Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

691results about "Temperature measurement in motors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

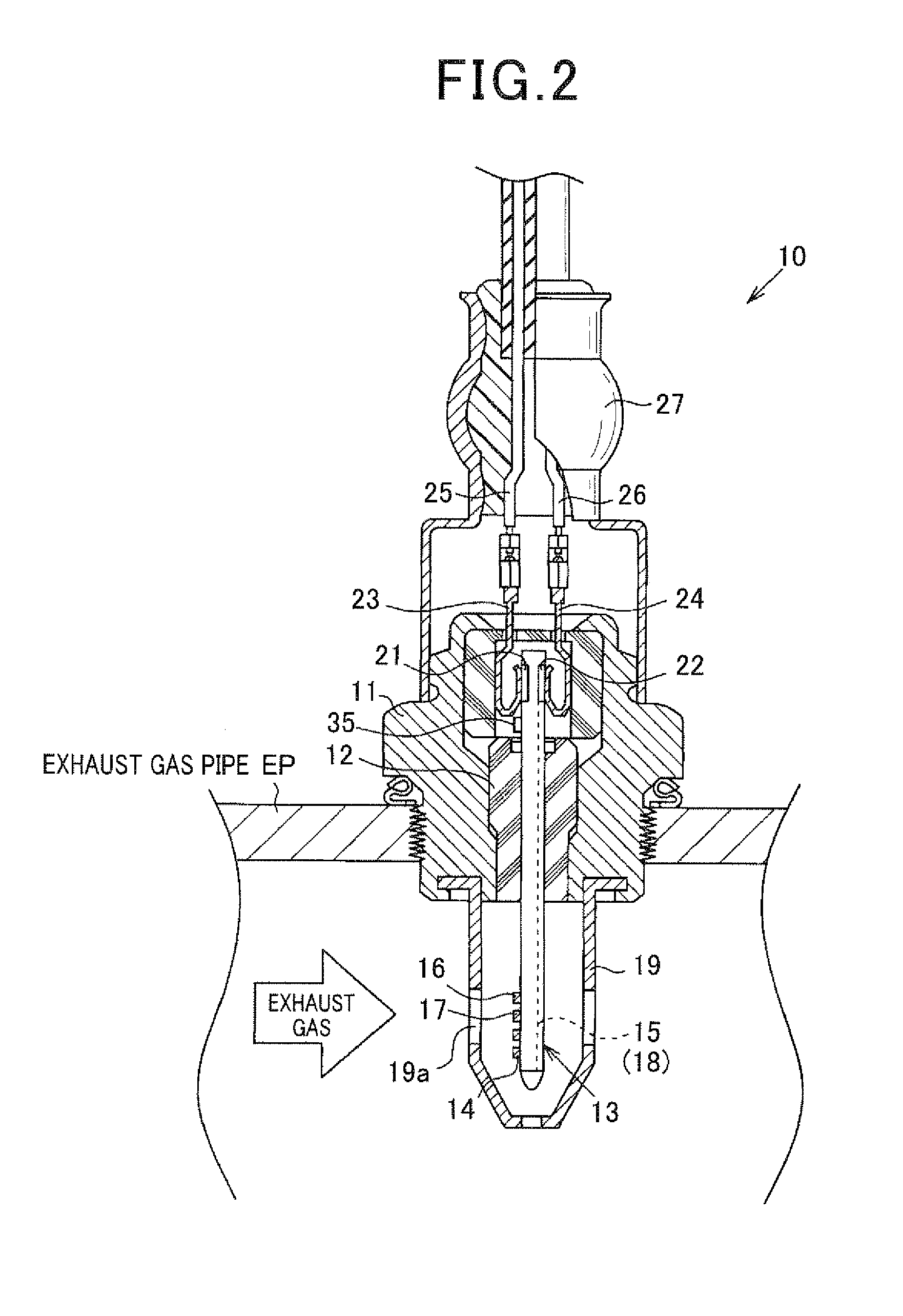

Temperature sensor

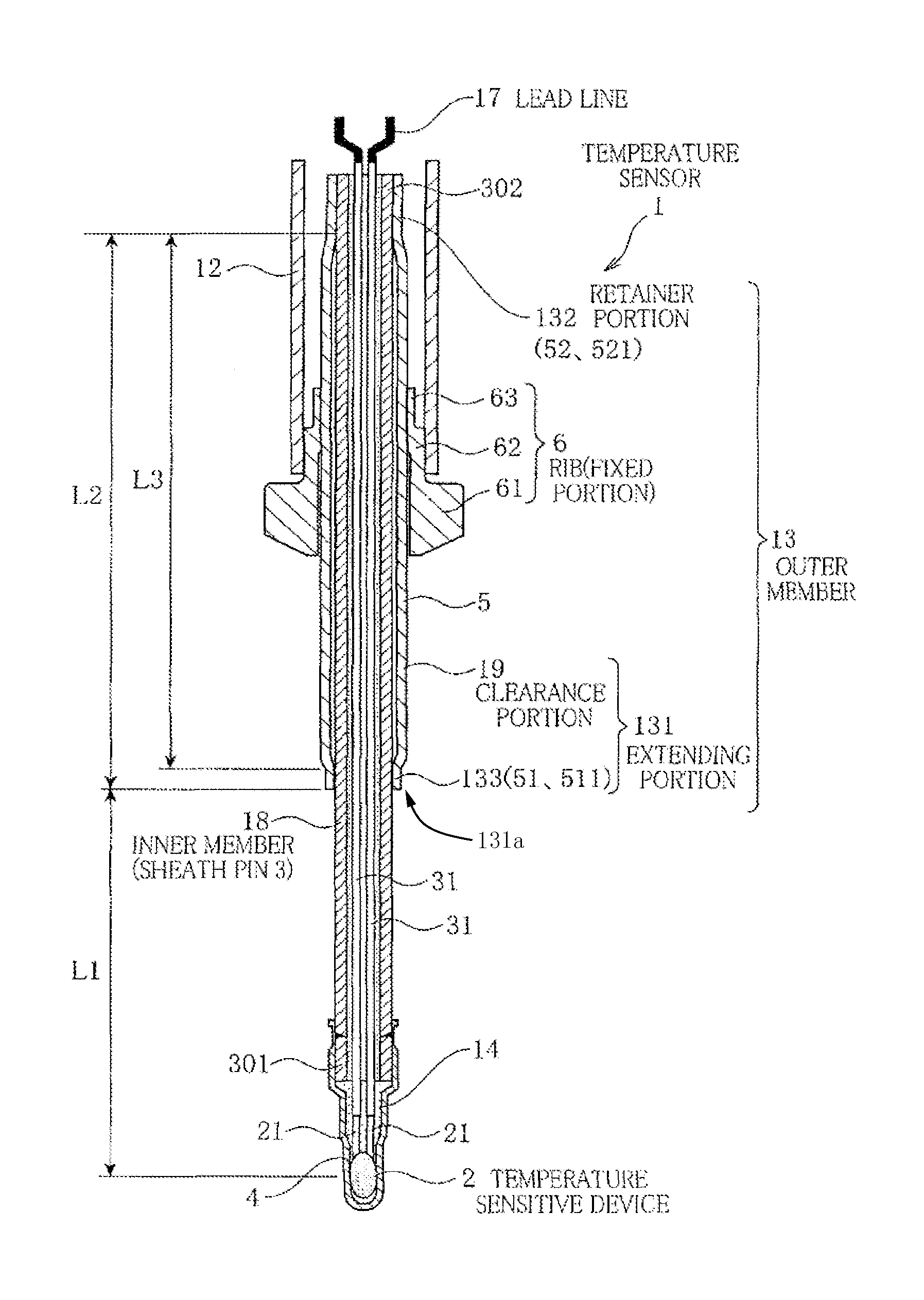

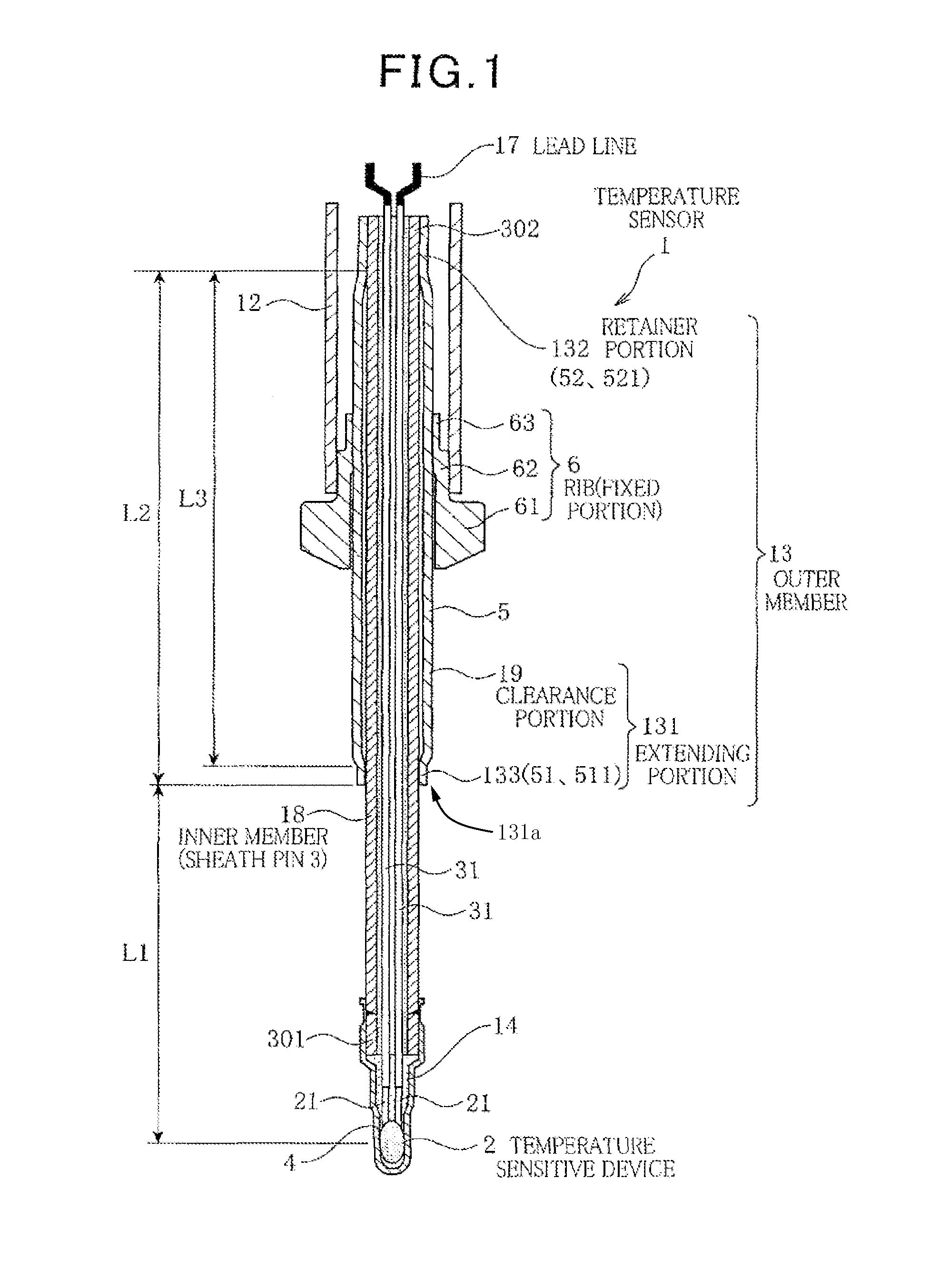

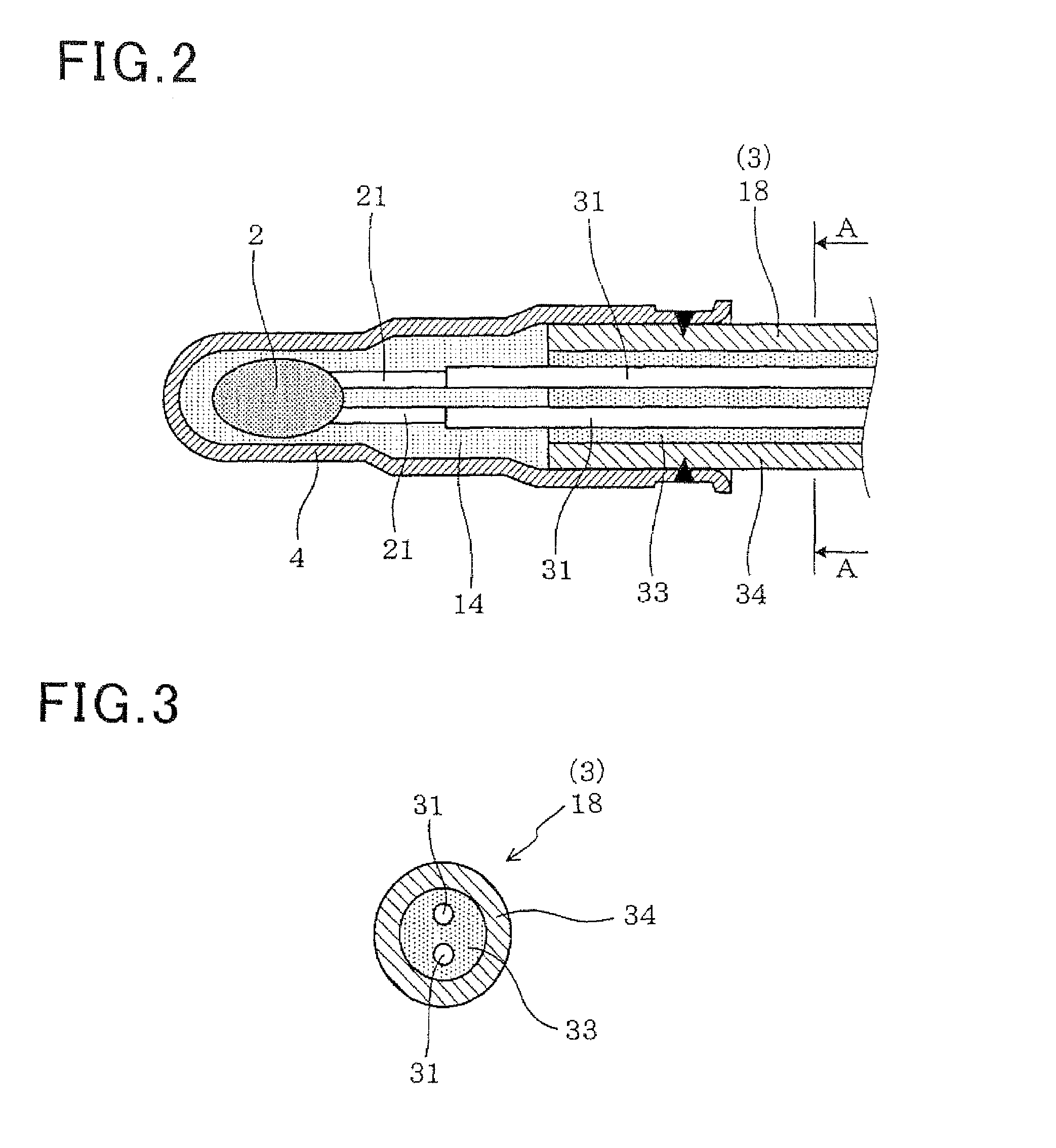

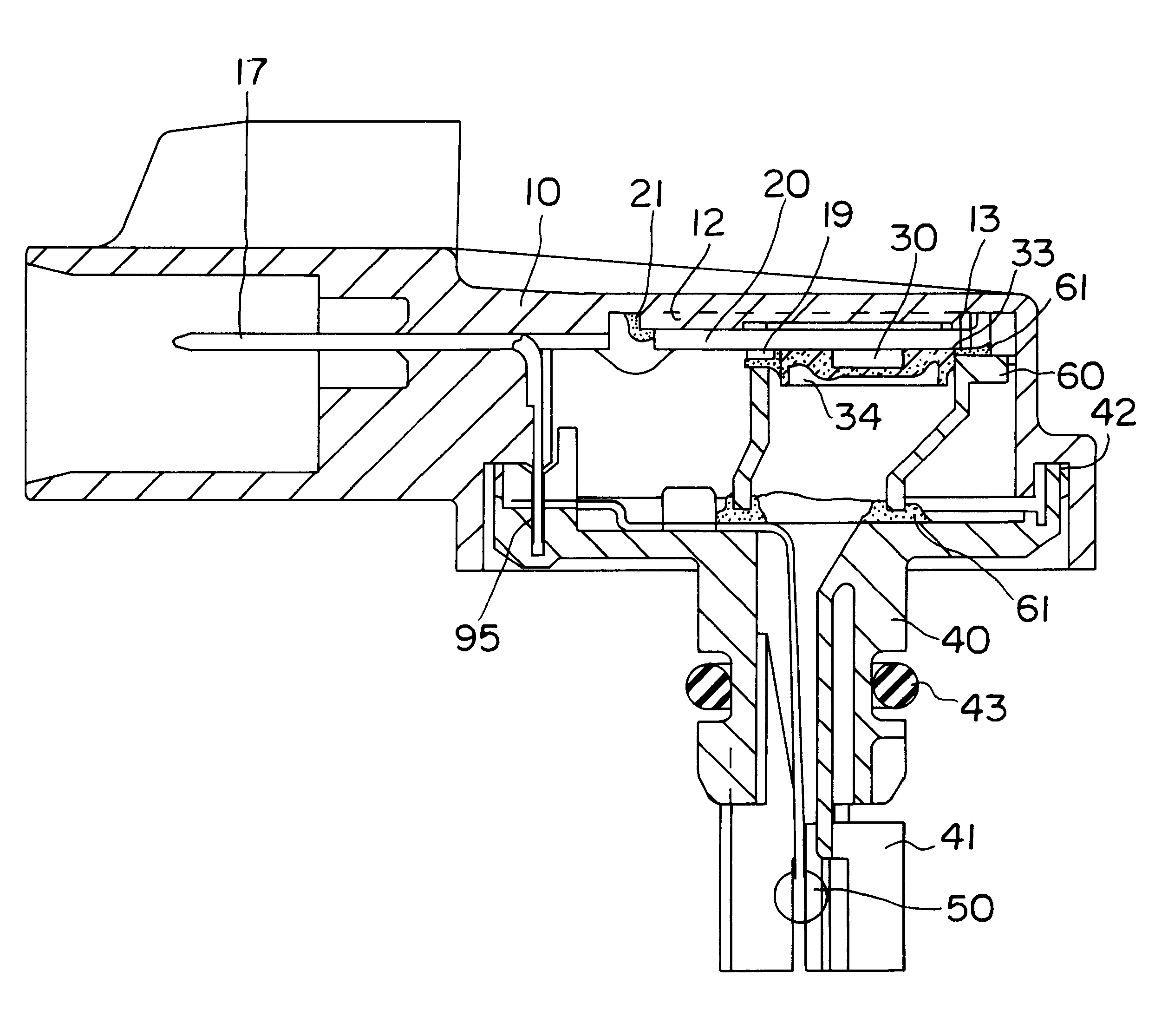

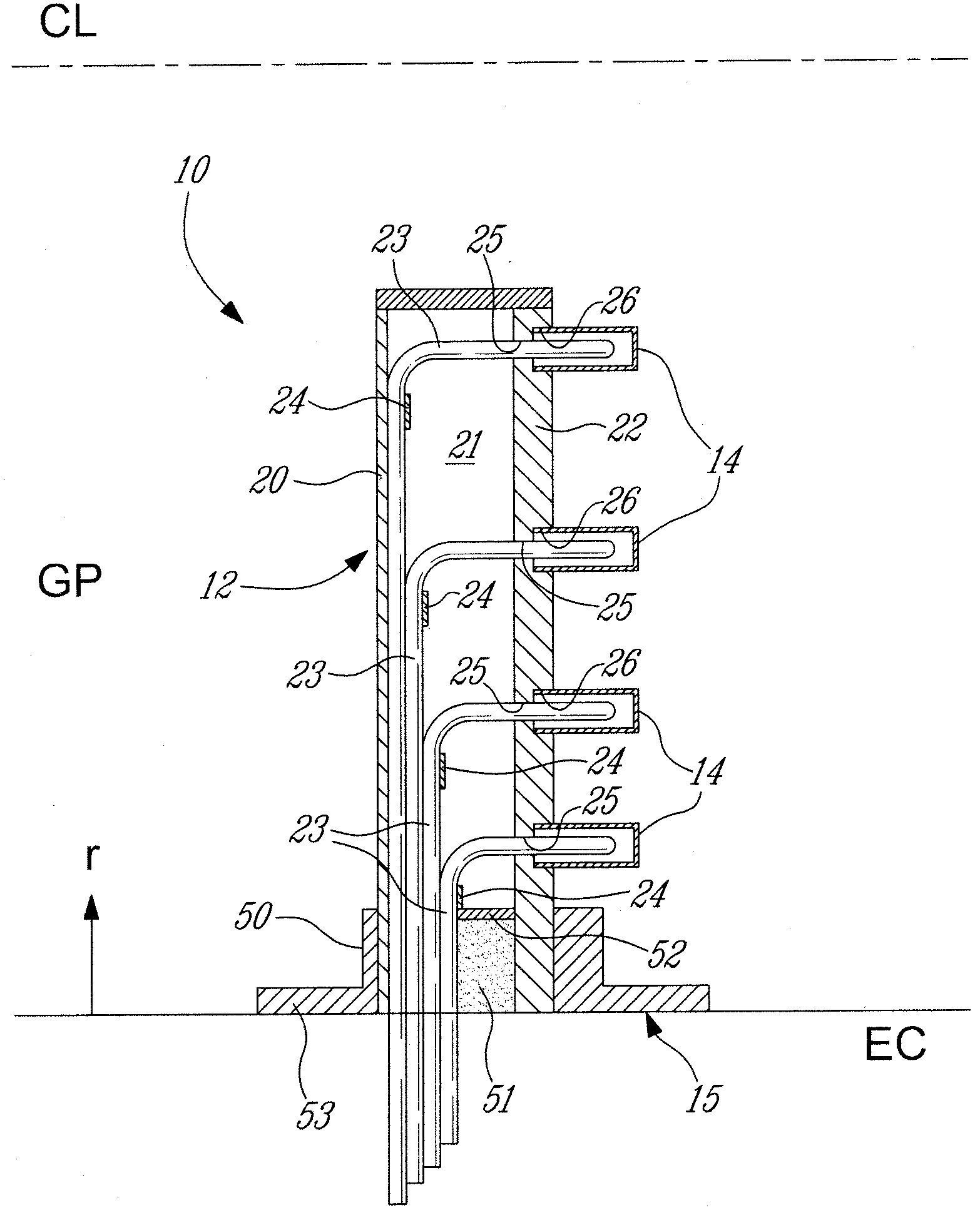

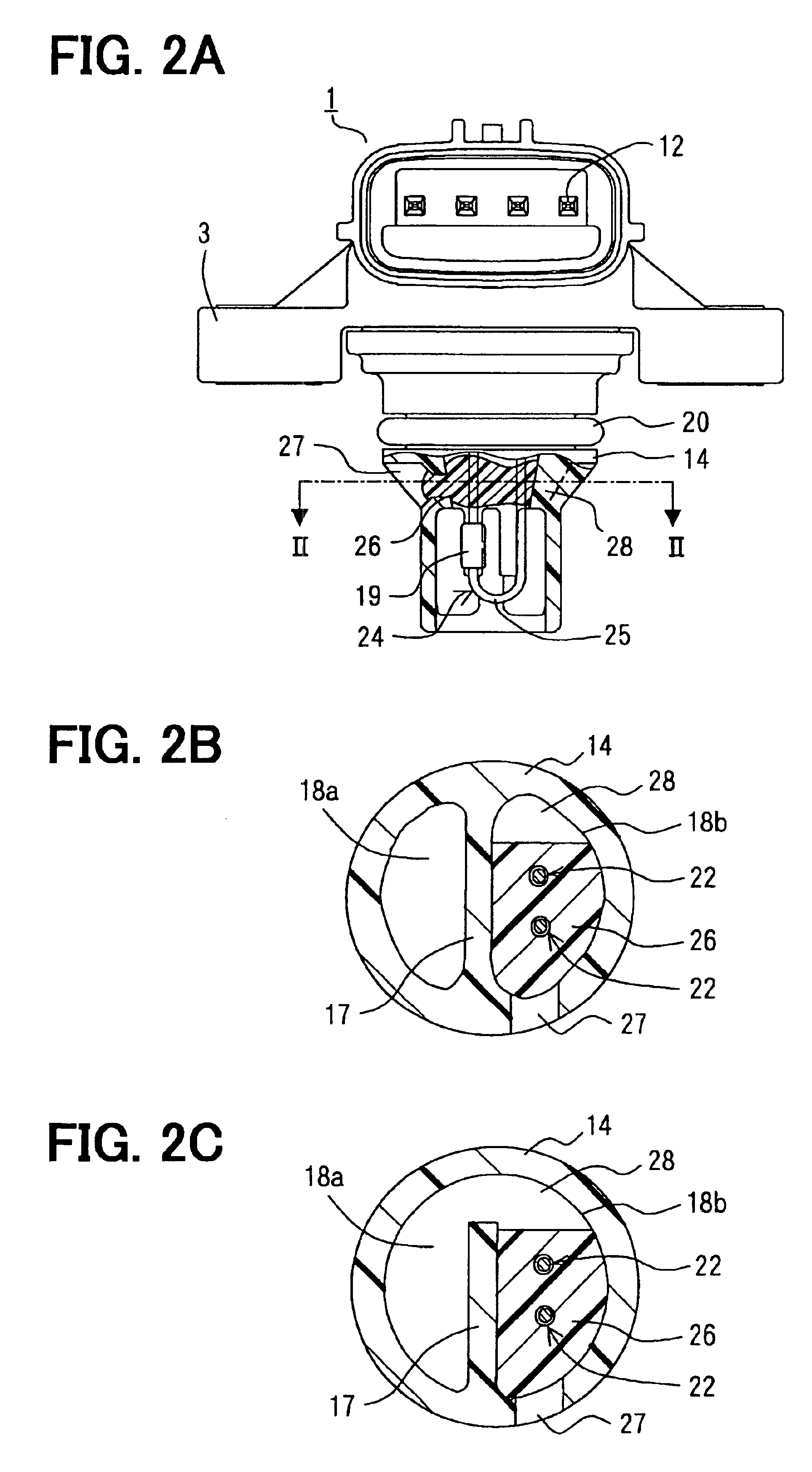

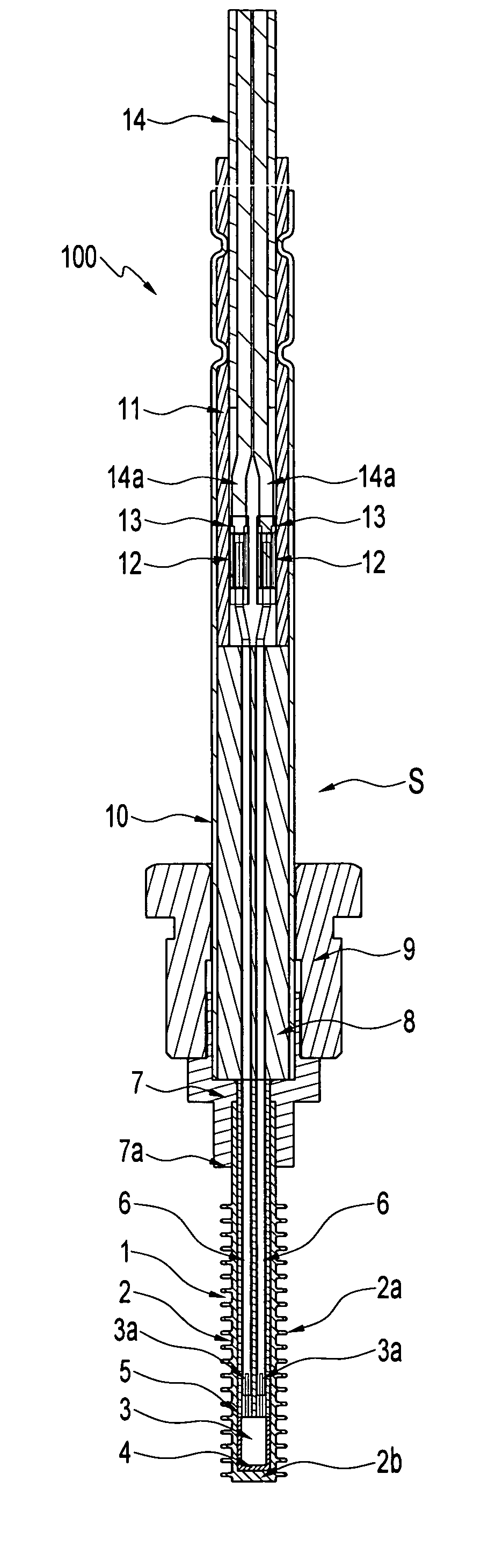

ActiveUS8864375B2Reduce vibrationReduce the overall heightThermometer detailsTemperature measurement in motorsInternal combustion engineExhaust pipe

