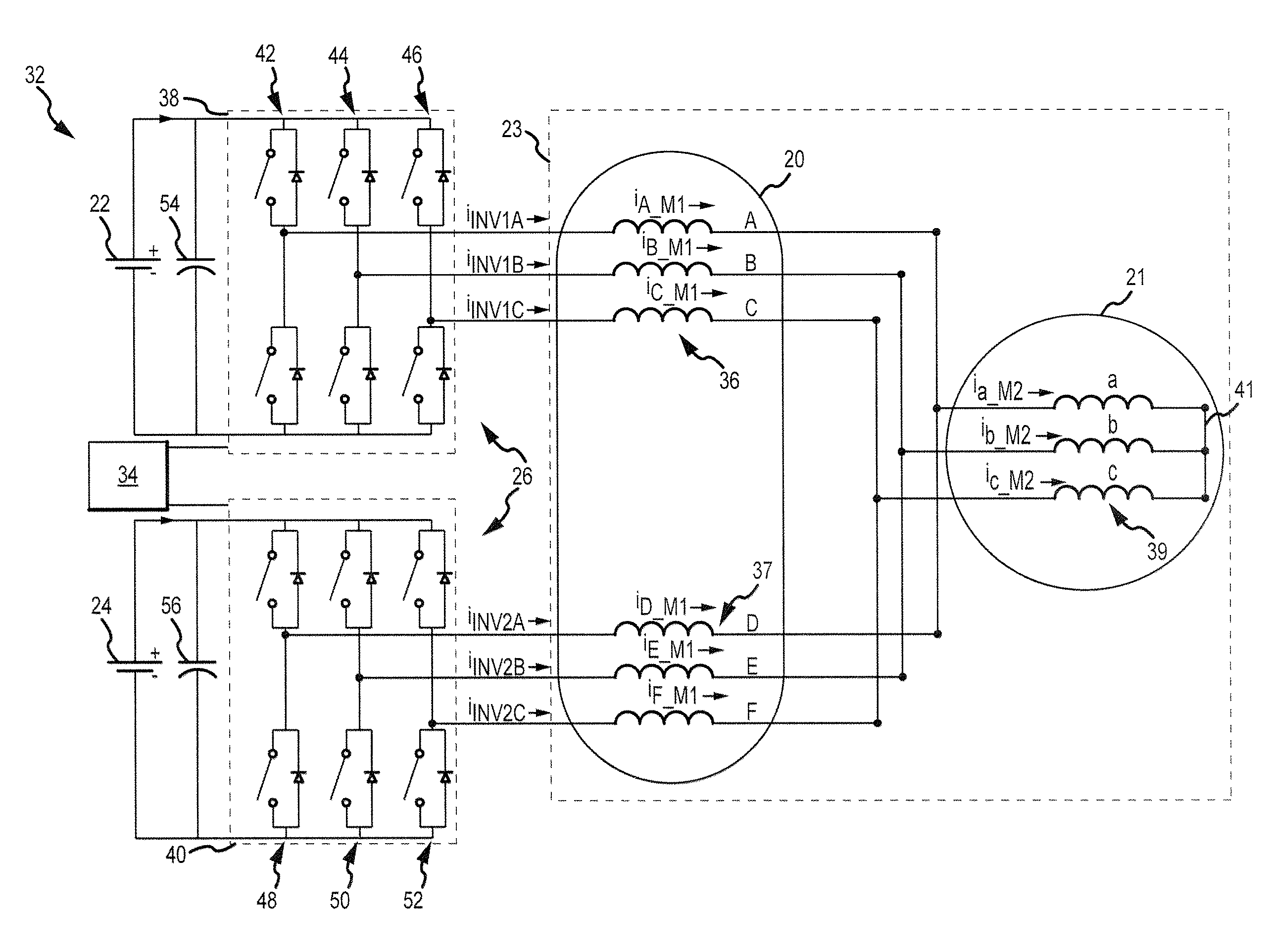

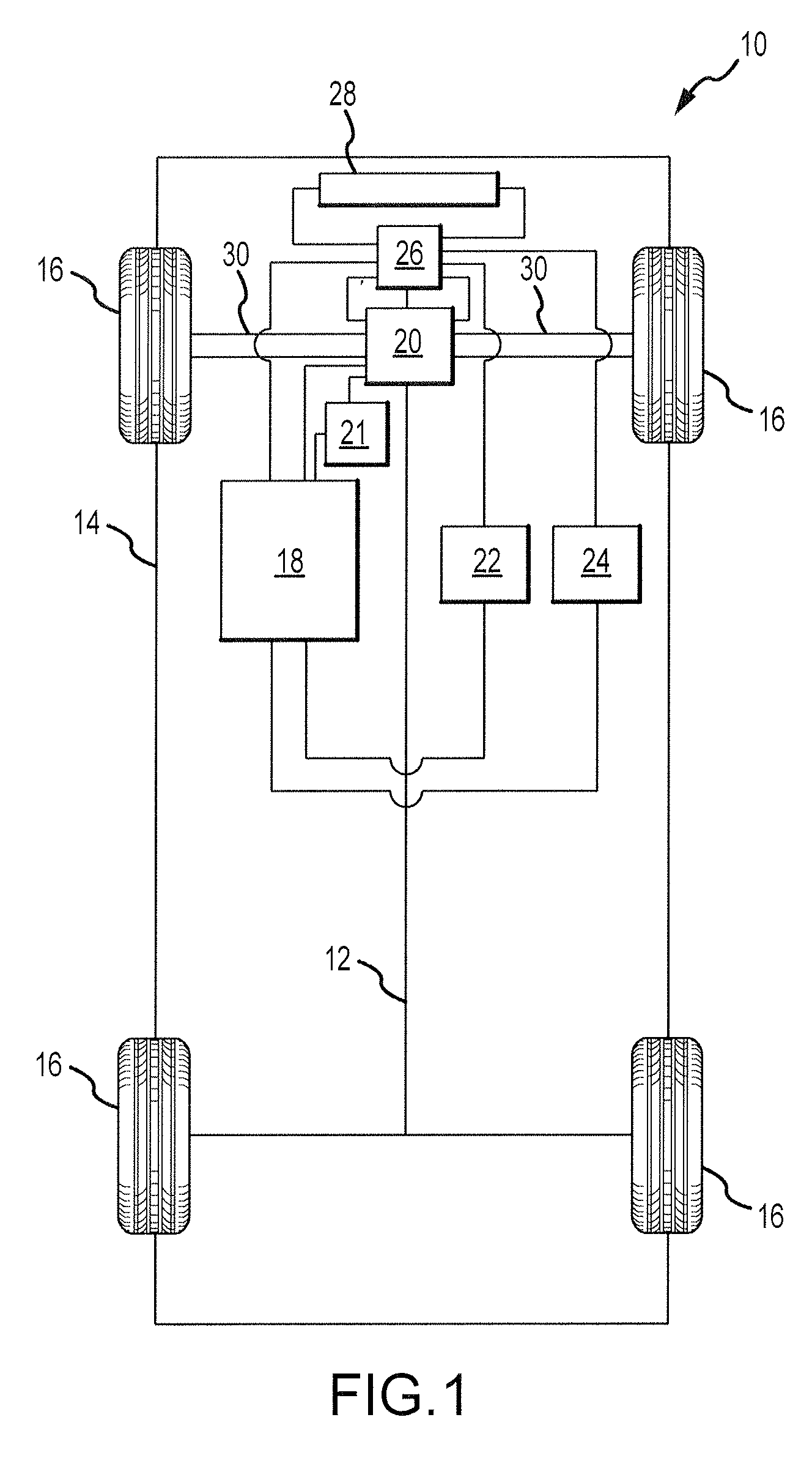

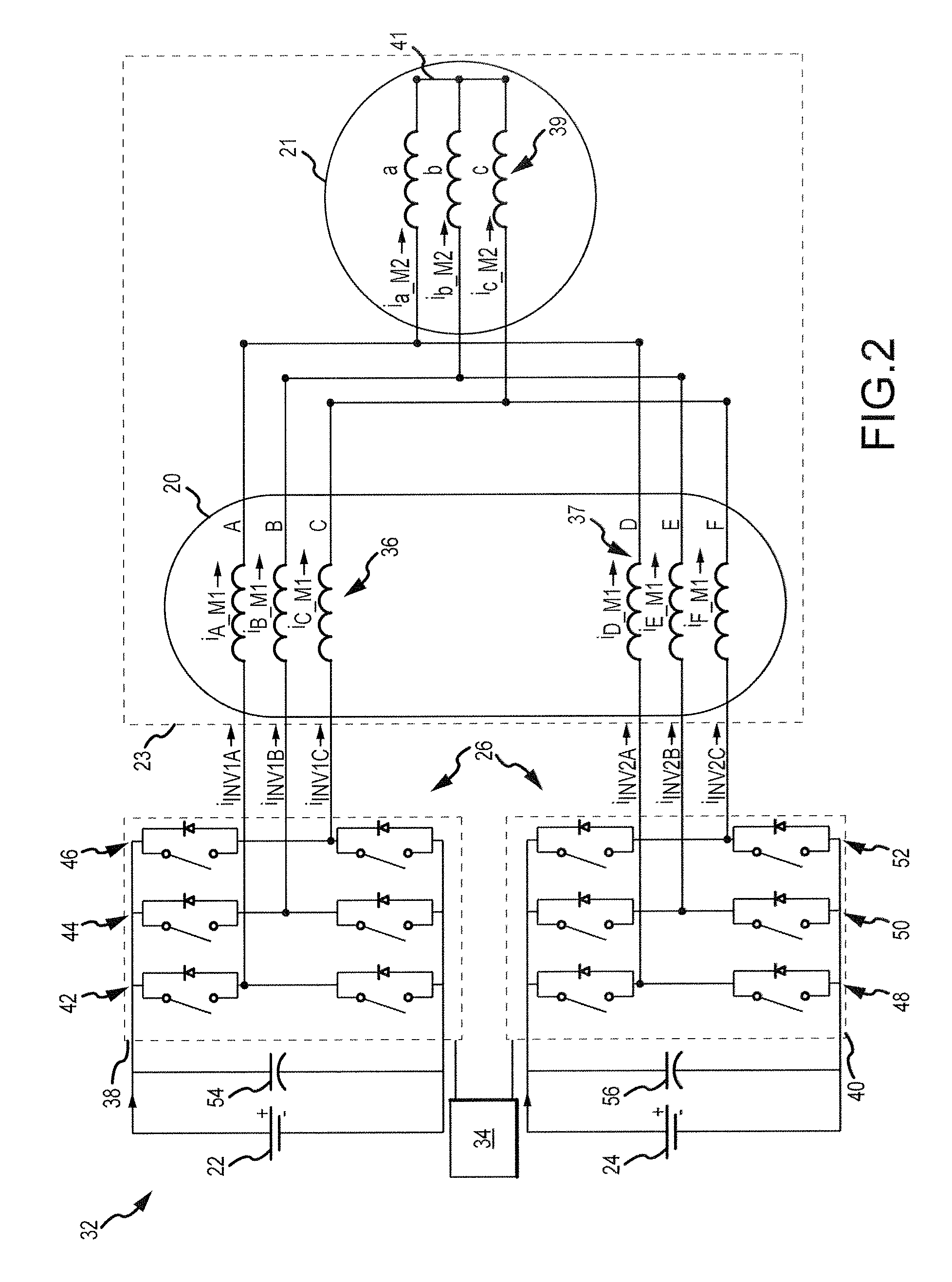

Series-coupled two-motor drive using double-ended inverter system

ActiveUS20090033251A1Well formedHybrid vehiclesDC motor speed/torque controlMotor driveMotor Drive Unit

Systems and apparatus are provided for an inverter system for use in a vehicle. The inverter system comprises a six-phase motor having a first set of three-phase windings and a second set of three-phase windings and a three-phase motor having a third set of three-phase windings, wherein the third set of three-phase windings is coupled to the first set of three-phase windings and the second set of three-phase windings. The system further comprises a first energy source coupled to a first inverter adapted to drive the six-phase motor and the three-phase motor, wherein the first set of three-phase windings is coupled to the first inverter, and a second energy source coupled to a second inverter adapted to drive the six-phase motor and the three-phase motor, wherein the second set of three-phase windings is coupled to the second inverter. A controller is coupled to the first inverter and the second inverter.

Owner:GM GLOBAL TECH OPERATIONS LLC

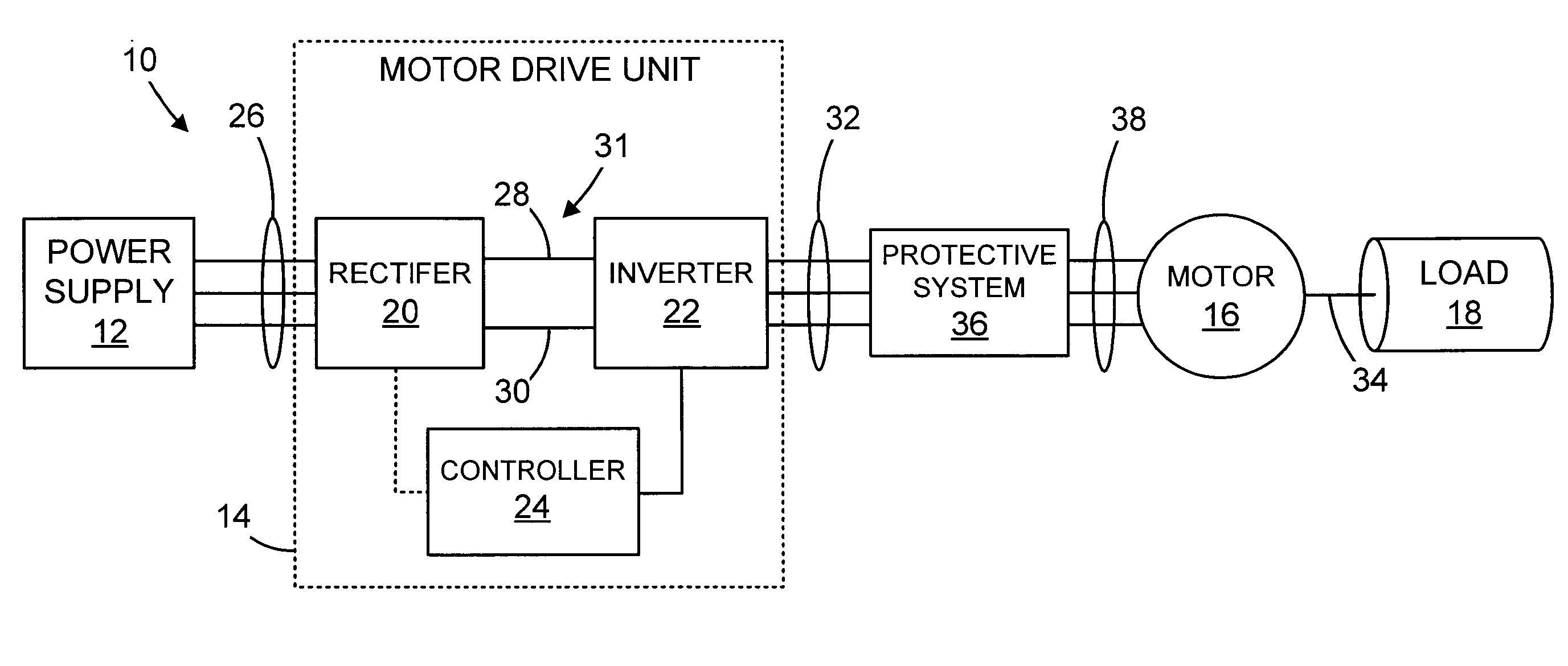

System and method for protecting a motor drive unit from motor back EMF under fault conditions

A system and method for protecting a motor drive unit from an associated motor includes a motor drive unit protection system. The motor drive unit protection system includes at least one switch configured to be connected between a motor drive unit and a plurality of motor leads of the motor driven by the motor drive unit. The motor drive unit protection system also includes a controller configured to monitor the motor drive unit or the motor to determine a fault condition indicative of the motor potentially operating as a generator. Upon determining the fault condition, the controller is configured to cause the at least one switch to connect the plurality of motor leads together to protect the motor drive unit from the motor when the motor is operating as a generator.

Owner:ROCKWELL AUTOMATION TECH

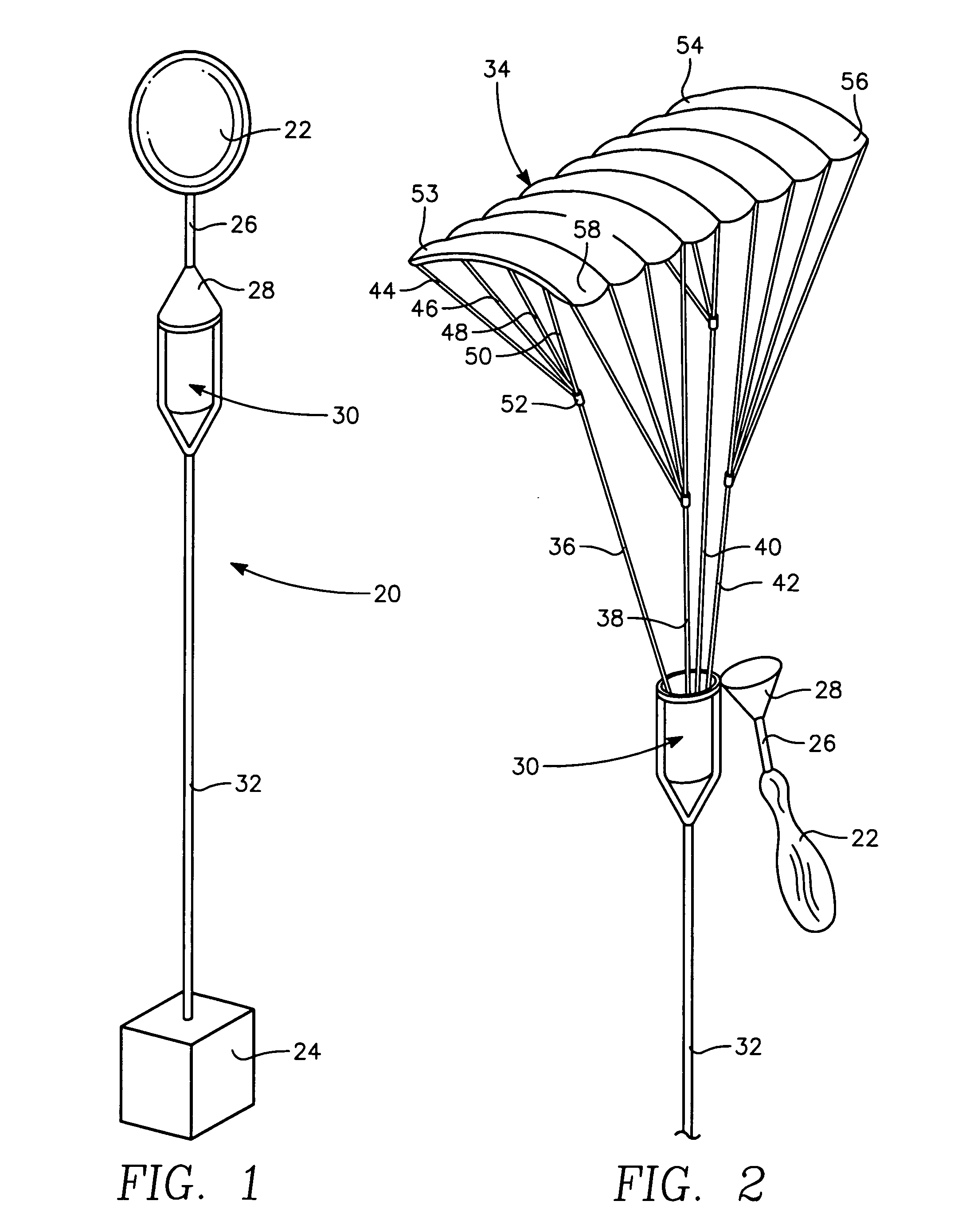

Autonomously controlled GPS-guided parafoil recovery apparatus

InactiveUS20070272801A1Simple designParachutes testing apparatusNon-canopied parachutesNon destructiveRadiosonde

A GPS-guided parafoil recovery system which provides for the recovery of a radiosonde sensor and other electronic equipment and weather balloon without damage by allowing for a safe, non-destructive precision landing of the sensor at a specified landing site. The recovery system includes a parafoil having a plurality of control lines and an electro-mechanical motor drive unit. The motor drive unit has control electronics and servo motors which are used to control the glide path trajectory of the parafoil and provide for a safe non-destructive precision landing of the sensor by adjusting the length of each of control lines of the parafoil as the parafoil travels to the landing site.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