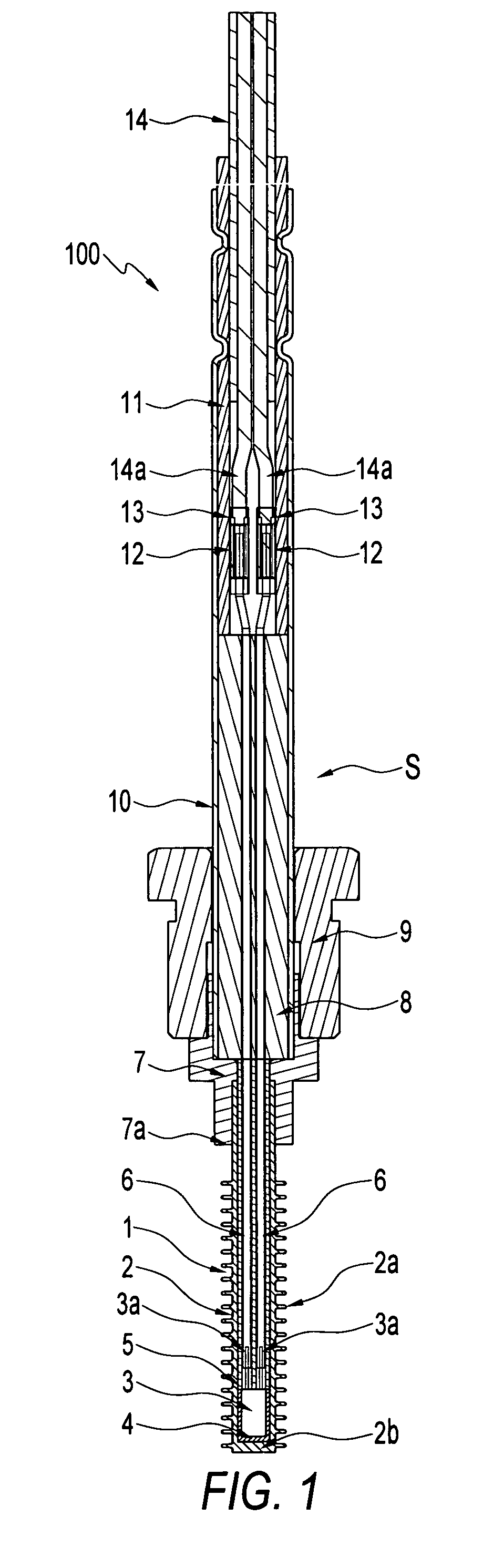

The temperature sensor 1 is equipped with a temperature sensitive device 2 to be disposed inside an exhaust pipe of an internal combustion engine, signal lines 31 connected at a top end side to the temperature sensitive device 2 and at a rear end side to leads for connection with an external circuit, an inner member 18 having a sheath pin 3 in which the signal lines 31 are disposed, and an outer member 13 disposed to cover at least a portion of an outer periphery of the inner member 18. The outer member 13 includes a fixed portion (rib 6) to be fixed to an upper wall of the exhaust pipe, a retainer portion 132 retaining the inner member 18, and an extending portion 131 formed closer to a top end side than the retainer portion 132. The extending portion 131 includes a clearance portion 19 disposed so as to have an air gap between itself and the inner member 18 and a front interference portion 133 disposed in a condition that a maximum air gap between the front interference portion 133 and the inner member 18 in a radius direction is 0.2 mm or less.

Owner:DENSO CORP

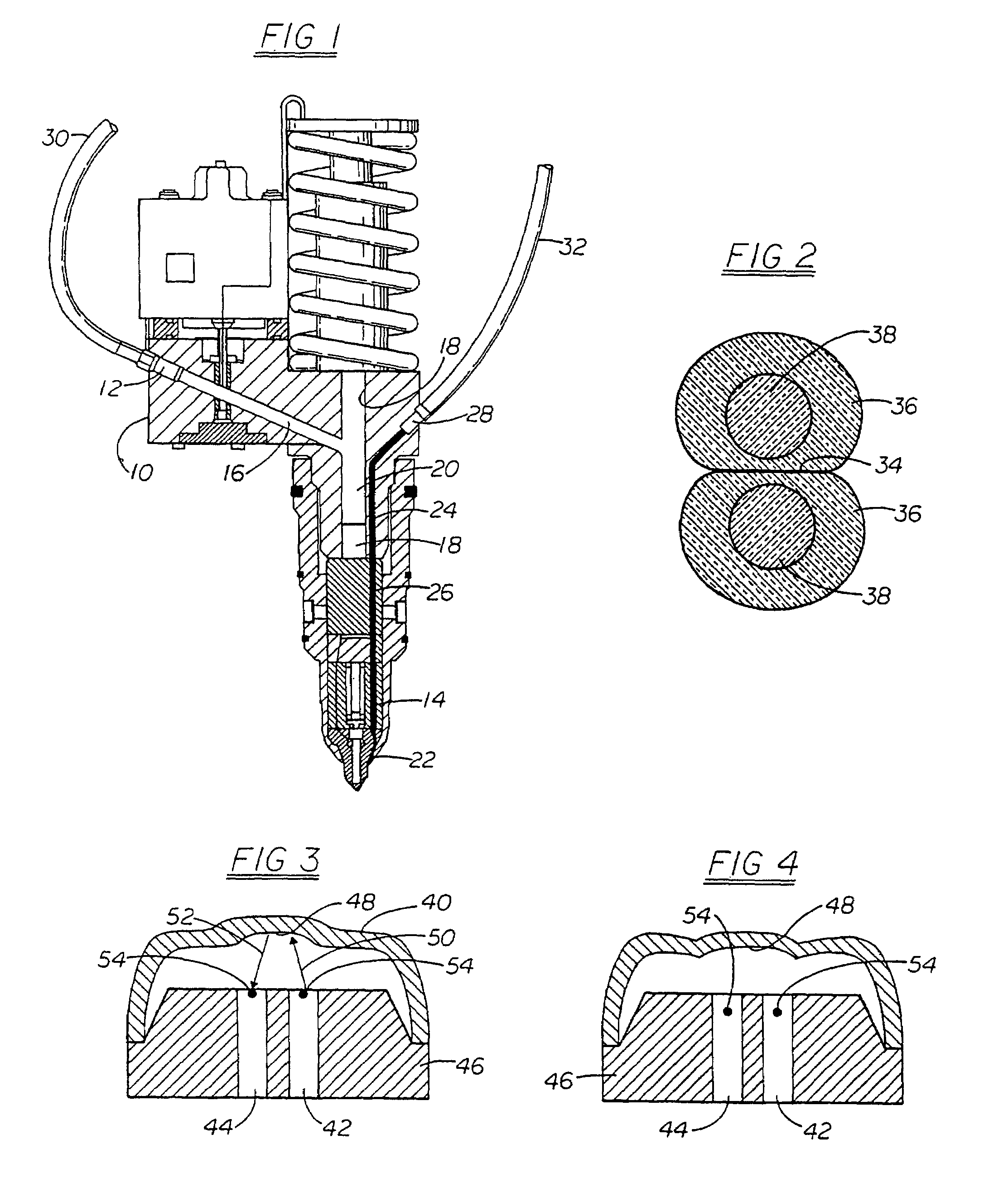

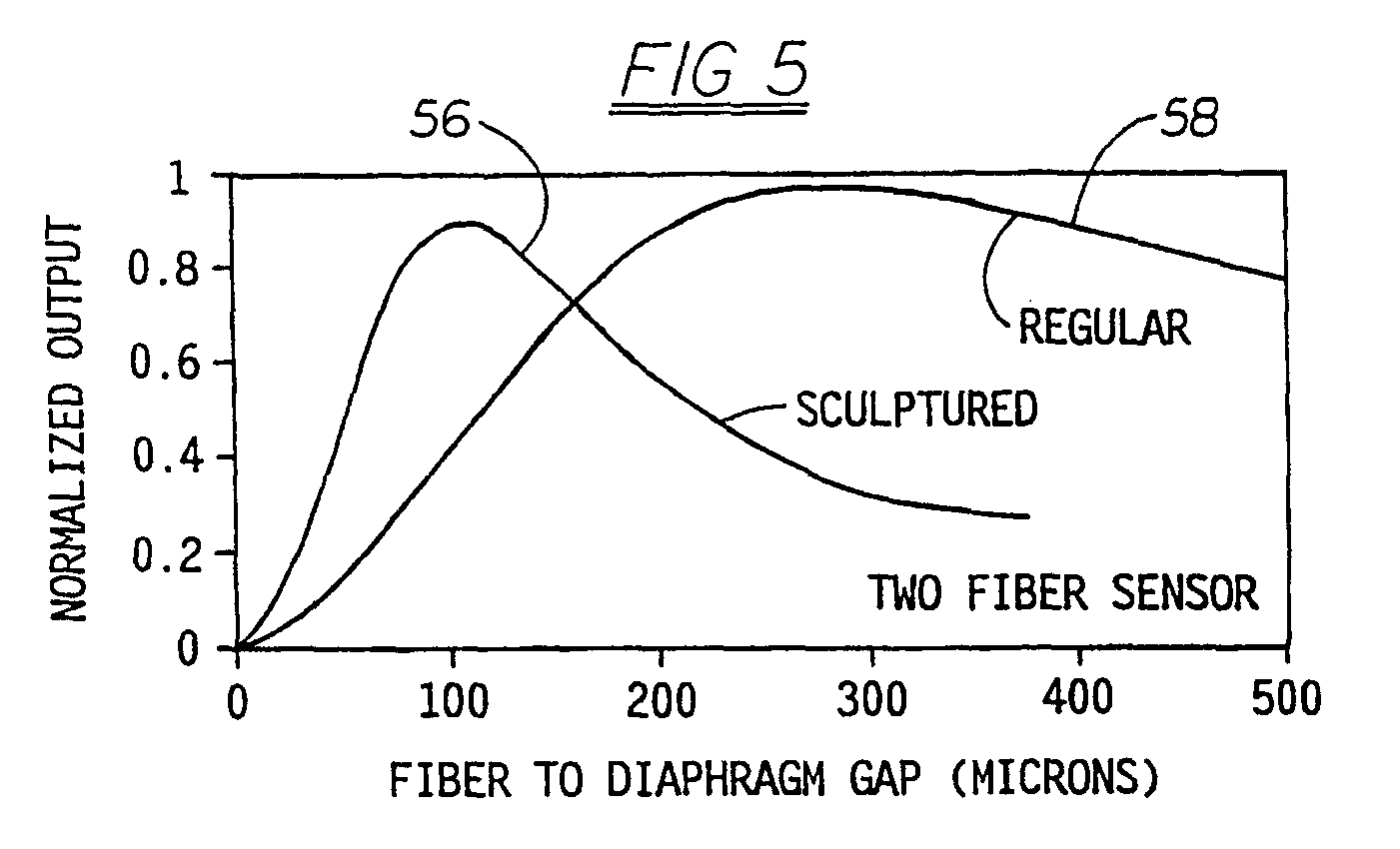

Fuel injectors with integral fiber optic pressure sensors and associated compensation and status monitoring devices

InactiveUS7340118B2Cost-effective and accurateAccurate and repeatable spray patternsTemperature measurement in motorsElectrical controlFiberCombustion chamber