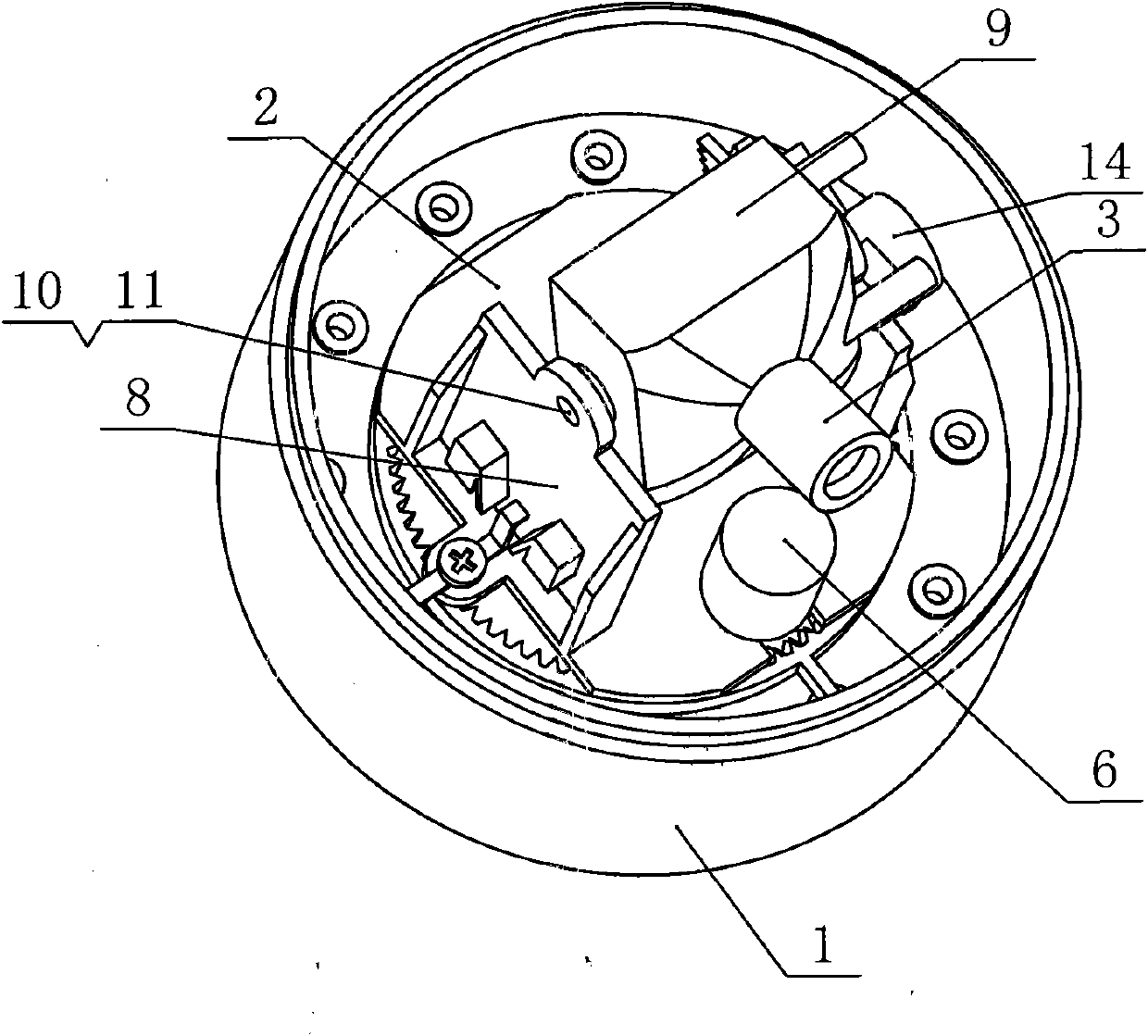

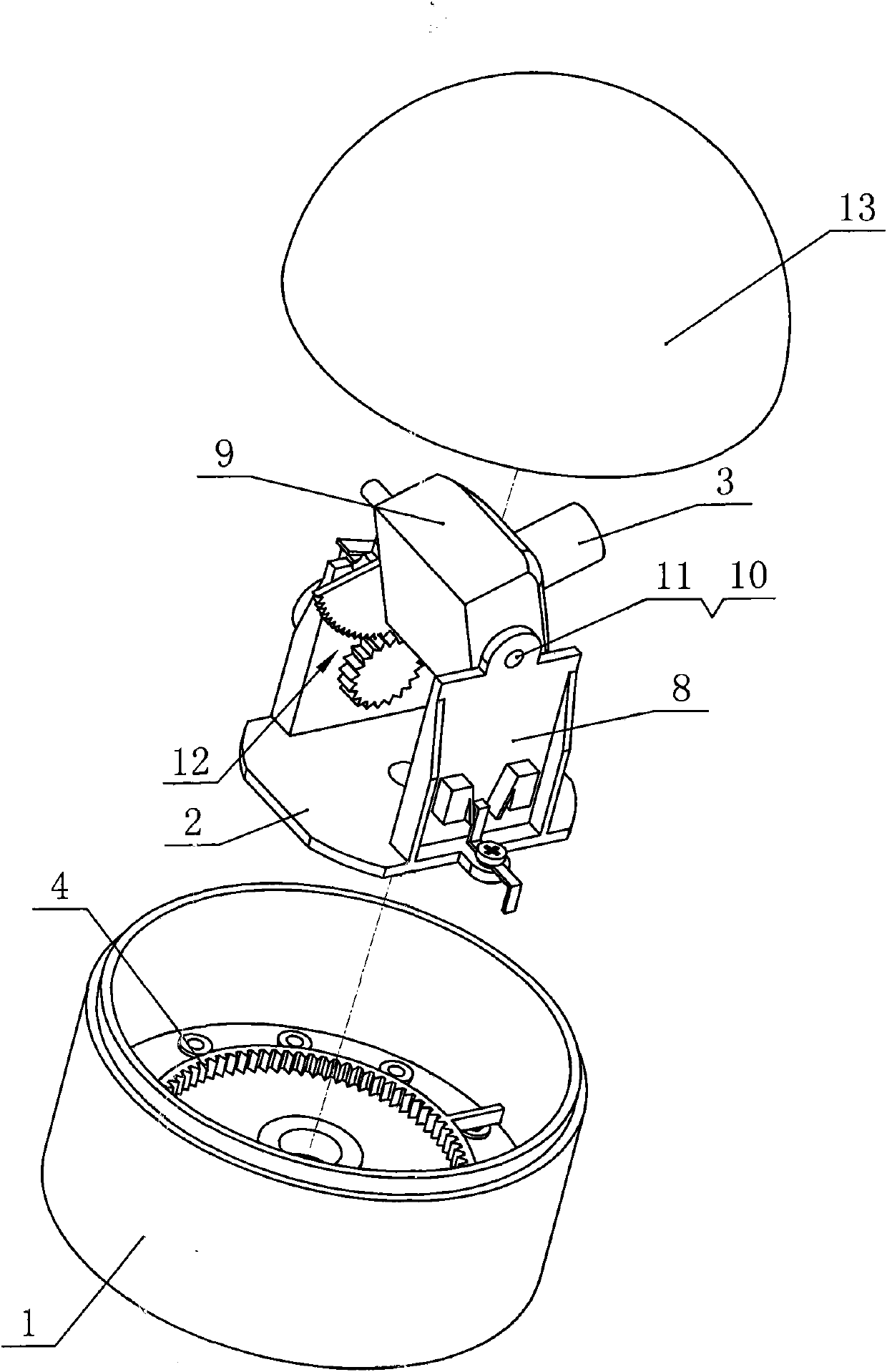

High-precision positioning rotational station

ActiveCN101907217AHigh measurement accuracyImprove measurement reliabilityStands/trestlesRotary stageLongitude

The invention relates to a high-precision positioning rotational station, comprising a horizontal rotating platform, a vertical rotating platform, a horizontal driving motor, a vertical driving motor and a controller. The controller comprises a power supply unit, a data communication circuit, a control unit and a motor drive unit. The high-precision positioning rotational station is characterizedin that the control unit comprises a data processing unit, a real-time longitude and latitude memory, a positioning longitude and latitude memory and a comparator. Because of the arrangement of the real-time longitude and latitude memory, the positioning longitude and latitude memory and the comparator, a control center can send out final positioning longitude and latitude information of the horizontal rotating platform and the vertical rotating platform and can continuously send out the information for more than one time for improving the reliability, and the controller of the rotational platform can control the horizontal driving motor and the vertical driving motor to work after the comparison of the comparator to obtain a relative longitude and latitude position only by receiving the final positioning longitude and latitude once, thereby improving the measurement precision and the reliability of the high-precision positioning rotational station.

Owner:ZHEJIANG TENDENCY TECH

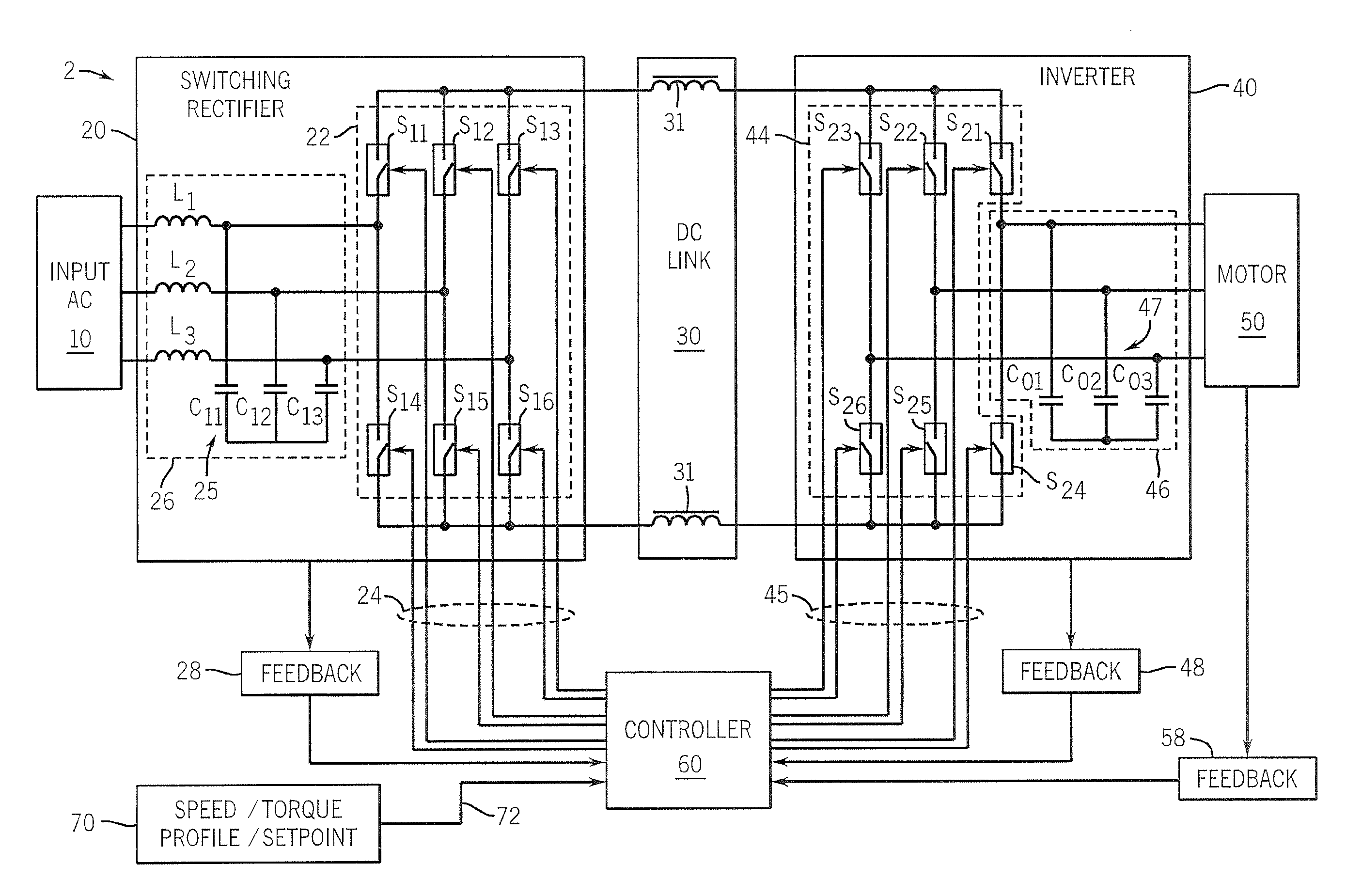

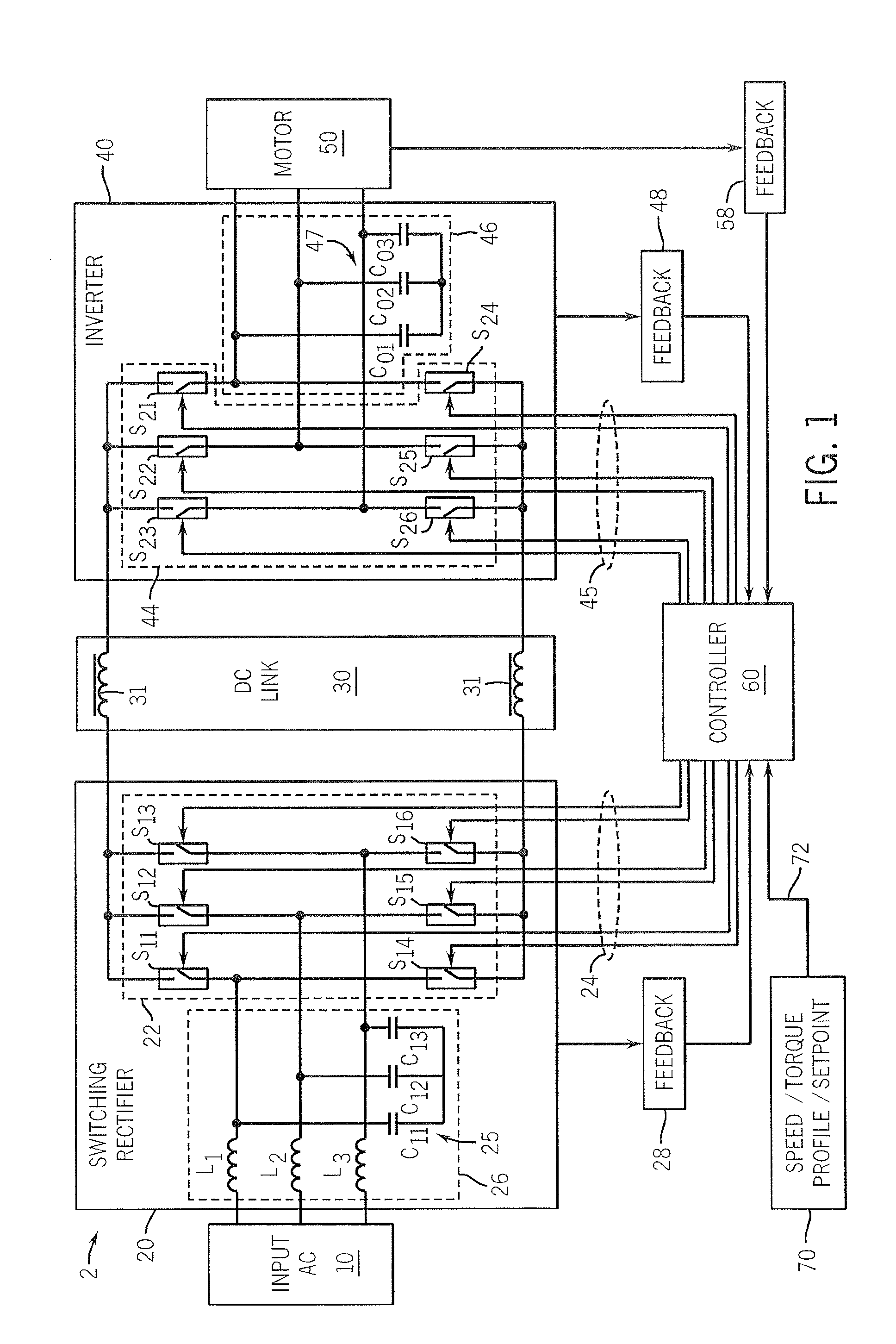

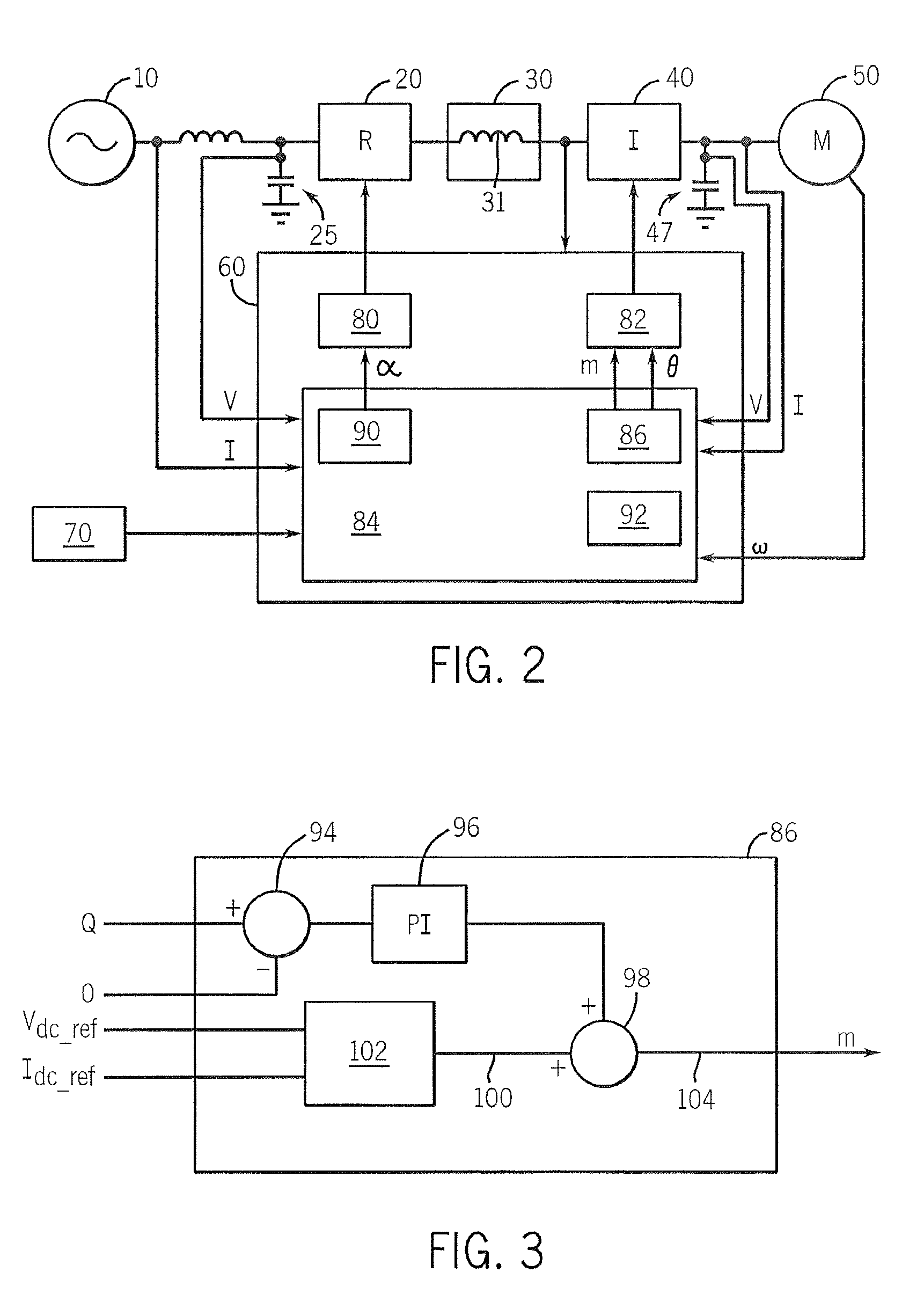

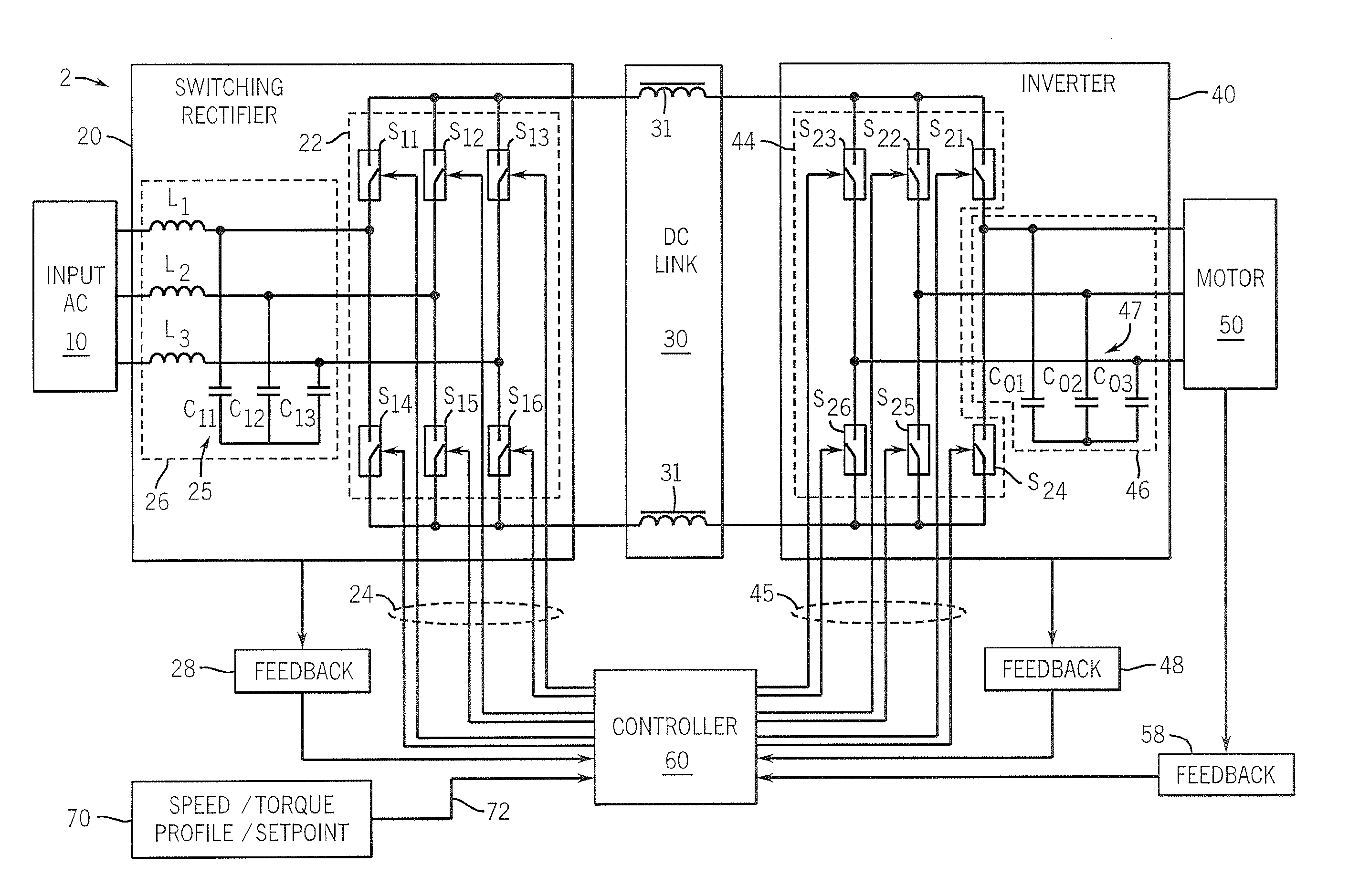

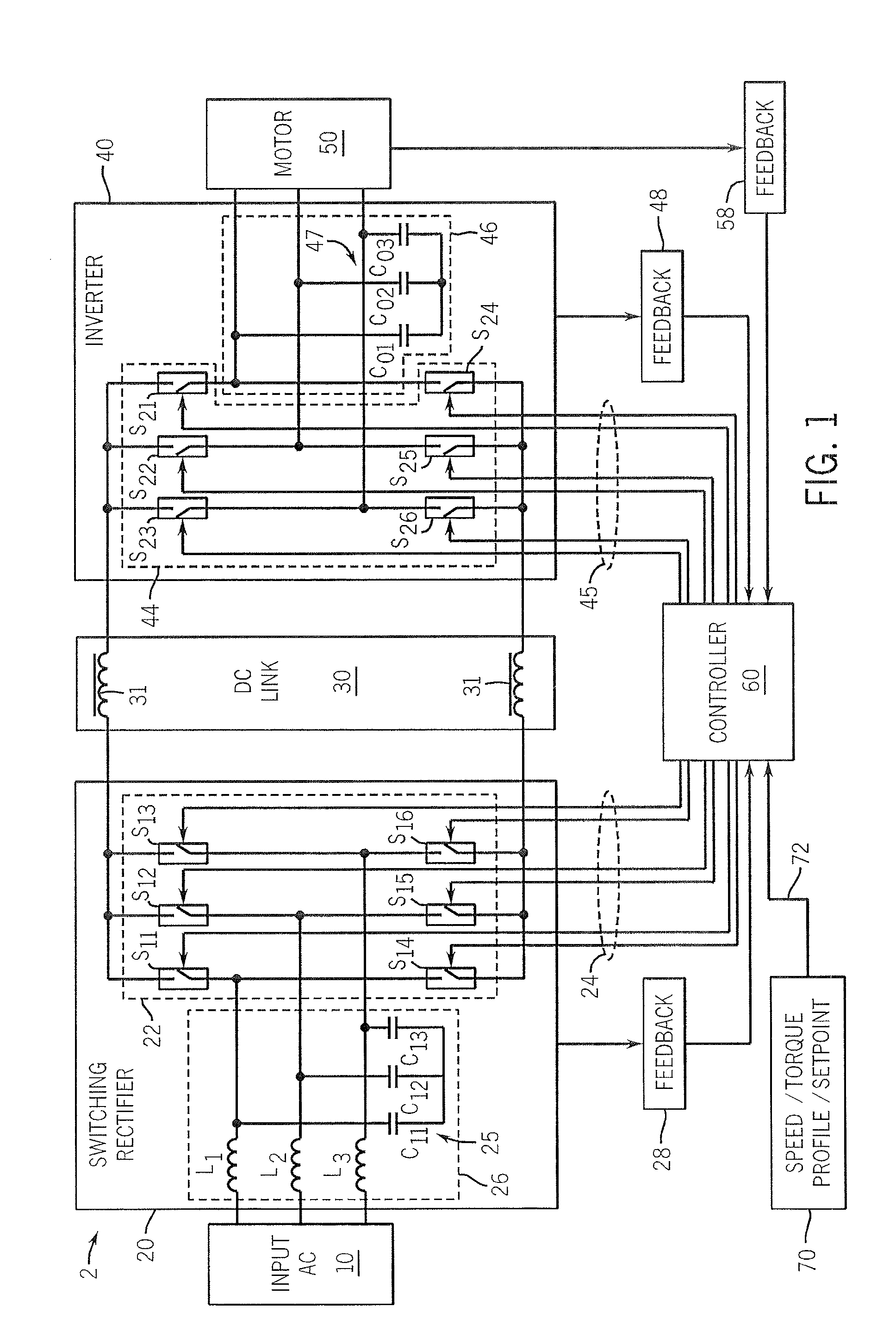

Motor Drive Using Flux Adjustment to Control Power Factor

ActiveUS20090085510A1Single-phase induction motor startersMotor/generator/converter stoppersMotor speedMotor drive

The switching rectifier and switching inverter on a motor drive unit are modulated to indirectly change the magnitude of current and voltage stored in DC link by controlling the magnetic field of the motor to correct for both power factor lead and power factor lag over a wide range of motor speeds and conditions while maintaining a predetermined motor operating point.