Owner:WLODARCZYK MAREK T +1

Flowing fluid conditioner

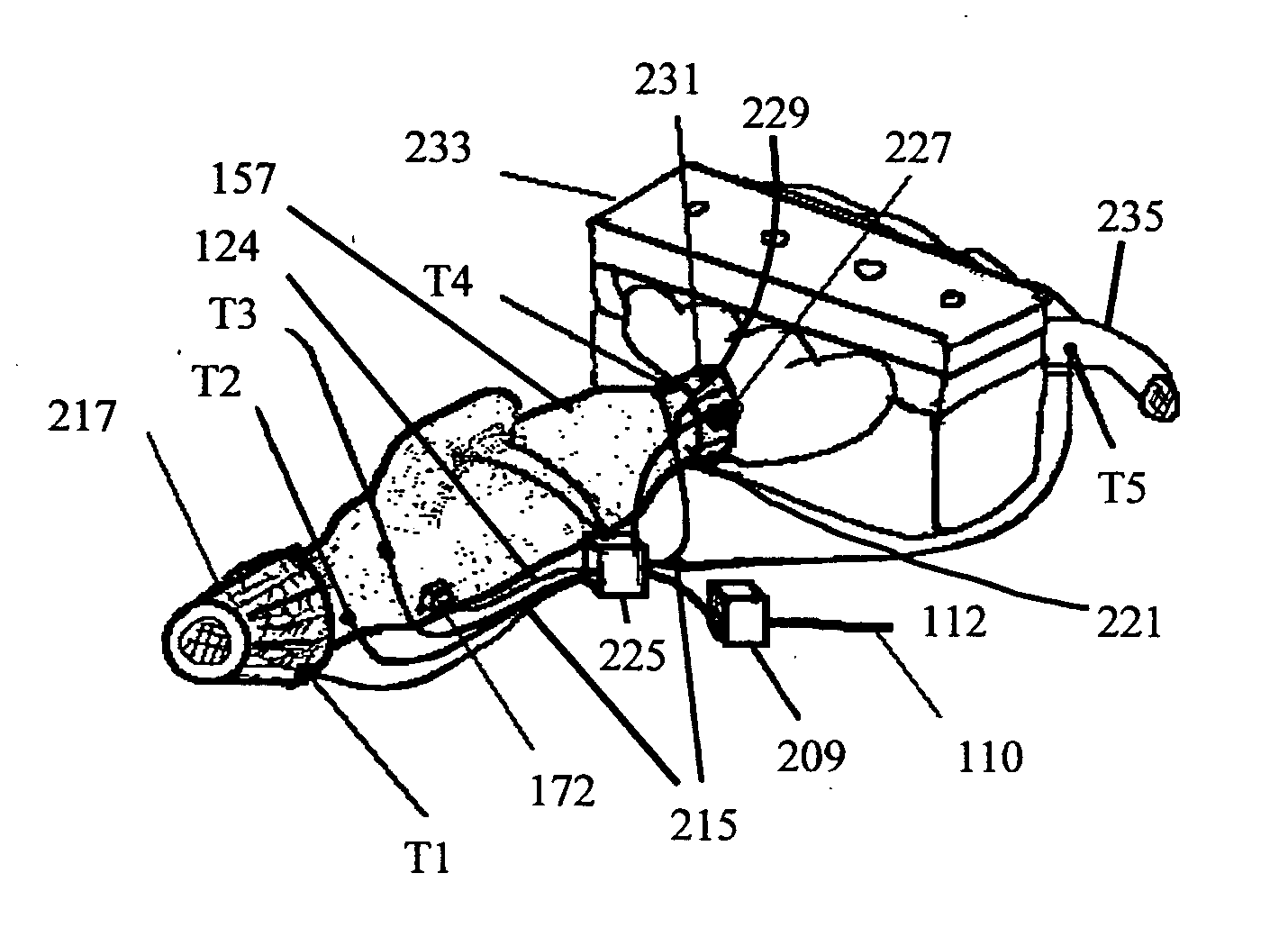

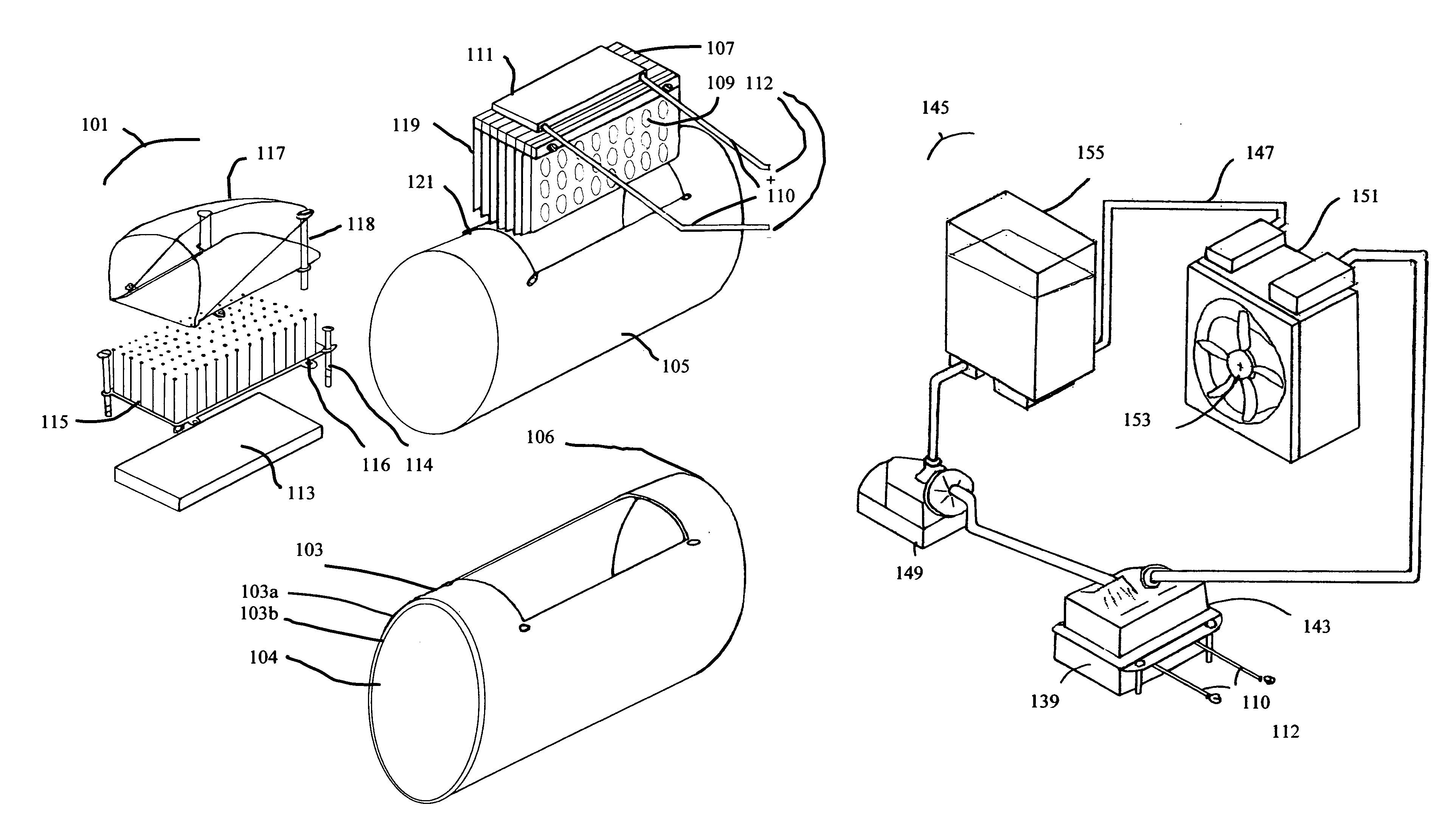

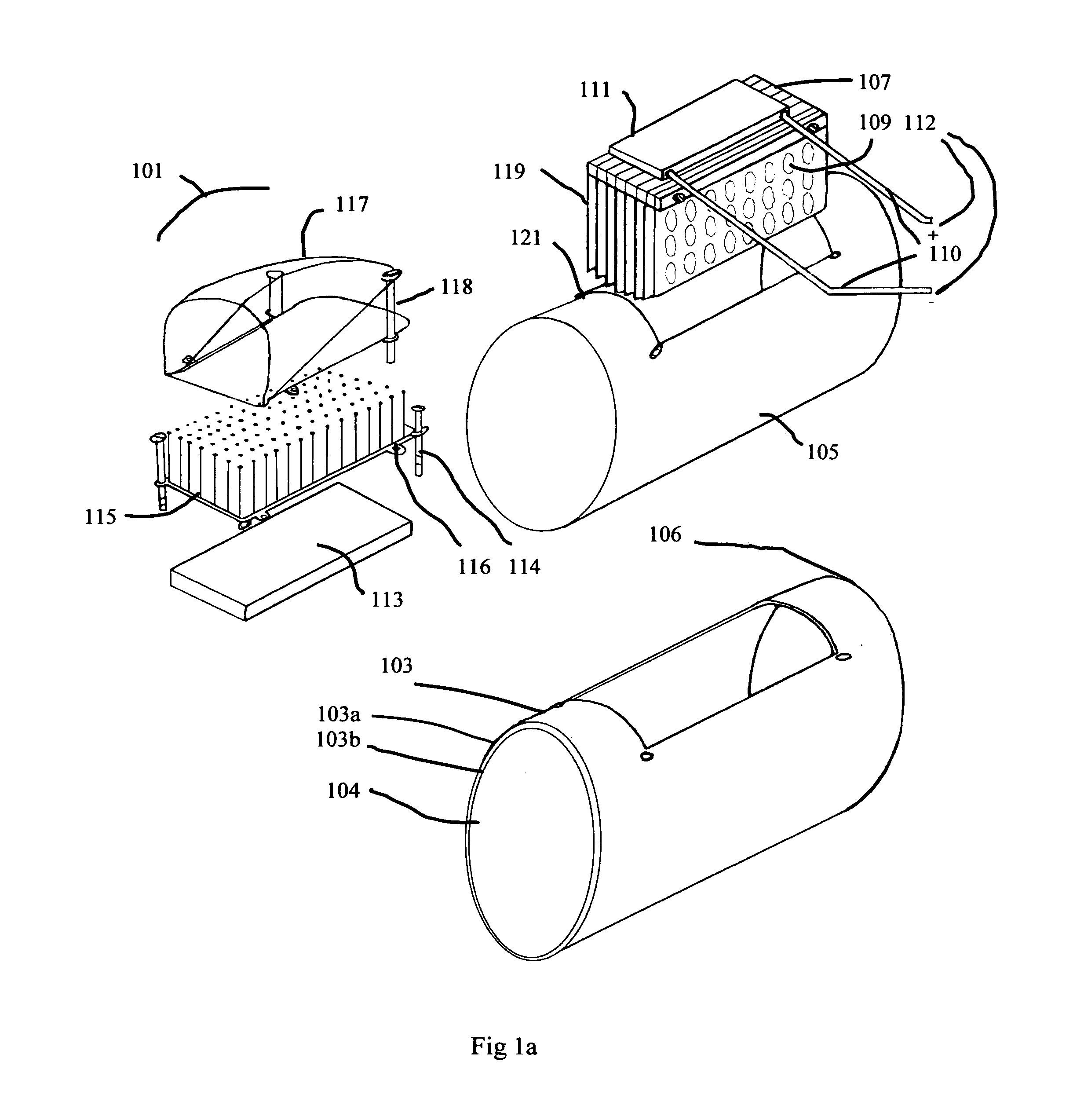

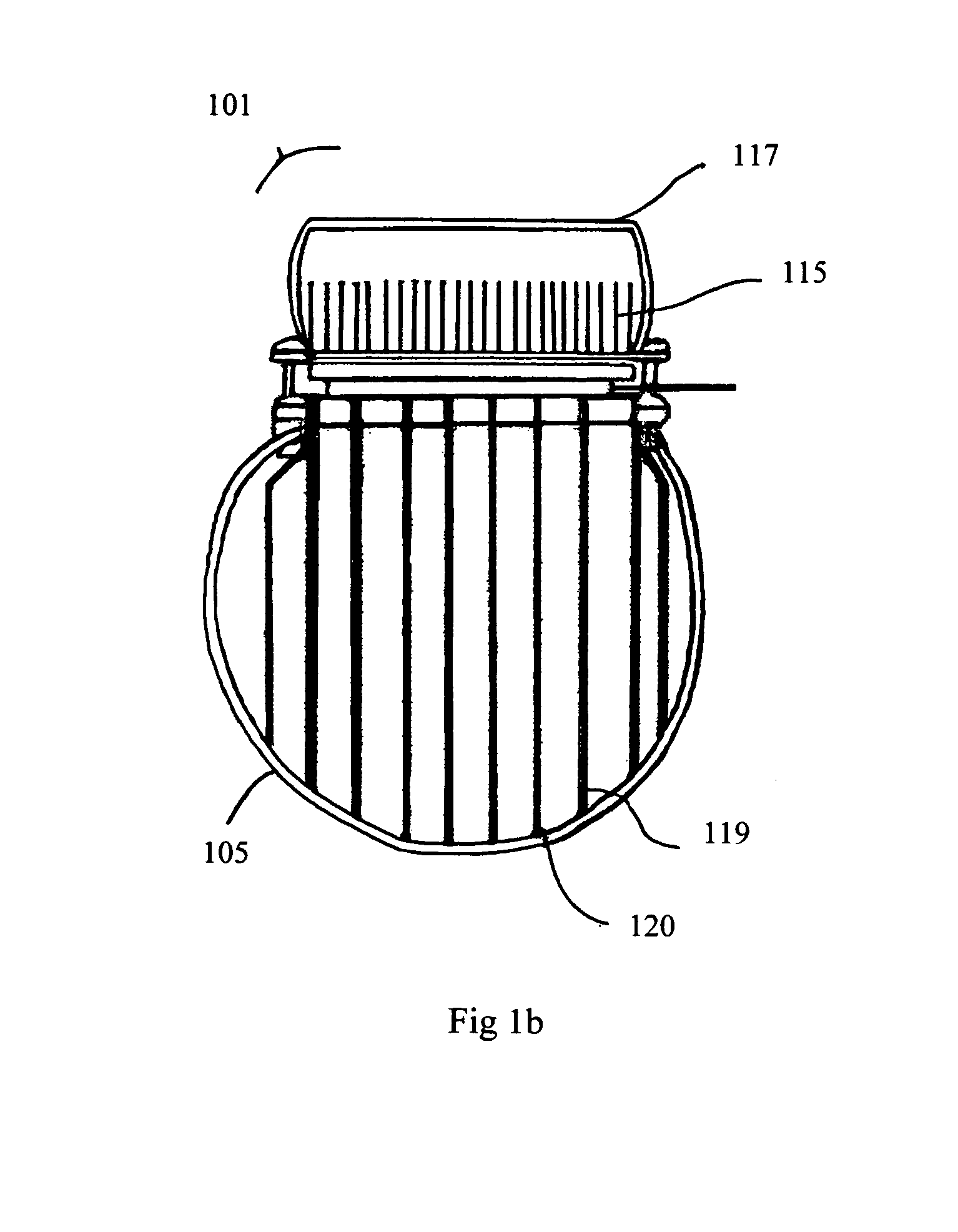

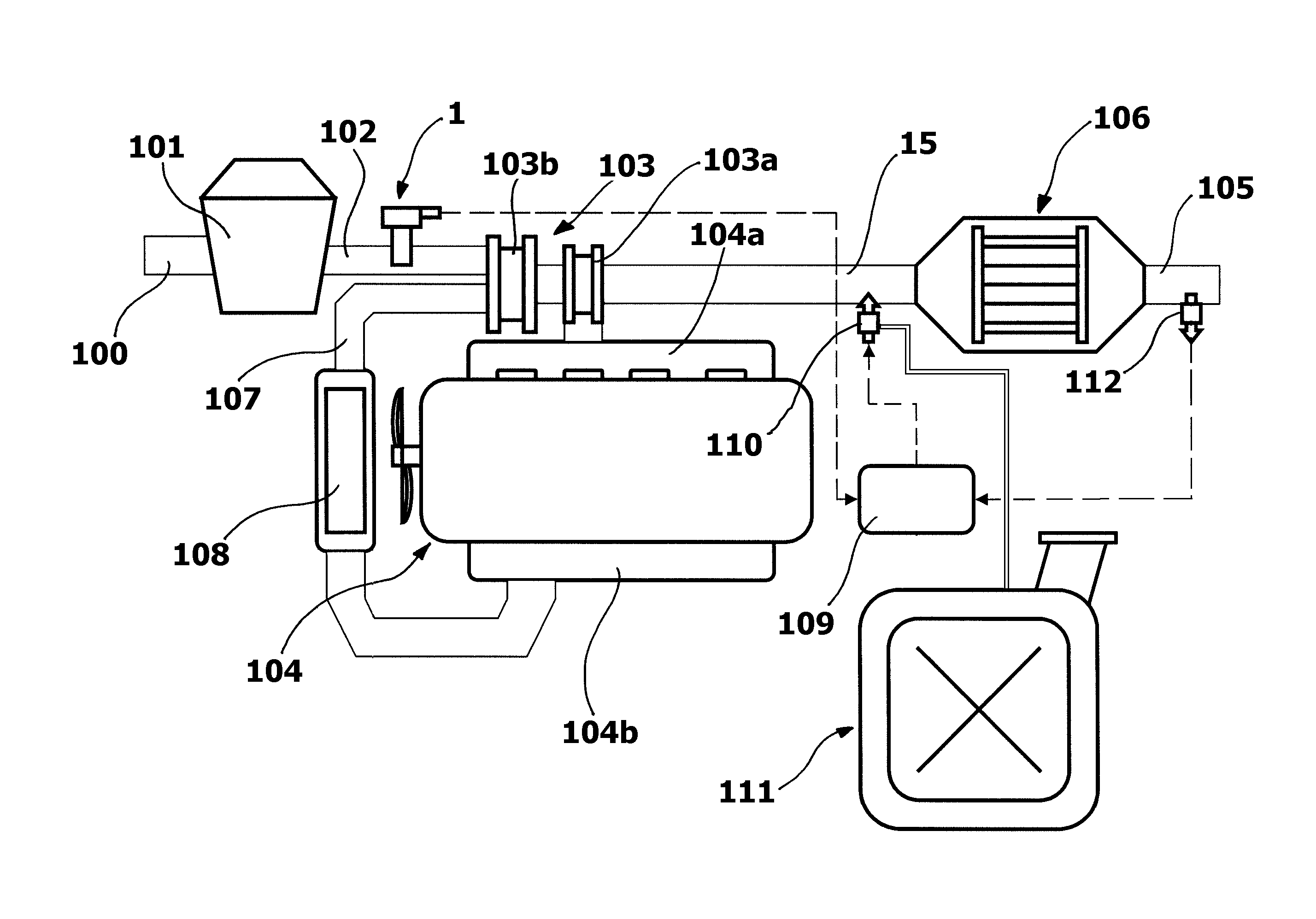

InactiveUS20050081834A1Reduce fuel consumptionEmission reductionTemperature measurement in motorsElectrically conductive connectionsTemperature conditioningIntercooler

A method and system for temperature conditioning of engine intake air by use of controllable intercooler which consists of an active thermoelectric device and a controllable valve system which optimally directs the path of airflow through a plurality of chambers in response to signals from a controller in order to optimally provide temperature conditioned air to the engine. System features temperature storage isolated from heat soaked engine components allowing immediate and efficient conditioning of airflow into an internal combustion engine. Intelligent control of this device removes parasitic power drains during high demand situations.

Owner:PERKINS MICHAEL T

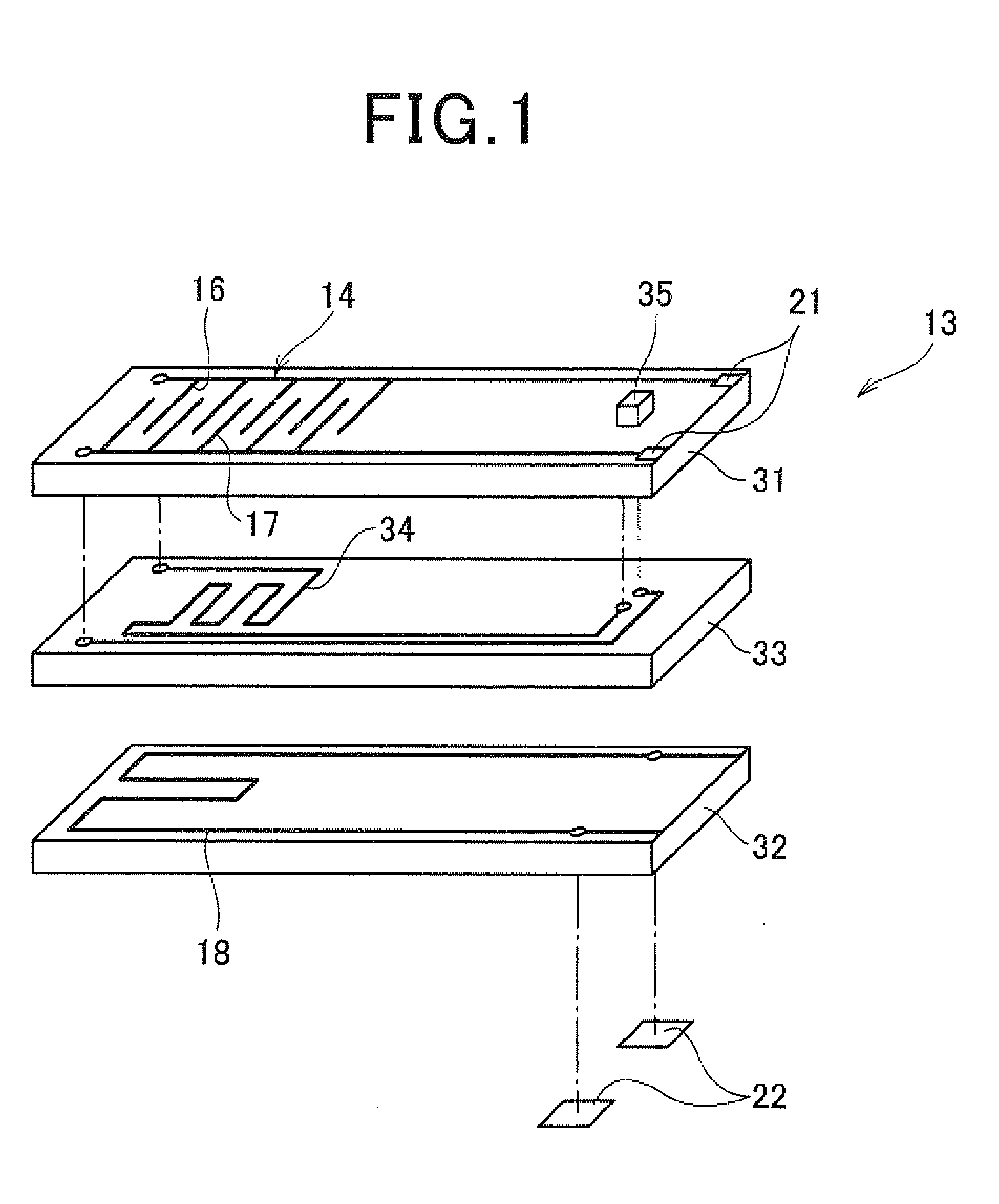

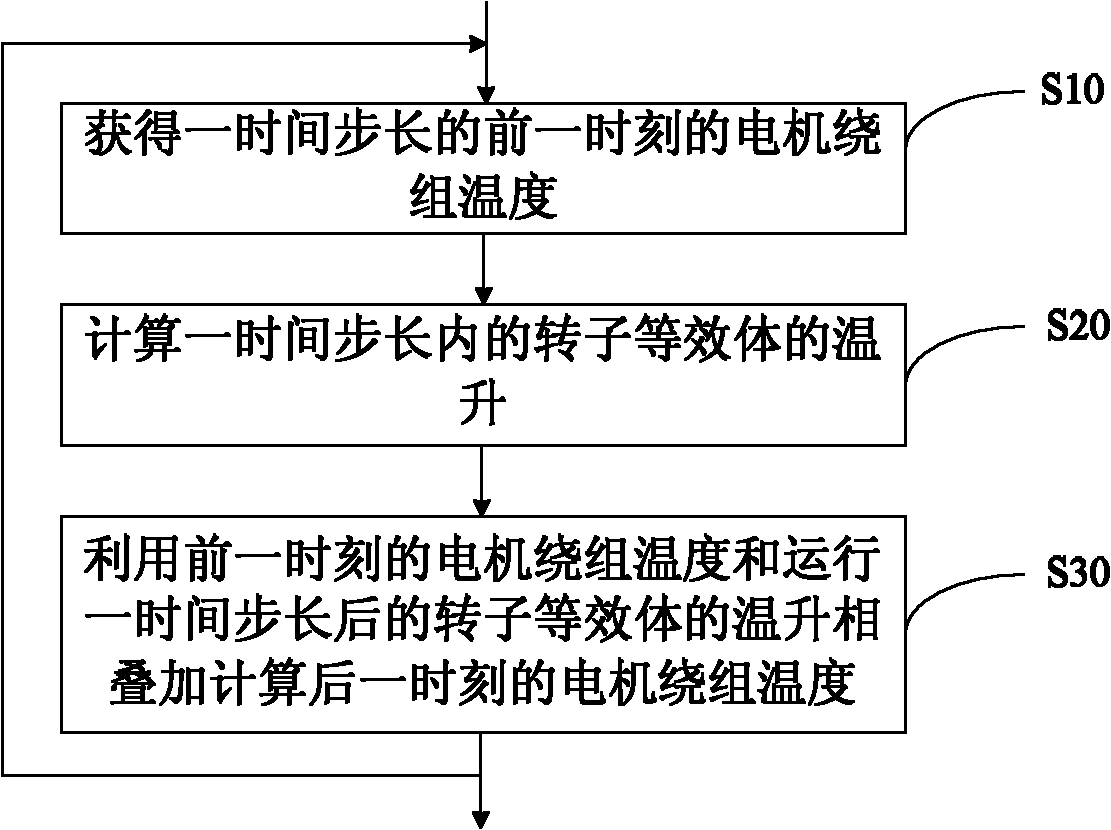

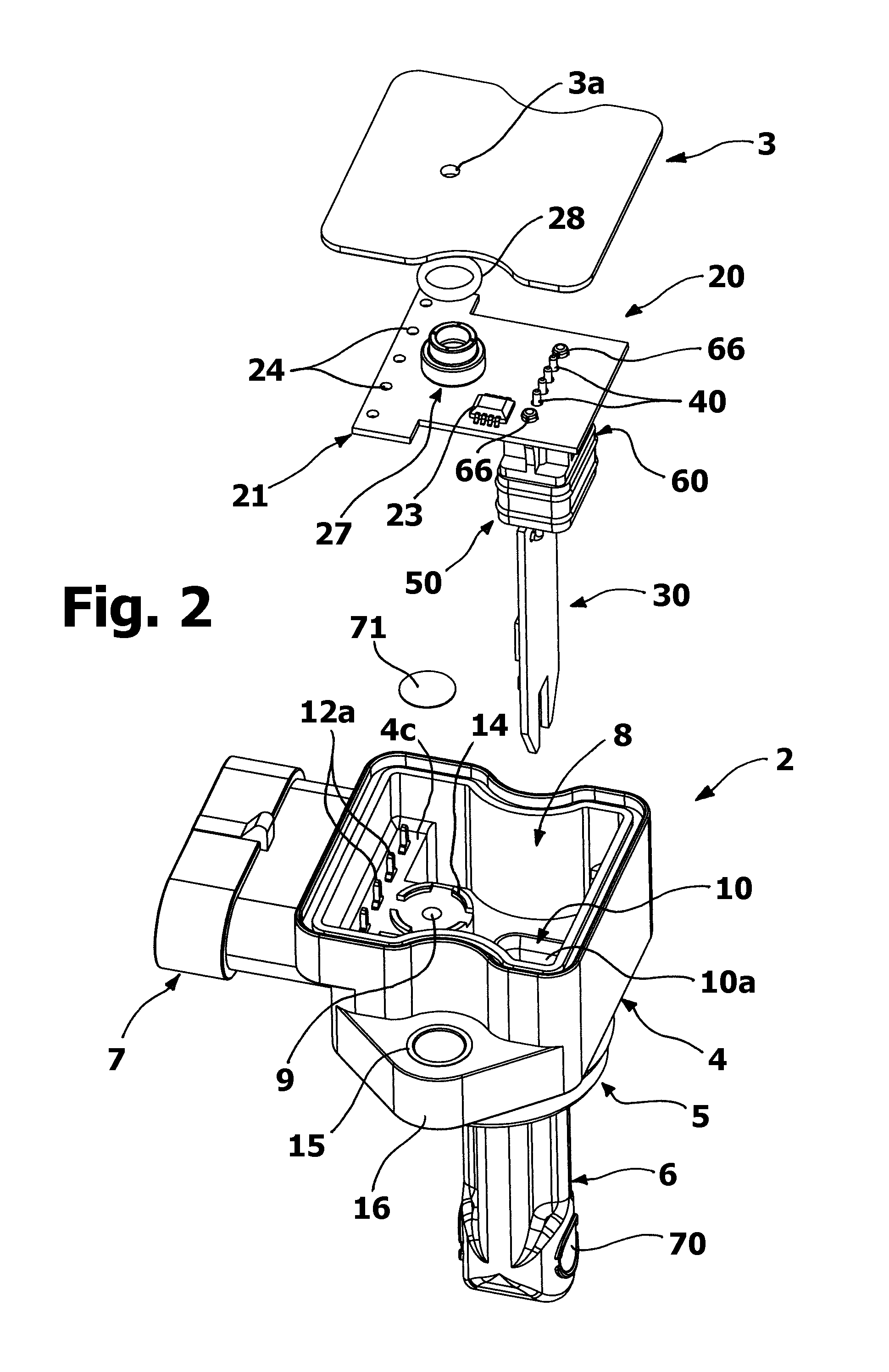

Particulate matter detection sensor and particulate matter detection sensor unit

ActiveUS20110283773A1Reduce in quantitySimple structureTemperature measurement in motorsExhaust apparatusMicrocomputerElectrical resistance and conductance

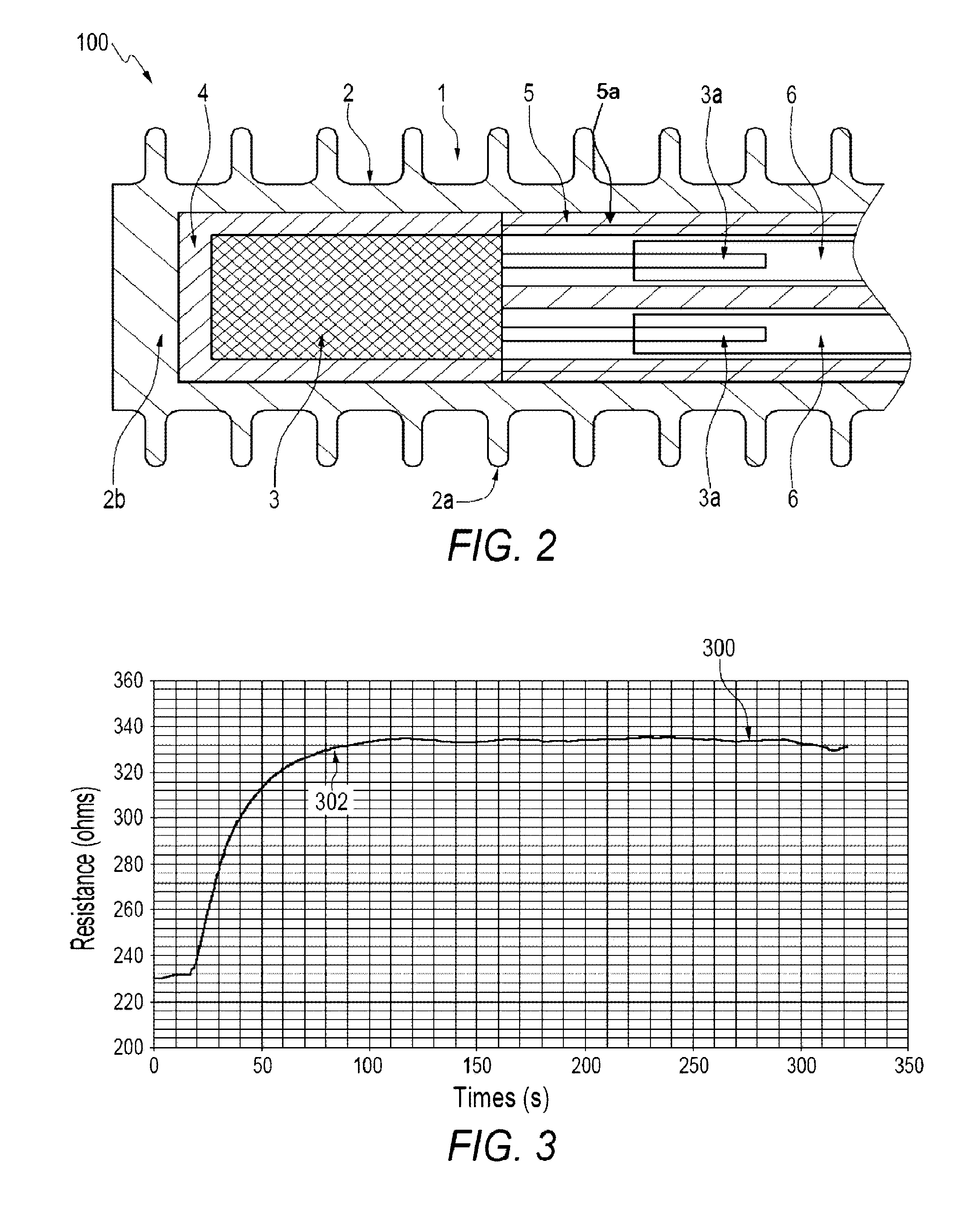

In a PM detection sensor with a sensor element having a pair of detection electrodes formed on a substrate, quantity of PM accumulated in the detection electrode is calculated on the basis of a resistance change between the detection electrodes. A series circuit composed of a temperature detection resistance and a capacitor connected in series is formed on a conductive path in the sensor element. A microcomputer in an ECU instructs a power source to supply a DC voltage to the resistance and the capacitor to make a first state in which no current flows in the resistance when a quantity of PM accumulated in the sensor element is detected. The microcomputer instructs the power source to supply an AC voltage to the resistance and the capacitor to make a second state in which a current flows in the resistance when a temperature of the sensor element is detected.

Owner:DENSO CORP

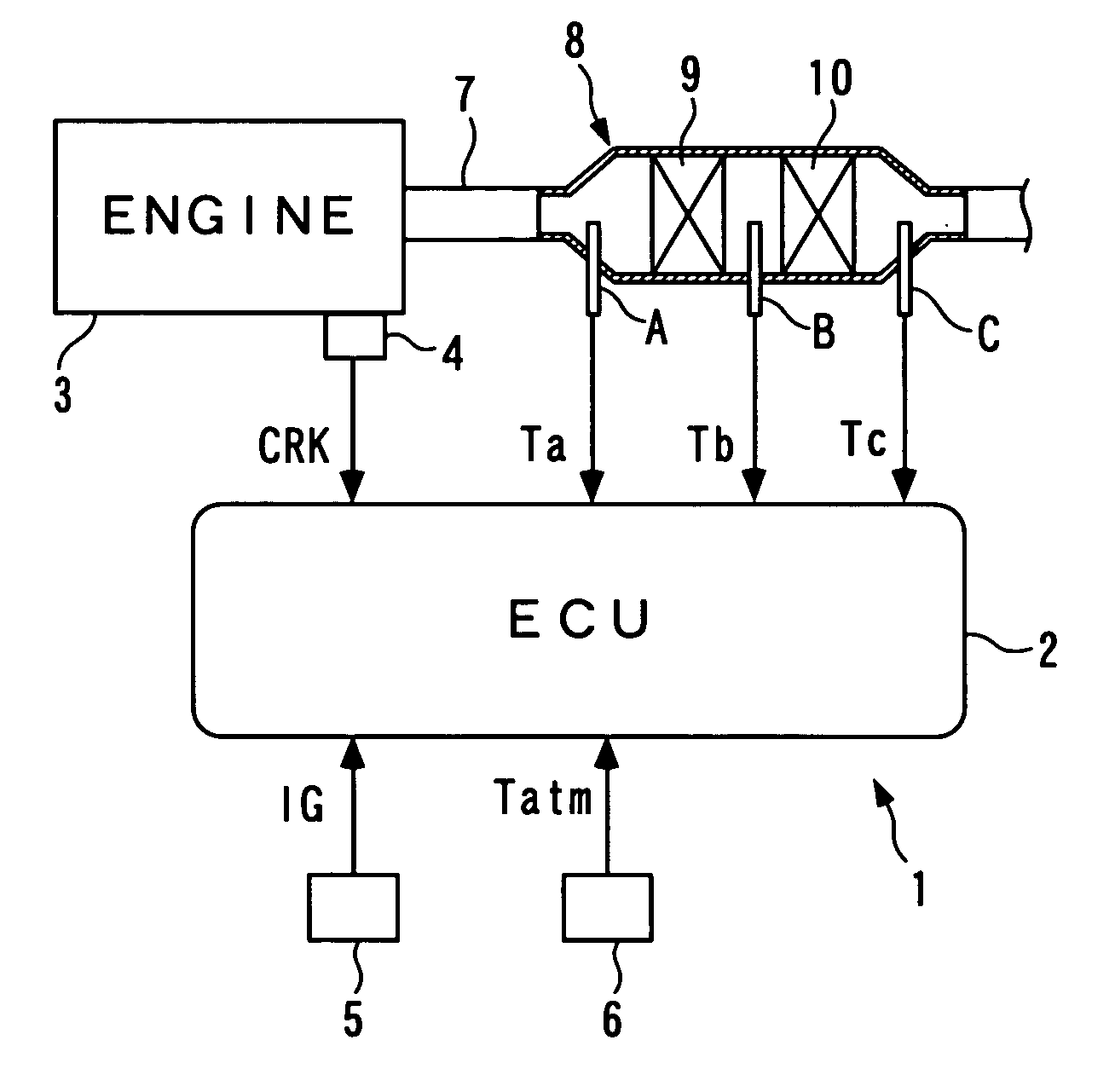

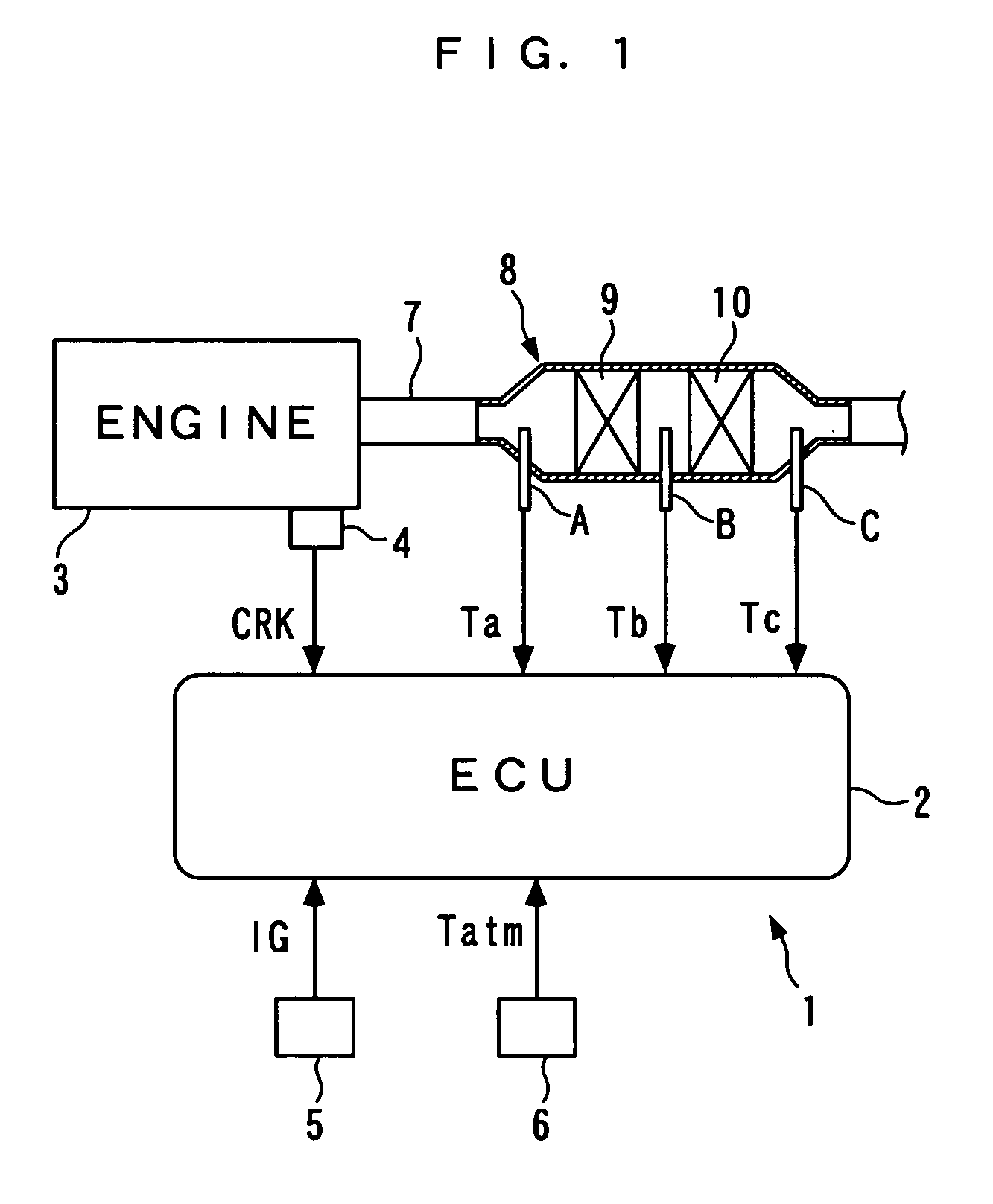

Failure determination system and method for temperature sensors, as well as engine control unit

A failure determination system for determining failures of temperature sensors, which is capable of easily and accurately determining failures of the sensors in actual operating temperature ranges thereof, even when the ranges are different from each other. Temperatures detected by exhaust gas temperature sensors are stored as initial temperatures when the engine has stopped. Temperatures detected by the respective sensors after stoppage of the engine are made dimensionless based on the corresponding initial temperatures to thereby calculate dimensionless values. An estimated dimensionless value of a temperature to be detected when each sensor is normal is set in advance as an estimated normal value. Failures of the sensors are determined based on results of comparisons of the dimensionless values with the estimated normal value.

Owner:HONDA MOTOR CO LTD

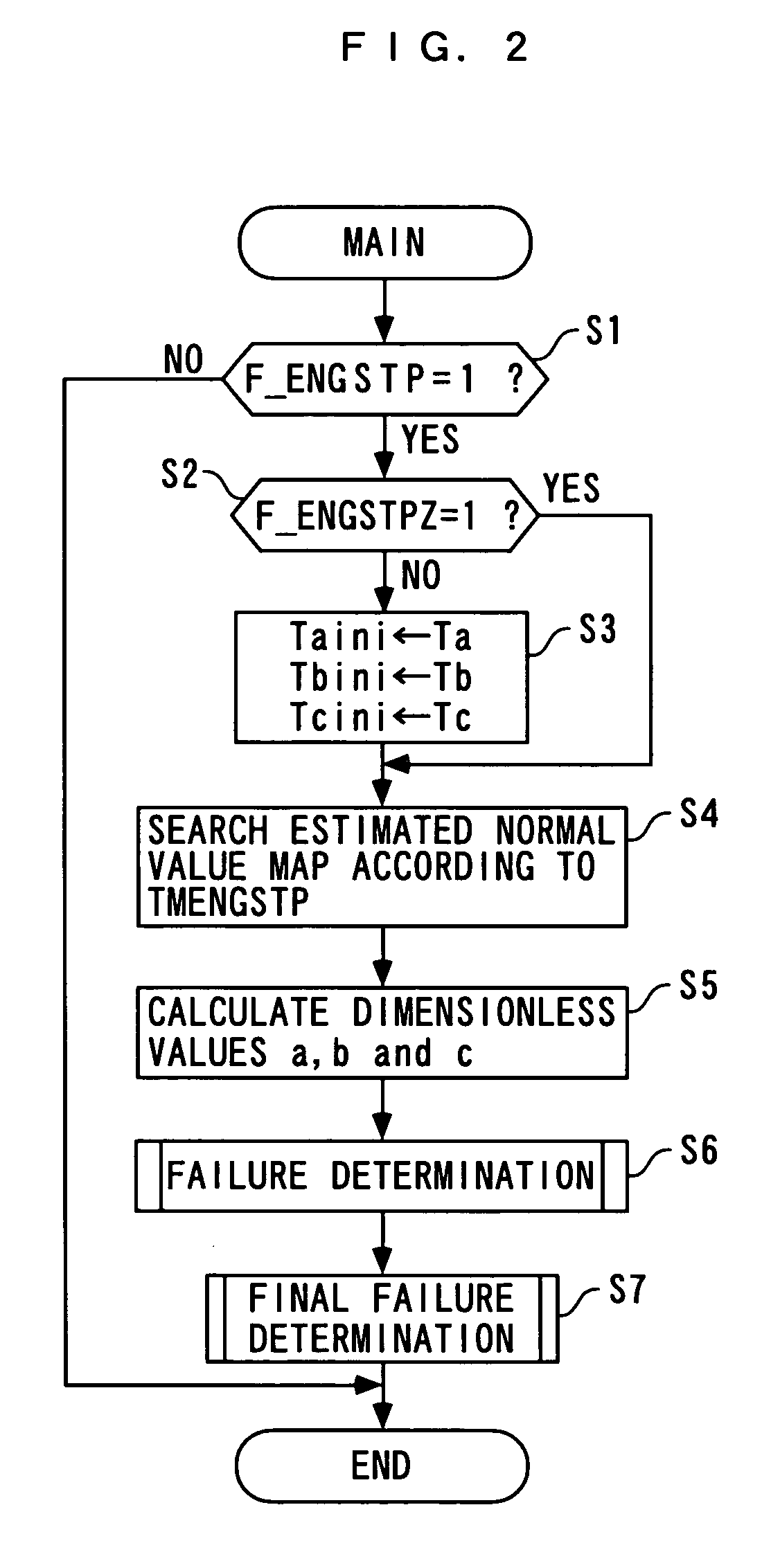

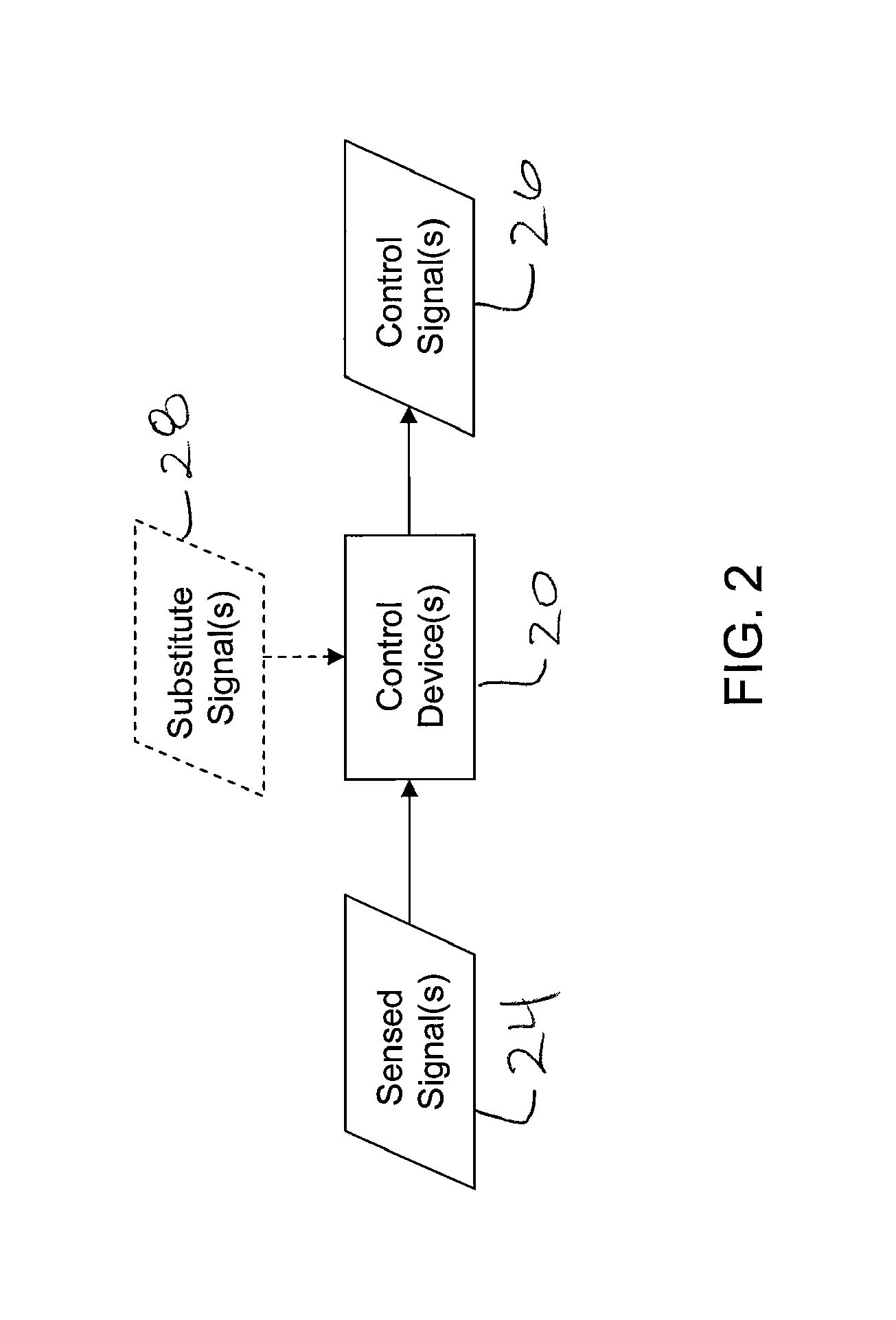

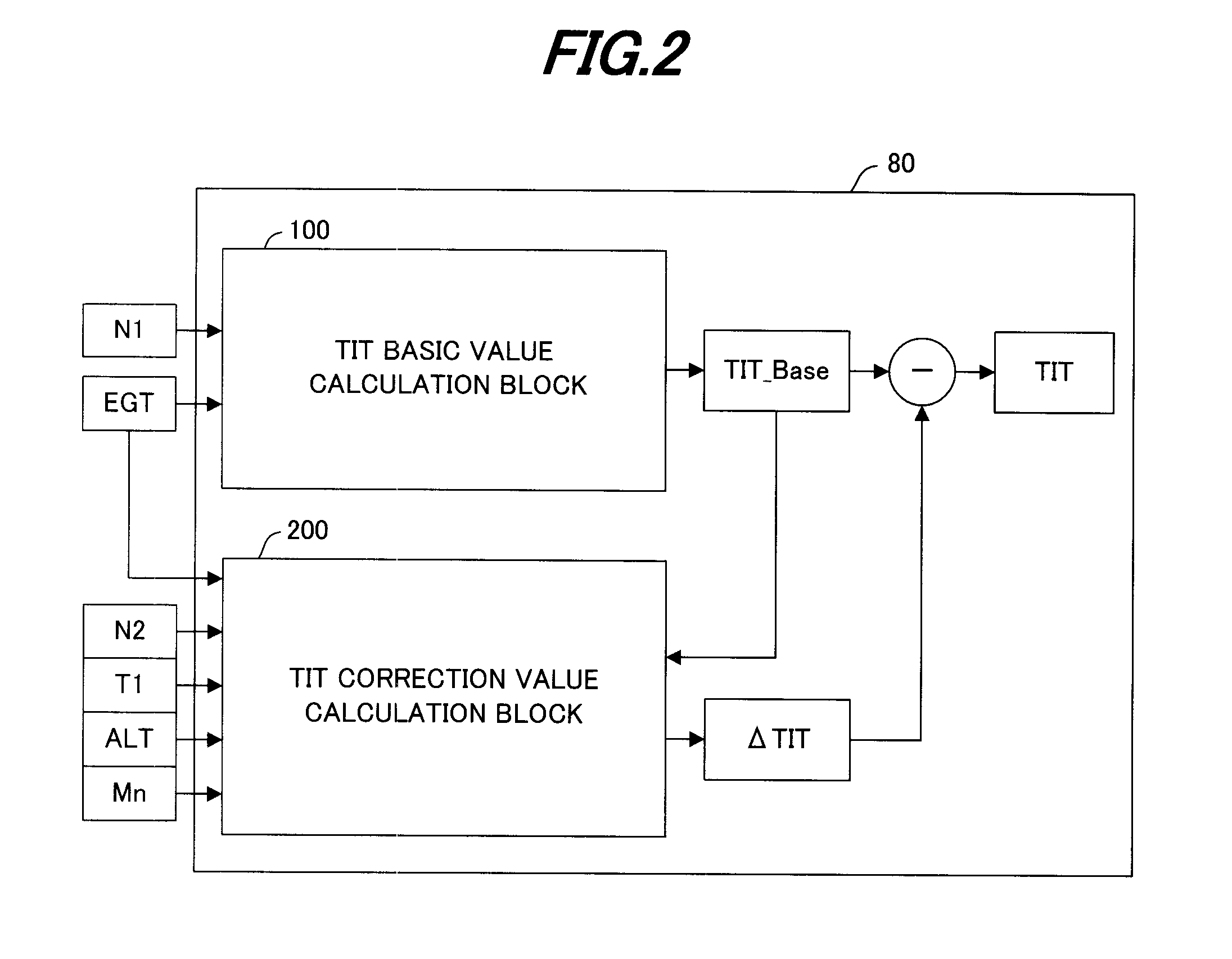

Aircraft engine control during icing of temperature probe

ActiveUS20120029786A1Turbine/propulsion fuel supply systemsAircraft power plantsControl signalIcing conditions

Methods for controlling an aircraft turbofan engine during icing of a temperature probe and devices for carrying out such methods are described. The methods may comprise: using one or more signals representative of temperature received from a heated temperature probe to generate one or more control signals for use in controlling the engine; determining that an icing condition associated with the probe exists; and using data representing one or more substitute signals in place of signals representative of temperature received from the heated temperature probe to generate the one or more control signals for use in controlling the engine.

Owner:PRATT & WHITNEY CANADA CORP

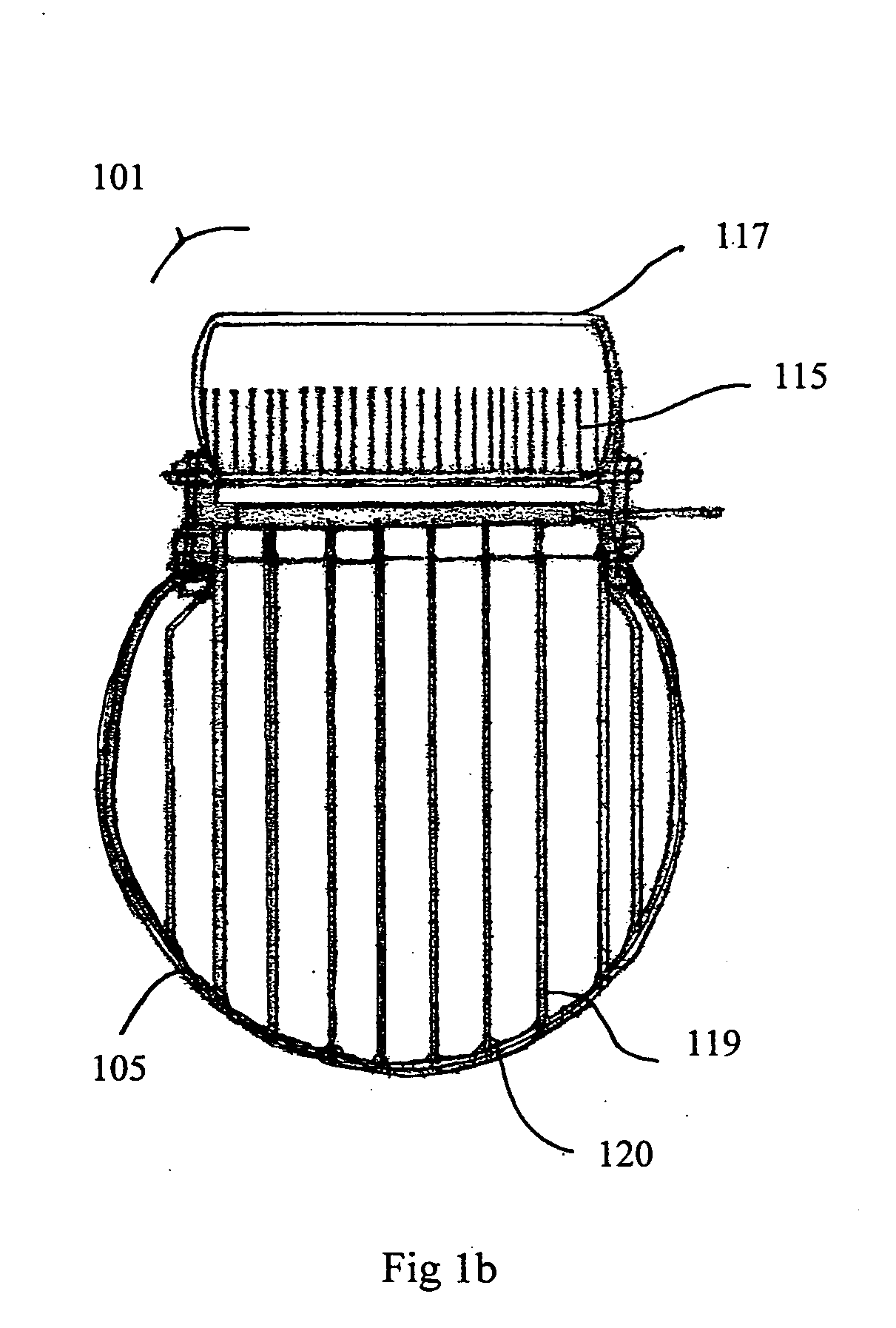

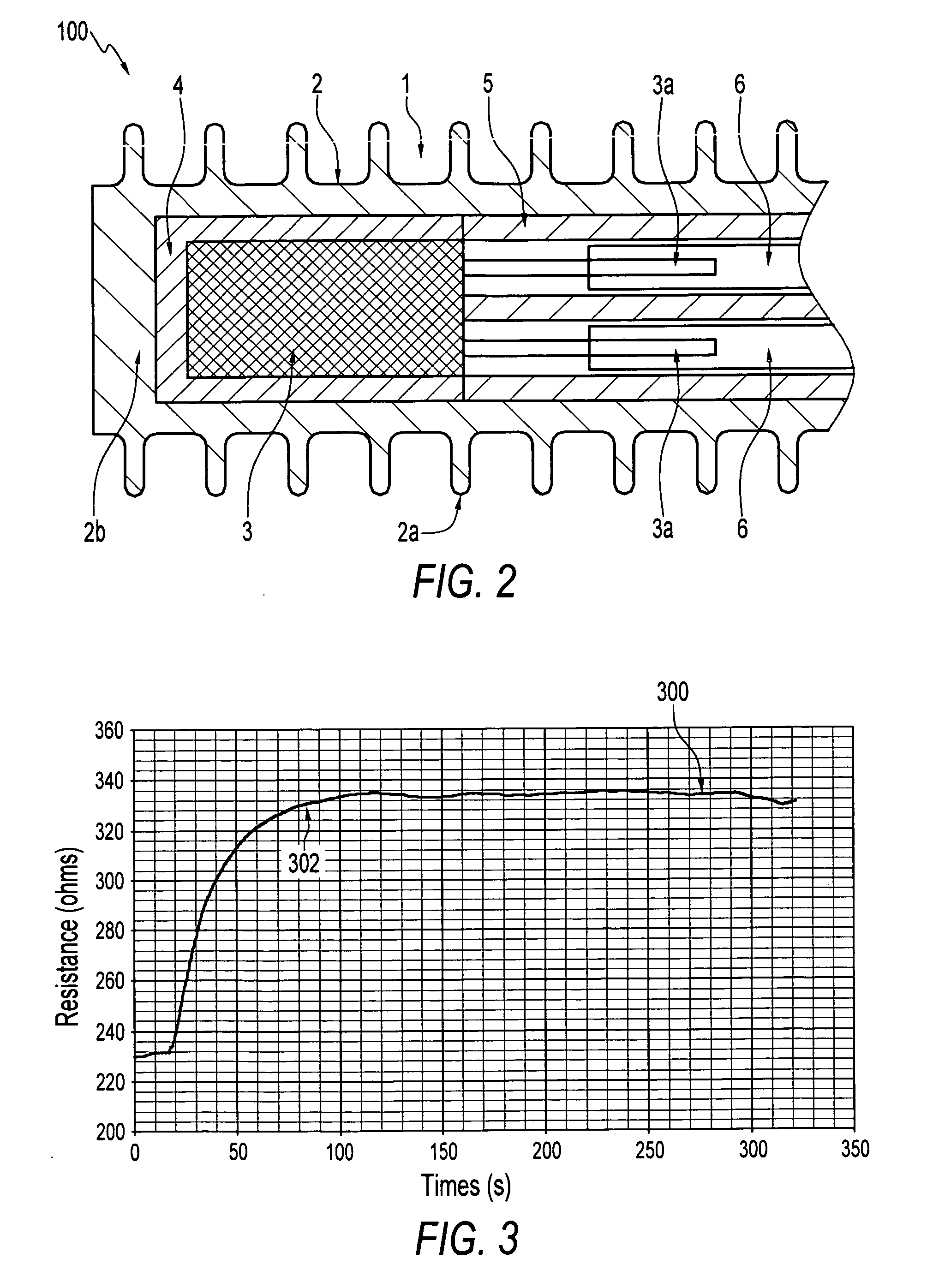

Temperature sensor that achieves a fast response in an exhaust gas environment

InactiveUS20070195857A1Fast response timeImprove accuracyThermometer detailsTemperature measurement in motorsEngineeringConvection heat

A temperature sensor and method of forming the same includes a temperature sensing portion having a metal housing configured with at least one circular fin on a surface of the metal housing. A temperature sensing element is generally associated with the temperature sensing portion, wherein a potting is located within a gap formed between the temperature sensing element and the metal housing and joined with a ceramic tube for carrying a plurality of high temperature metal lead wires to and from the temperature sensing portion, thereby forming a temperature sensor utilized in an exhaust gas environment to measure temperature and improve a response time and accuracy of the temperature sensor due to an increase in surface area of the sensor tip for a given thermal mass for convection heat transfer.