Owner:ROCKWELL AUTOMATION TECH

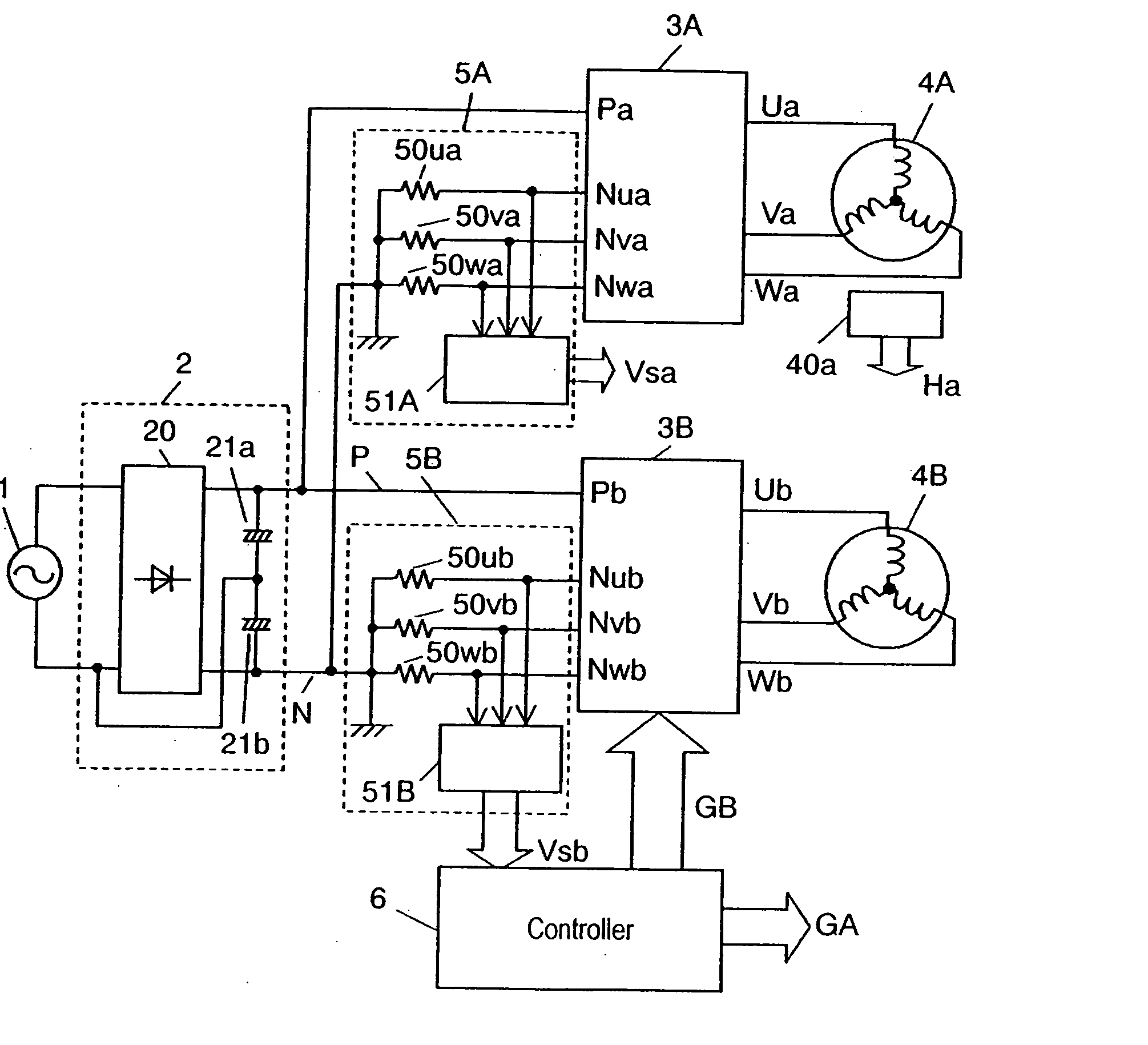

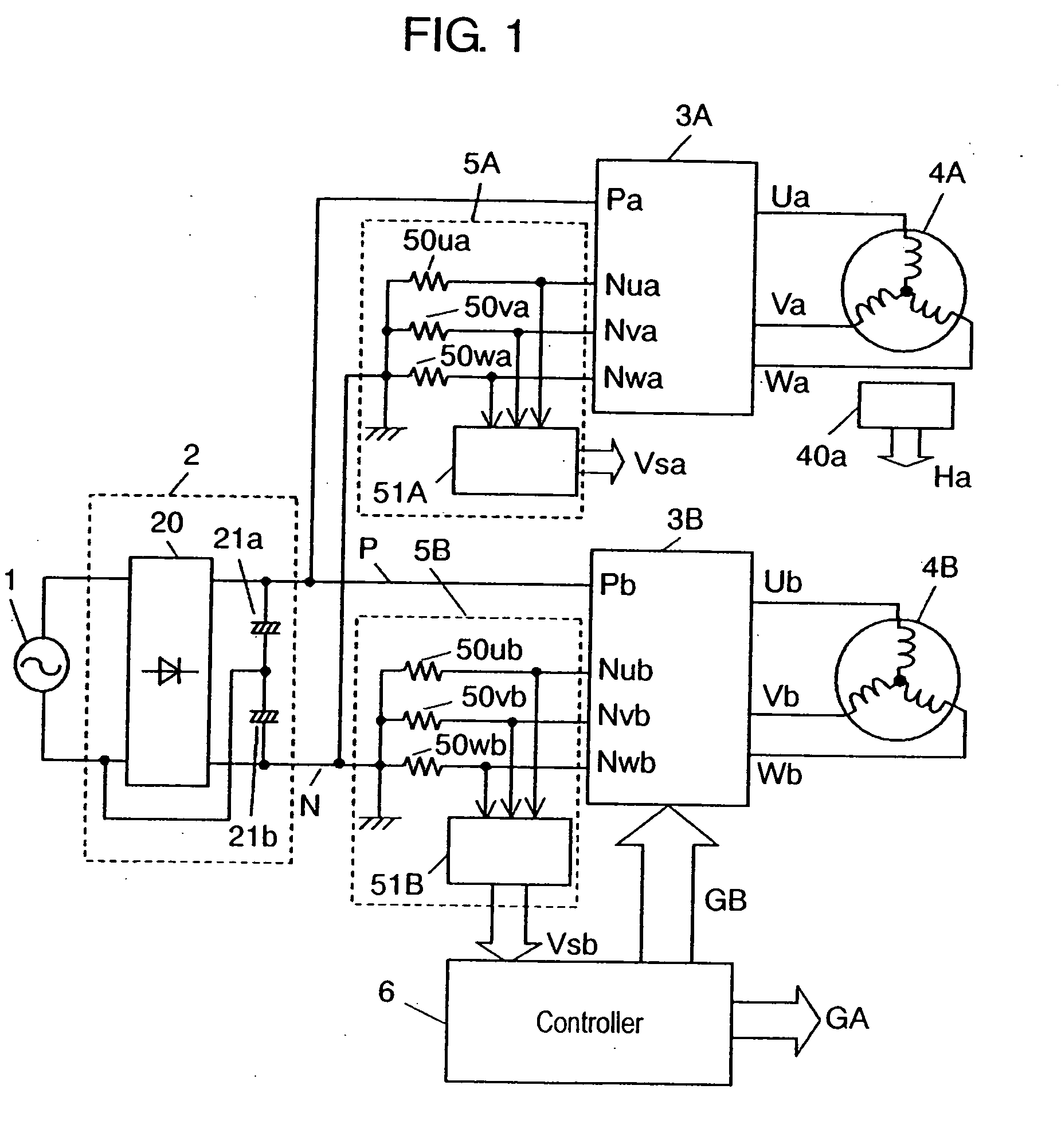

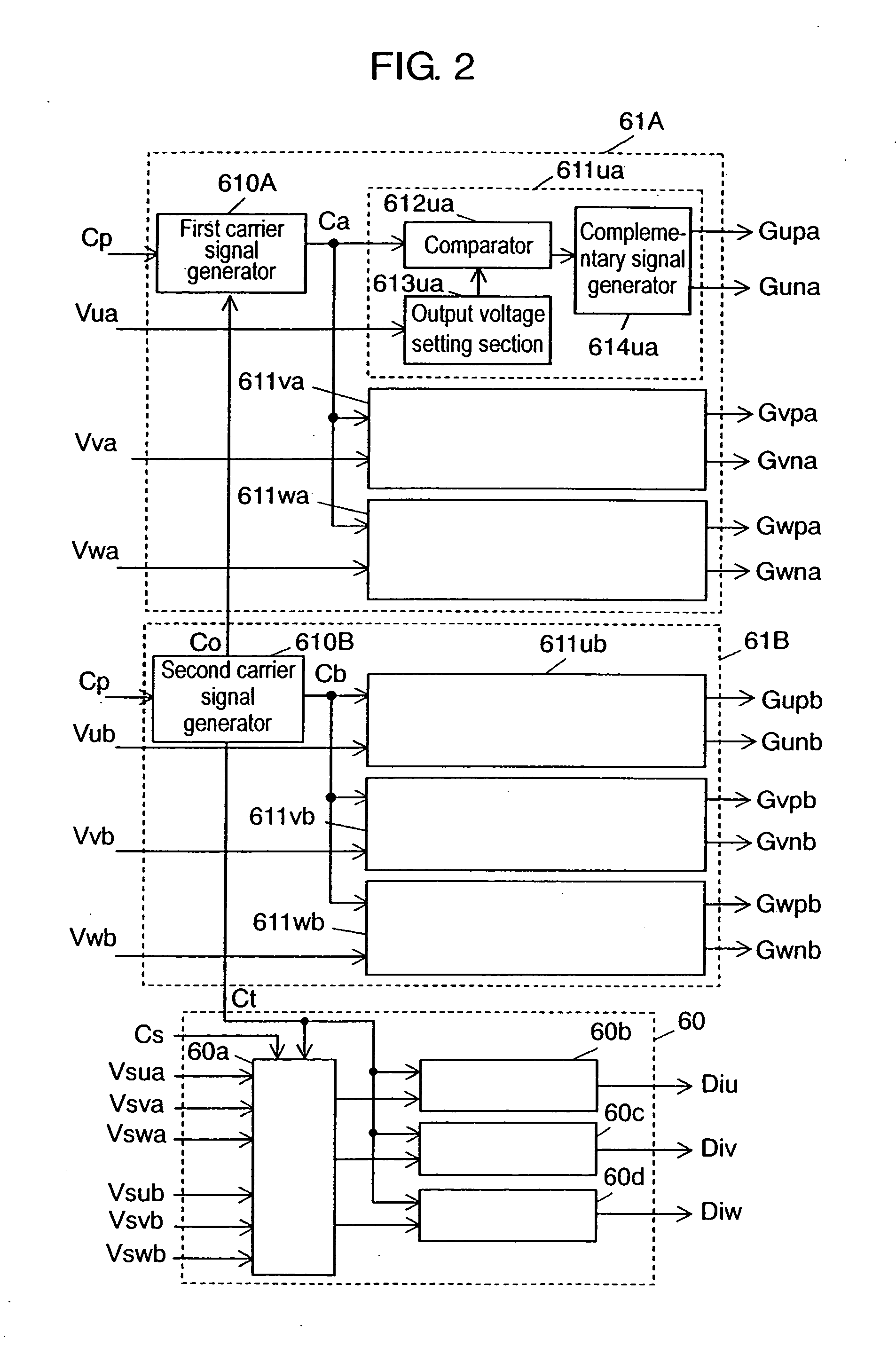

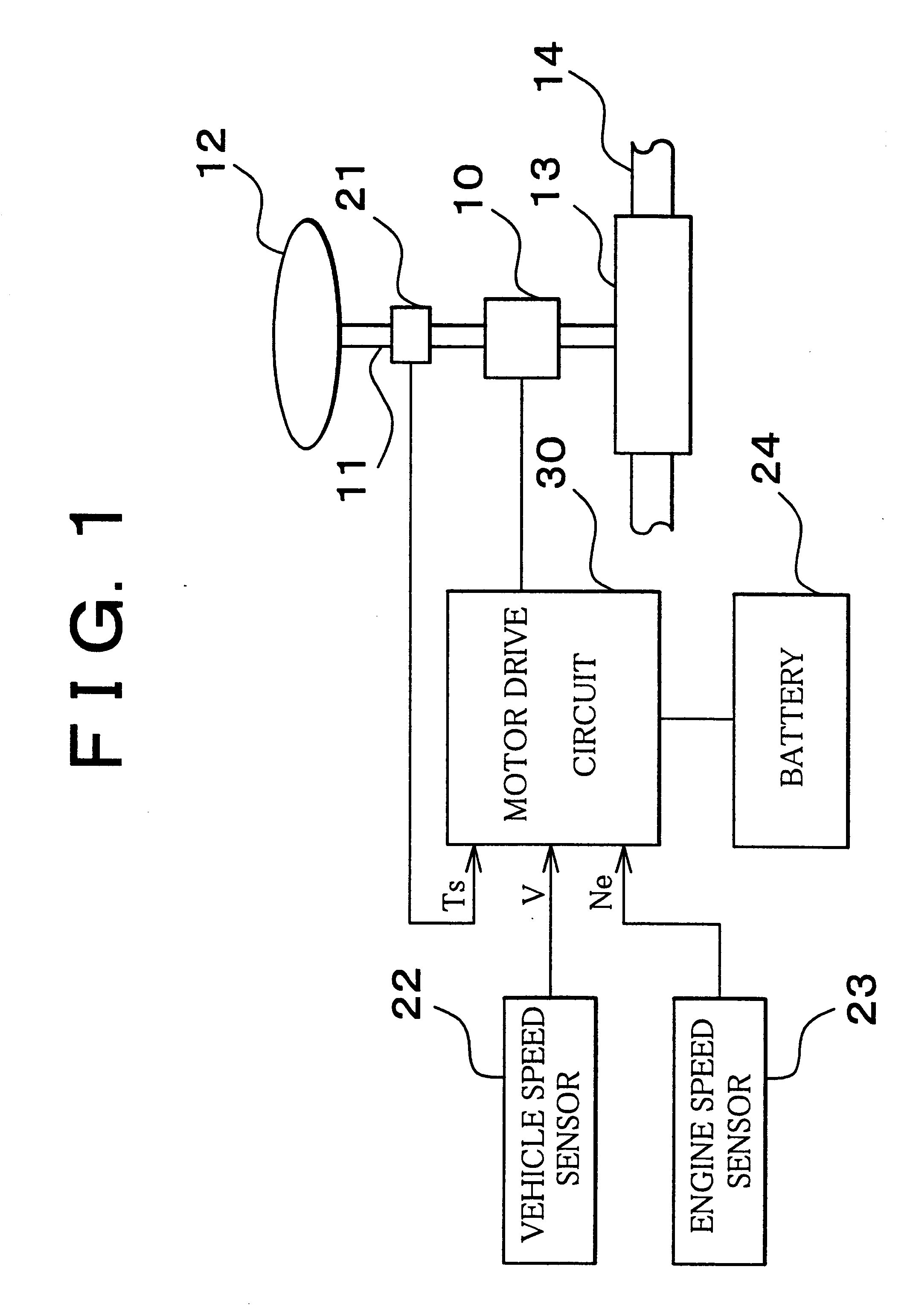

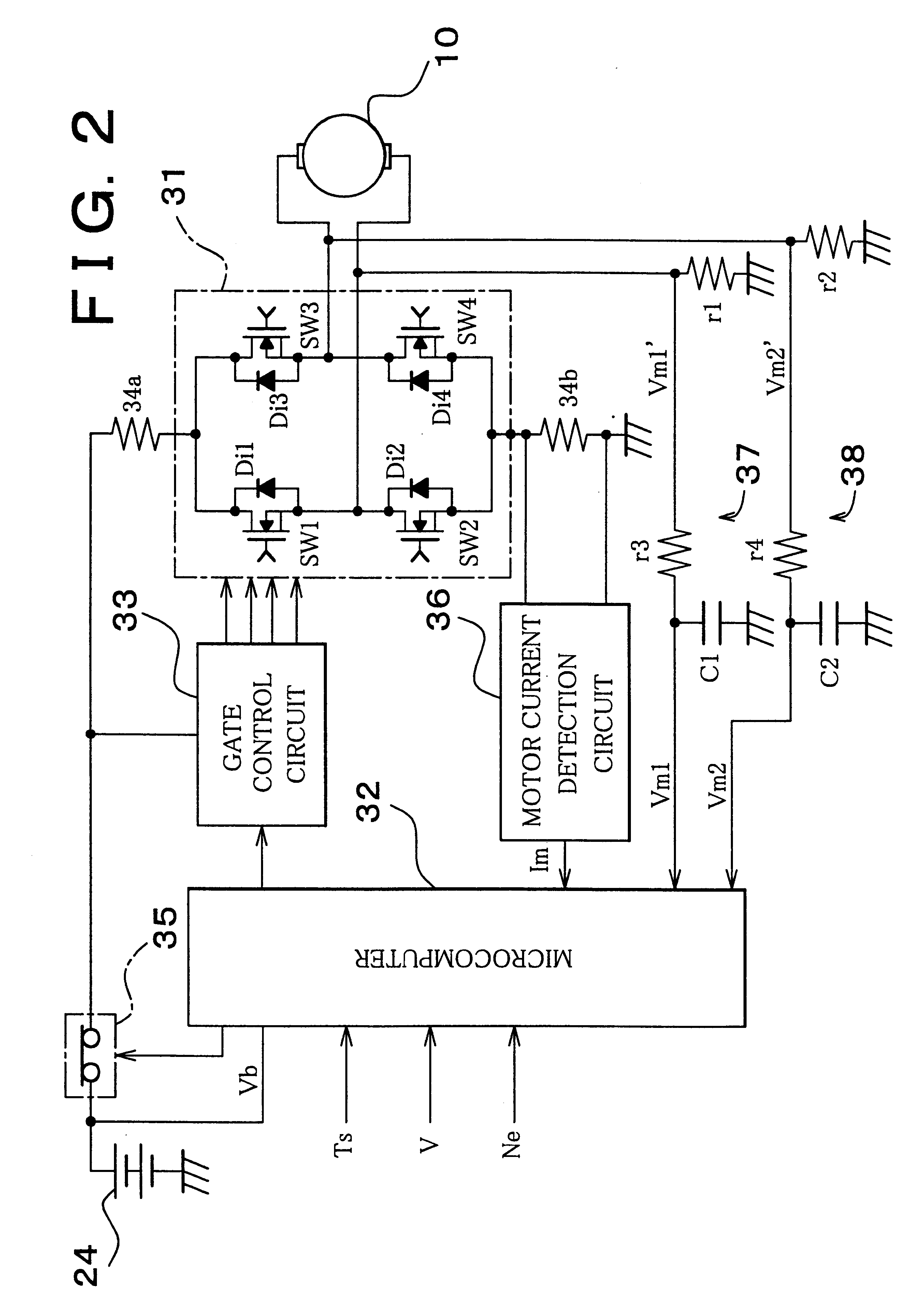

Motor drive unit

InactiveUS20070013325A1Eliminate switching noise interferenceImprove accuracyAc-dc conversion without reversalAC motor controlMotor Drive UnitAC power

A motor drive unit comprises a DC power source, a plurality of inverter circuits for converting the a power of this DC power source to an AC power, current detectors for detecting an output current of at least one of those plurality of inverter circuits and a controller for performing PWM control of those plurality of inverter circuits. This controller is constructed in a way to synchronize a PWM period of the plurality of inverter circuits, so as to drive a plurality of motors at once by means of those plurality of inverter circuits respectively.