Owner:HONEYWELL INT INC

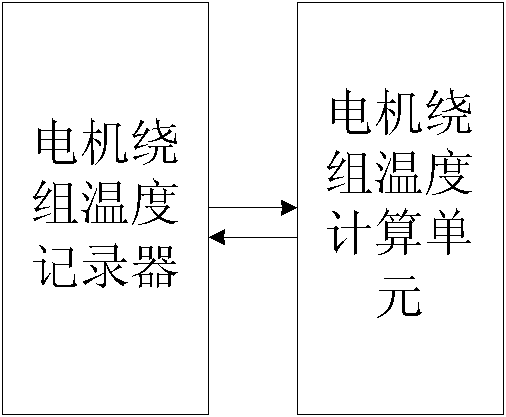

Electric motor, electric motor winding temperature detection method and device as well as electric motor winding thermal protection method and device

ActiveCN102156000ARealize real-time monitoringFully reflect the effect of temperature riseThermometer detailsTemperature measurement in motorsElectric machineEngineering

The invention discloses an electric motor, an electric motor winding temperature detection method and device as well as an electric motor winding thermal protection method and device. The electric motor winding temperature detection method comprises the following steps: acquiring the electric motor winding temperature at the previous moment; then calculating temperature rise of a rotor equivalentbody after operating for one time step; and finally calculating the electric motor winding temperature at the next moment by superimposing the electric motor winding temperature at the previous moment with the temperature rise of the rotor equivalent body after operating for one time step. According to the electric motor winding temperature detection method, the electric motor winding temperatureis monitored in real time; the performance of the electric motor is exerted; and the sensitivity of the electric motor is improved.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

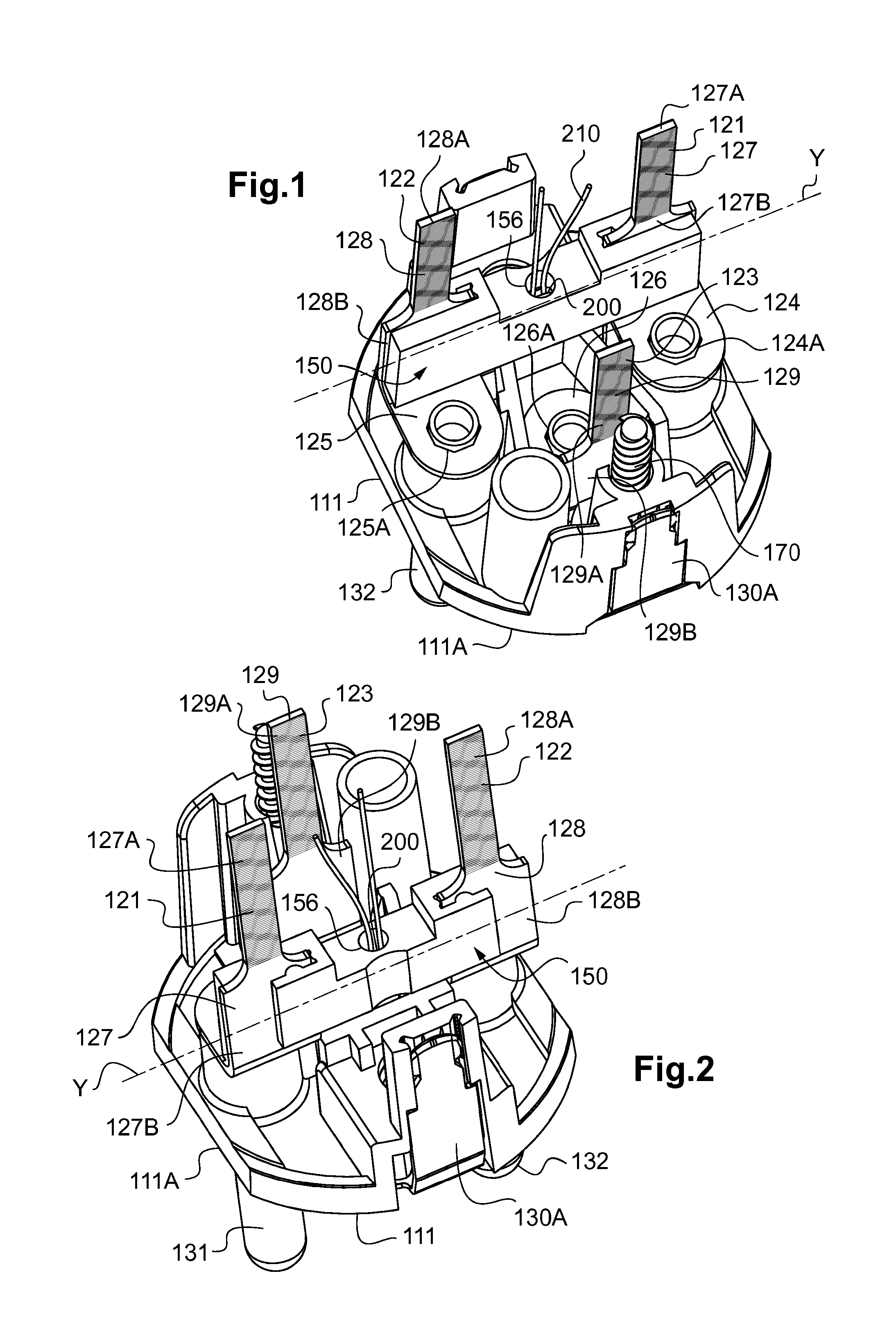

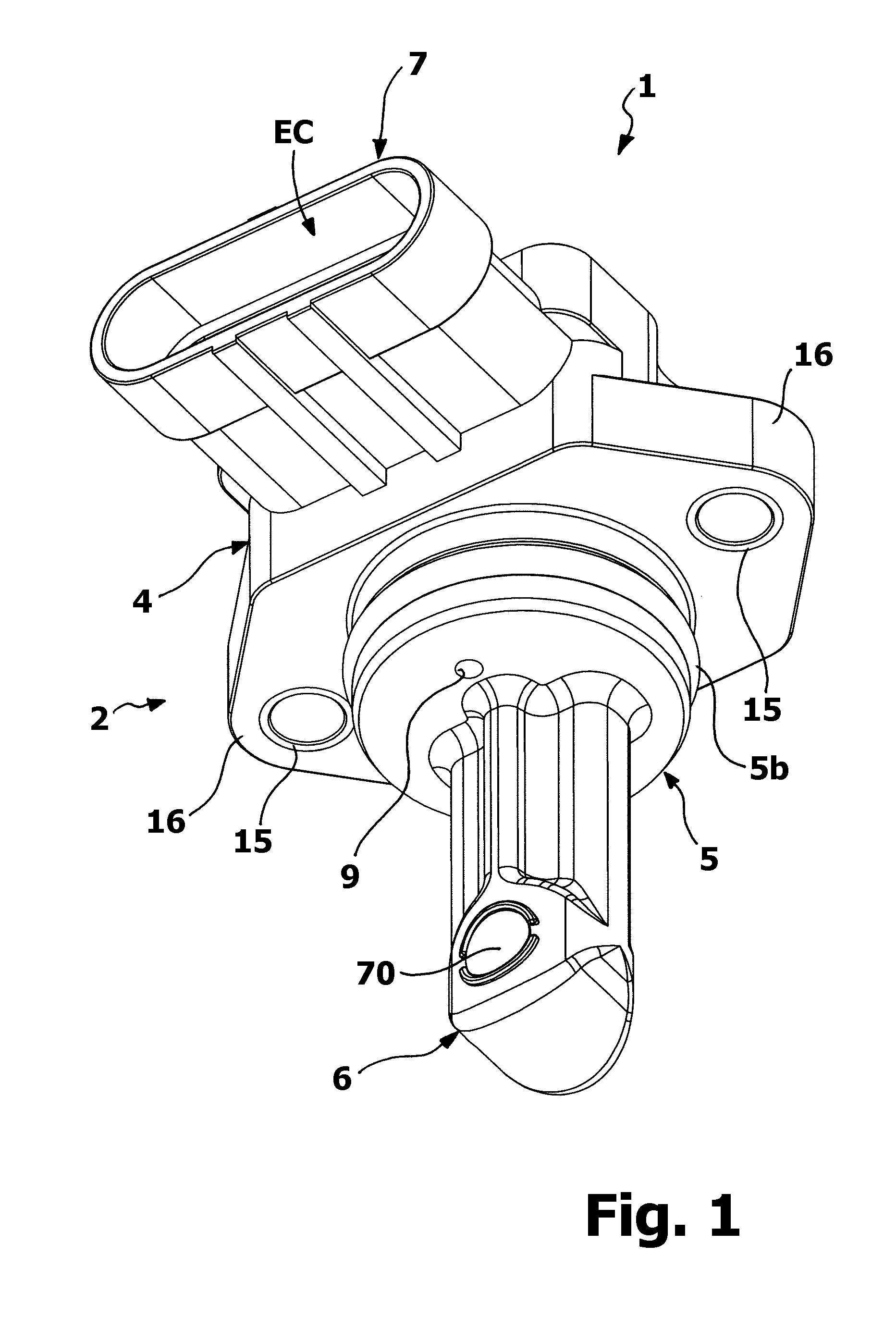

Securing means for a device for detecting the pressure and temperature in the intake tube of an internal combustion engine

A device for detecting the pressure and the temperature in the intake tube of an internal combustion engine, including a temperature sensor, a pressure sensor and a substrate each of which are secured in a housing with as little stress as possible with the pressure sensor secured on a substrate together with an evaluation circuit. The temperature sensor measures precise temperature measurement. In order to introduce a fluid medium that is under pressure, a neck part is secured to the housing and an adapter is joined both to the substrate and to the neck part via adhesive seals that decouple mechanical stress from the pressure and temperature detectors.

Owner:ROBERT BOSCH GMBH

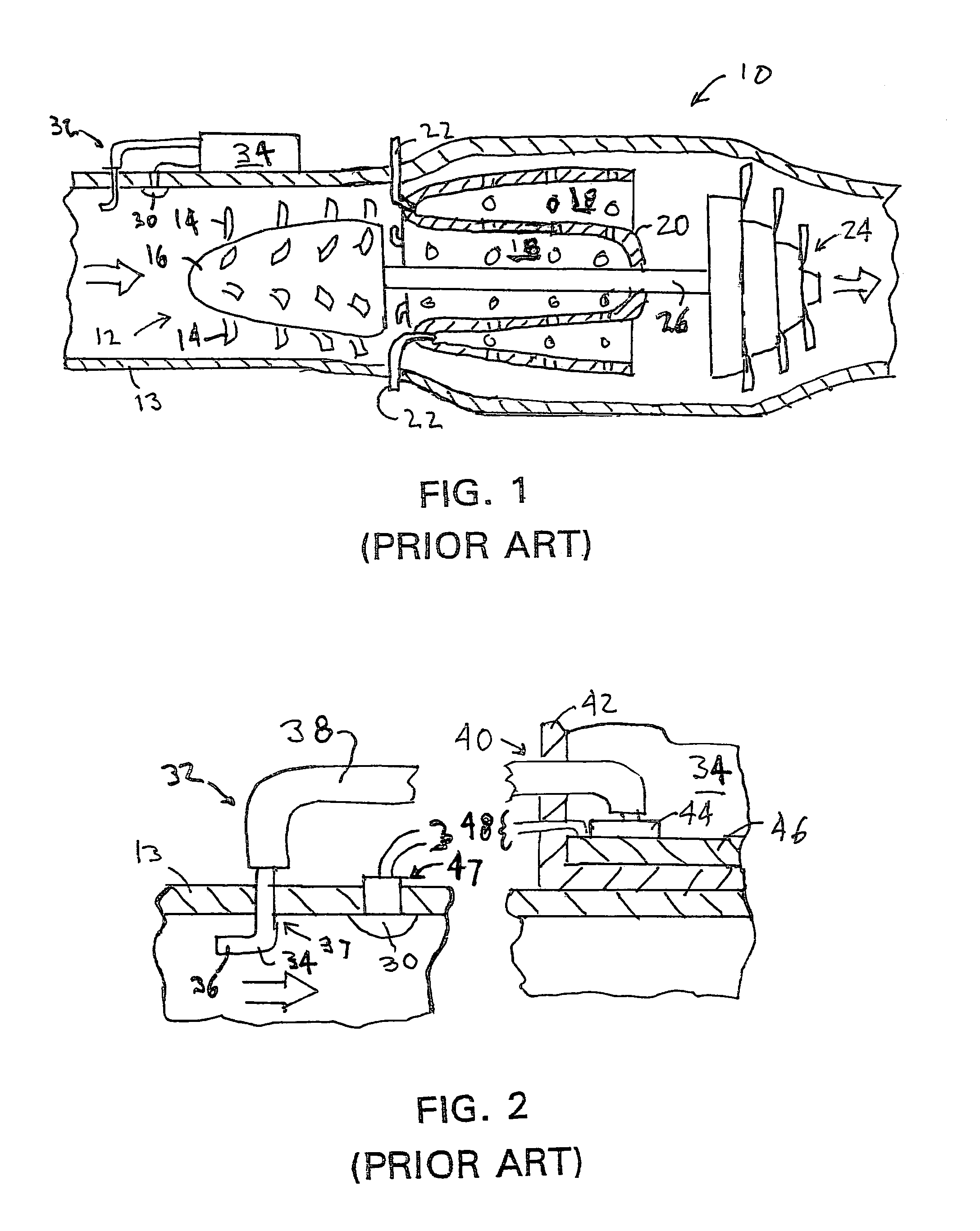

Temperature measurement in a gas turbine engine combustor

InactiveUS20140278200A1Thermometer detailsTemperature measurement in motorsCombustorCombustion chamber

A method and system for determining a temperature of a working gas passing through a passage to a turbine section of a gas turbine engine. The method includes identifying an acoustic frequency at a first location in the engine upstream from the turbine section, and using the acoustic frequency for determining a first temperature value at the first location that is directly proportional to the acoustic frequency and a calculated constant value. A second temperature of the working gas is determined at a second location in the engine and, using the second temperature, a back calculation is performed to determine a temperature value for the working gas at the first location. The first temperature value is compared to the back calculated temperature value to change the calculated constant value to a recalculated constant value. Subsequent first temperature values at the first location may be determined based on the recalculated constant value.