Owner:PANASONIC CORP

Automatically focused remote iris image acquisition device, method and recognition system

ActiveCN101814129AExpand collection rangeAcquisition speed is fastTelevision system detailsCharacter and pattern recognitionCamera lensLong-focus lens

Owner:TIANJIN IRISTAR TECH LTD

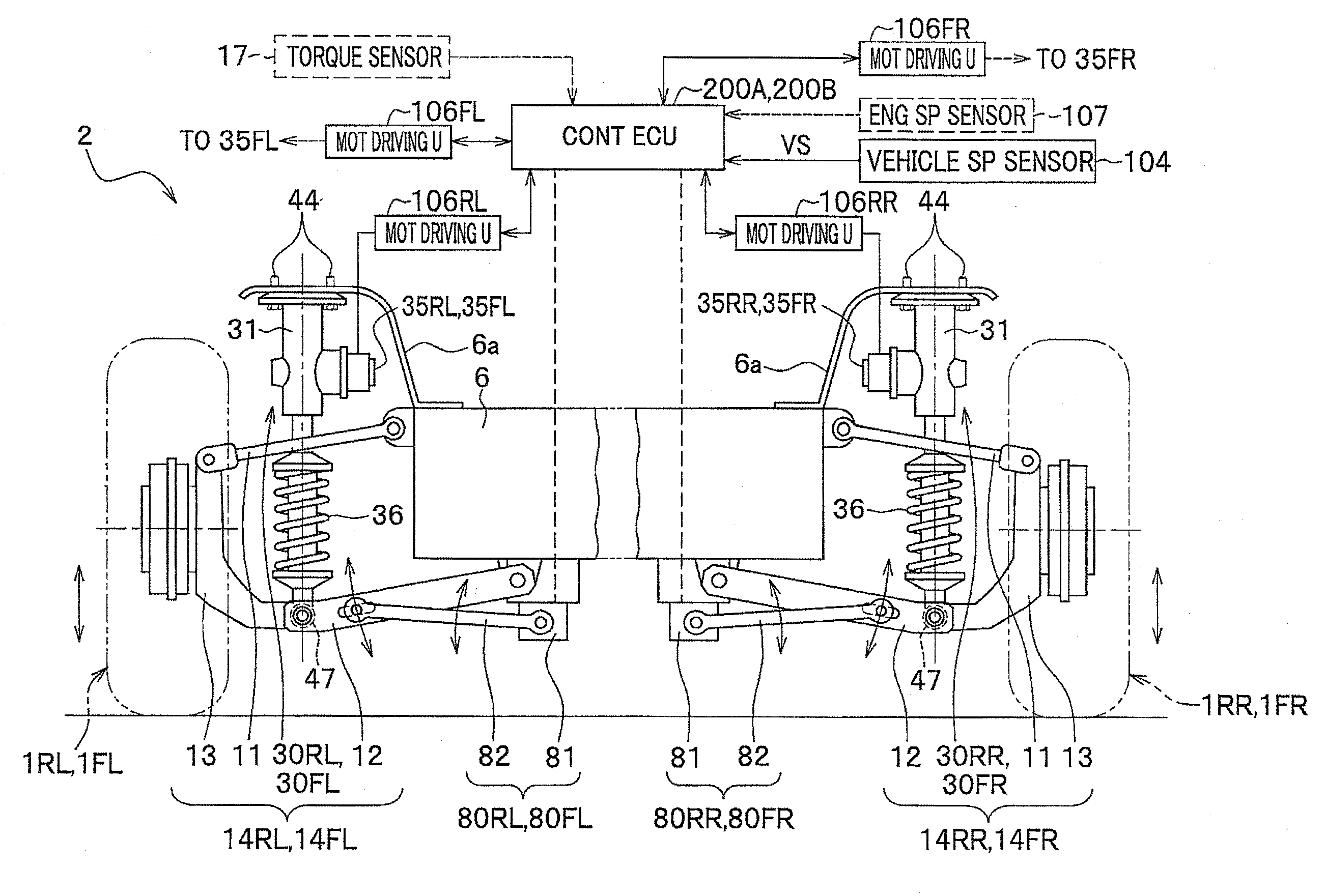

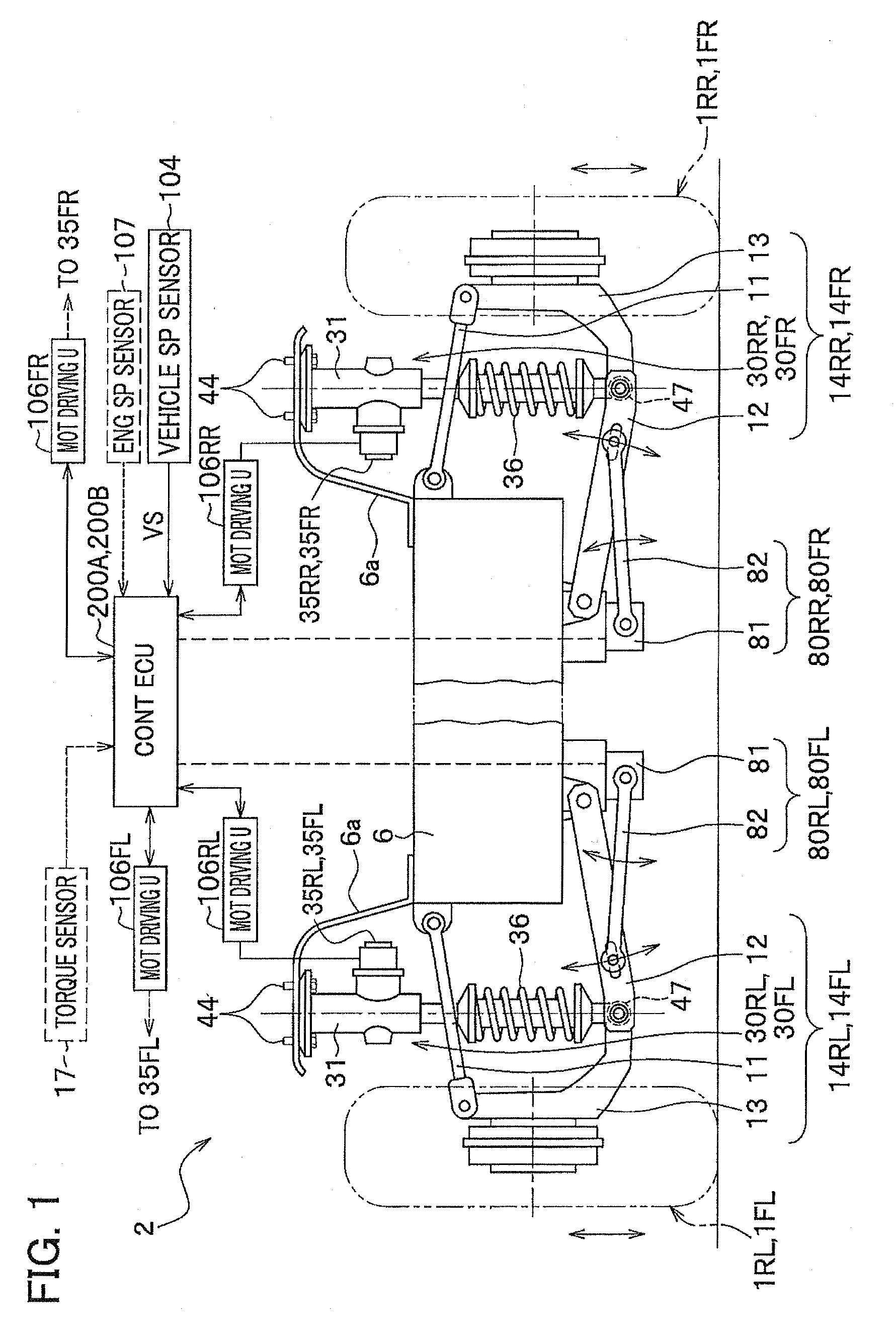

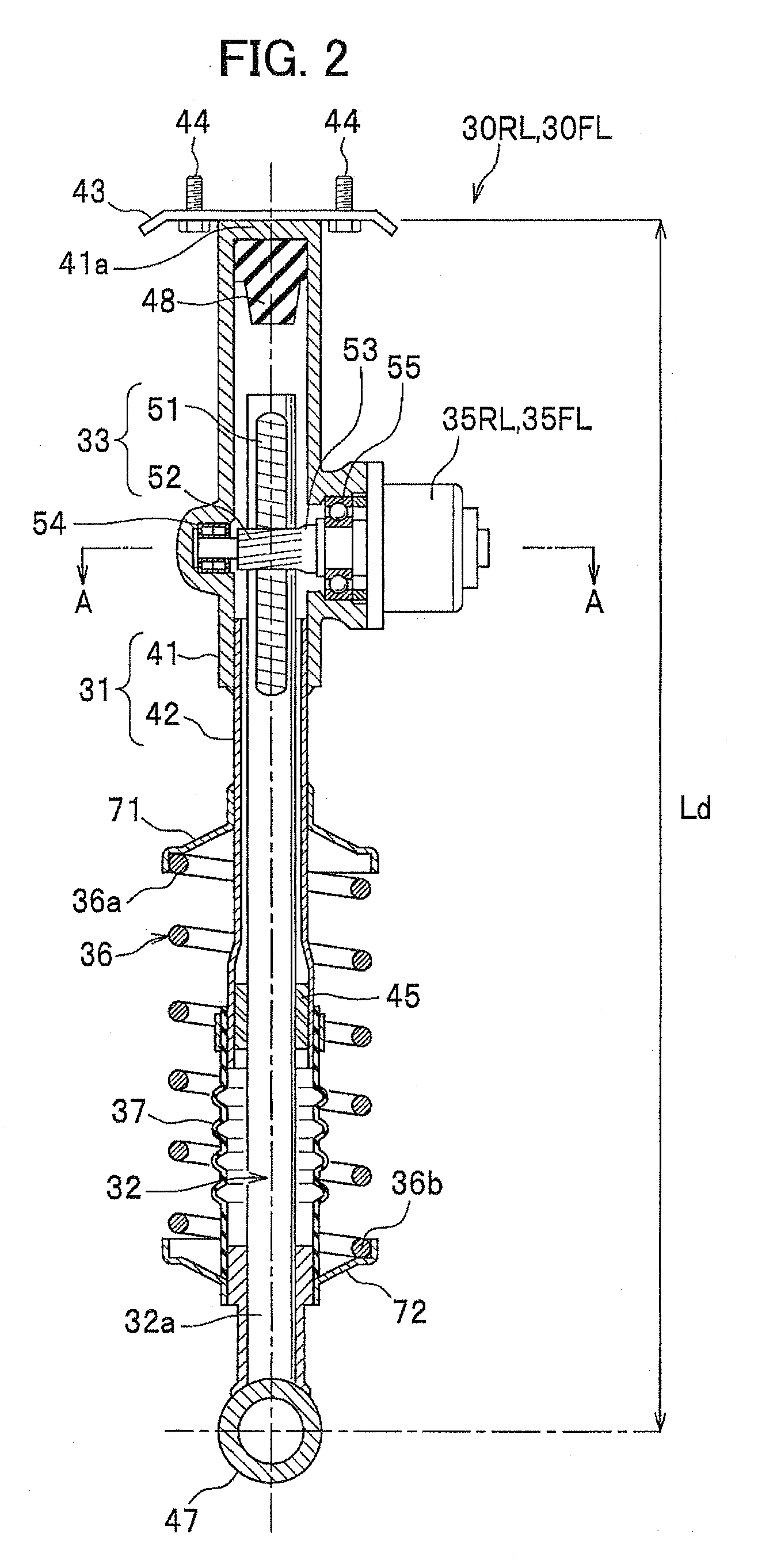

Electric damper

ActiveUS20090224502A1Suppress transmissionSpringsDigital data processing detailsControl signalMotor Drive Unit

An electric damper which does not transmit unbalance wheel vibration to a vehicle body is provided. A low-pass cutoff frequency setting unit and a high-pass cutoff frequency setting unit respectively set the cutoff frequencies for band-stop filters to a frequency band corresponding to unbalance wheel vibration based on a signal indicating a vehicle speed from a vehicle speed sensor, and a function as a band-stop filter comprising a low-pass filter computation unit, a high-pass filter computation unit and an adder is computed for a displacement rate of the vertical motion of a wheel calculated by a differentiating unit in a damper control unit. A damper control amount computation unit calculates a control amount of controlling an electric motor for a motor-driven damper based on the calculated filtered displacement rate, and outputs a control signal to a motor driving unit through a driving circuit output unit.

Owner:HONDA MOTOR CO LTD

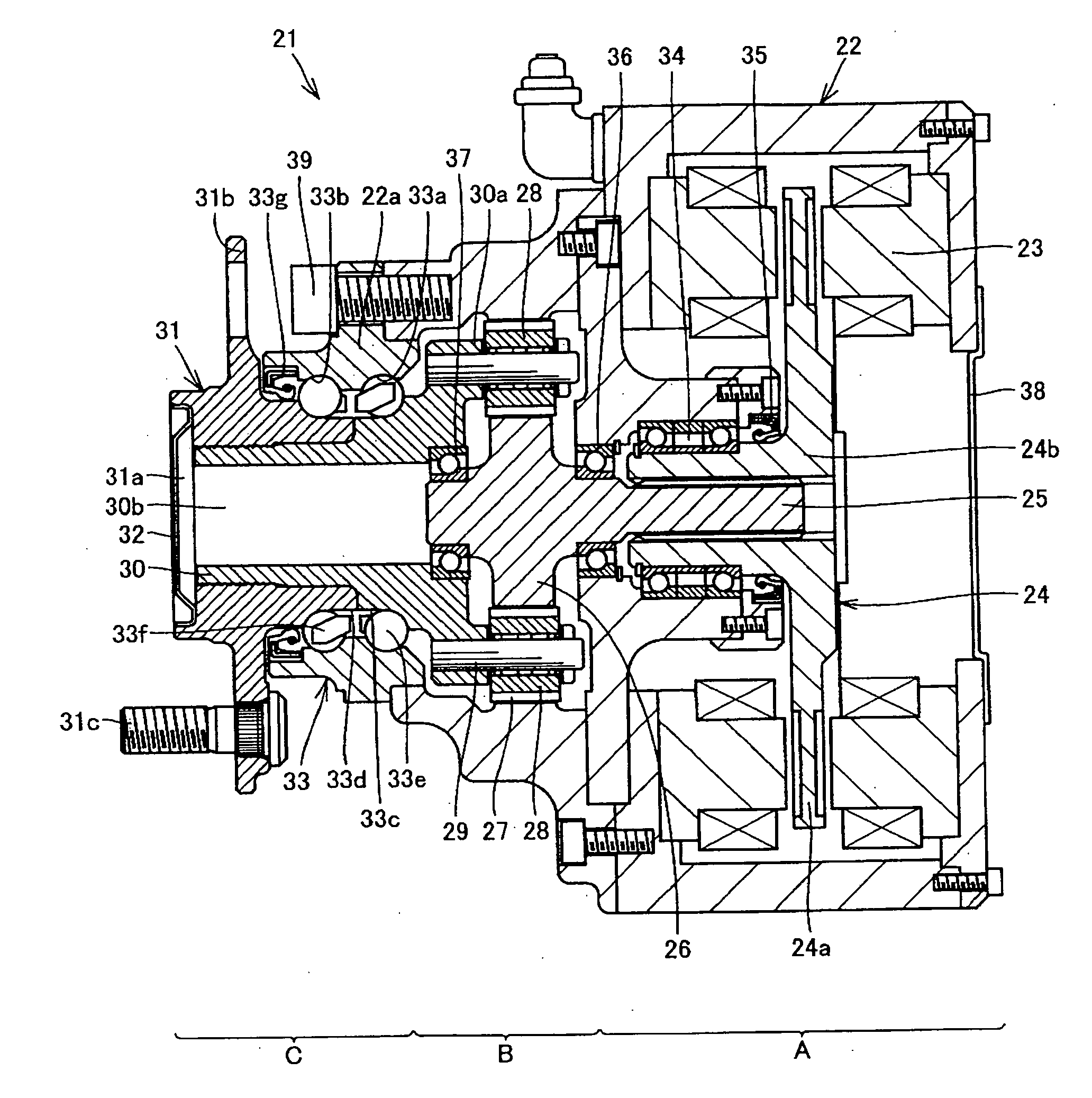

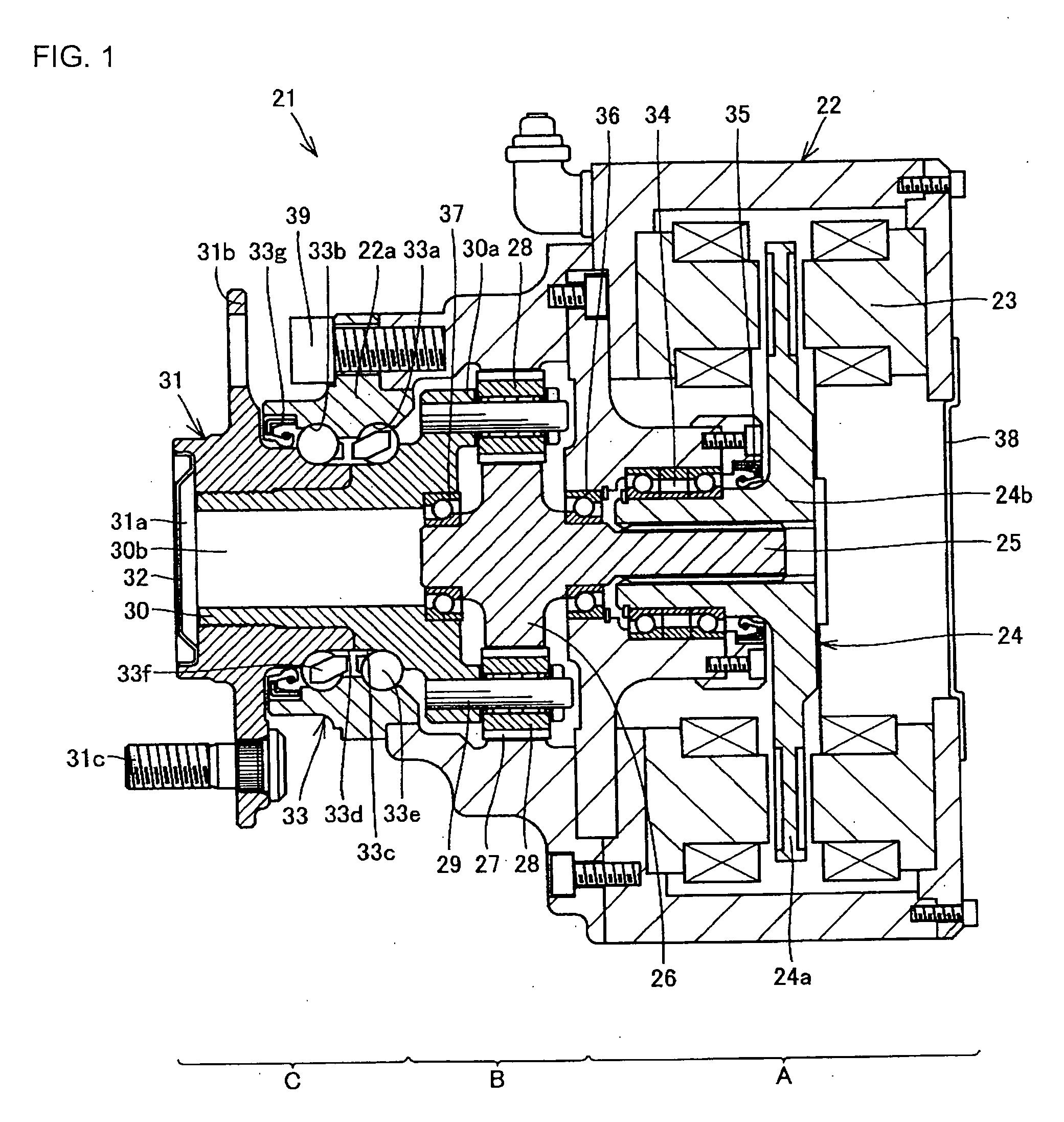

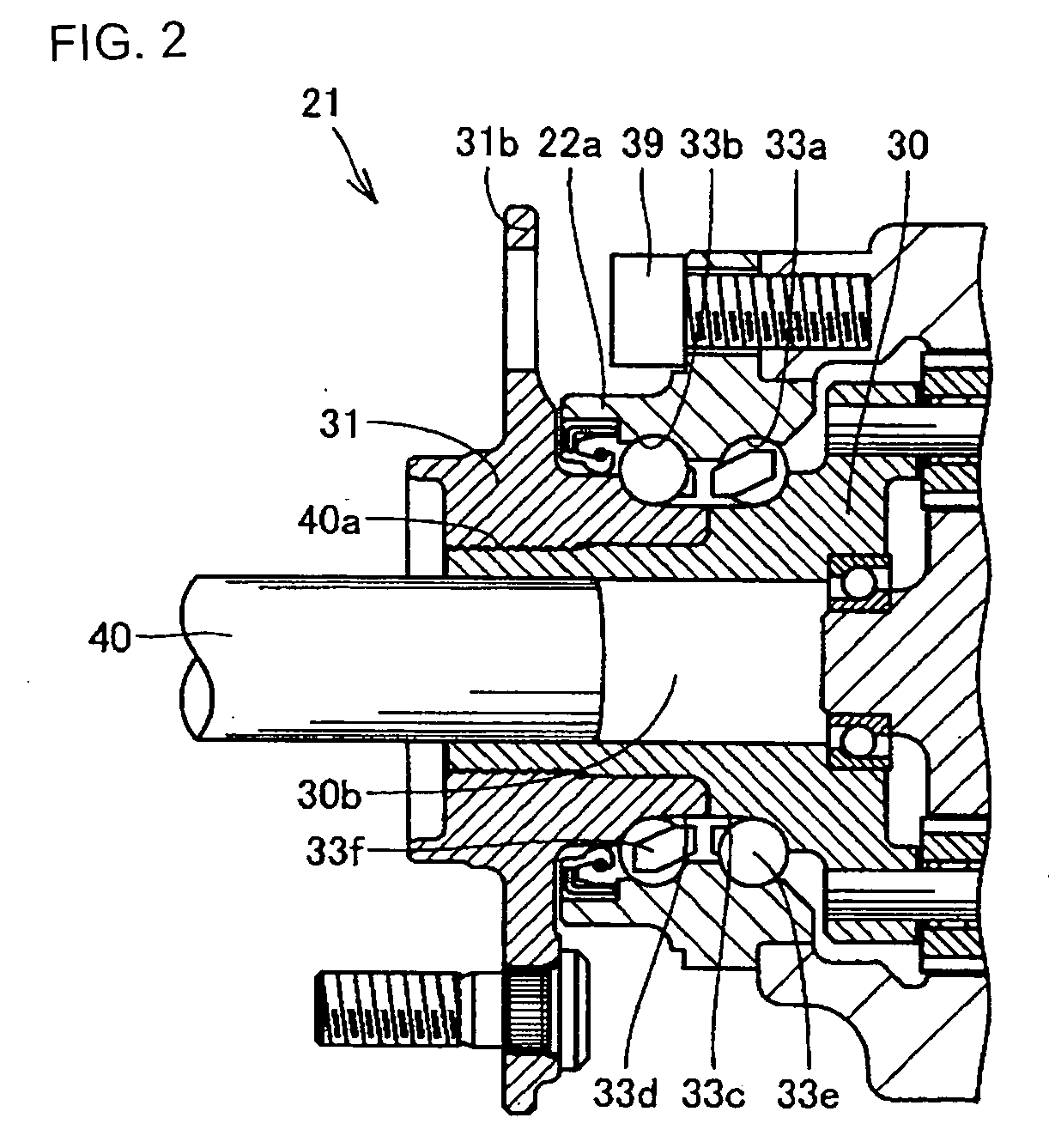

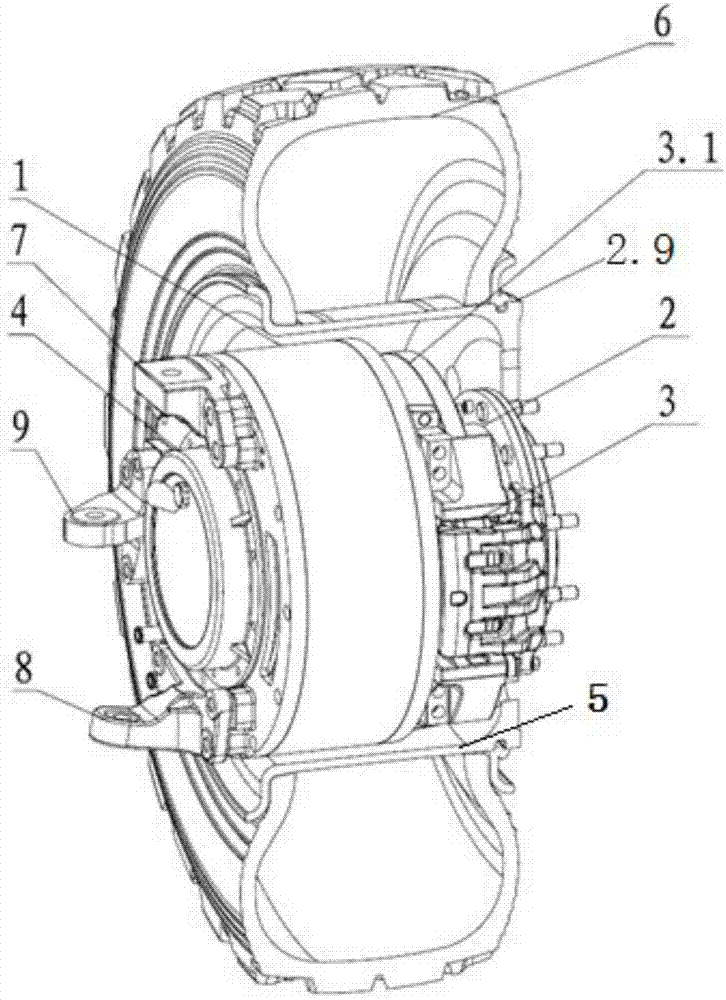

In-Wheel Motor Drive Unit

ActiveUS20090101424A1Suppression of torque lossReduce contact resistanceHybrid vehiclesRolling contact bearingsMotor Drive UnitMechanical engineering

An in-wheel motor drive unit (21) comprises a casing (22), a motor part (A), a deceleration part (B), a wheel hub (31), and a wheel hub bearing (33) rotatably supporting the wheel hub (31) with respect to the casing (22). The wheel hub bearing (33) includes first and second outer track surfaces (33a) and (33b) provided on the inner diameter surface of the casing (22), a first inner track surface (33c) provided on the outer diameter surface of a wheel-side rotation member (30) and opposed to the first outer track surface (33a), a second inner track surface (33d) provided on the outer diameter surface of the wheel hub (31) and opposed to the second outer track surface (33b), and a plurality of rolling elements (33e) arranged between the outer track surfaces (33a) and (33b) and the inner track surfaces (33c) and (33d).