Owner:SIEMENS ENERGY INC

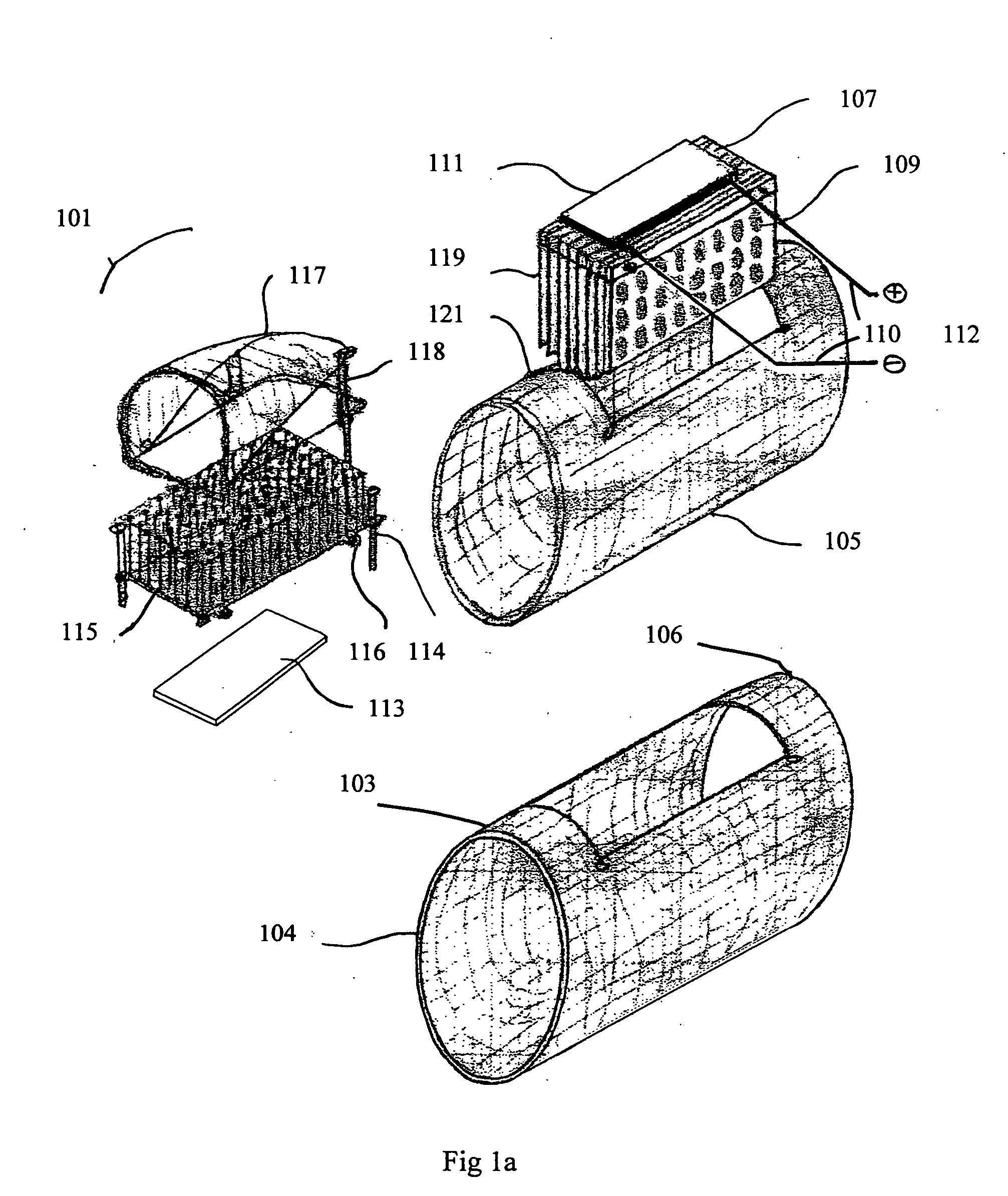

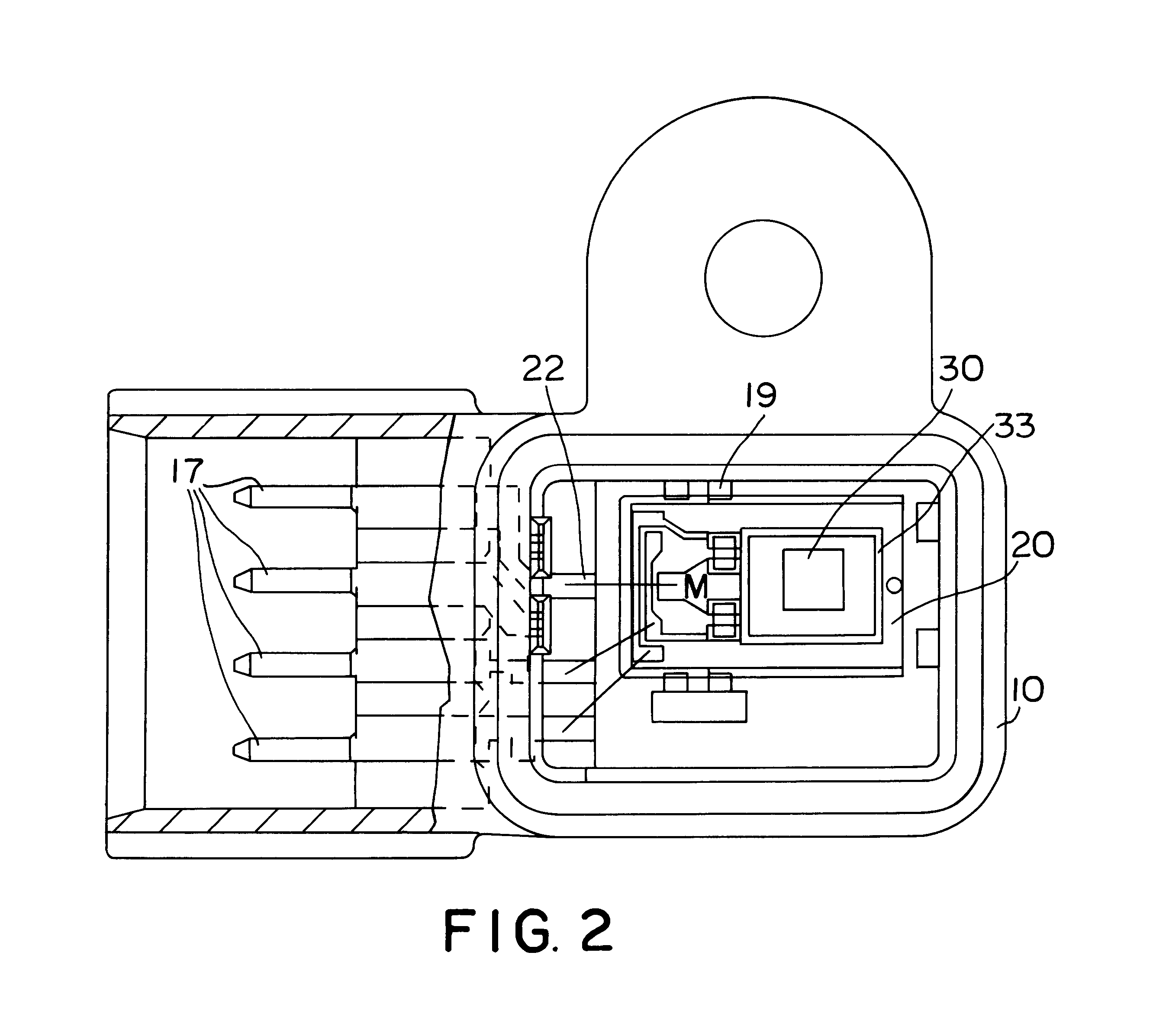

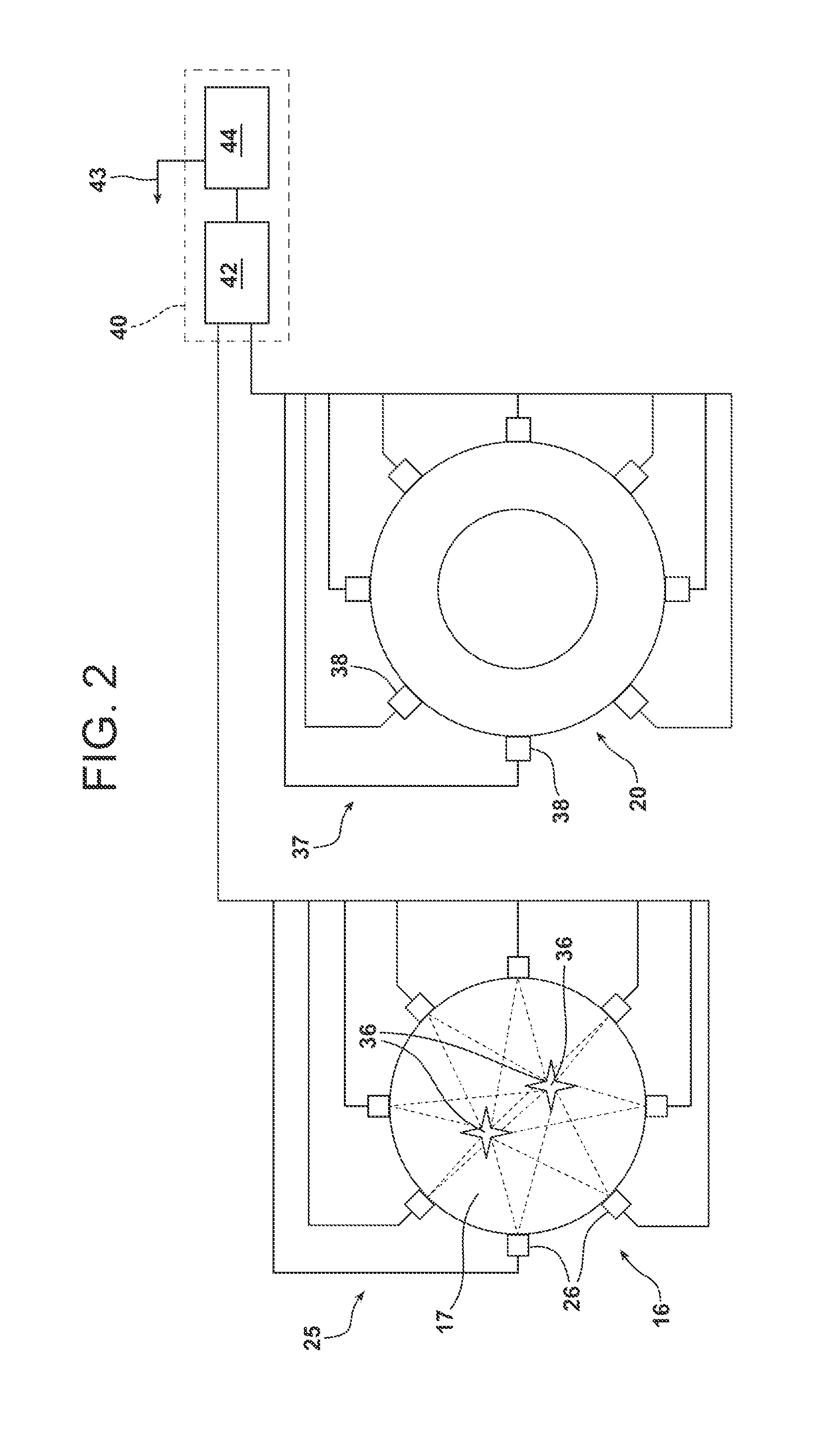

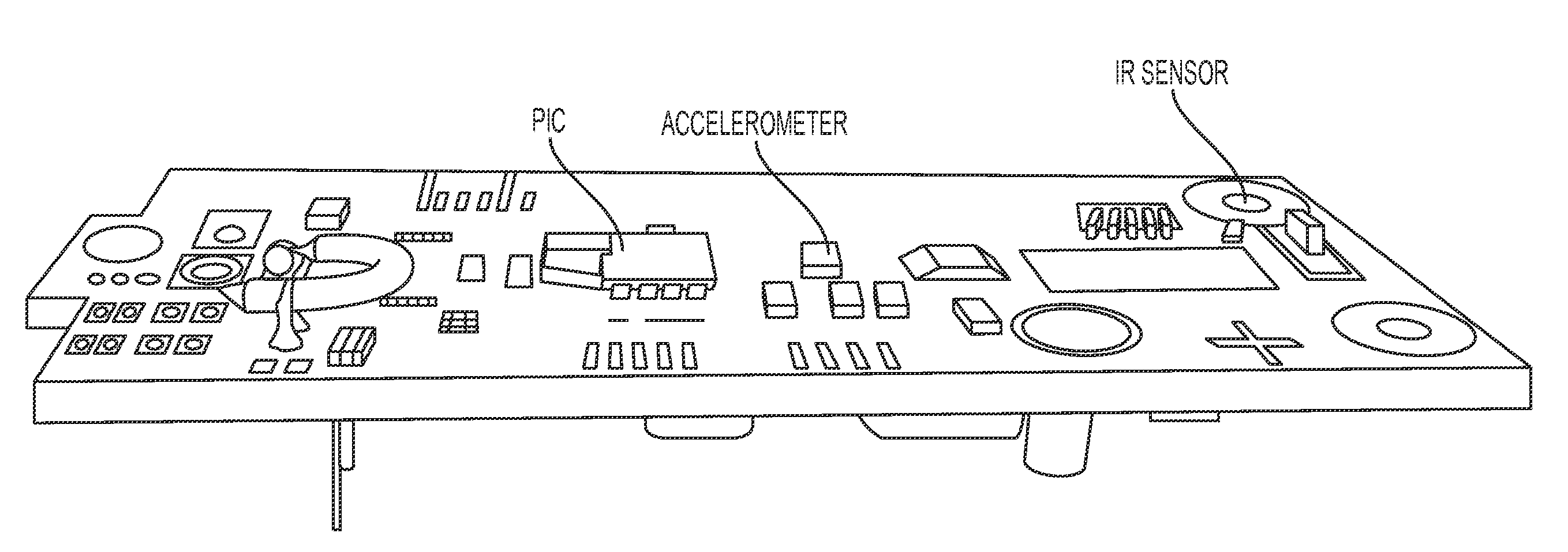

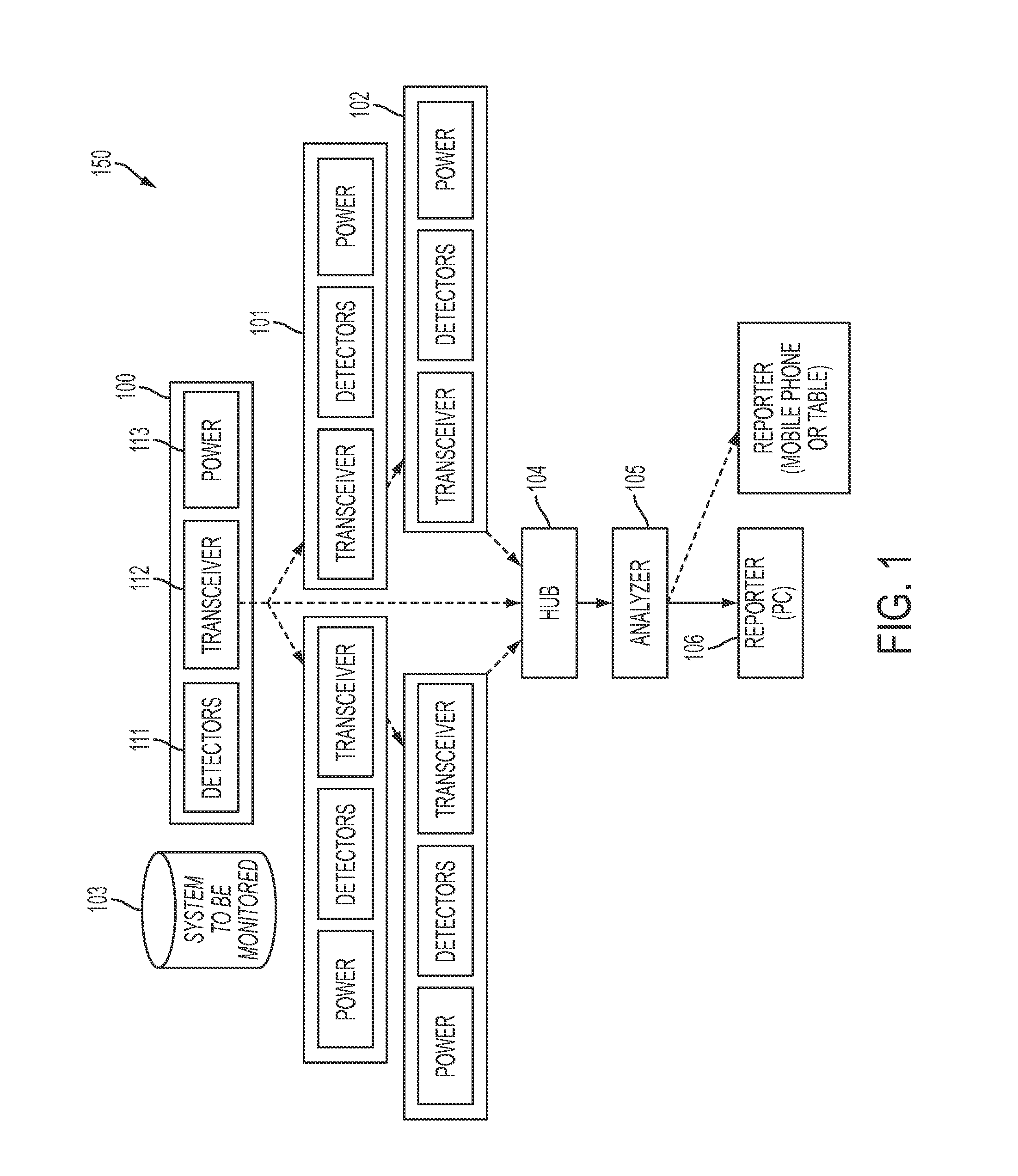

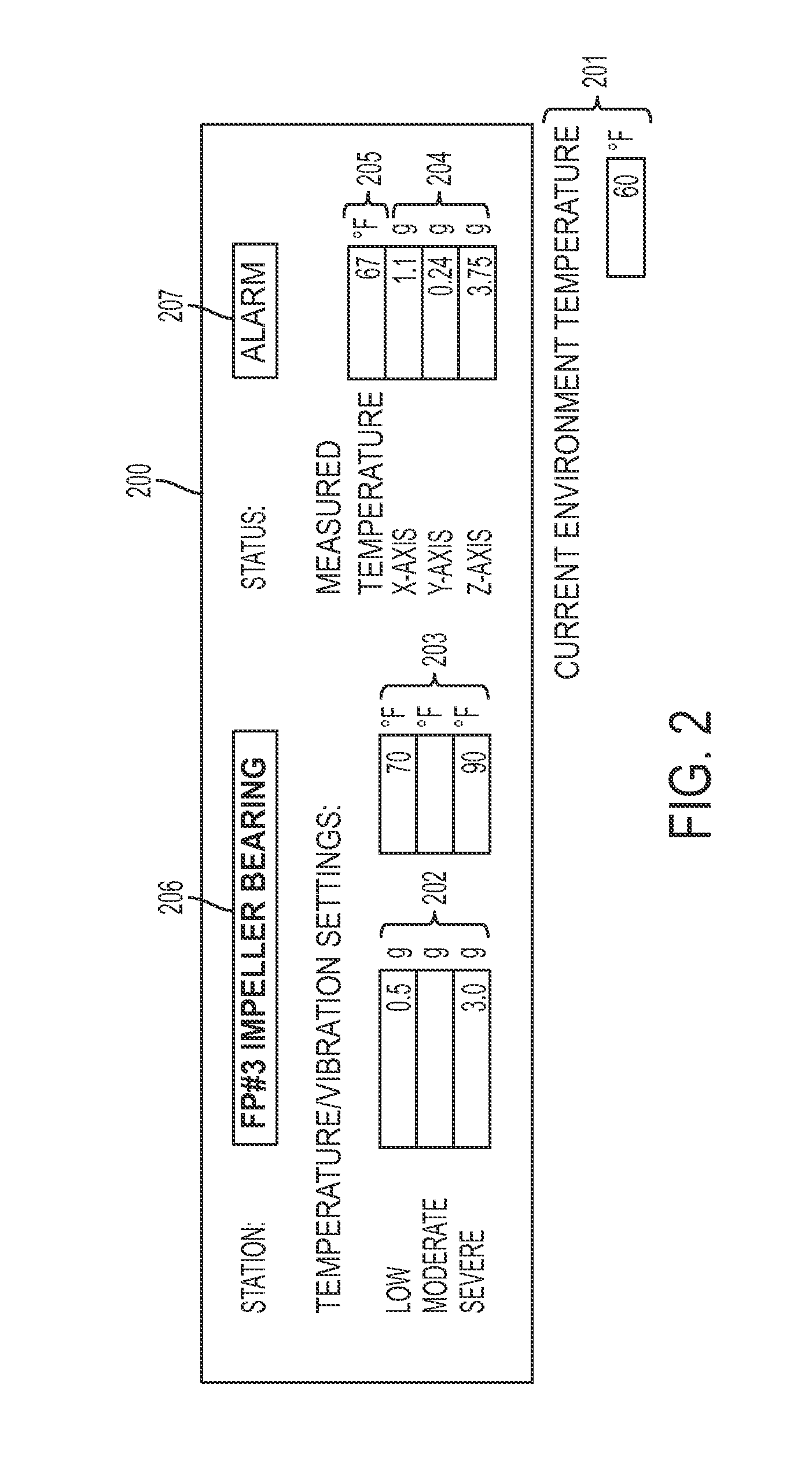

Monitoring systems and methods

A monitoring system includes a plurality of modules to sense temperature and vibrations of a motor assembly, a hub computer to collect the sensed temperature and vibrations, and an analyzer computer to analyze the collected temperature and vibrations. The modules contain detectors that measure a temperature and vibrations in three axes of the motor assembly, a transceiver integrated circuit that measures a die temperature of the transceiver integrated circuit, a microcontroller integrated circuit that self-adjusts its clock pulses, and a memory that stores parameters set for the operation of the modules. The microcontroller integrated circuit and the memory are configured to check parameters corruption upon transferring the parameters from the memory to the microcontroller integrated circuit and prior to utilizing by the microcontroller integrated circuit. The modules further have an enclosure that is compact in size and that can withstand severe industrial environment.

Owner:TDG AEROSPACE

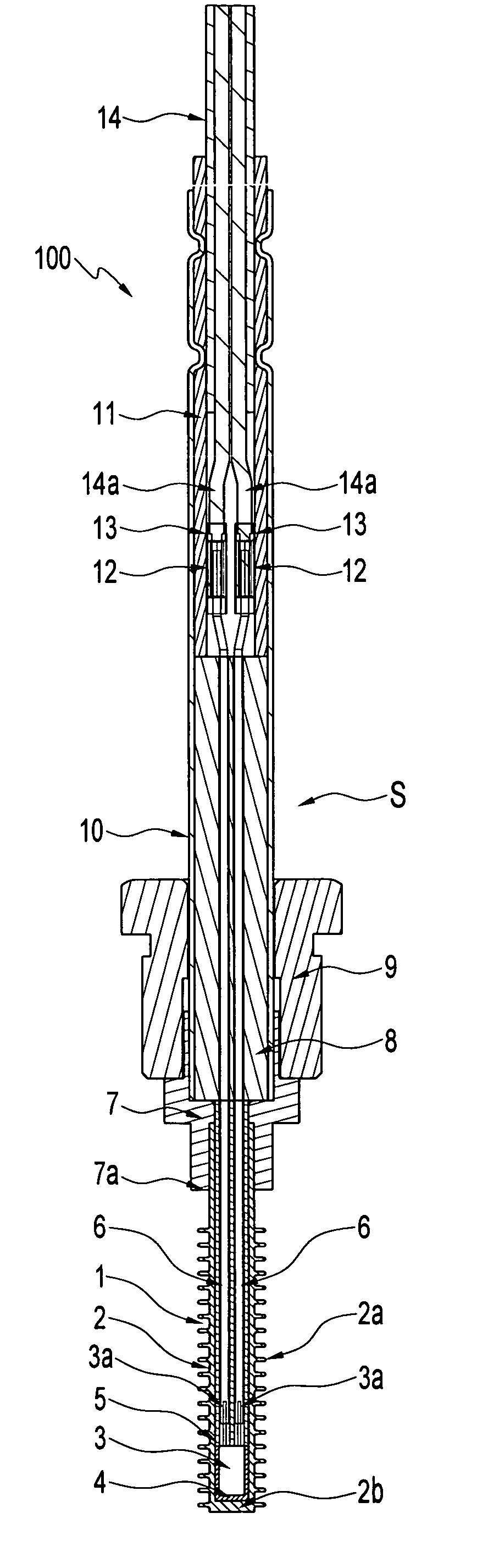

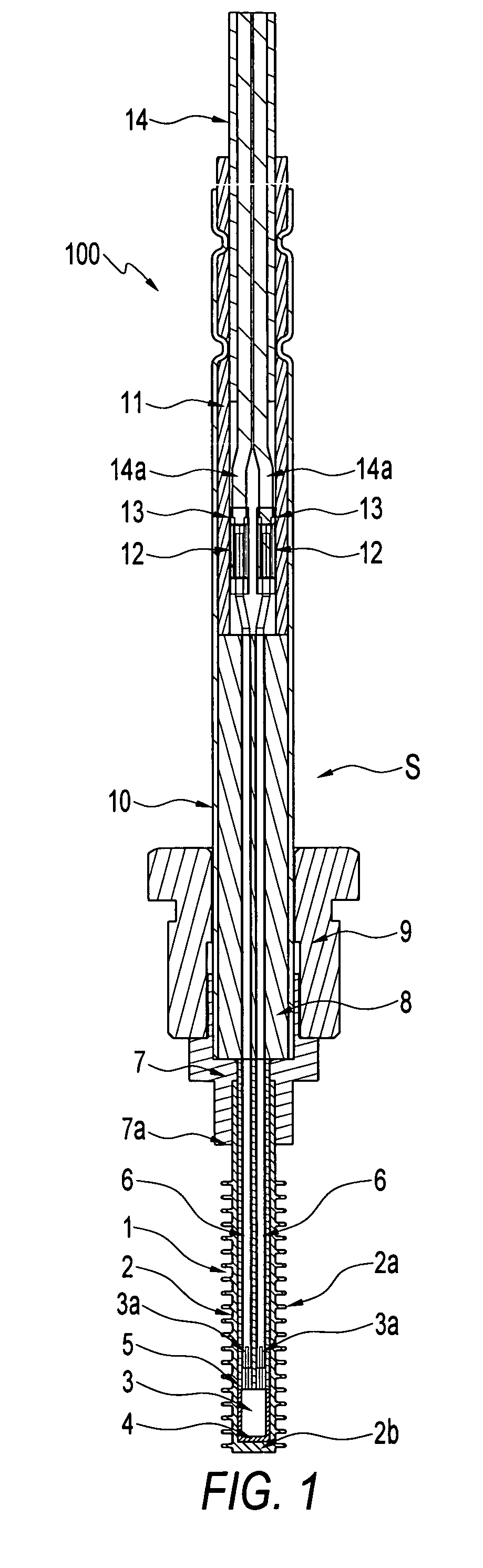

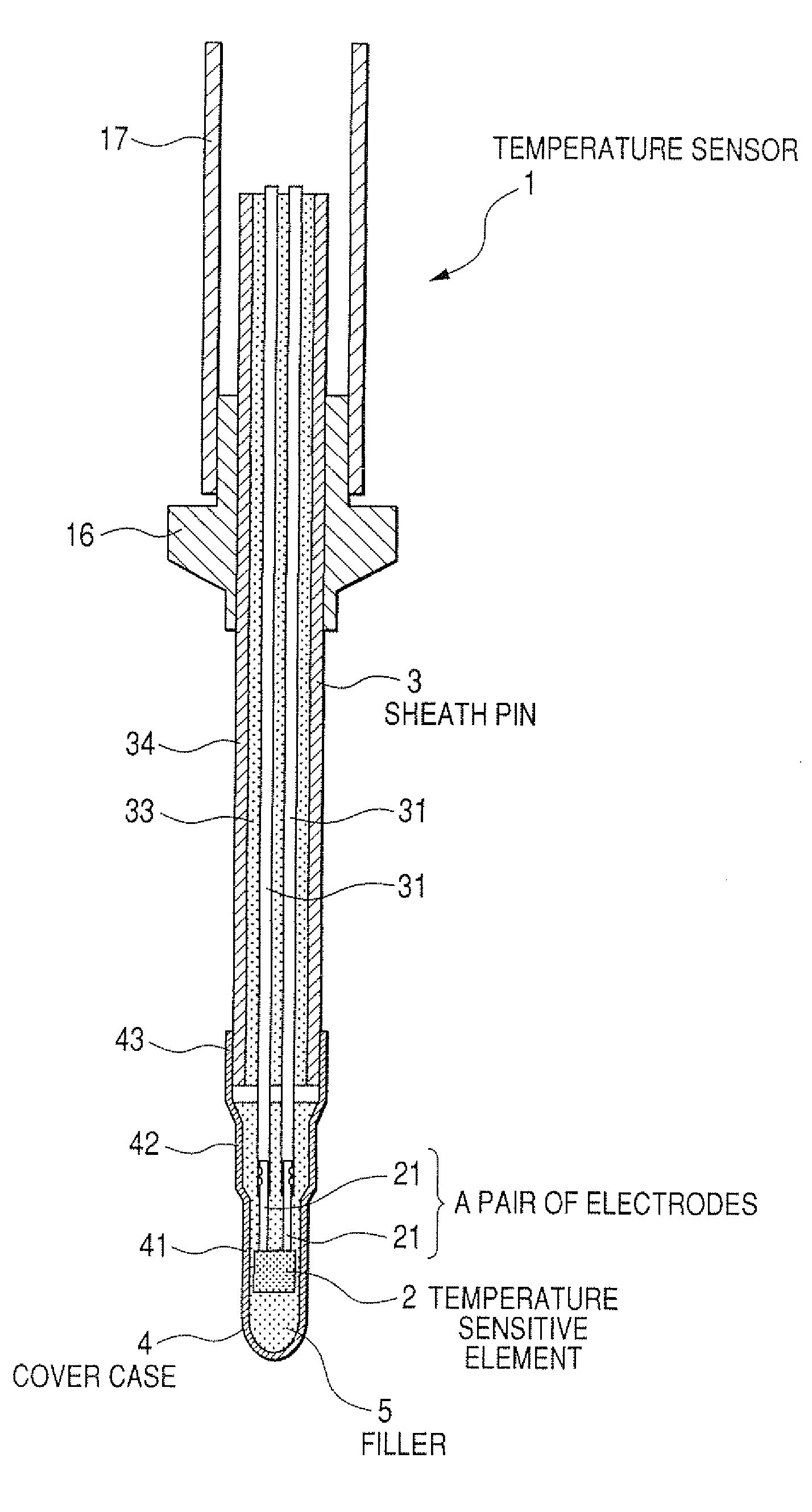

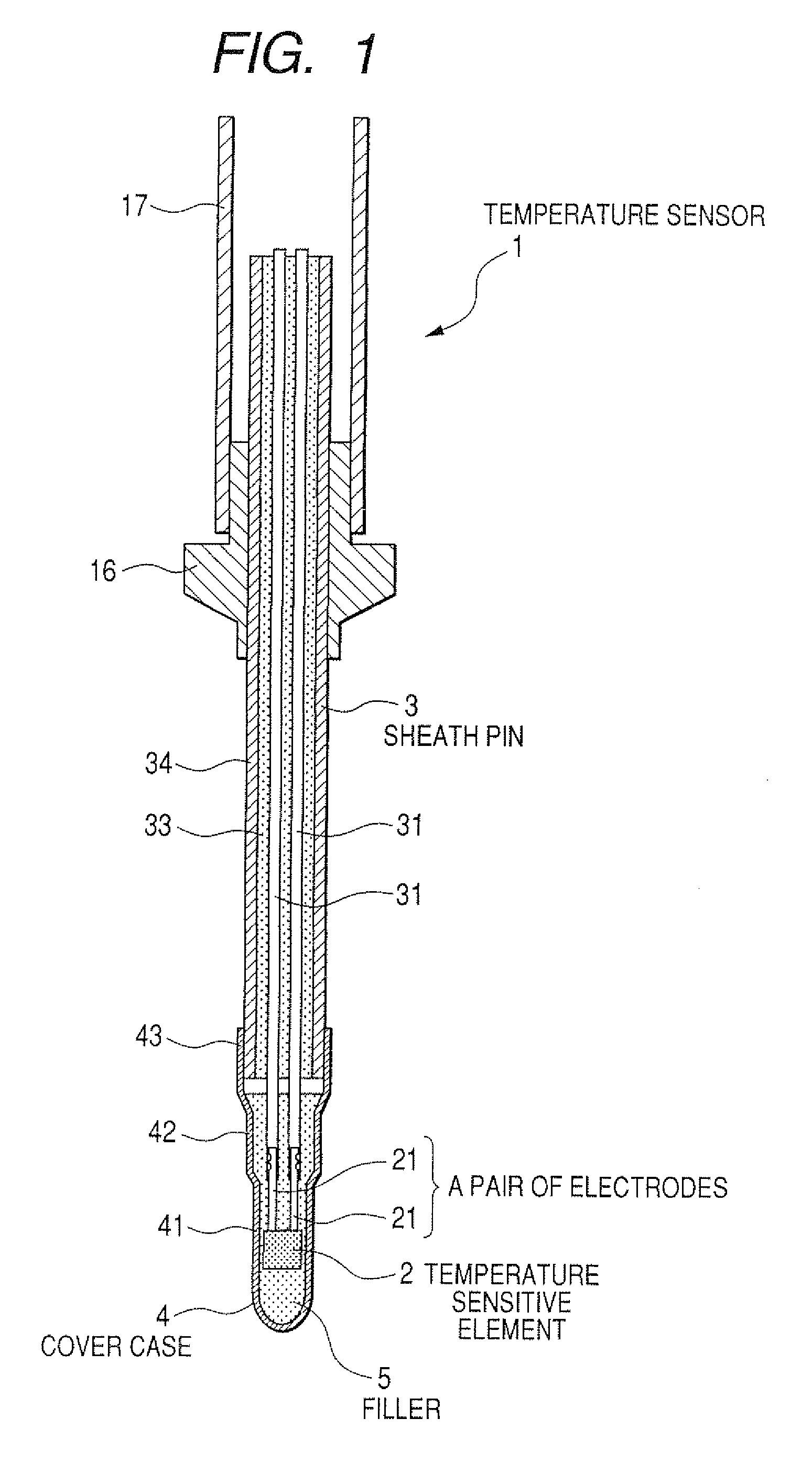

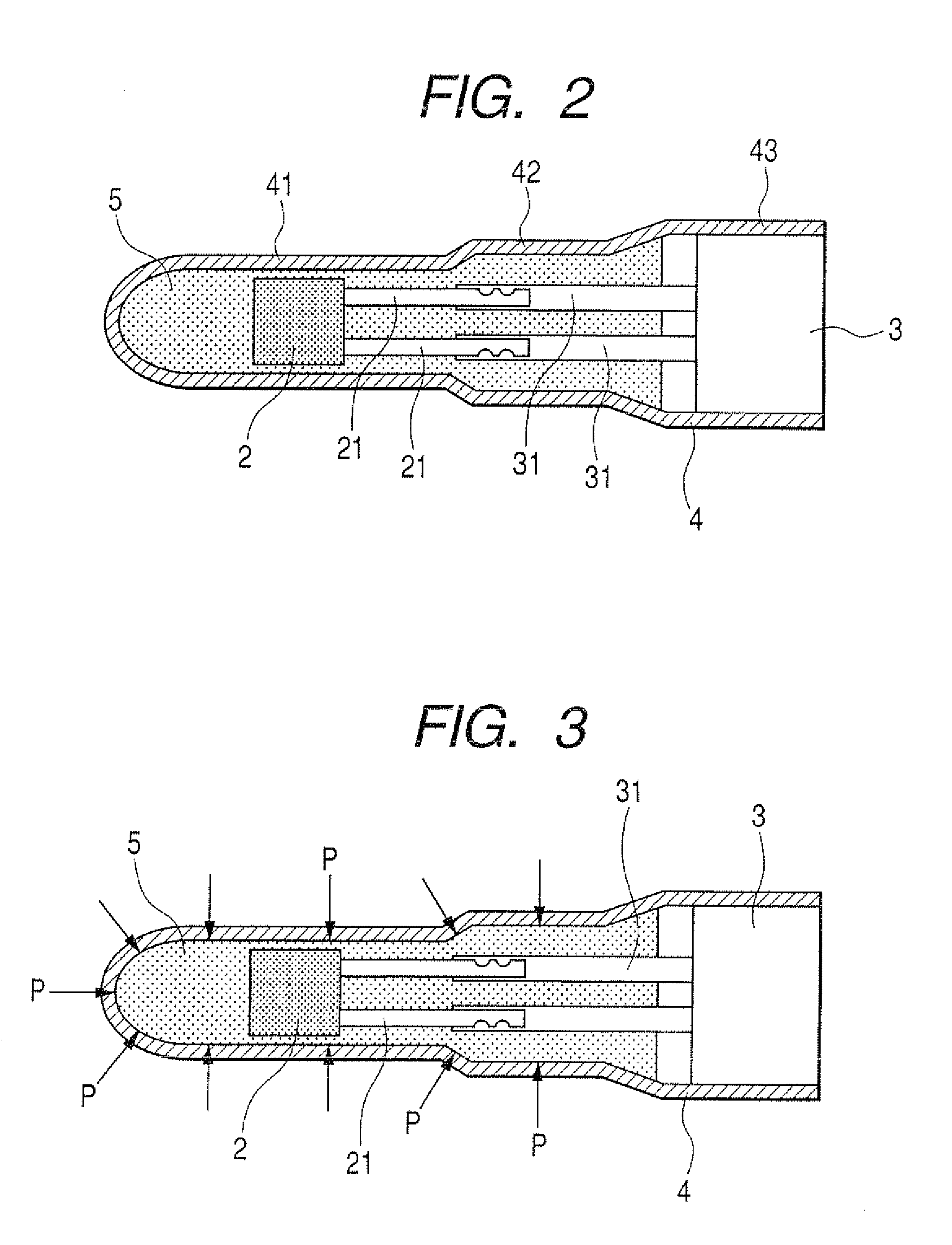

Temperature sensor and method of producing the temperature sensor

ActiveUS20080205484A1Avoid breakingImprove breathabilityThermometer detailsLine/current collector detailsPorosityElectrical resistance and conductance

In a temperature sensor having a temperature sensitive element, a sheath pin connected to the temperature sensitive element, and a cover case. The cover case, filled with a filler, accommodates the temperature sensitive element and the sheath pin. A hardening temperature of the filler is not less than an actual usage environment of the temperature sensor. Another temperature sensor has a temperature sensitive element exposed at a high temperature of not less than 750° C., a thermistor element, a sheath pin, an anti-vibration filler, and a metal cover case fixed to an end part of the sheath pin. The metal cover case accommodates the sheath pin and the thermistor element. The filler is made of a porous insulation material having a pore ratio within a range of 30 to 70% and filled around the thermistor element in the metal cover case.

Owner:DENSO CORP

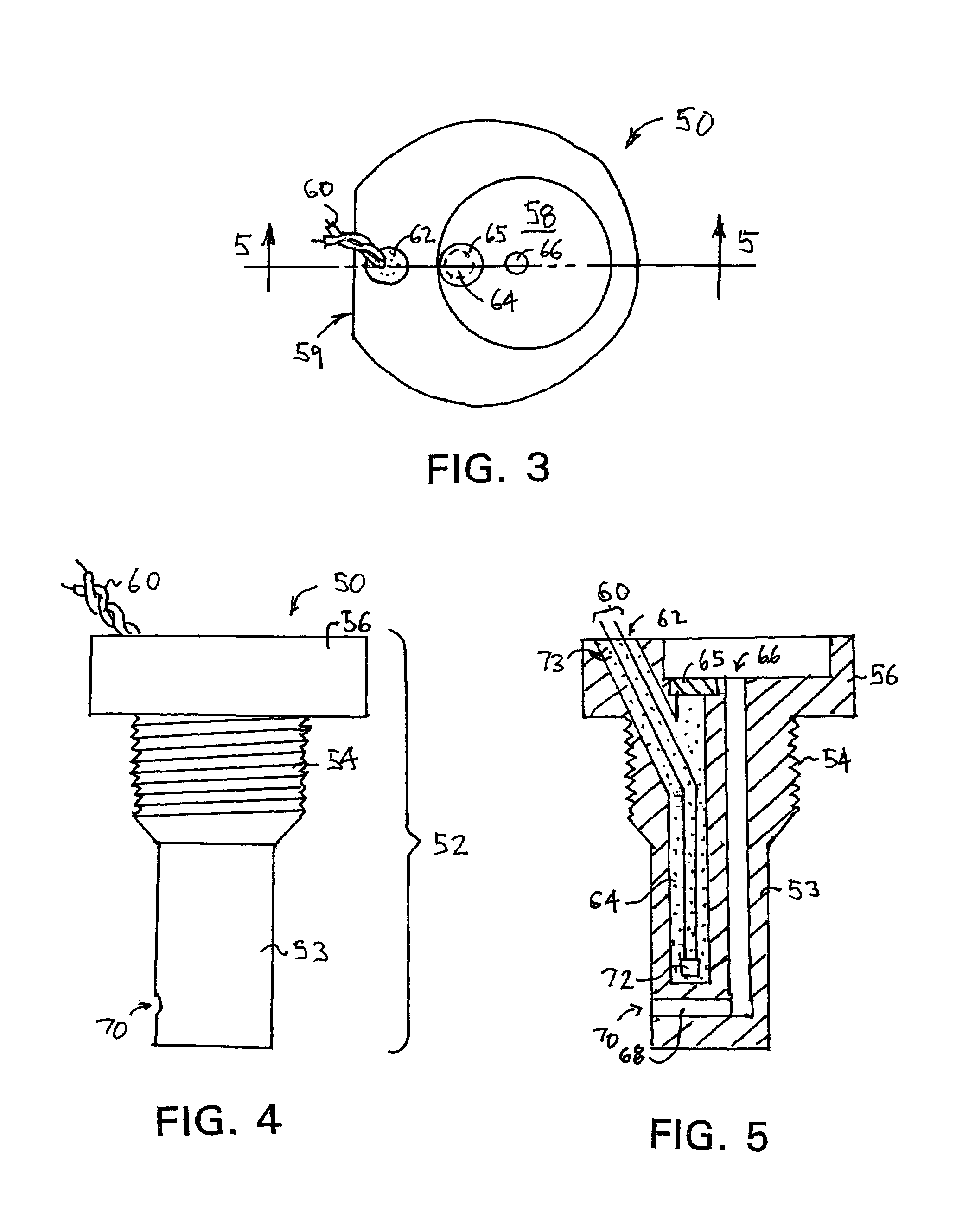

Combined temperature and pressure probe for a gas turbine engine

A probe that includes both a temperature transducer and a pressure sensing port is adapted to be mounted upon and extend into the intake housing of a gas turbine engine. The probe is operative to provide air temperature and pressure data to an engine controller for the gas turbine engine.