Owner:NTN CORP

Motorized window treatment

ActiveUS9810020B2Long lastingPrevent movementEnergy efficient ICTPower managementMotor speedElectrical battery

A motorized window treatment may provide a low-cost solution for controlling the amount of daylight entering a space through a window. The window treatment may include a covering material (e.g., a cellular shade fabric or a roller shade fabric), a drive assembly for raising and lowering the covering material, and a motor drive unit including a motor configured to drive the drive assembly to raise and lower the covering material. The motorized window treatment may comprise one or more battery packs configured to receive batteries for powering the motor drive unit. The batteries may be located out of view of a user of the motorized window treatment (e.g., in a headrail or in a battery compartment). The motorized window treatment may use various power-saving methods to lengthen the lifetime of the batteries, e.g., to reduce the motor speed to conserve additional battery power and extend the lifetime of the batteries.

Owner:LUTRON TECH CO LLC

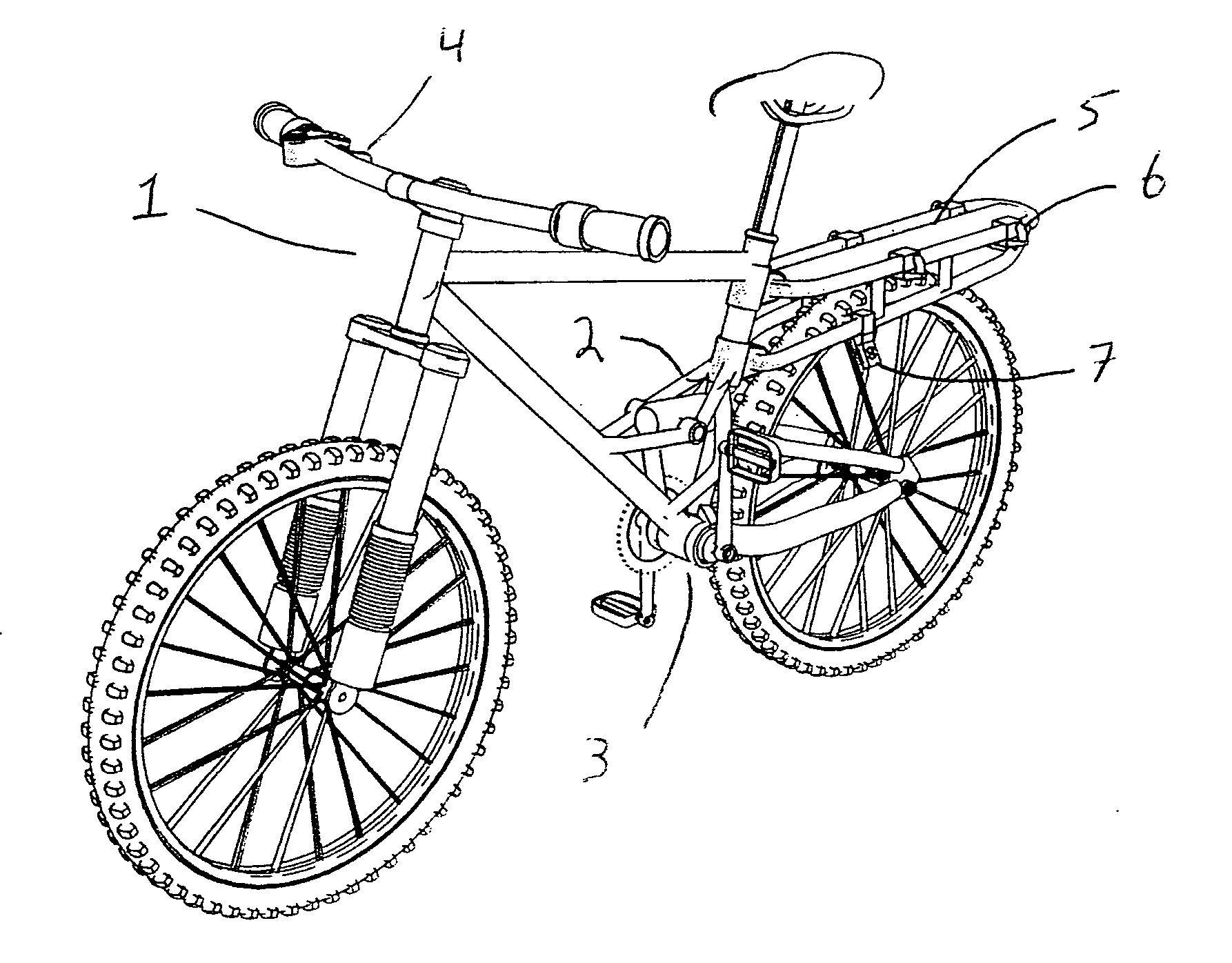

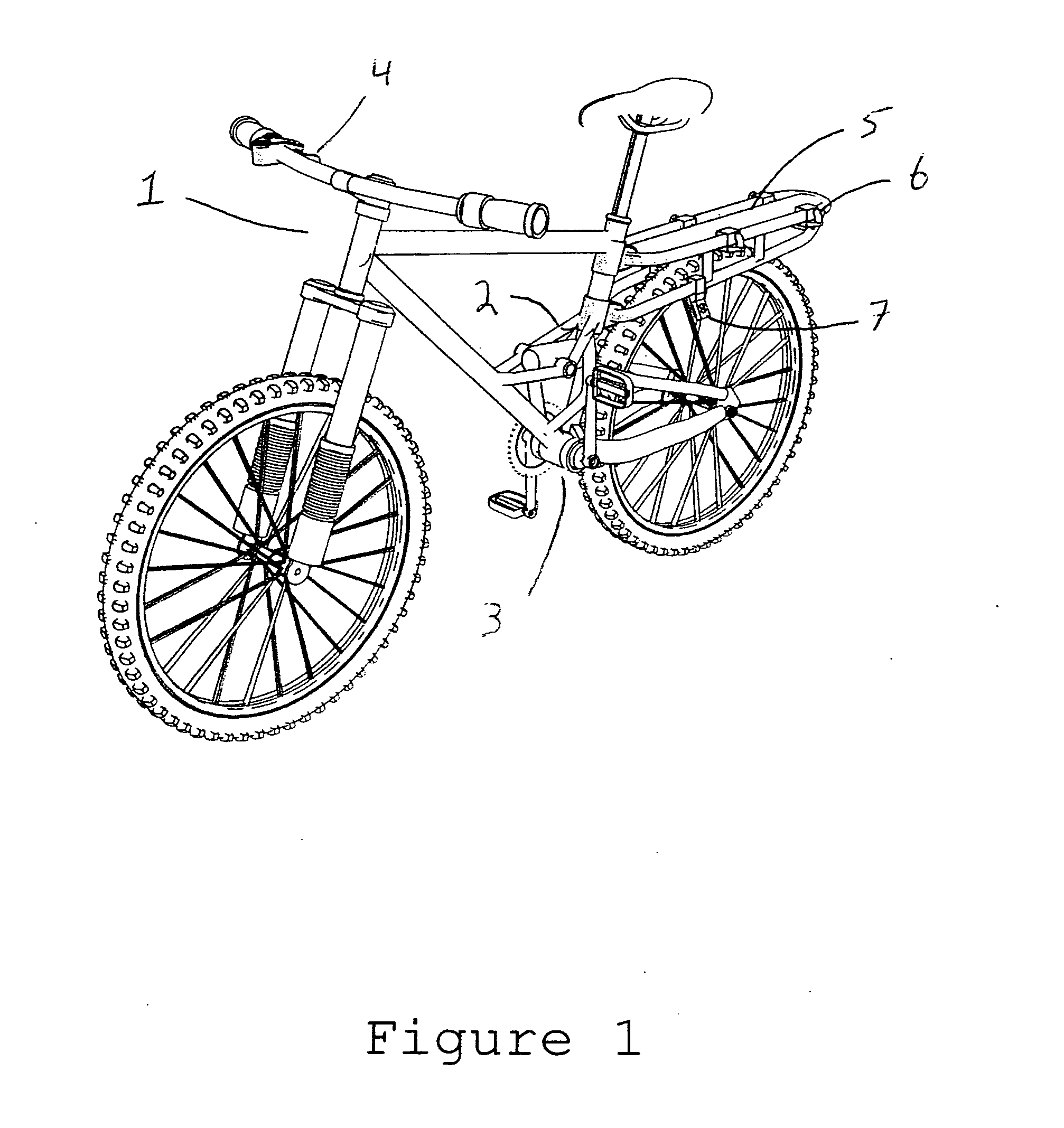

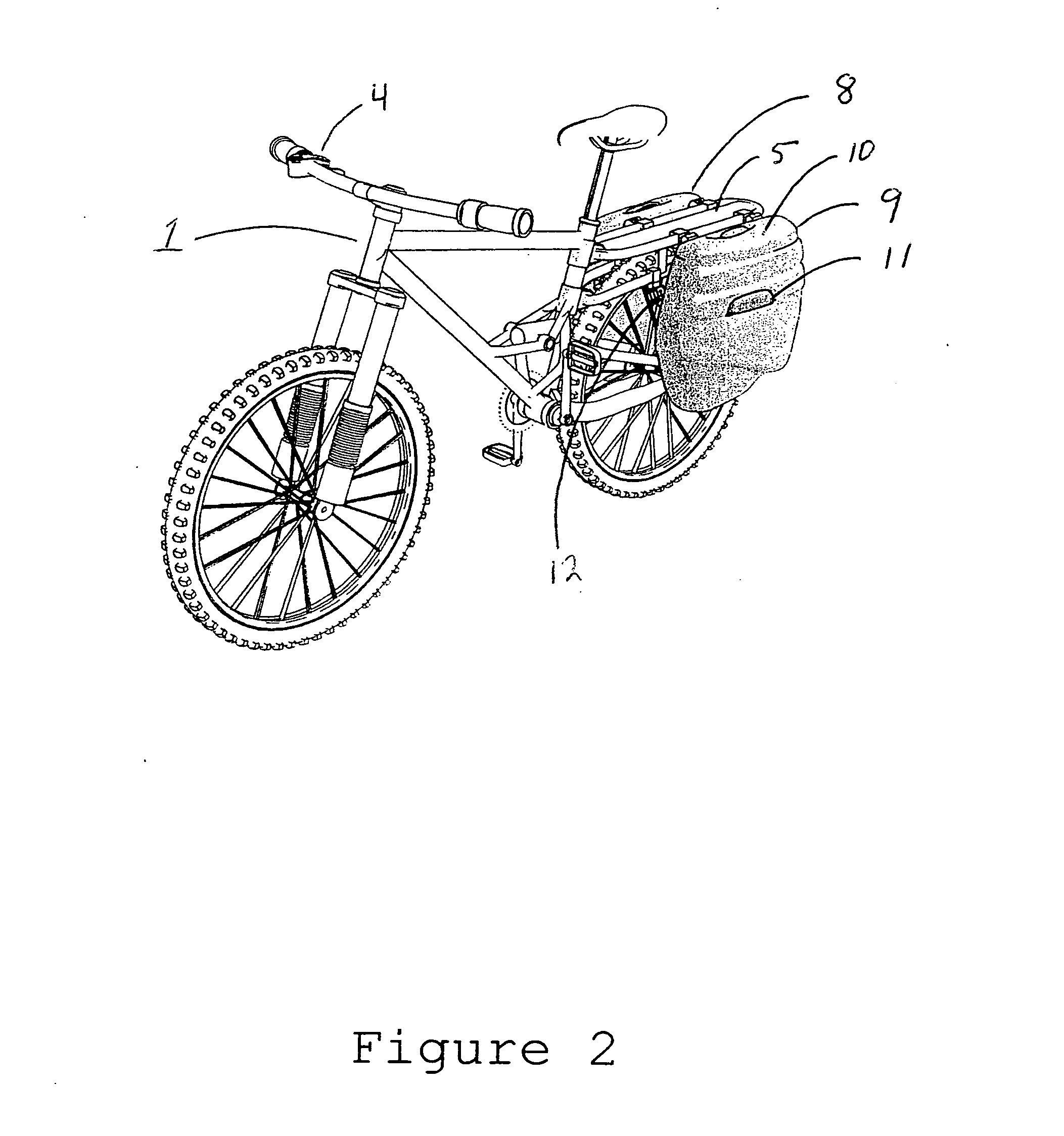

Bicycle with optional power assist

InactiveUS20050016785A1Minimize engineering compromiseThe process is simple and fastPropulsion by humans/animalsMotorcyclesPower couplingDrive shaft

A bicycle is fitted with rear panniers that provide electric motor assist and a power supply for the bicycle when desired. In a preferred embodiment the bicycle has a power coupling permanently attached at the rear wheel, for receiving an output drive shaft or power coupling from the motor pannier when that pannier is installed. The drive coupling may have gear reduction. To accommodate relative up and down motion between the pannier-supporting rack and the rear tire in a rear suspension bicycle, the motor drive unit in the motor pannier articulates, or the final drive unit on the bicycle can articulate, but this is more difficult because the rear suspension motion can be complex. Both panniers are secured by a quick connect device, for both mechanical attachment and electrical connection. The bicycle functions as a normal unpowered bike when the panniers are removed.

Owner:YOUNG GRANT E

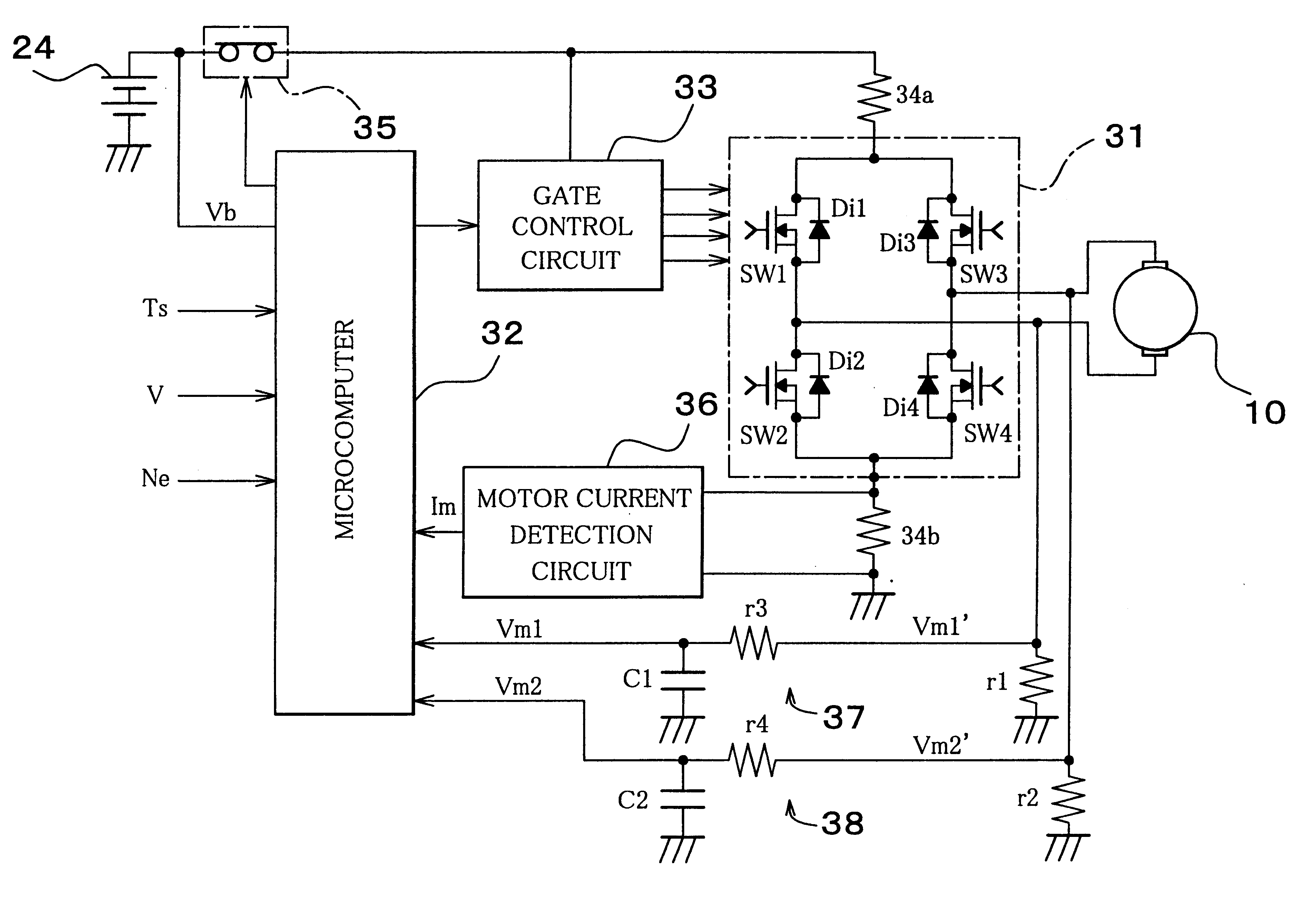

Motor drive unit and method of detecting malfunction of motor drive unit

A DC motor is connected to diagonal positions of a bridge circuit having of four sides including switching elements and reflux diodes. At least one of two terminals is connected to a power line, and at least the other terminal is grounded. By performing pulse width modulation control of the switching elements, operation of the DC motor is controlled. When the DC motor is in operation, the sum of the terminal voltages of the DC motor is equal to the power voltage. When the DC motor is out of operation, the sum of the voltages is set to a predetermined voltage. If the sum of the voltages has deviated from the power voltage or the predetermined voltage by at least a predetermined value, the occurrence of a malfunction is judged.

Owner:TOYOTA JIDOSHA KK

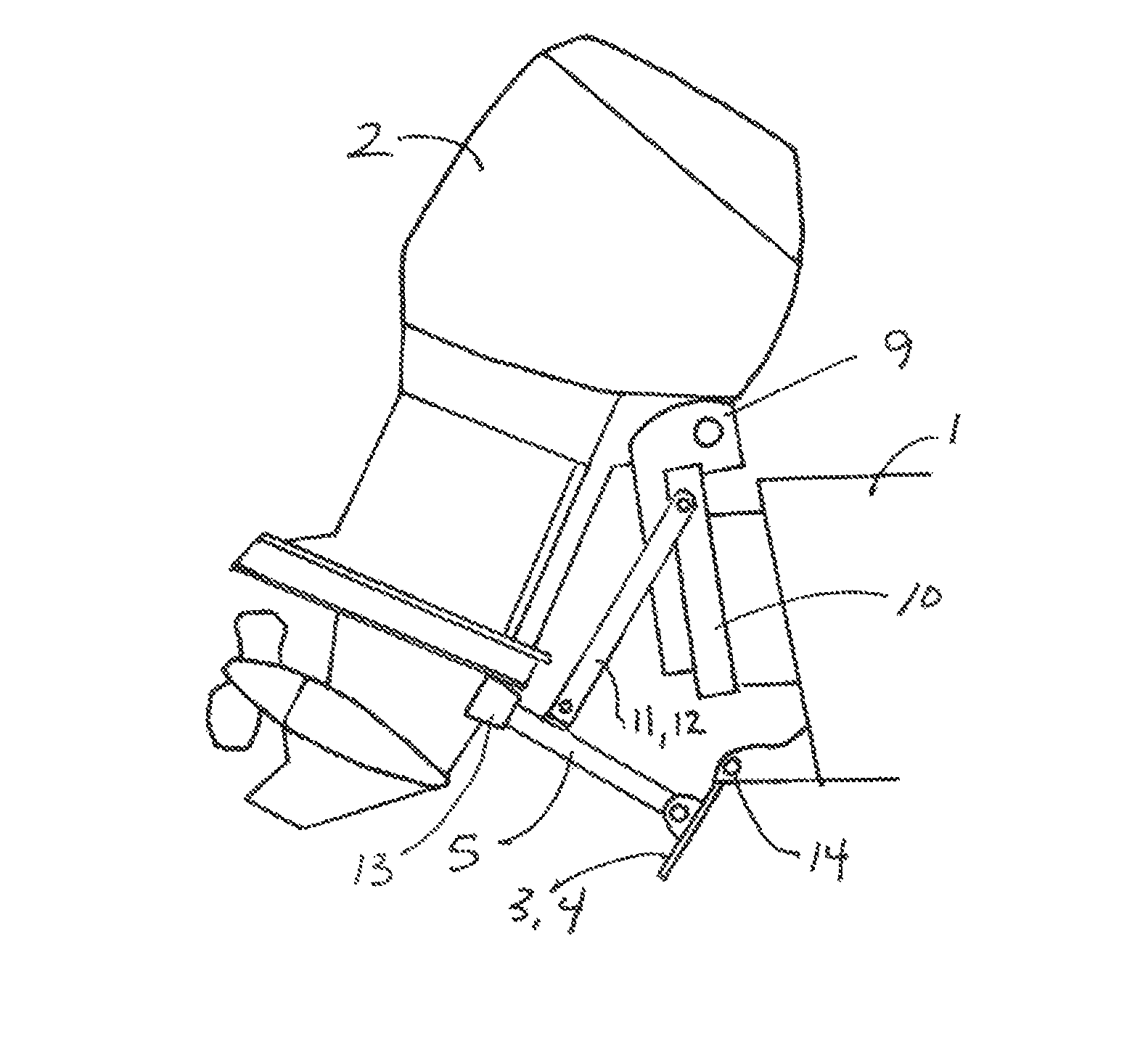

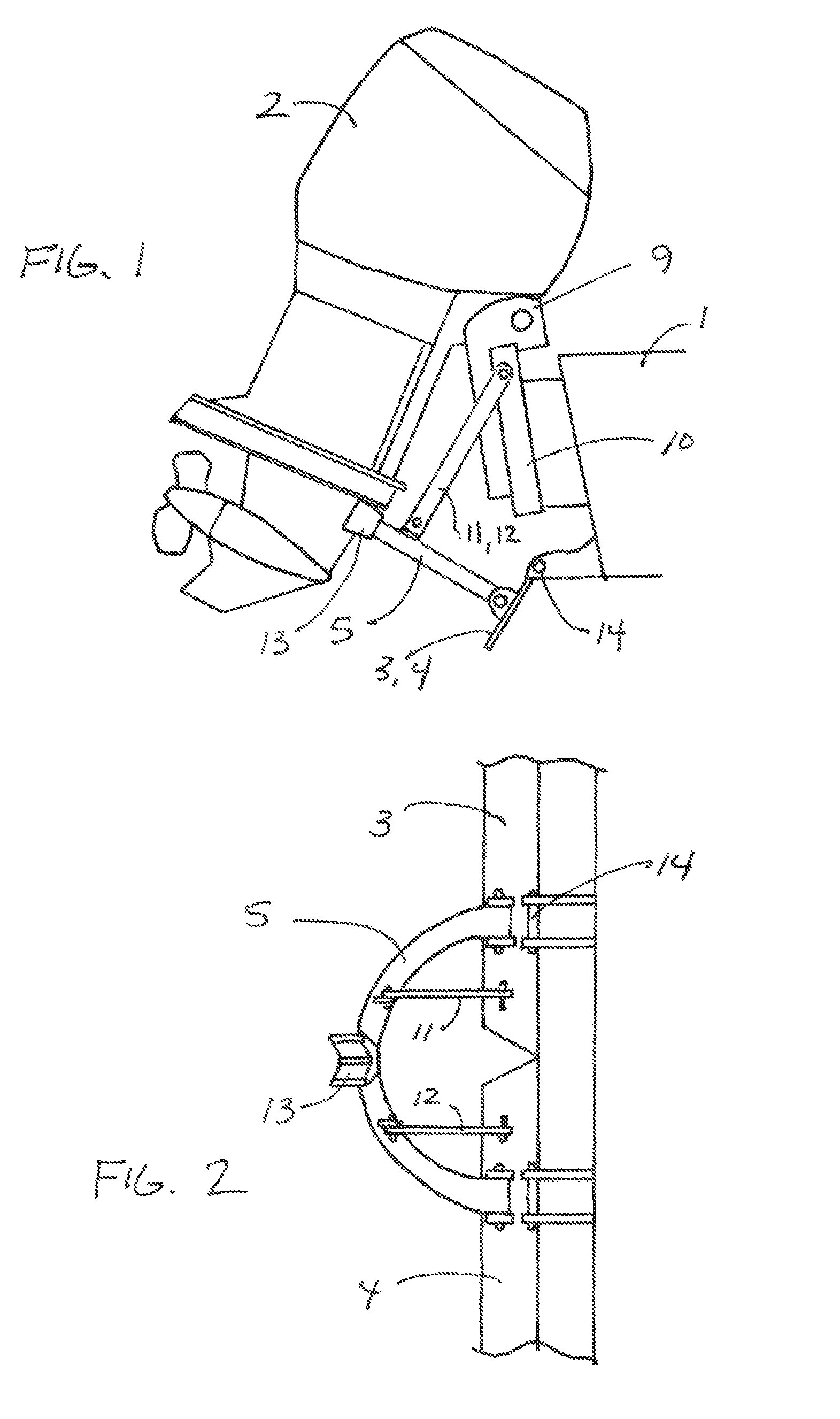

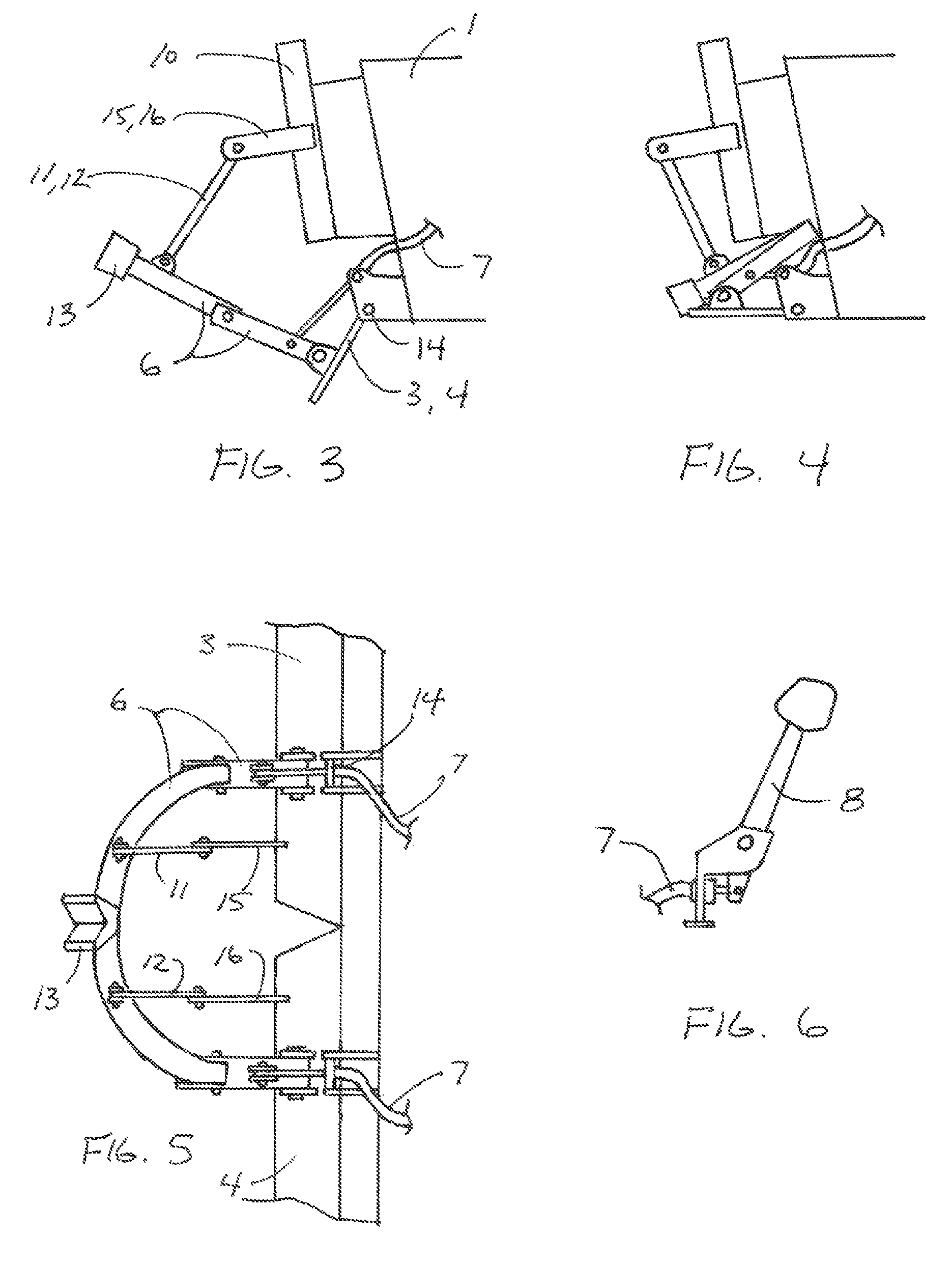

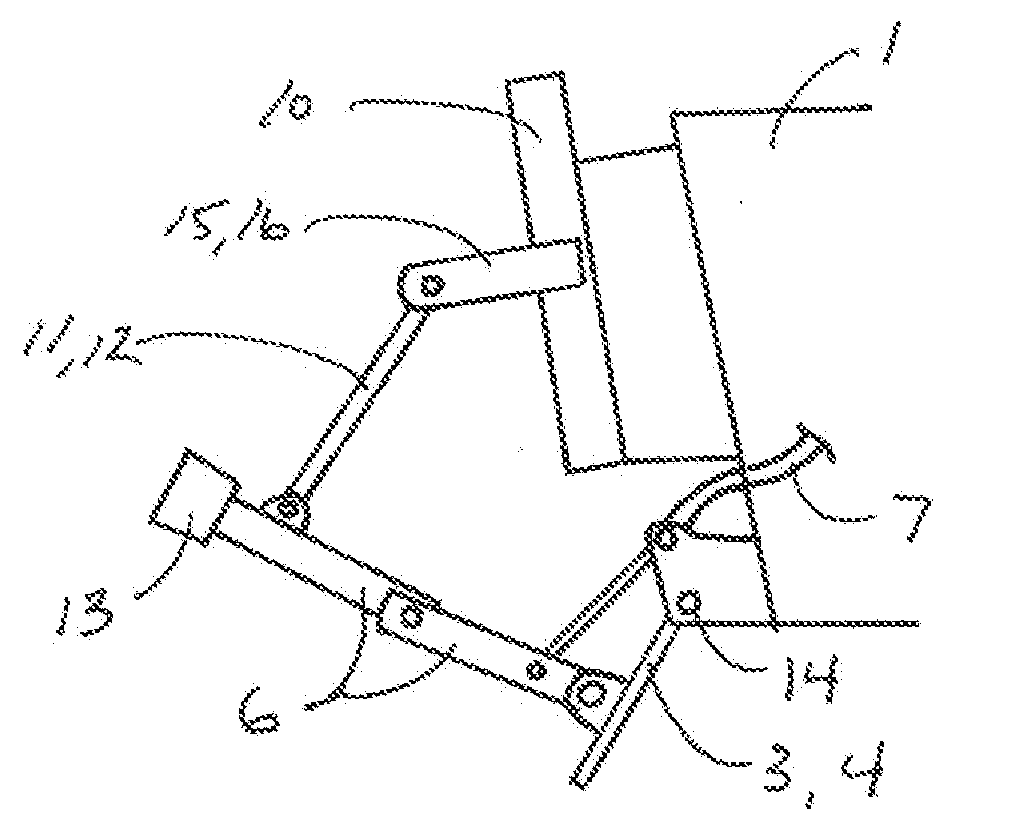

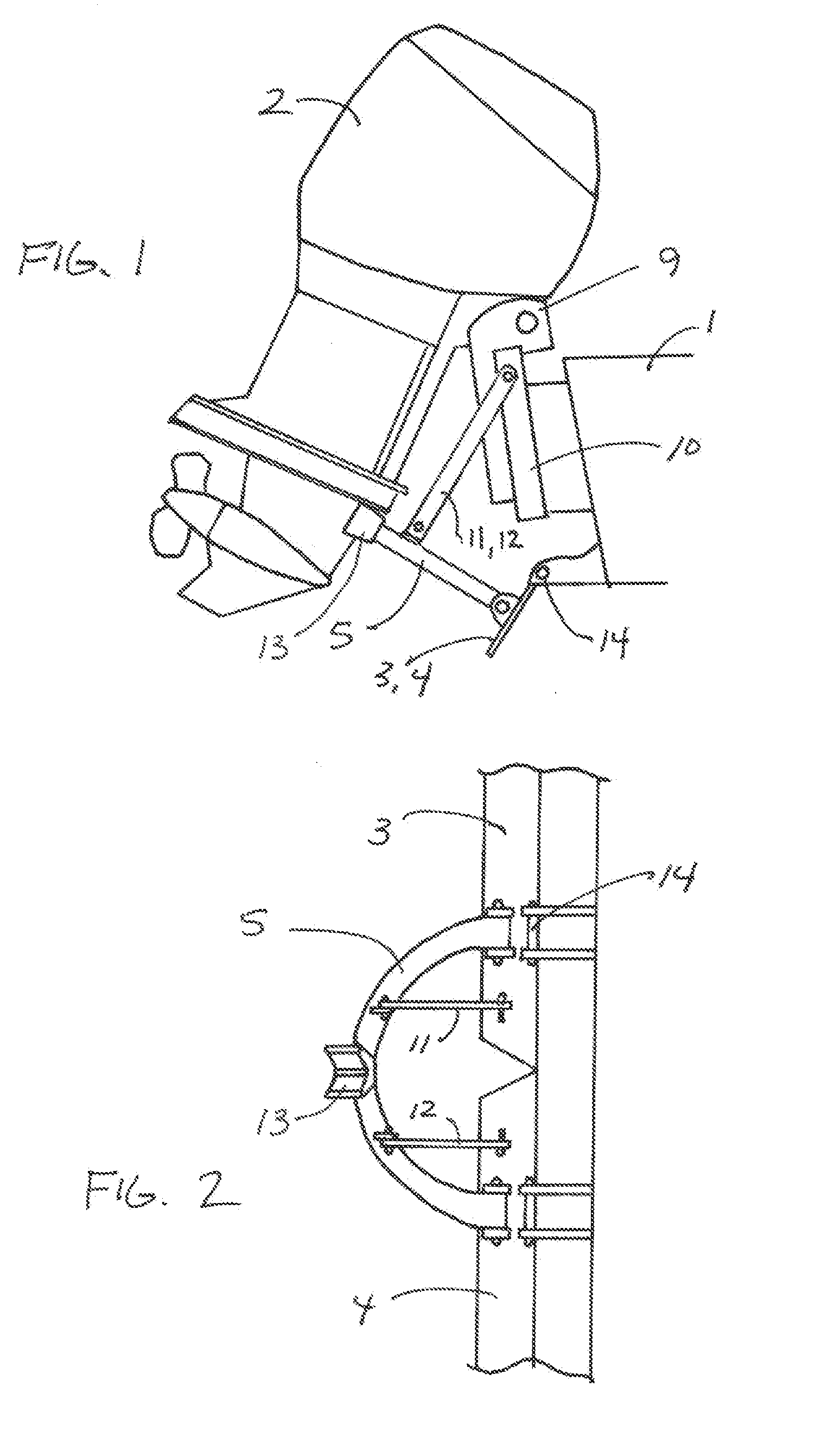

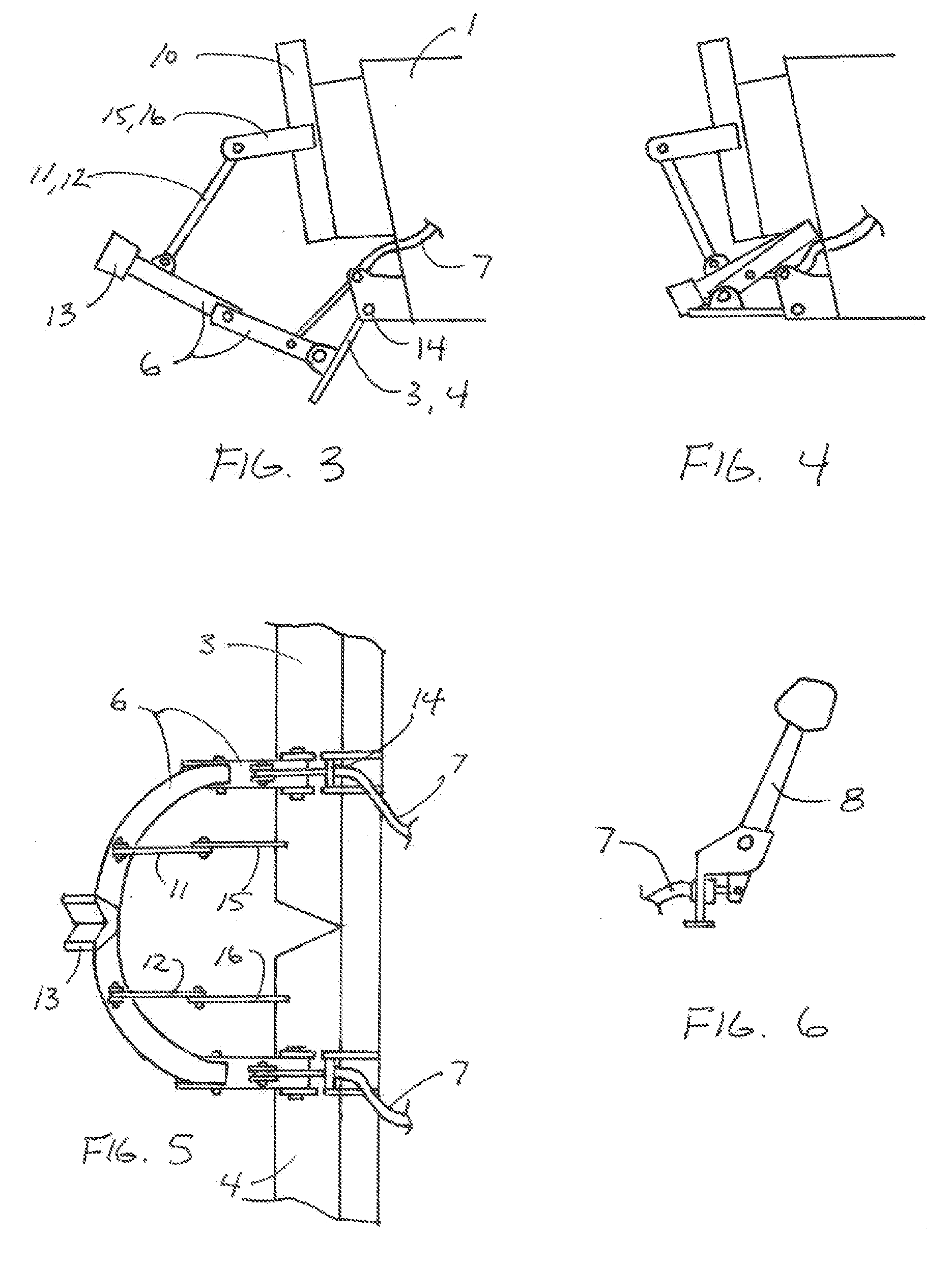

Boat drive-supported wake generating device

InactiveUS8191493B2Block risePropulsion power plantsOutboard propulsion unitsElectronic control systemControl system

An apparatus which selectively increases the size of the wake of a boat with an outboard or sterndrive motor system. The apparatus has one or more plates attached to the boat hull which, when rotated below the bottom of the hull, extend into the flow of water when underway, increasing the size of the wake due to the dynamic displacement of water. A support bar mechanism transmits propulsive force from the motor drive unit to the plates to overcome resistive hydraulic loads. Linkages may be used to locate the support bar mechanism. In one embodiment, the support bar mechanism is comprised of a plurality of members and pivots such that the support bar mechanism can be stowed substantially out of the flow of water until larger wakes are desired. In other embodiments, mechanical cable, fluidic, or electrical control systems are used to control the configuration of the support bar mechanism.

Owner:BAYWOL ROGER J

Boat drive-supported wake generating device

InactiveUS20100251952A1Large wakeBlock risePropulsion power plantsOutboard propulsion unitsControl systemElectronic control system

An apparatus which selectively increases the size of the wake of a boat with an outboard or sterndrive motor system. The apparatus has one or more plates attached to the boat hull which, when rotated below the bottom of the hull, extend into the flow of water when underway, increasing the size of the wake due to the dynamic displacement of water. A support bar mechanism transmits propulsive force from the motor drive unit to the plates to overcome resistive hydraulic loads. Linkages may be used to locate the support bar mechanism. In one embodiment, the support bar mechanism is comprised of a plurality of members and pivots such that the support bar mechanism can be stowed substantially out of the flow of water until larger wakes are desired. In other embodiments, mechanical cable, fluidic, or electrical control systems are used to control the configuration of the support bar mechanism.

Owner:BAYWOL ROGER J

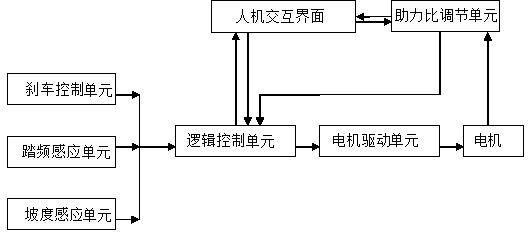

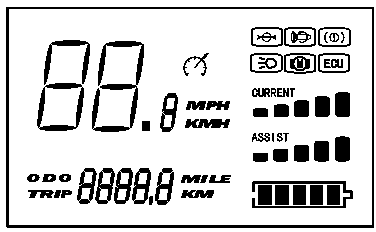

Electric power bicycle driving system capable of recognizing state of road

InactiveCN103434604ALow costGood riding comfortRider propulsionElectric machineInteraction interface

The invention relates to an electric power bicycle driving system capable of recognizing the state of a road. The electric power bicycle driving system comprises a brake control unit, a cadence sensing unit, a gradient sensing unit, a human-computer interaction interface, a logic control unit, a motor driving unit, a motor and a power rate regulating unit. The brake control unit, the cadence sensing unit and the gradient sensing unit are connected to the logic control unit respectively, the logic control unit is connected to the motor driving unit, the power rate regulating unit and the human-computer interaction interface respectively, the motor is simultaneously connected with the motor driving unit and the power rate regulating unit, and the power rate regulating unit is connected with the human-computer interaction interface at the same time. The logic control unit and the human-computer interaction interface mutually conduct feedback regulation, and the human-computer interaction interface and the power rate regulating unit mutually conduct feedback regulation. According to the electric power bicycle driving system, the power rate of the motor can be regulated by manually regulating a control button of the human-computer interaction interface, the gradient of the road can be also monitored at any time through the gradient sensing unit, the power rate of the motor can be increased or decreased according to uphill or downhill, and therefore a cyclist is always in a comfortable state.