Owner:SWONGER JR KARL WILLIAM

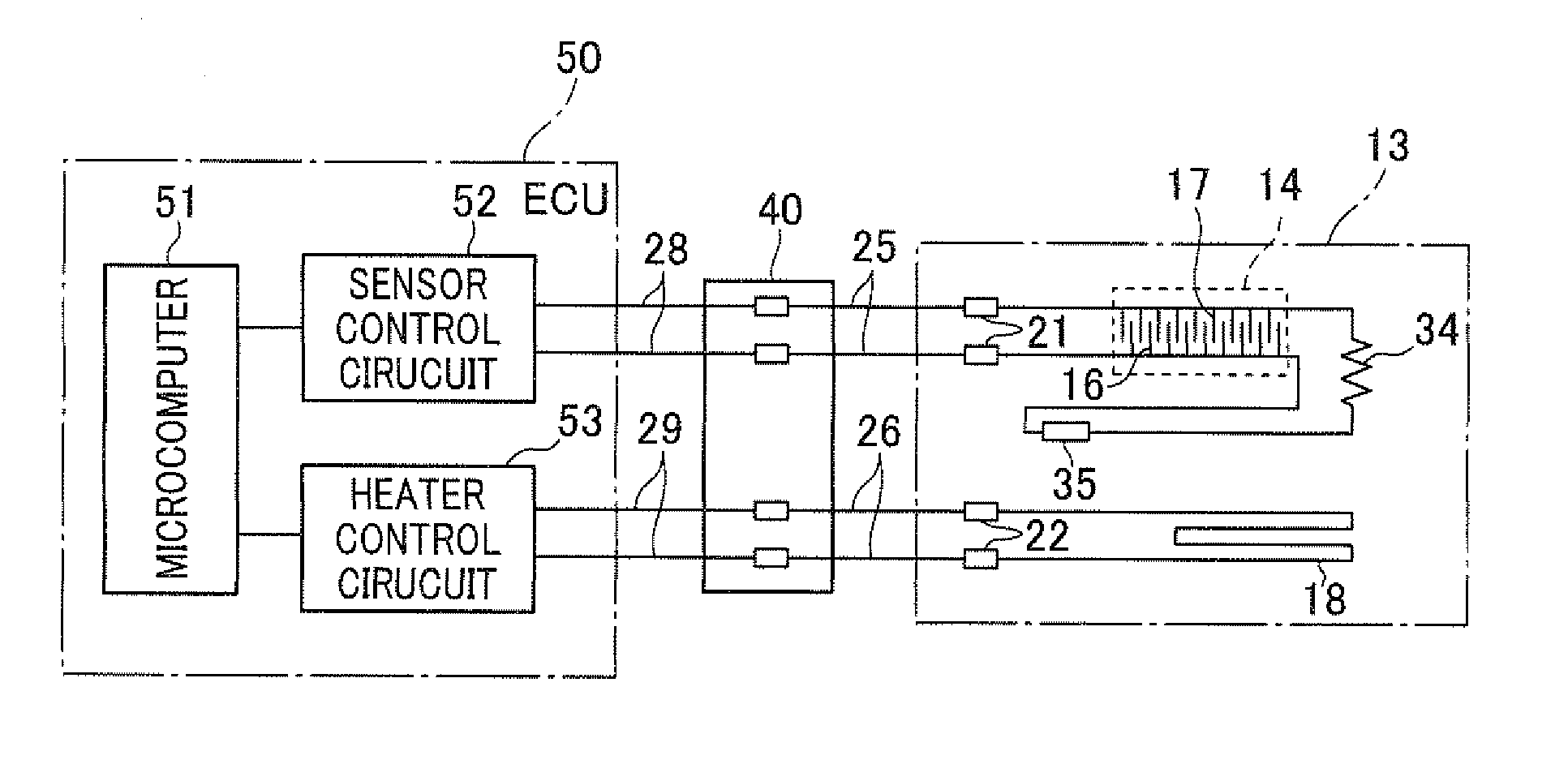

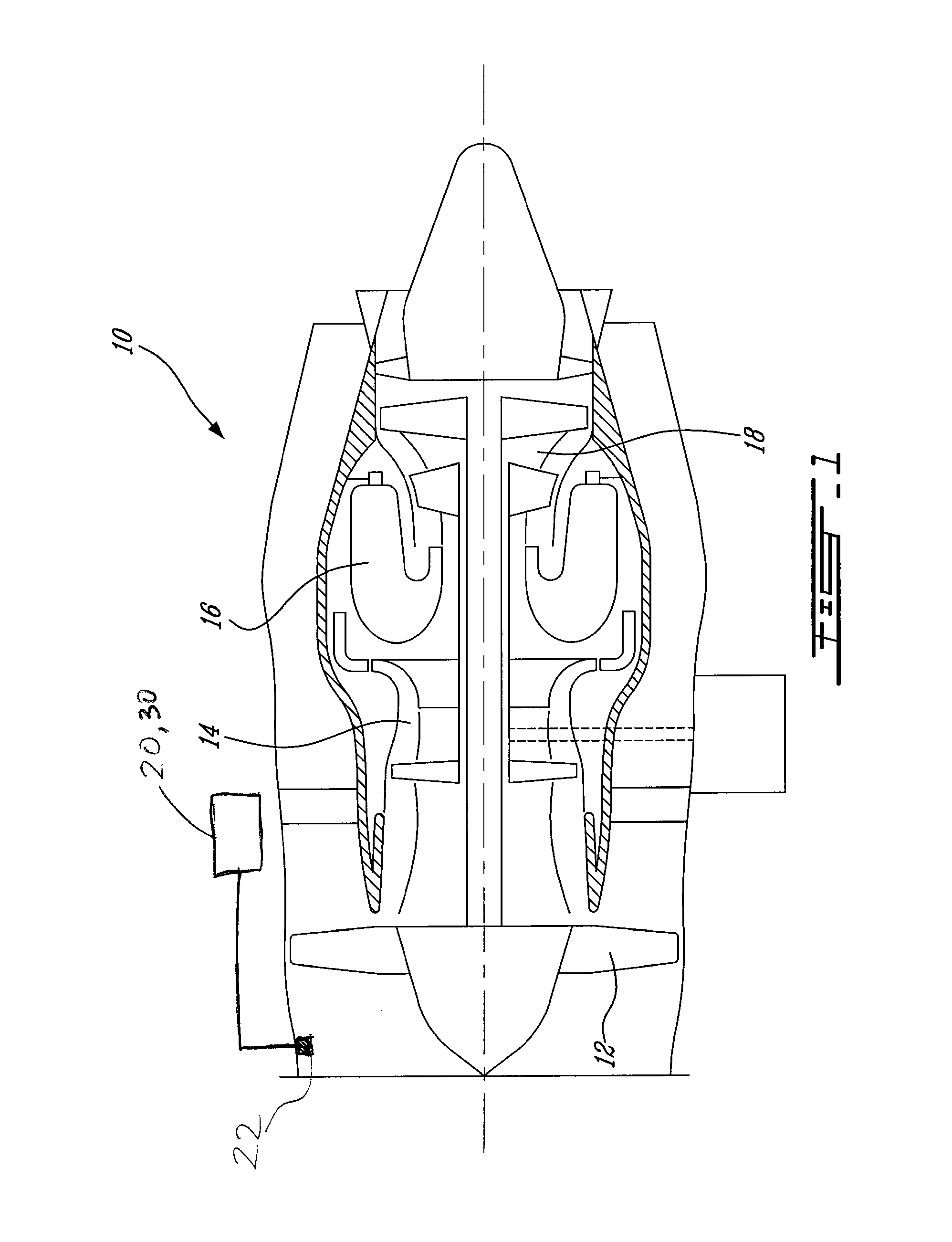

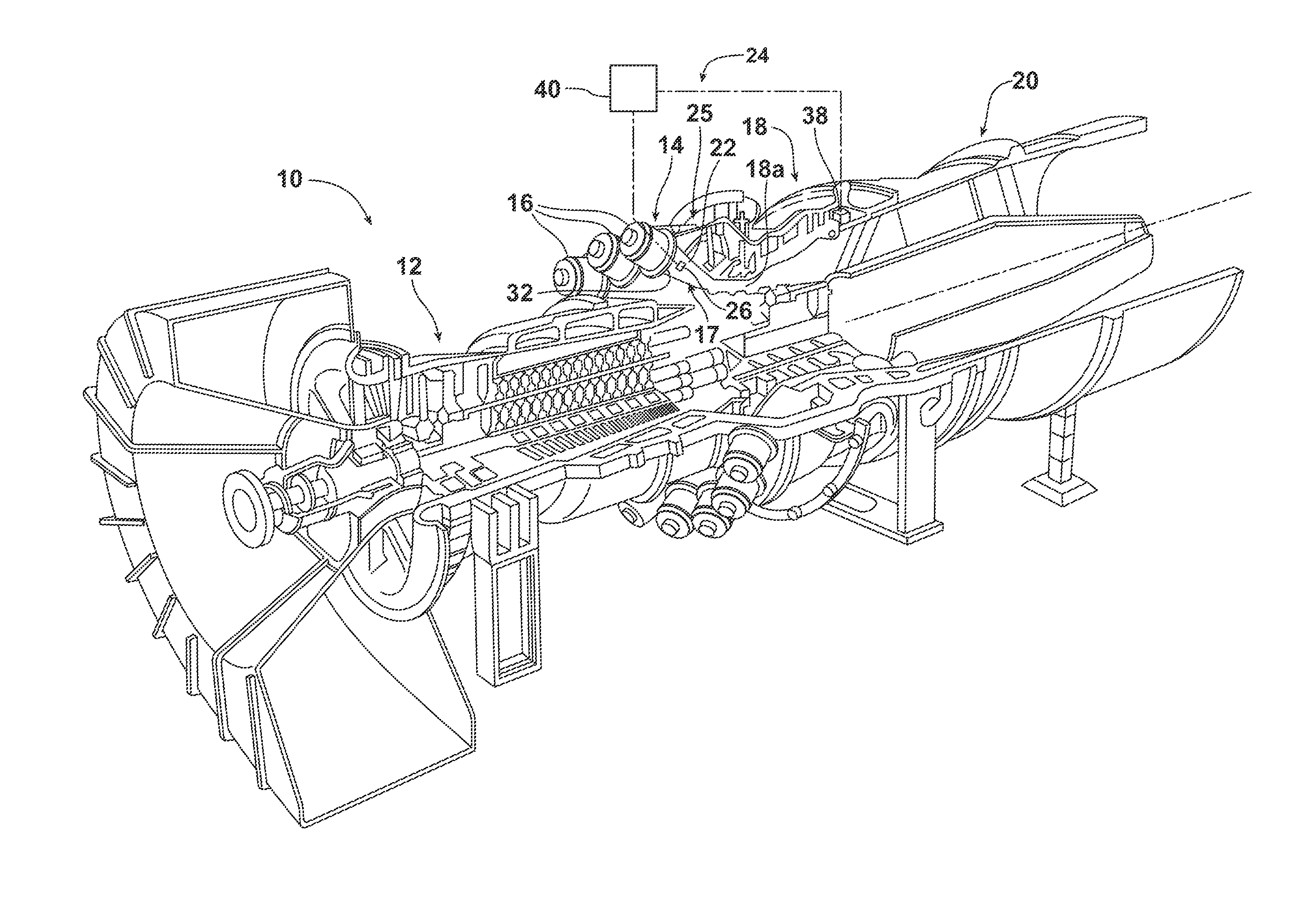

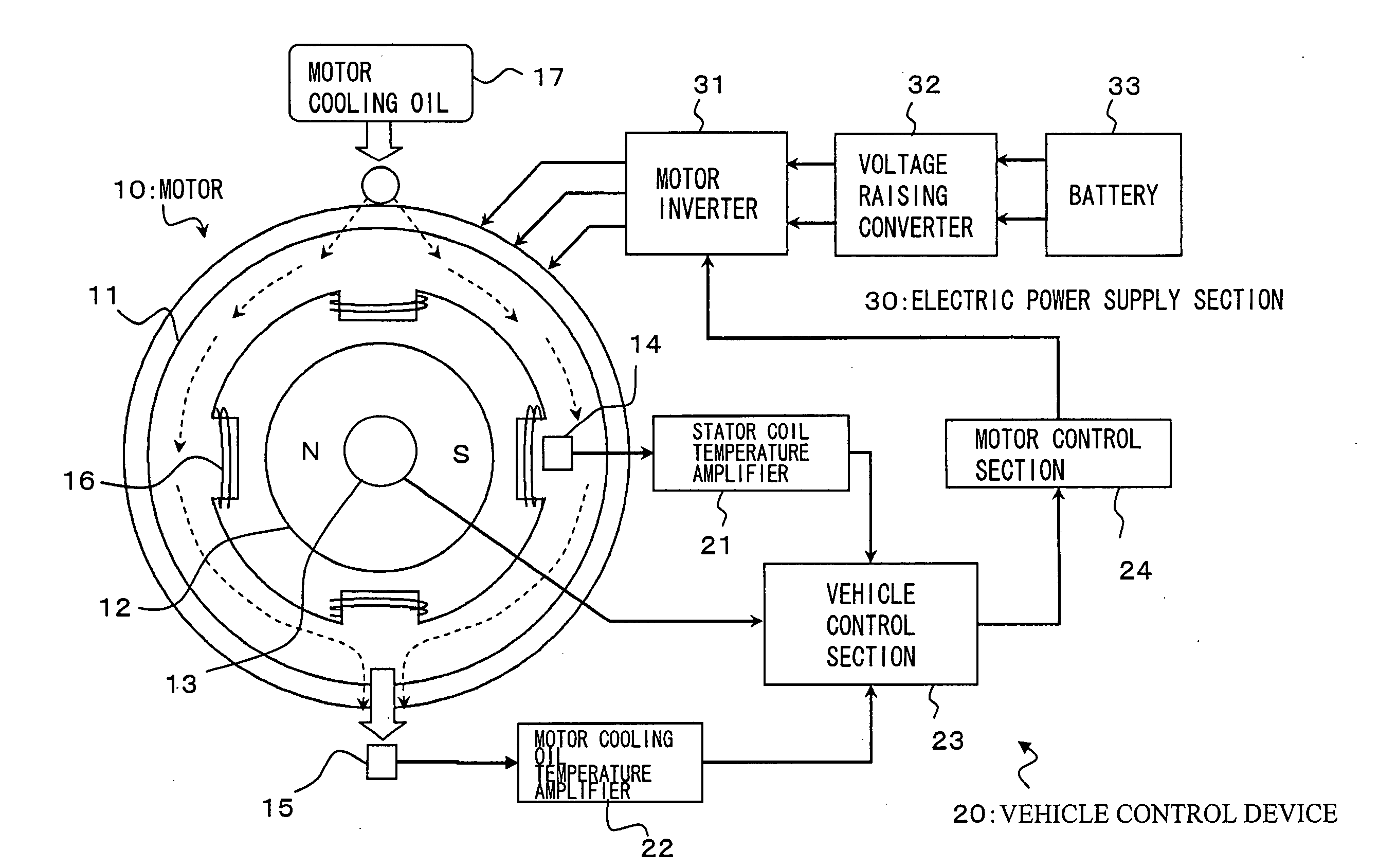

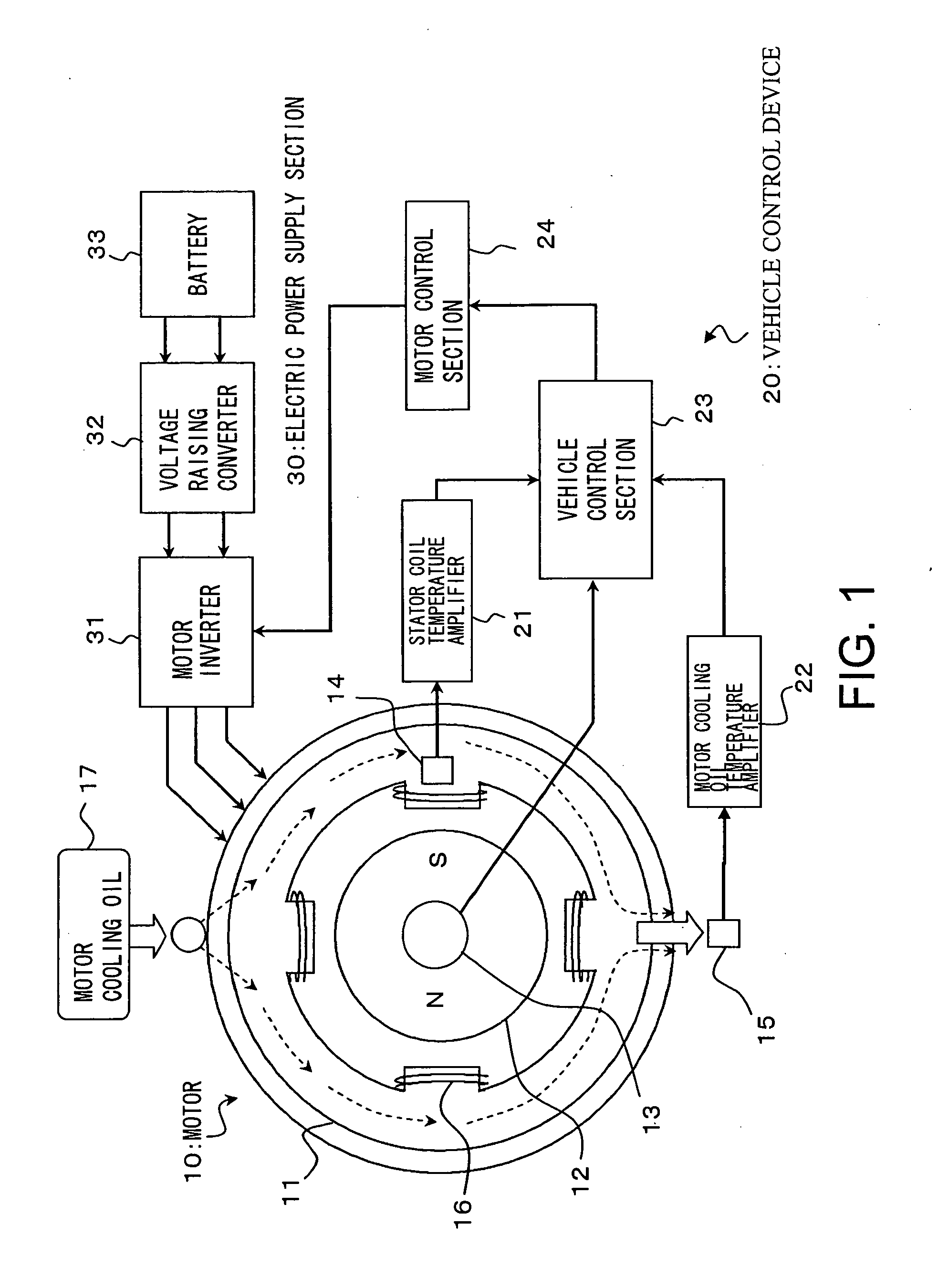

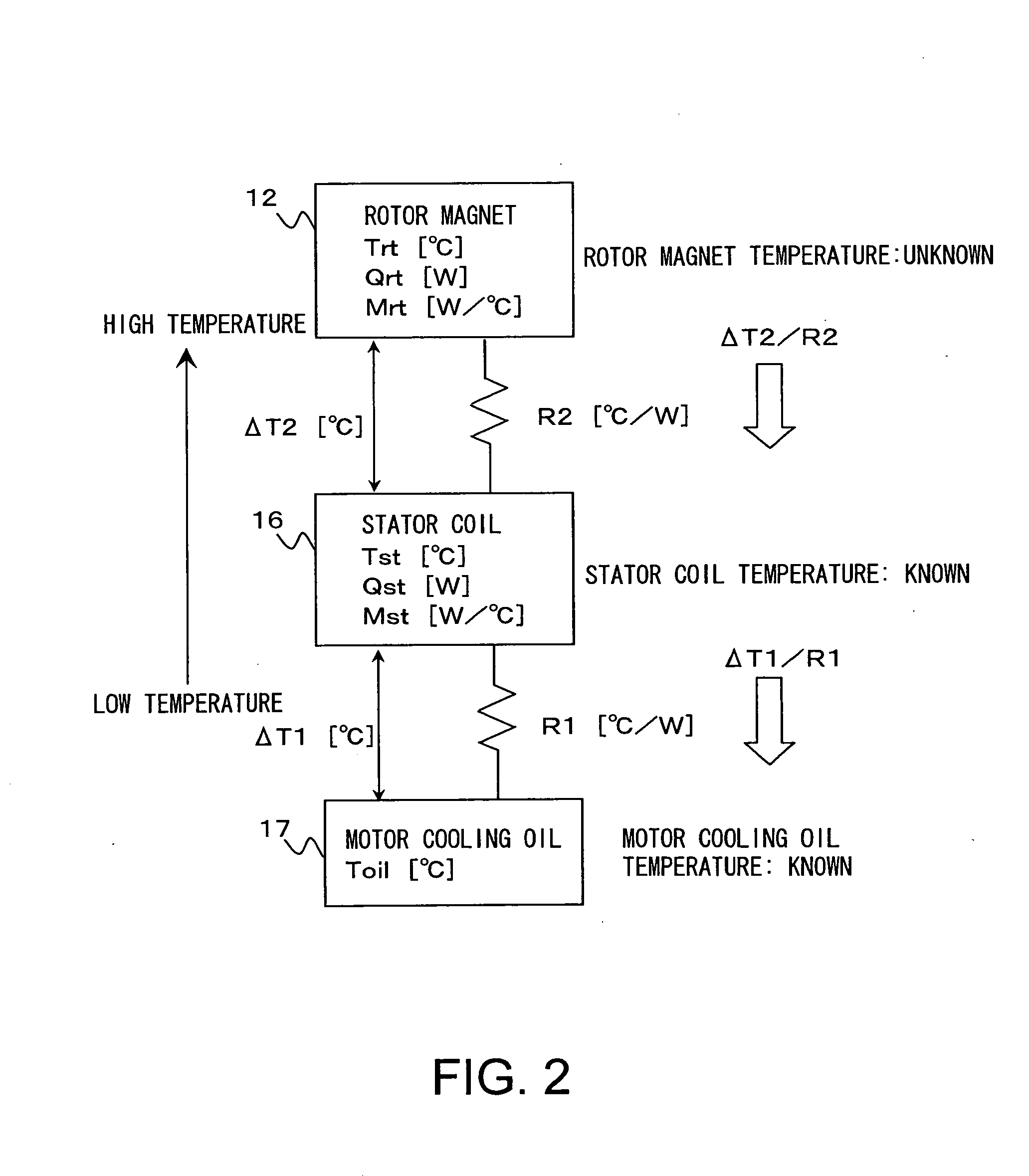

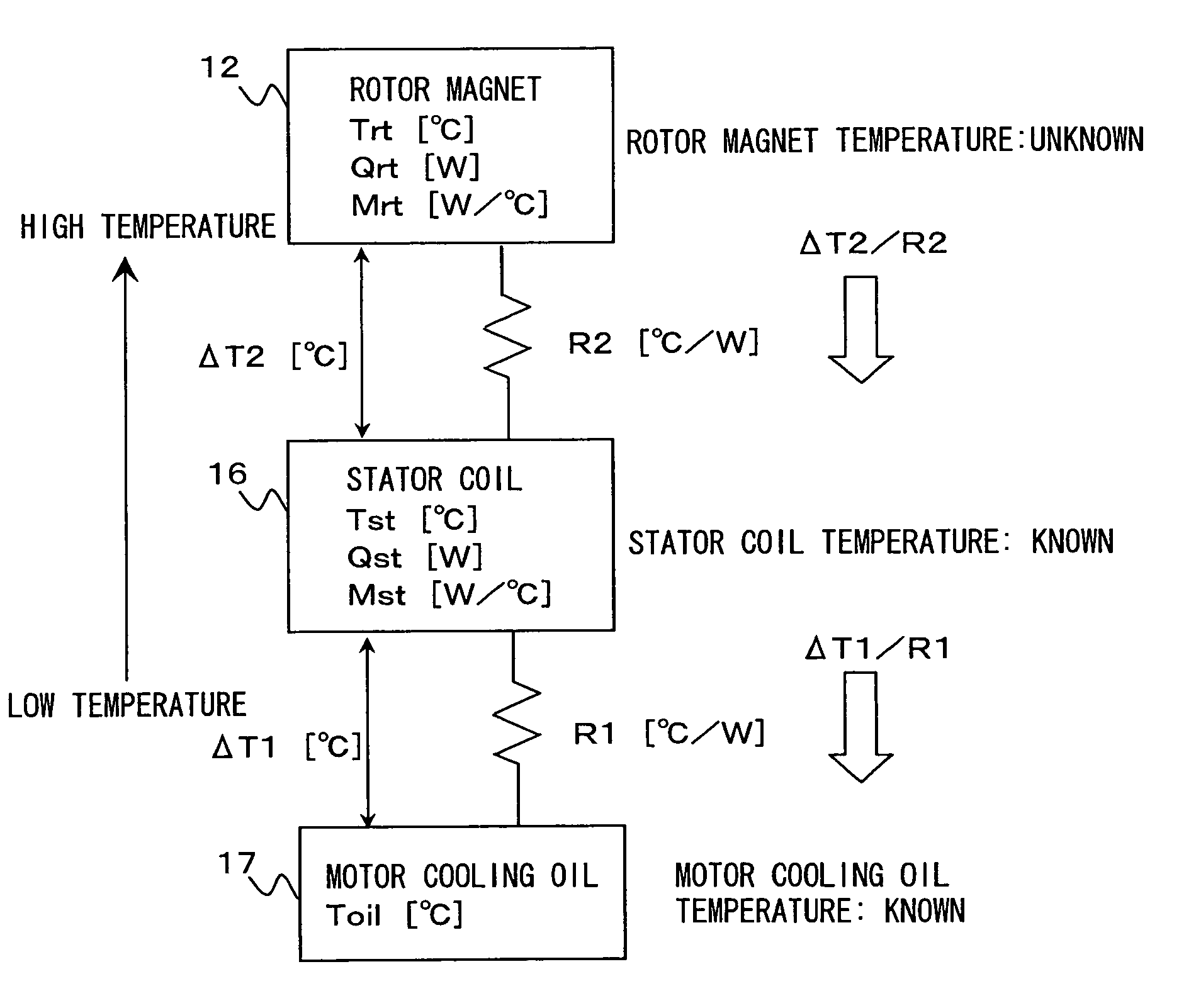

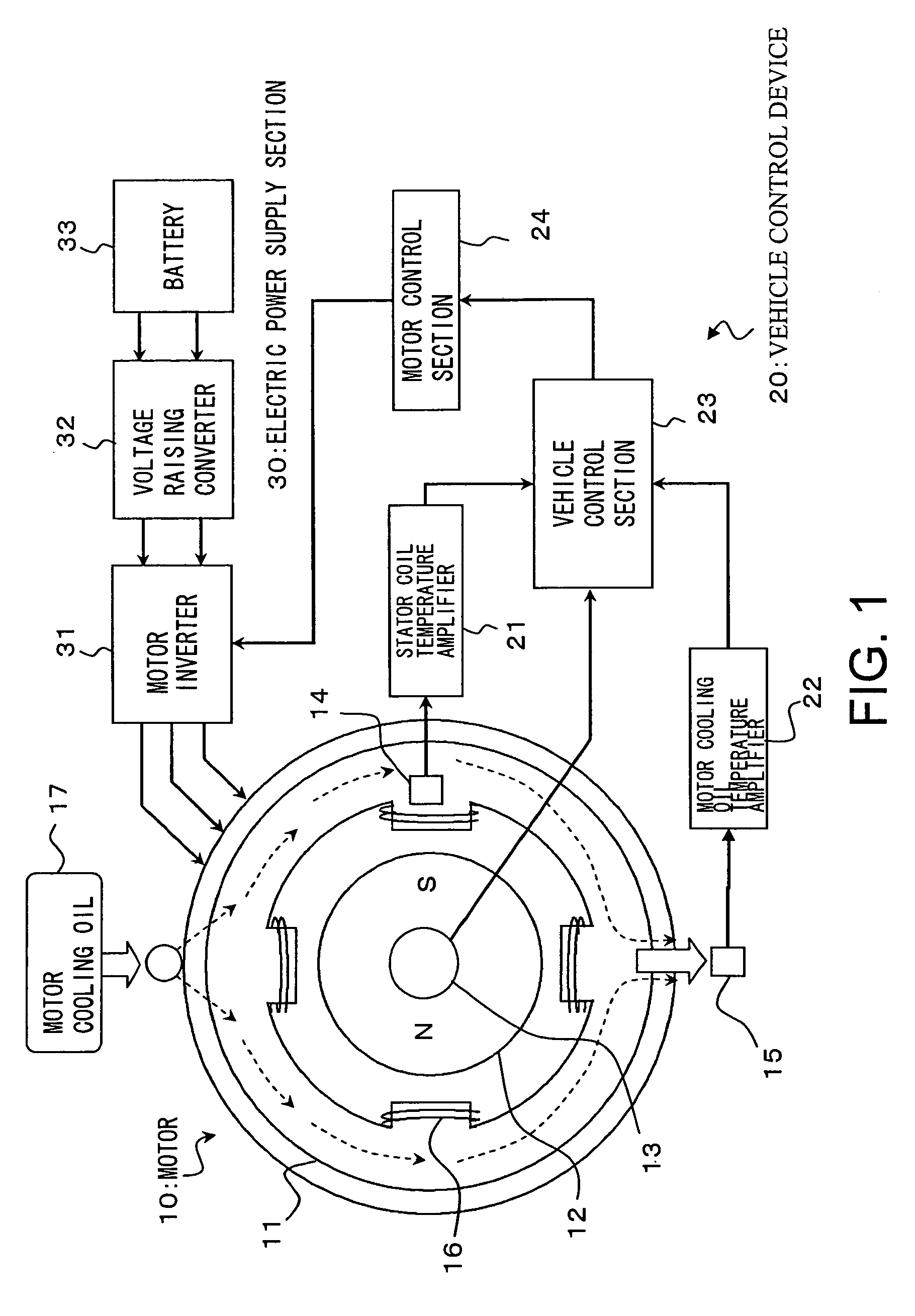

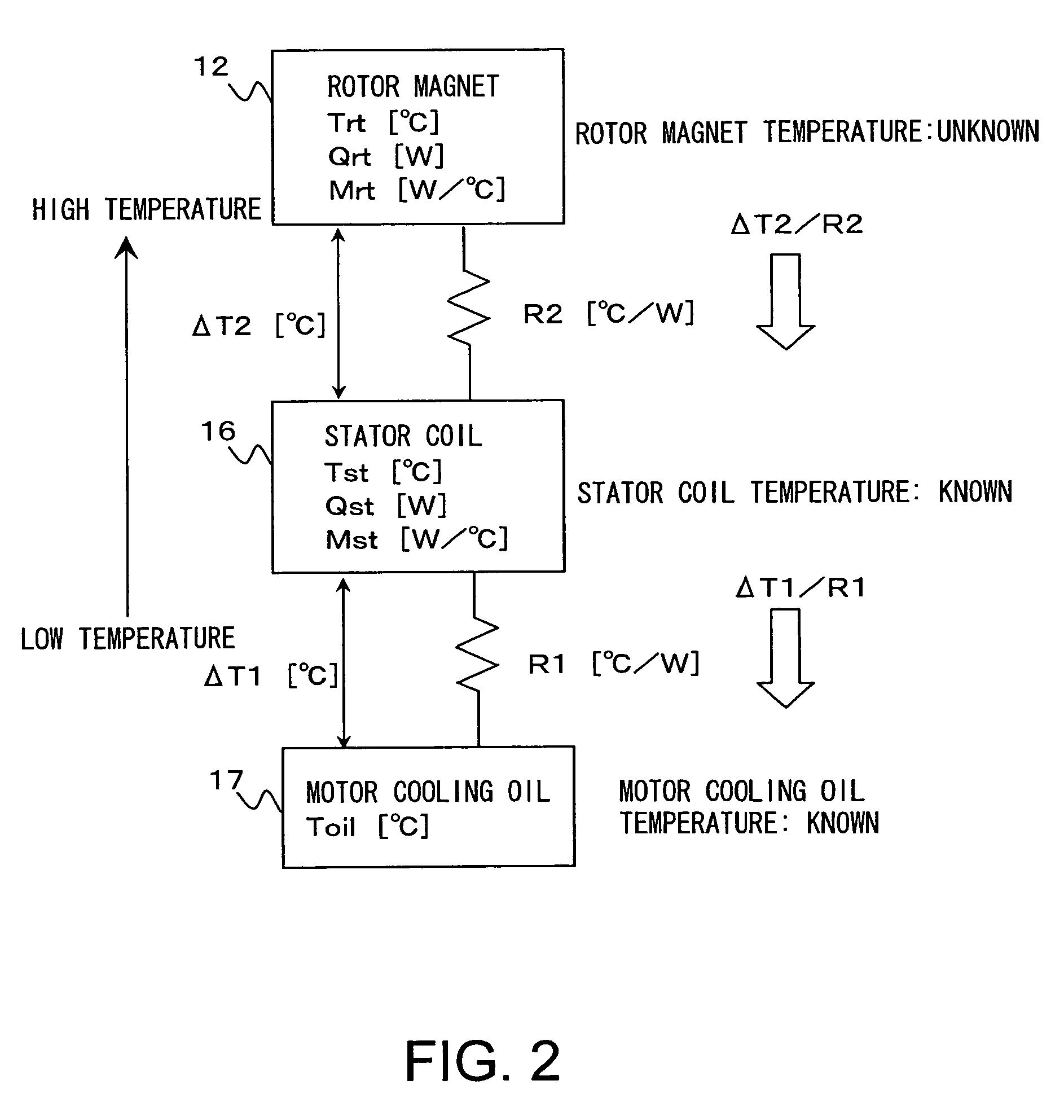

Motor Control Device, Control Method, and Control Program

InactiveUS20090284202A1Increase computing loadAccurate estimateHybrid vehiclesTemperature measurement in motorsRotor magnetsAudio power amplifier

The temperature of a stator coil is measured by a temperature sensor (14), amplified by a stator coil temperature amplifier (21), and transmitted to a vehicle control section (23). Further, motor cooling oil (17) for cooling the outer periphery of the stator cools the stator coil (16) along an end coil section of the stator coil (16). The temperature of the motor cooling oil raised by the stator coil (16) is measured by a temperature sensor (15) and transmitted also to the vehicle control section (23) via a motor cooling oil temperature amplifier (22). The vehicle control section (23) estimates the temperature of a rotor magnet based on a thermal model (relationship between temperature, a heat production amount, and heat resistance) of the motor cooling oil, the stator coil, and the rotor magnet by using the motor cooling oil temperature and the stator coil temperature as input values and sends a control instruction to a motor control section (24).

Owner:TOYOTA JIDOSHA KK

Multi-element thermocouple