Owner:孙敏

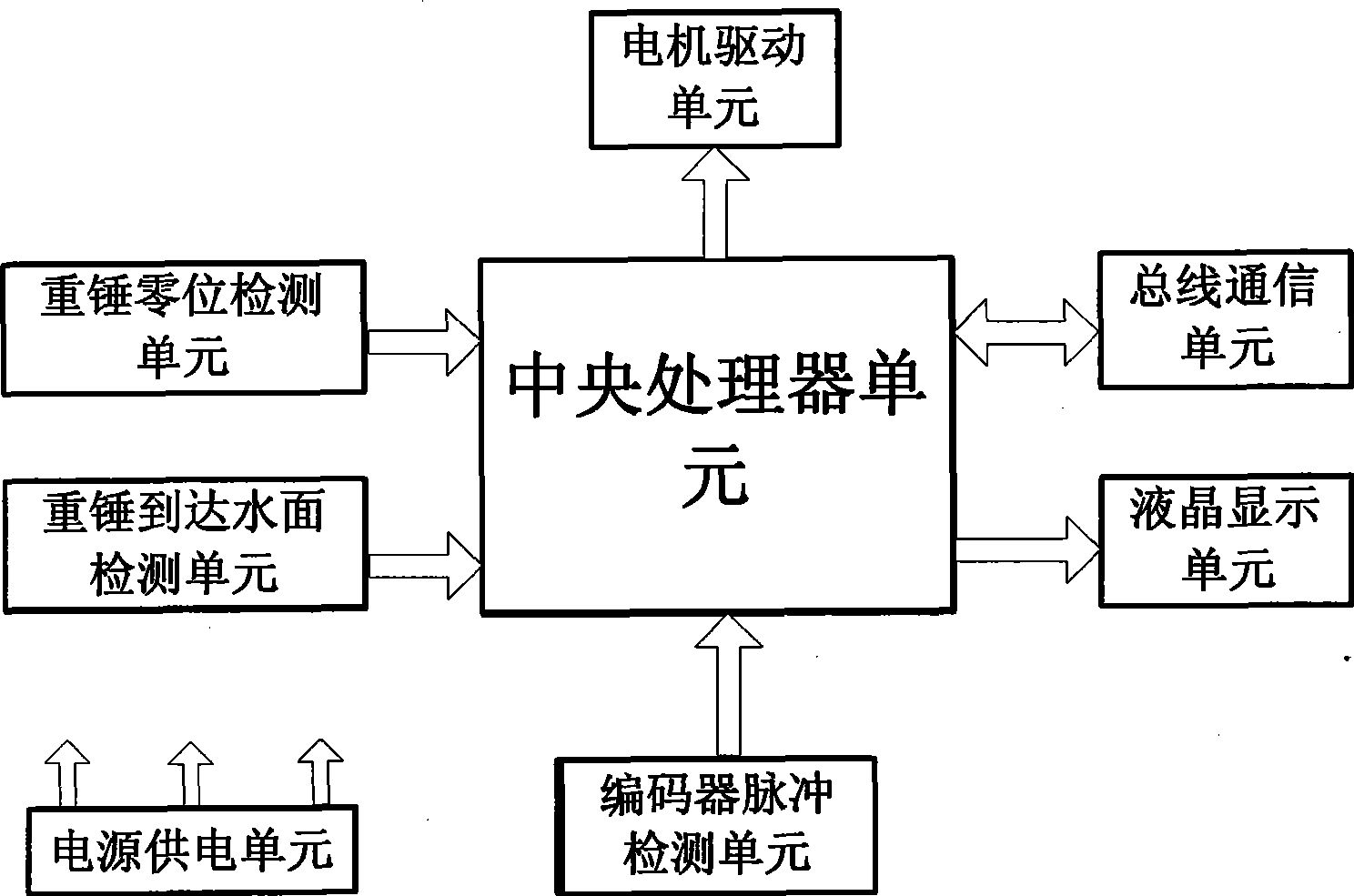

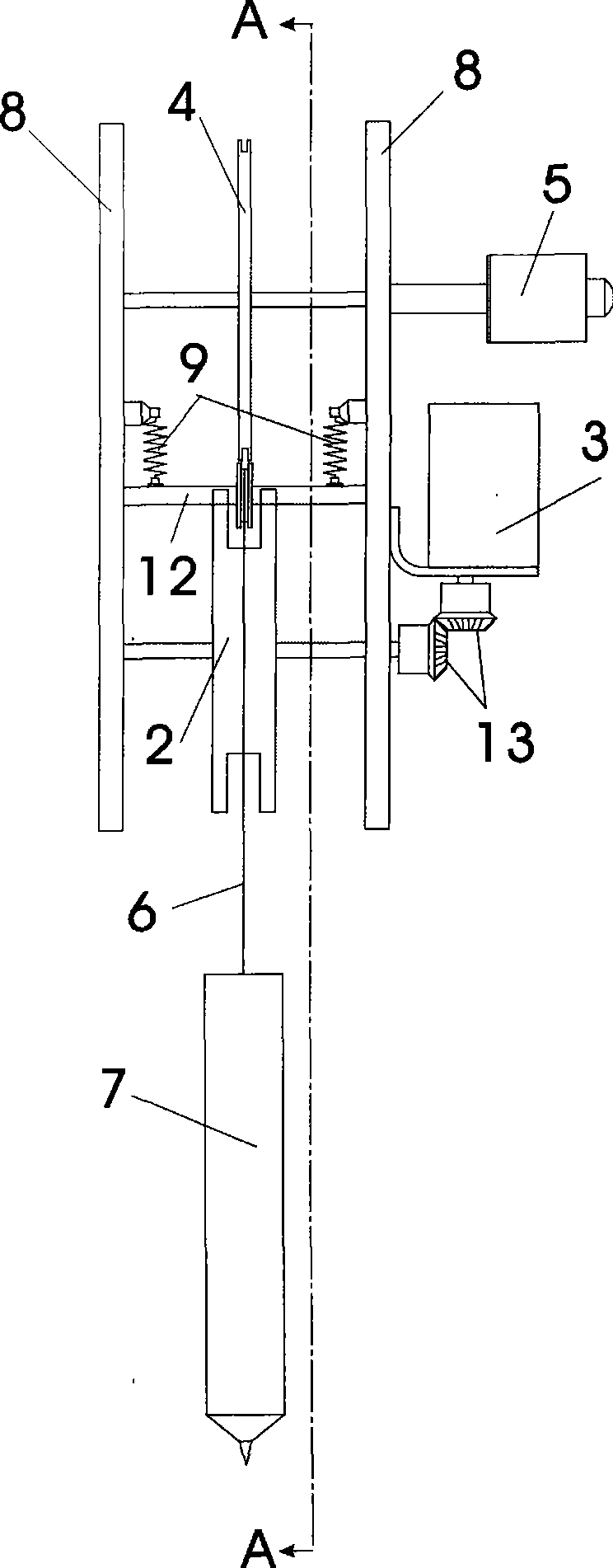

Liquid level detection type self-calibration high-precision water gauge

ActiveCN101464177AAvoid enteringAvoid Cumulative ErrorsMachines/enginesLevel indicatorsDrive wheelEngineering

A liquid level detection-type self-calibration high-precision water level gauge comprises a controller, a steel wire take-up pulley, a motor, a measurement driving wheel, a rotary encoder, a steel wire rope and a heavy hammer. A rotating shaft of the motor is connected with a rotating shaft of the steel wire take-up pulley; the steel wire take-up pulley is wound with one end of the steel wire rope, and the other end is connected with the heavy hammer through the measurement driving wheel; the rotary encoder is connected with a measurement driving wheel shaft; the controller includes a central processing unit which outputs a motor control signal to a motor driving unit to drive the motor to rotate; a zero position detection signal of a heavy hammer zero position detection unit, a water surface detection signal of the heavy hammer arriving at a water surface detection unit, and an encoding impulse signal of an encoder impulse detection unit are input to the central processing unit; and the data is processed by the central processing unit which also transfers the data to an external data processing unit. By adopting the active liquid level detection method and the zero position self-calibration method, the invention can prevent the heavy hammer from dropping into the water, and eliminate the accumulated error produced by the skidding of the steel wire rope and the impulse loss of the encoder, thereby ensuring high-precision and wide-range measurement of the water level.

Owner:GUANGZHOU SUNTRANS MEASUREMENT & CONTROL SYST

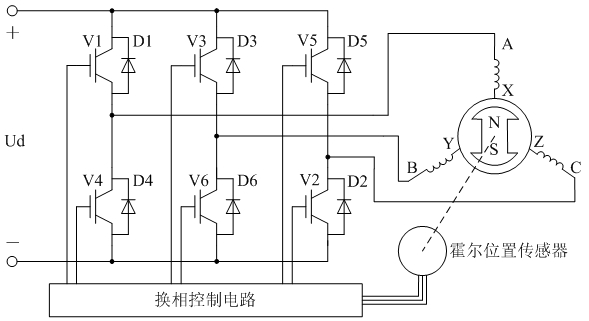

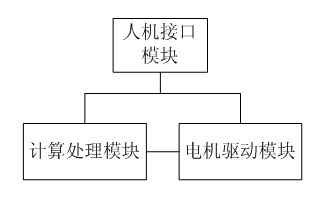

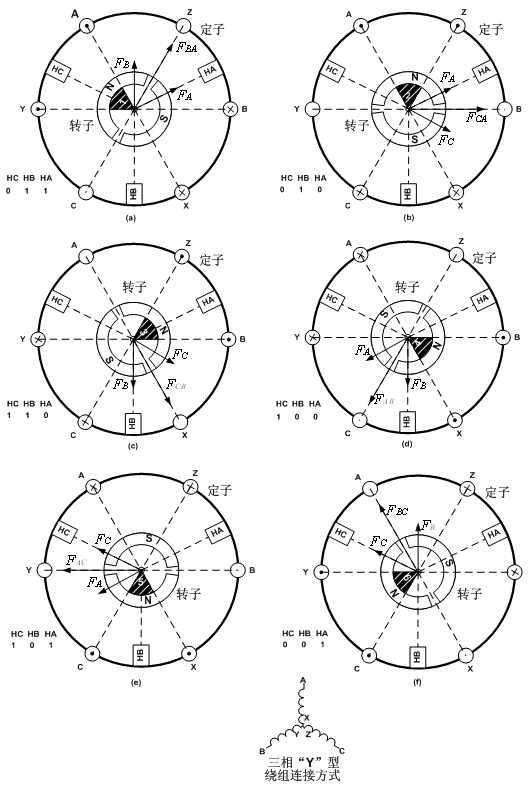

Hall phase sequence detecting method and device of brushless direct-current motor

InactiveCN102025305APhase sequence detection steps are simpleHigh degree of automationElectronic commutatorsMotor Drive UnitPhysics

The invention discloses a Hall phase sequence detecting method of a brushless direct-current motor, relating to the technical field of the brushless direct-current motor. Based on the operating principle of the brushless direct-current motor and the magnetic potential synthesis principle, the method adopts the magnetic potential of a fixed stator to position a rotor, and obtains the position of the rotor by reading a signal of a Hall position sensor, thus determining the relation of the magnetic potential of a stator and the position of the rotor. The invention also discloses a phase sequence detecting device of the brushless direct-current motor, comprising a computational processing module, a motor-driven module and a man-machine interface module, wherein the man-machine interface module comprises an input unit and an output display unit; a motor-driven unit is in a three-phase inverse bridge-type structure; and the calculated processing module is respectively connected with the motor-driven module, the input unit and the output display unit by signals. Compared with the prior art, the detecting device has the advantages that the structure is simple, the use is convenient, the cost is low and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

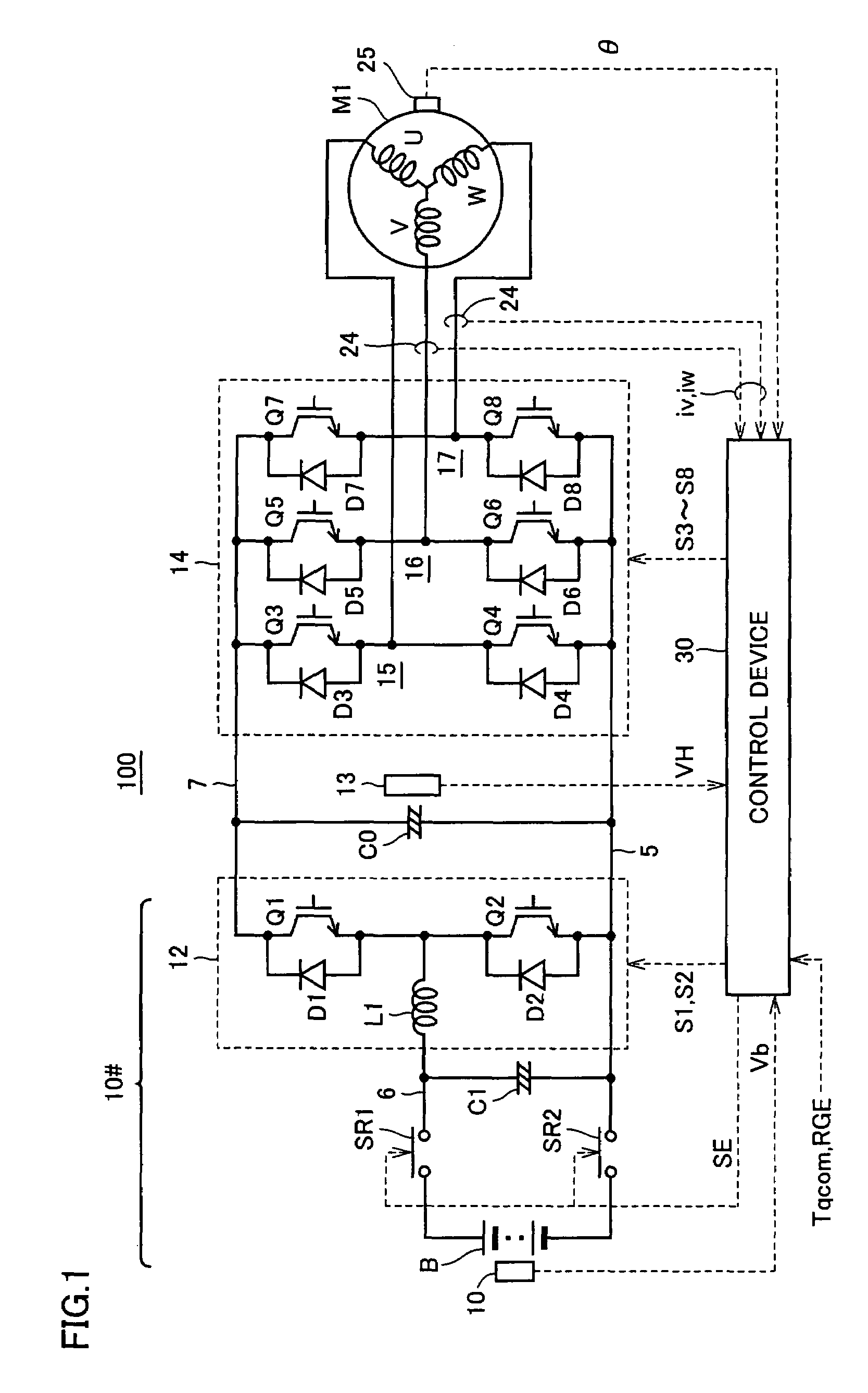

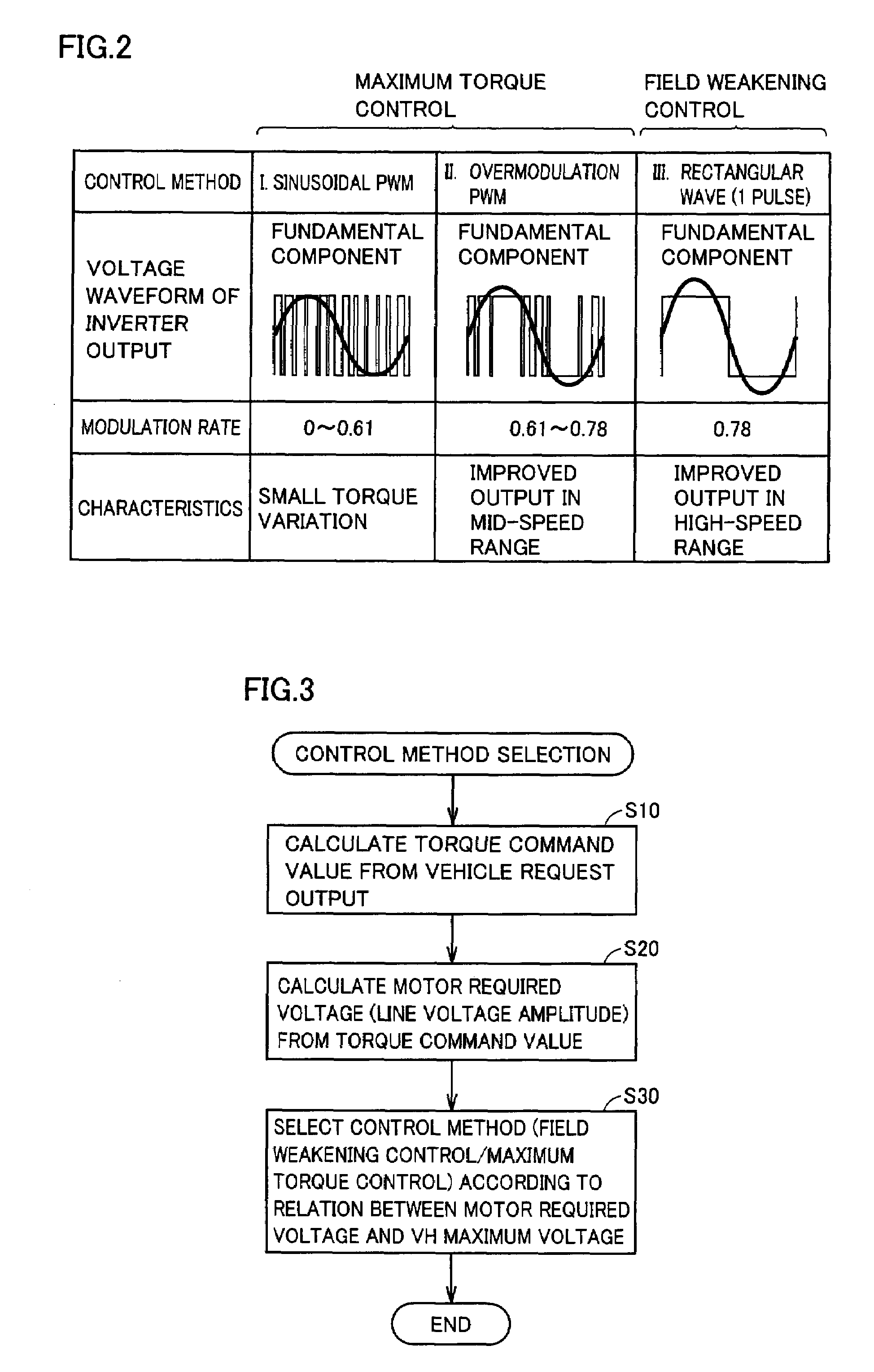

Control device for motor drive system and electric vehicle including the same

ActiveUS7723945B2Preventing excessive motor currentReduce manufacturing costDC motor speed/torque controlVector control systemsMotor driveMotor Drive Unit

A square wave voltage having an amplitude equal to an output voltage of a converter is applied to an AC motor by a square wave control block. Torque control of the AC motor is performed basically by changing the voltage phase of the square wave voltage according to the torque deviation. When the motor revolution is suddenly changed, a instruction value correction unit sets a voltage instruction value of the output voltage of the converter according to a change ratio of the motor revolutions. This improves control of the motor current by changing the voltage applied to the motor in accordance with the sudden change of the motor revolutions without waiting for torque feedback control having a low control response.

Owner:DENSO CORP

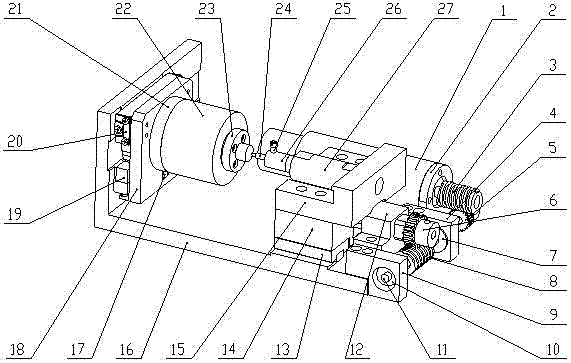

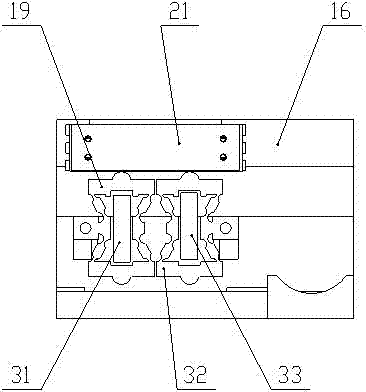

In-situ micro-nano indentation/scratch test platform and test method

ActiveCN104729911AOvercoming detectionOvercoming the lack of tangential forceInvestigating material hardnessMicro nanoScientific instrument

The invention relates to an in-situ micro-nano indentation / scratch test platform and a test method, and belongs to the field of electromechanical integrated precision scientific instruments. An X axis precision scratch unit and a Y axis large-stroke stick-slip drive scratch assembly are assembled at the tail of a base, a Z axis macro-movement adjusting mechanism is assembled at the middle of the base, a motor driving unit is assembled at the head of the base, a precision pressing driving and displacement signal detecting unit is installed on the Z axis macro-movement adjusting mechanism, and a precision three-axis force sensor used for detecting an indentation pressing force and a normal force and a tangential force of a scratch is installed on the X axis precision scratch unit. The in-situ micro-nano indentation / scratch test platform has the advantages of compact structure, miniaturization, integration, and capability of better ensuring the assembly precision, effectively improving the overall rigidity and dynamic properties and improving the overall test precision while overcoming the defect that an existing test platform cannot be used for quantitatively detecting the normal force and the tangential force in a scratch process.

Owner:JILIN UNIV

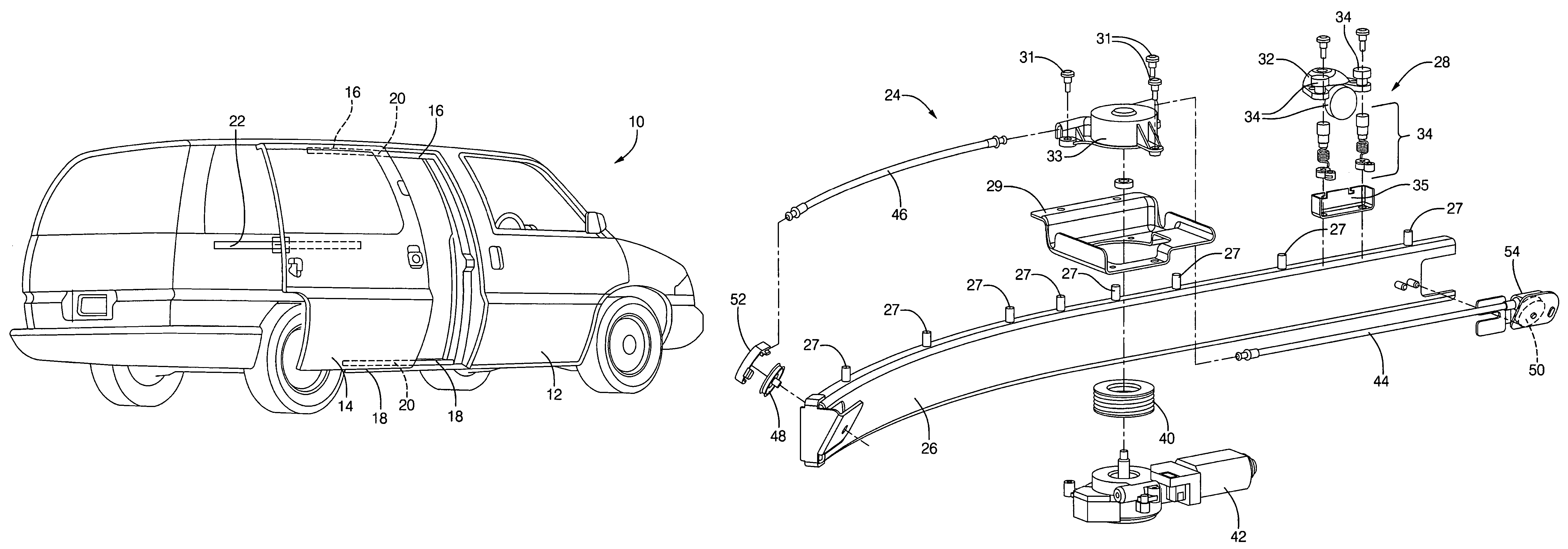

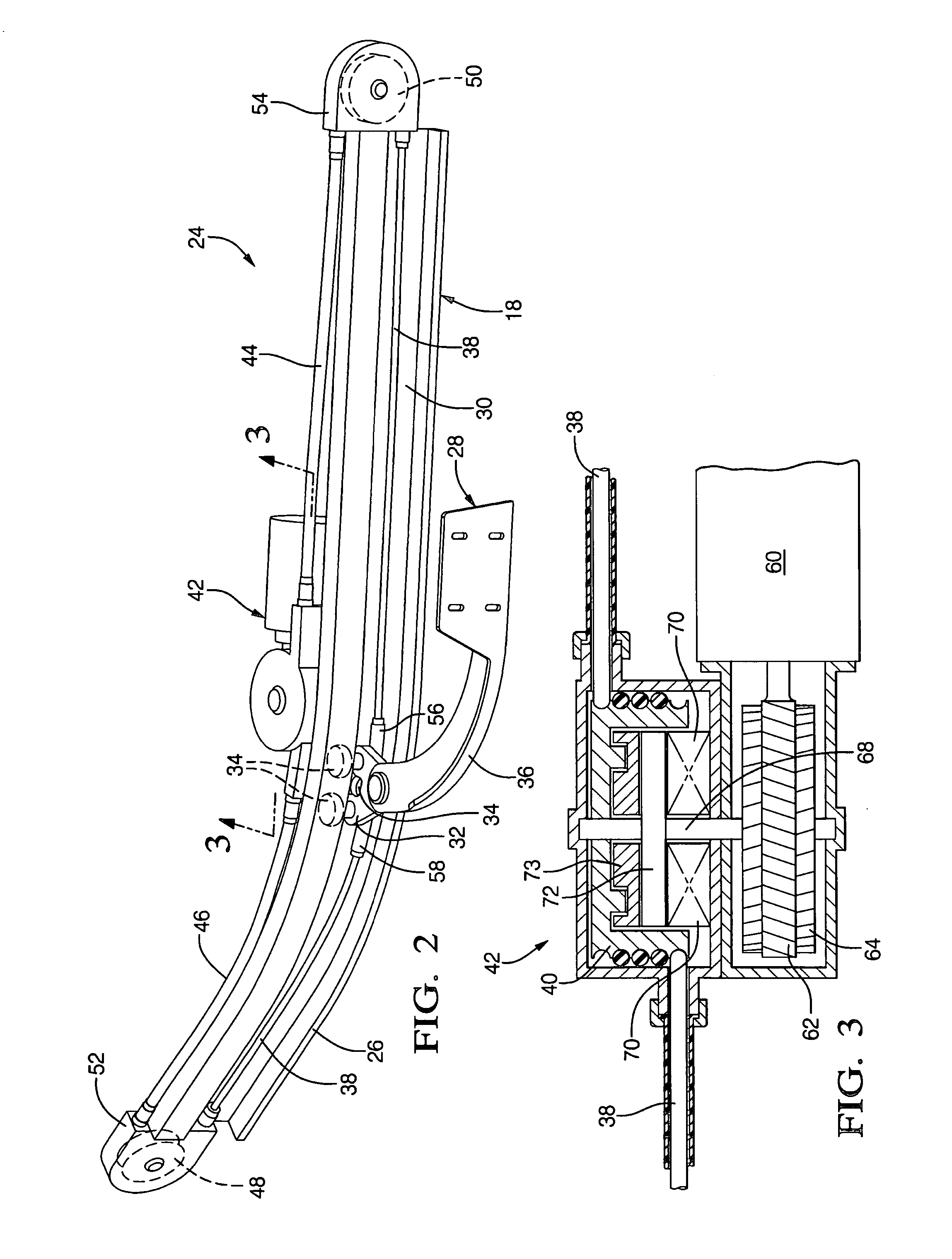

Apparatus and method for providing a modular sliding door mechanism

A modular drive assembly for a sliding door, comprising: a guide track having a hinge slidably received therein; a pair of pulleys disposed on either end of the guide track; a pair of cables each having an end that is secured to the hinge and the other end is secured to a cable drum of a motor drive unit mounted to the guide track, the motor drive unit being configured to rotate the cable drum, wherein the cable drum is also capable of freely rotating within the motor drive unit when the motor drive unit is not rotating the cable drum, wherein rotation of the cable drum causes the hinge to move in the guide track as one of the cables wraps onto the cable drum while the other one of the cables wraps off of the cable drum.

Owner:STRATTEC POWER ACCESS

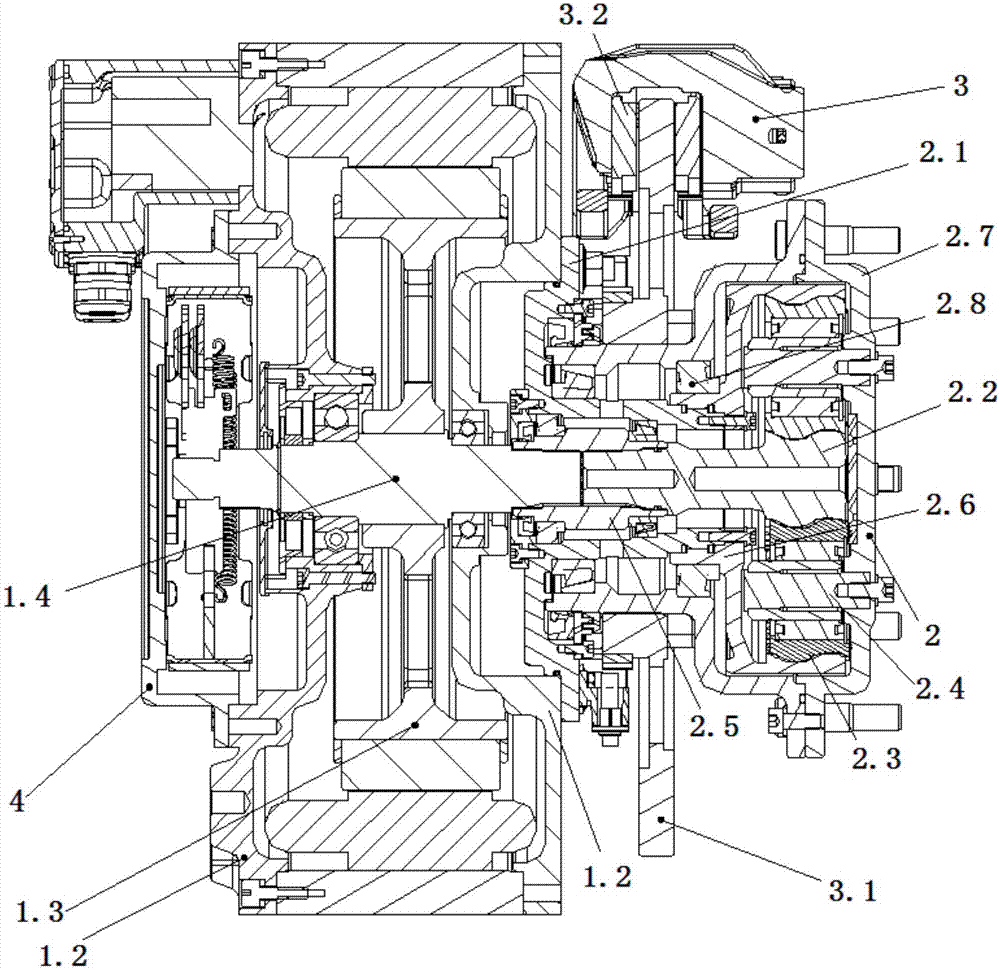

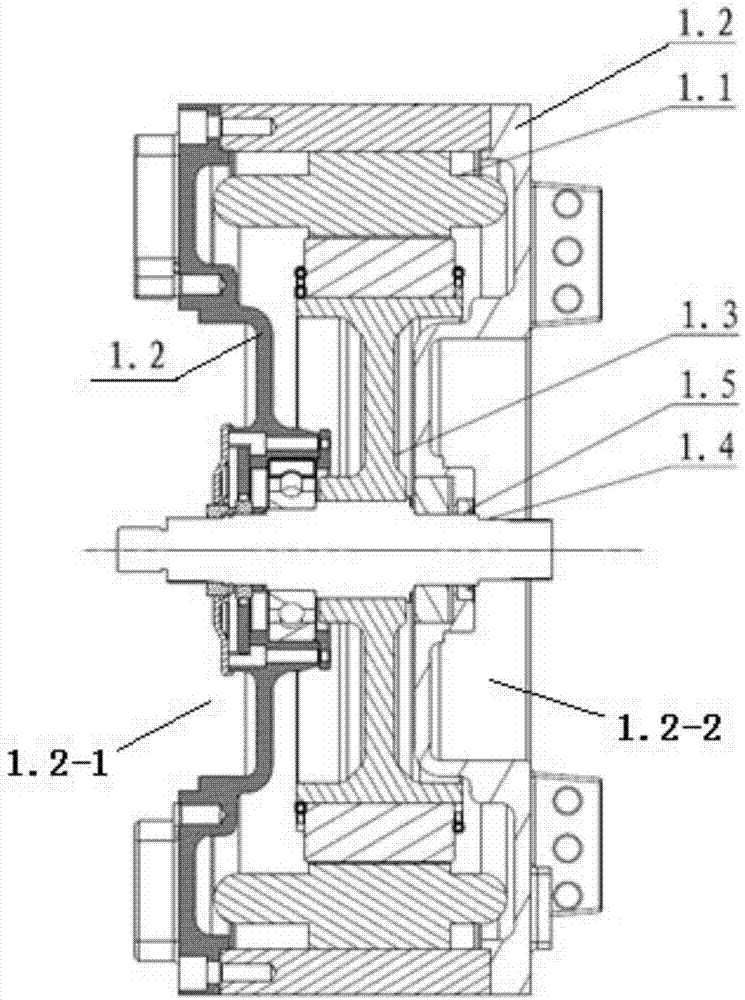

Integrated hub motor driving unit

ActiveCN107487175AReduce usage capacityRealize the parking brake functionBraking element arrangementsToothed gearingsElectric machineDrive motor

The invention discloses an integrated hub motor driving unit which comprises a driving motor arranged inside a rim. A motor shaft of the driving motor is supported on a motor shell through a motor bearing; one side of the motor shaft is connected with a parking brake, and the other side of the motor shaft is connected with a driving brake through a planetary deceleration mechanism; the planetary deceleration mechanism is a first-stage planetary wheel mechanism; and the input end of the planetary deceleration mechanism is connected with the motor shaft, and the output end of the planetary deceleration mechanism is connected with the rim and a brake disc of the driving brake. The integrated hub motor driving unit is simple in structure and convenient to use and replace, the functions of driving, braking and supporting are achieved at the same time, all the components are integrated in a wheel and compact in structure, the parking brake with the smaller capacity is used, and thus the excellent performance of the short braking distance and the high parking slope is achieved.

Owner:DONGFENG MOTOR CORP HUBEI

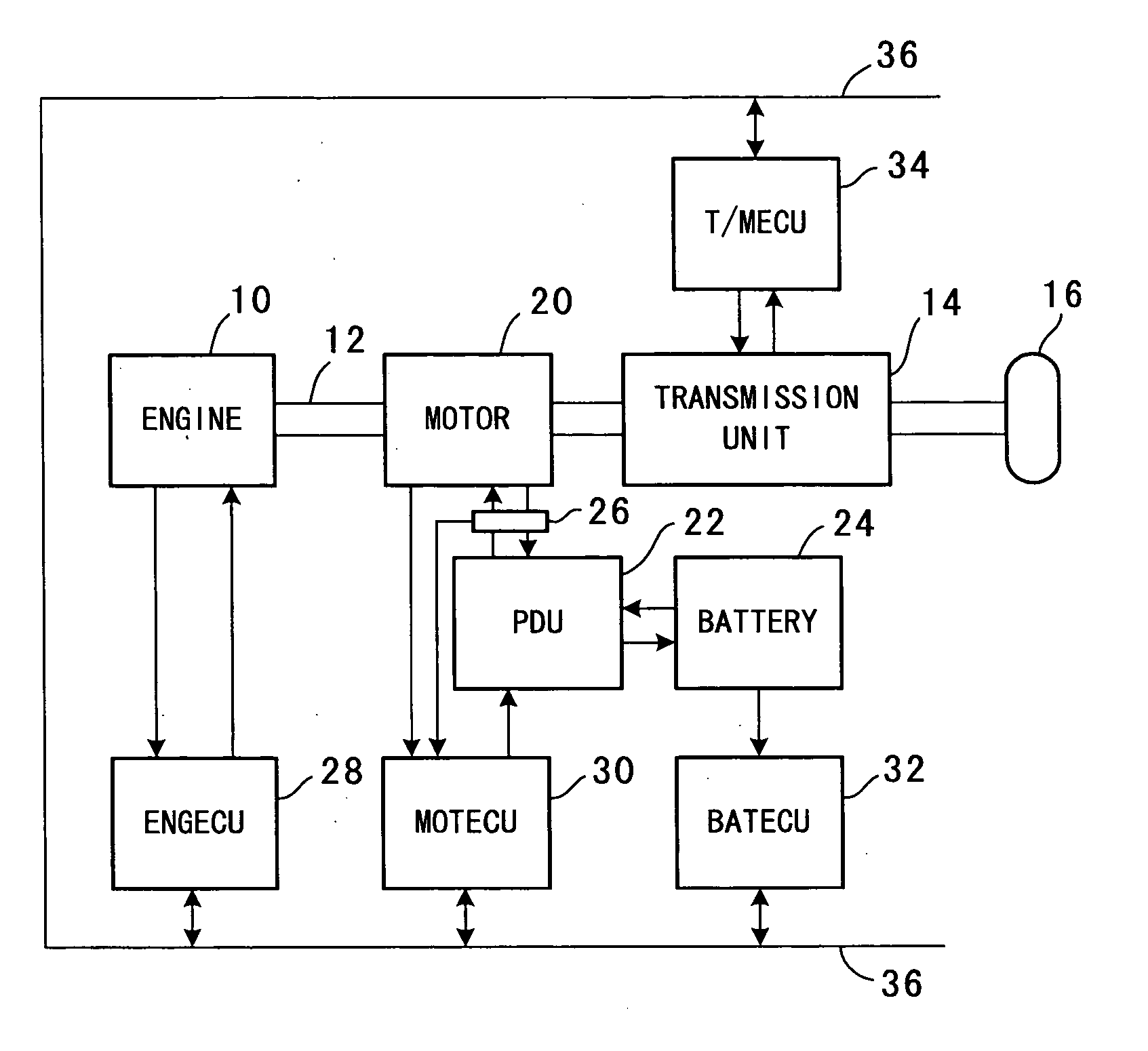

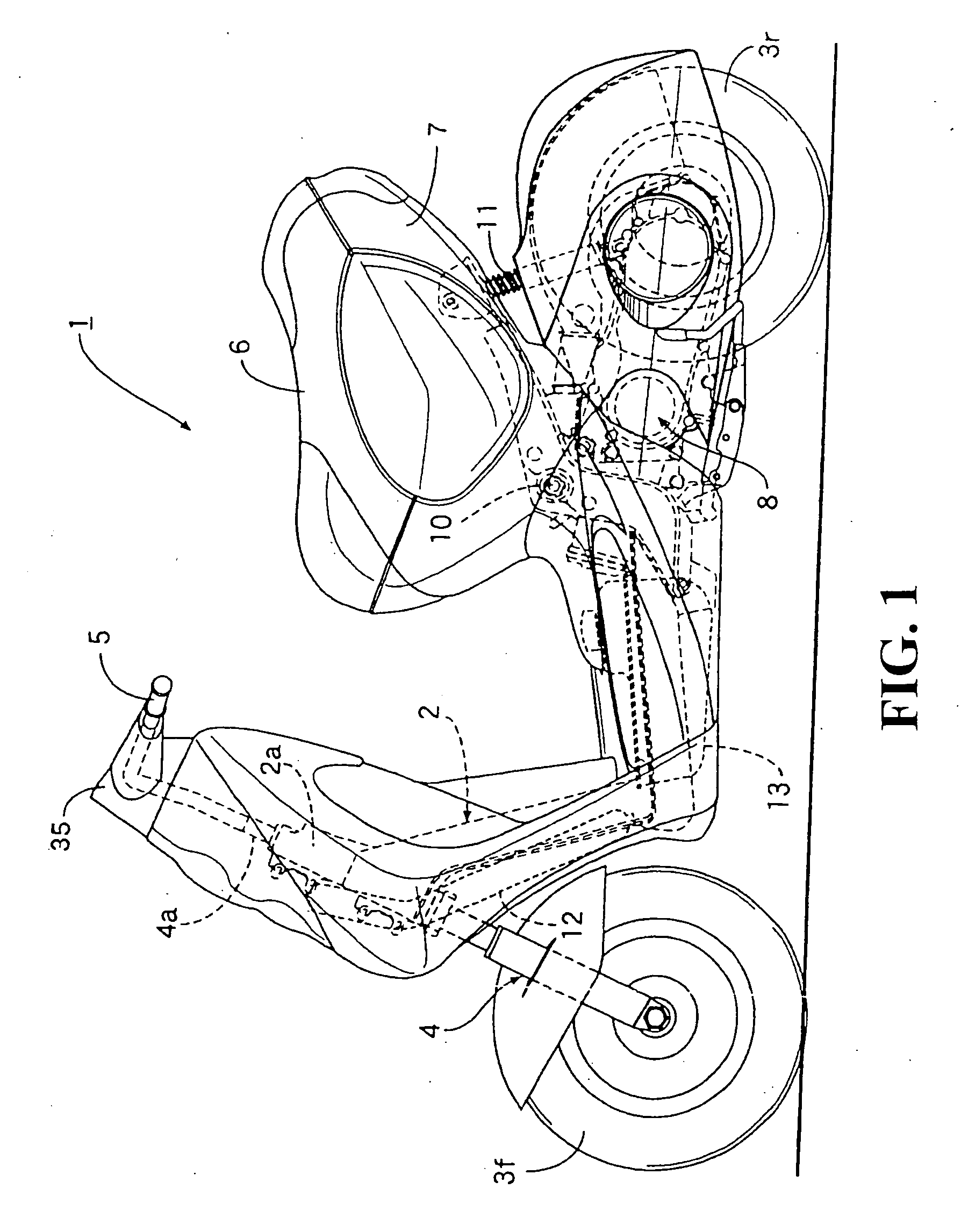

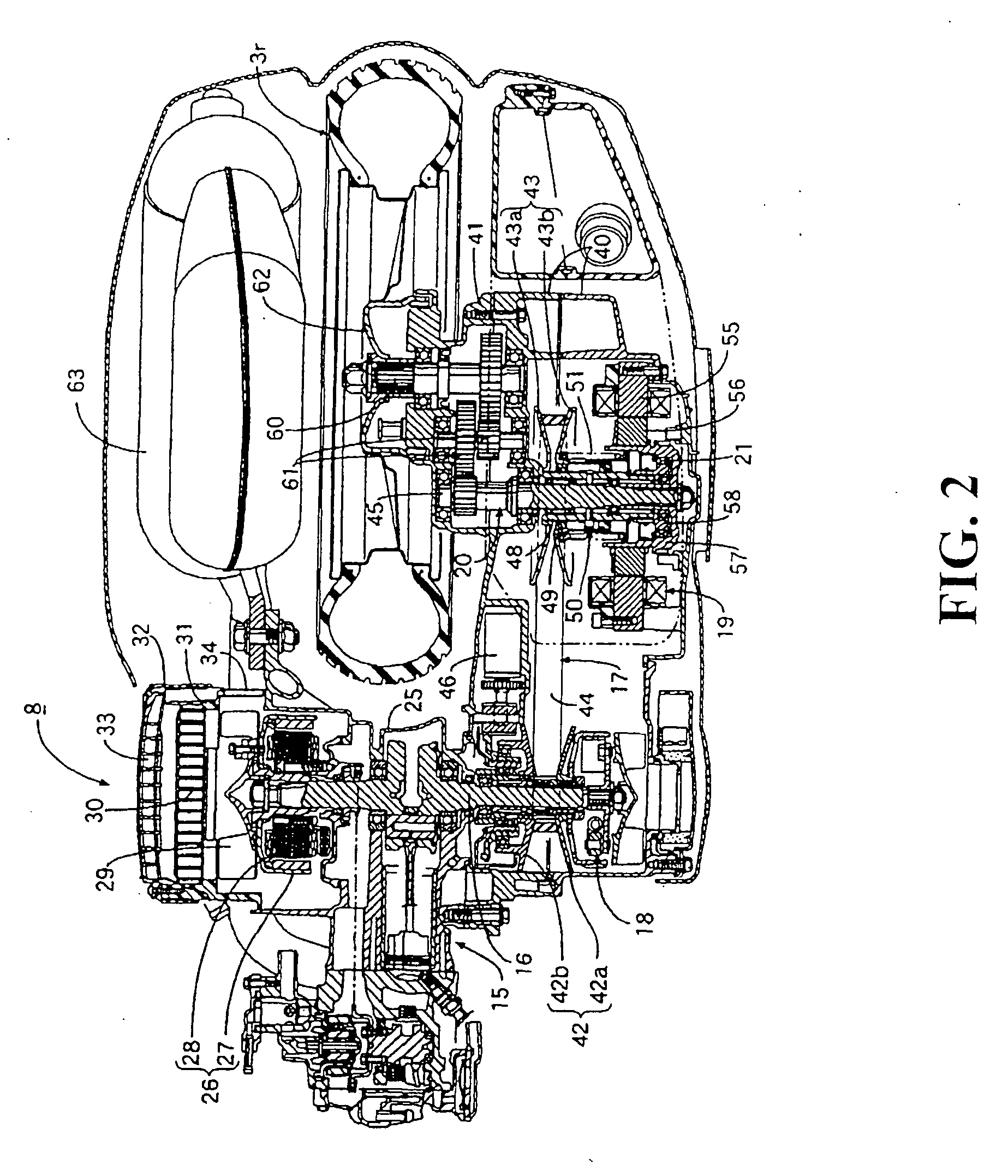

Control mechanism and display for hybrid vehicle

ActiveUS20060185917A1Excessive electrical dischargingSimple configurationHybrid vehiclesElectric propulsion mountingMotor driveDisplay device

A control mechanism for a hybrid vehicle having a motor driving means enabling its running through an output of an electric motor, and an engine driving means enabling its running through an output of an engine, includes a throttle sensor and a driving change-over control unit having a mode map for determining each of working regions M, E of the motor driving unit and the engine driving unit in response to a sensing signal θ of the throttle sensor. The mode map is provided with a critical region Ma adjacent to the working region E of the engine driving unit in the working region M of the motor driving unit and an informing unit (display device) to inform a driver of a fact that the motor driving unit is being operated in the critical region Ma. The display device also indicates a battery residual amount.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com