A multi-element thermocouple circuit includes at least two temperature measuring junctions. A first temperature measuring junction is formed by first and second thermoelements, each of the first and second thermoelements being formed of a noble metal or a noble metal alloy. The second temperature measuring junction, which connects to the distal end of the first thermoelement, is formed by third and fourth thermoelements, neither of which is formed from a noble metal or a noble alloy. A fifth thermoelement connects to the distal end of the second thermoelement and is formed of the same material as the fourth thermoelement. During operation, the distal ends of the third and fourth thermoelements define therebetween a first voltage difference corresponding to a temperature at the second temperature measuring junction, while the distal ends of the fourth and fifth thermoelements define a second voltage difference from which a temperature at the first temperature measuring junction may be obtained.

Owner:ROSEMOUNT AEROSPACE

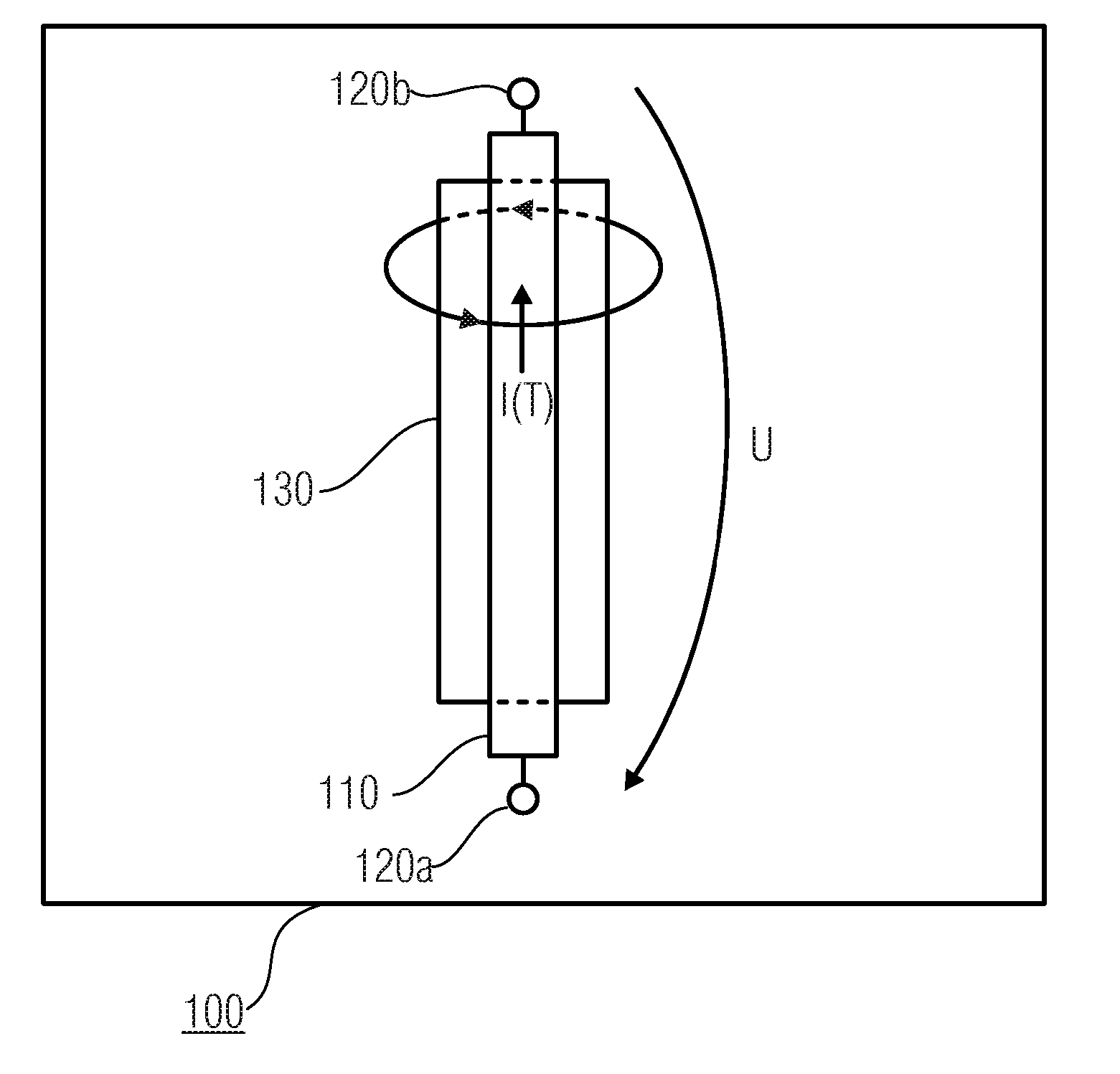

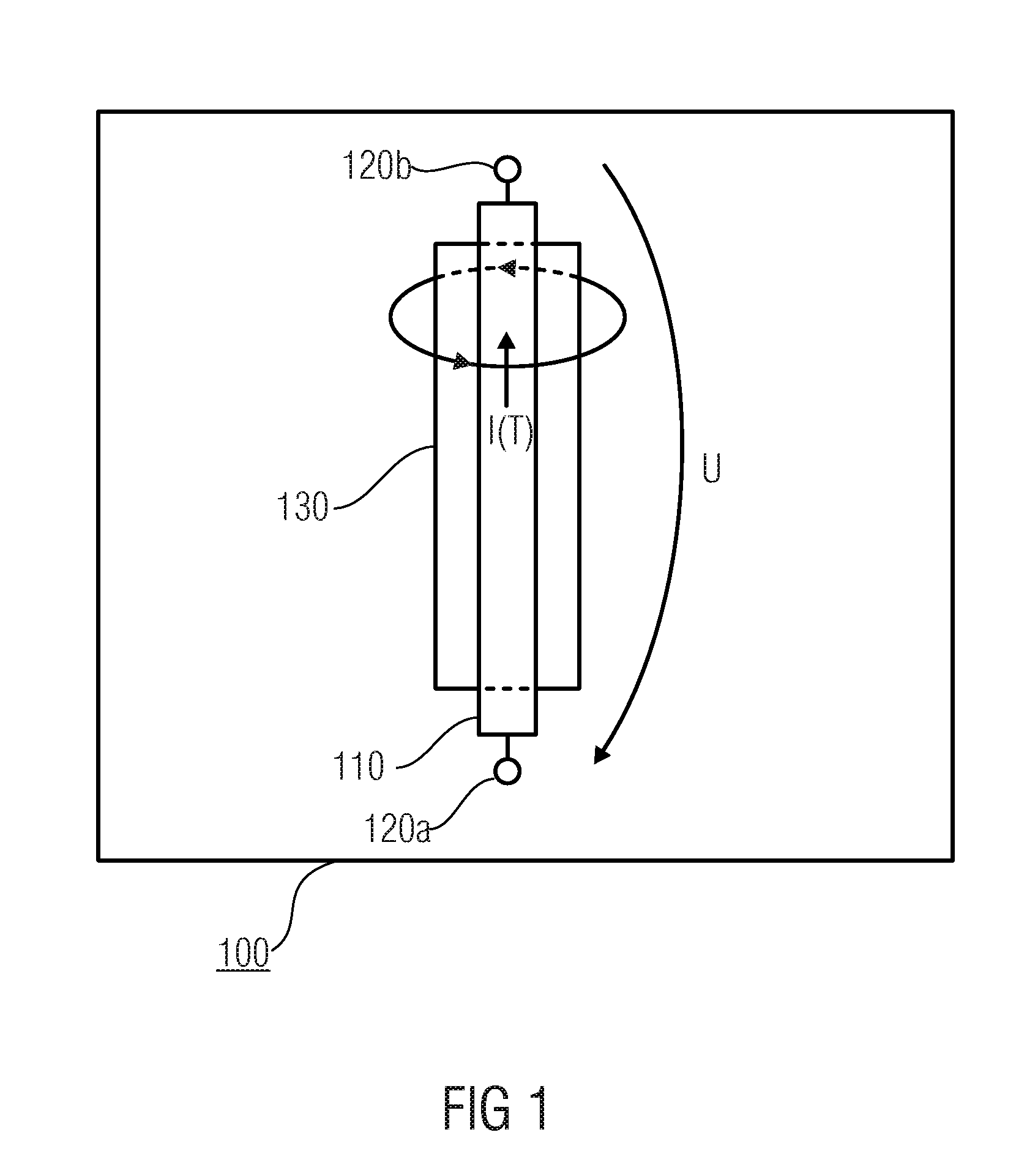

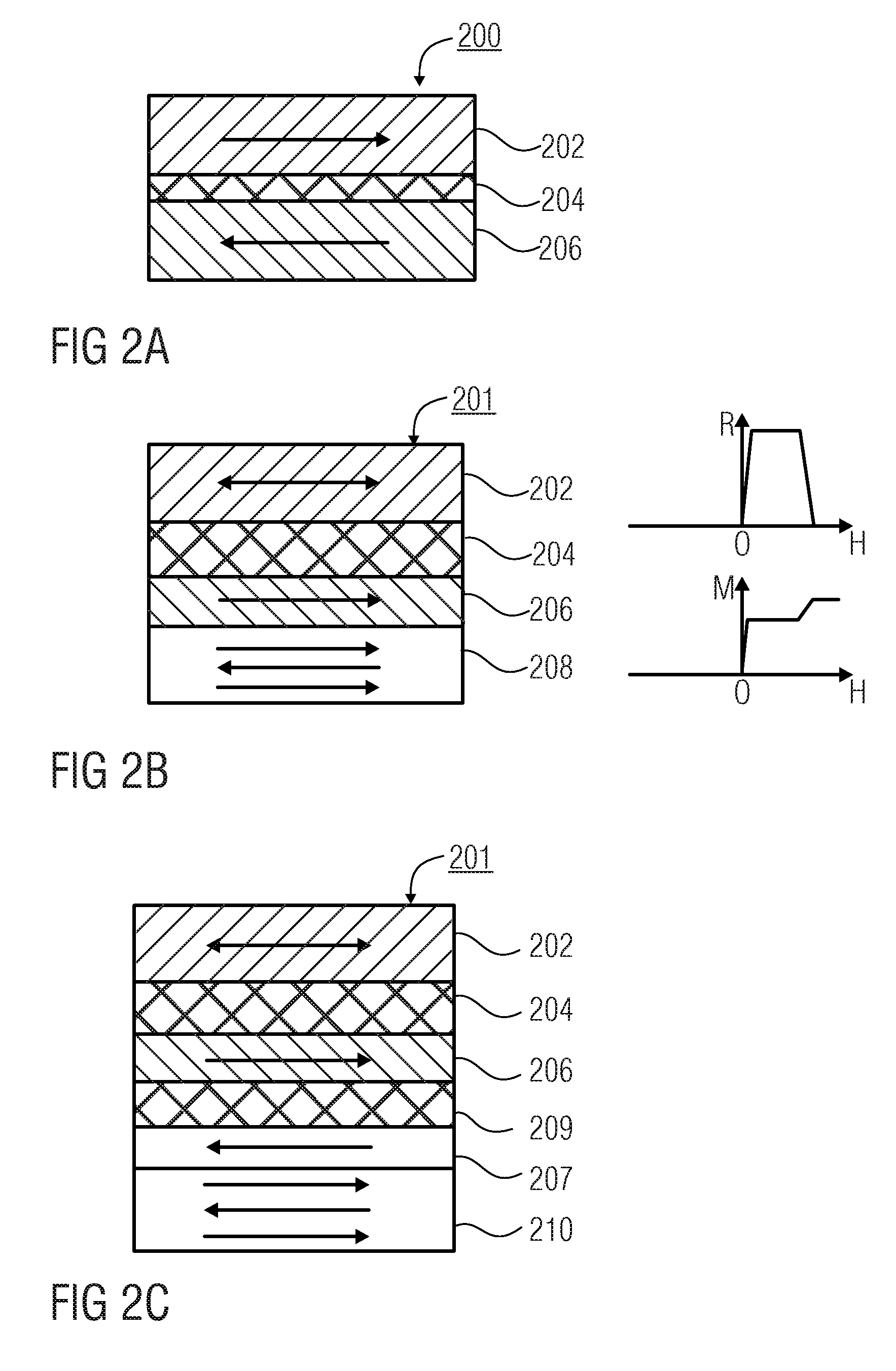

Concept for Detecting a Change of a Physical Quantity by Means of a Conductor Structure

InactiveUS20080084205A1Temperature measurement in motorsNanomagnetismElectrical conductorMagnetic reluctance

An apparatus for detecting a change of a physical quantity by means of a conductor structure having a processor for applying a defined supply signal to the conductor structure so as to effect a current flow through the conductor structure, the current flow being changeable by the physical quantity, and a detector for detecting a magnetic field caused by the current flow through the conductor structure by means of a magnetoresistive element allocated to the conductor structure, a change of the physical quantity being associated with a change of the detected magnetic field.

Owner:INFINEON TECH AG

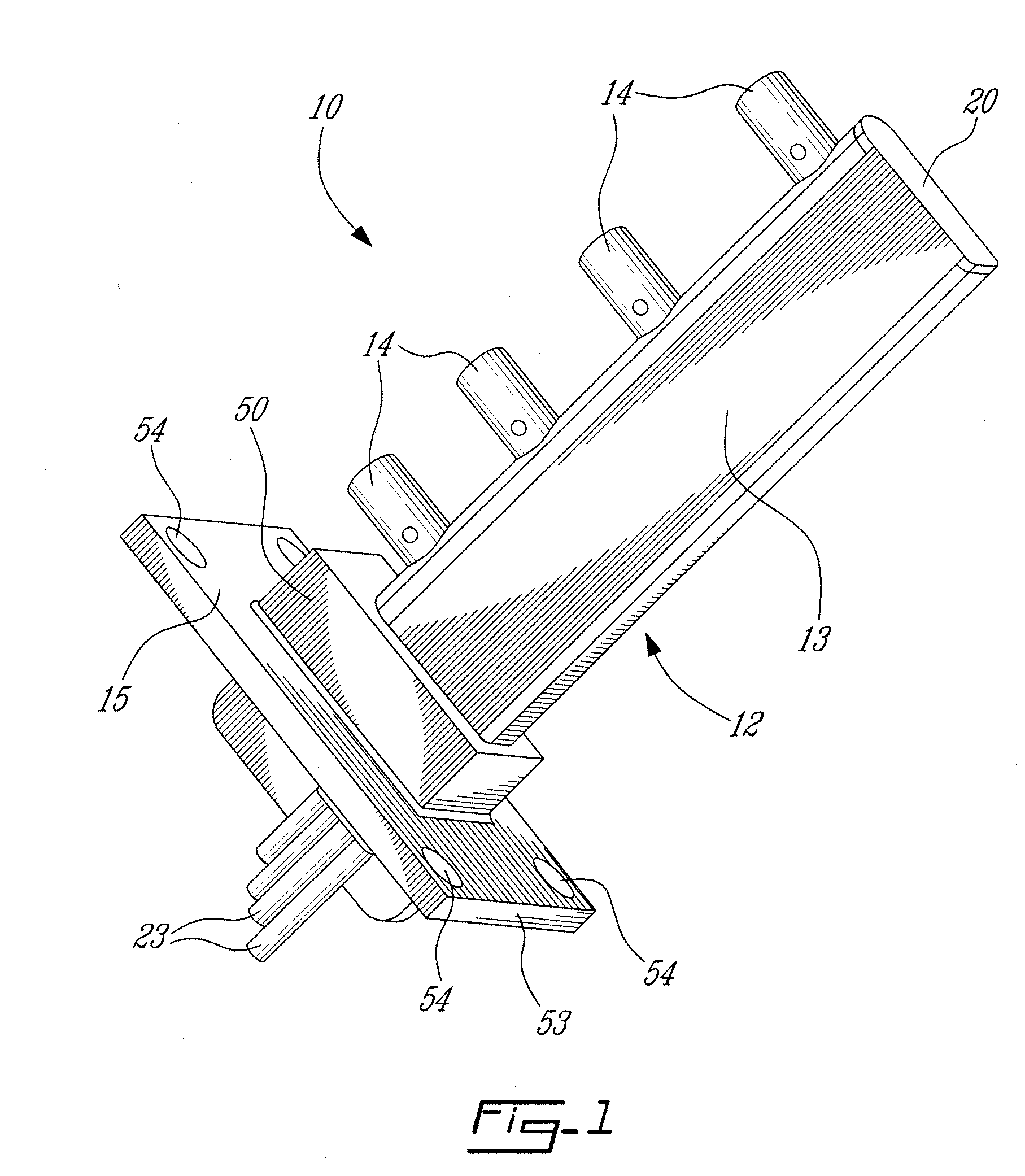

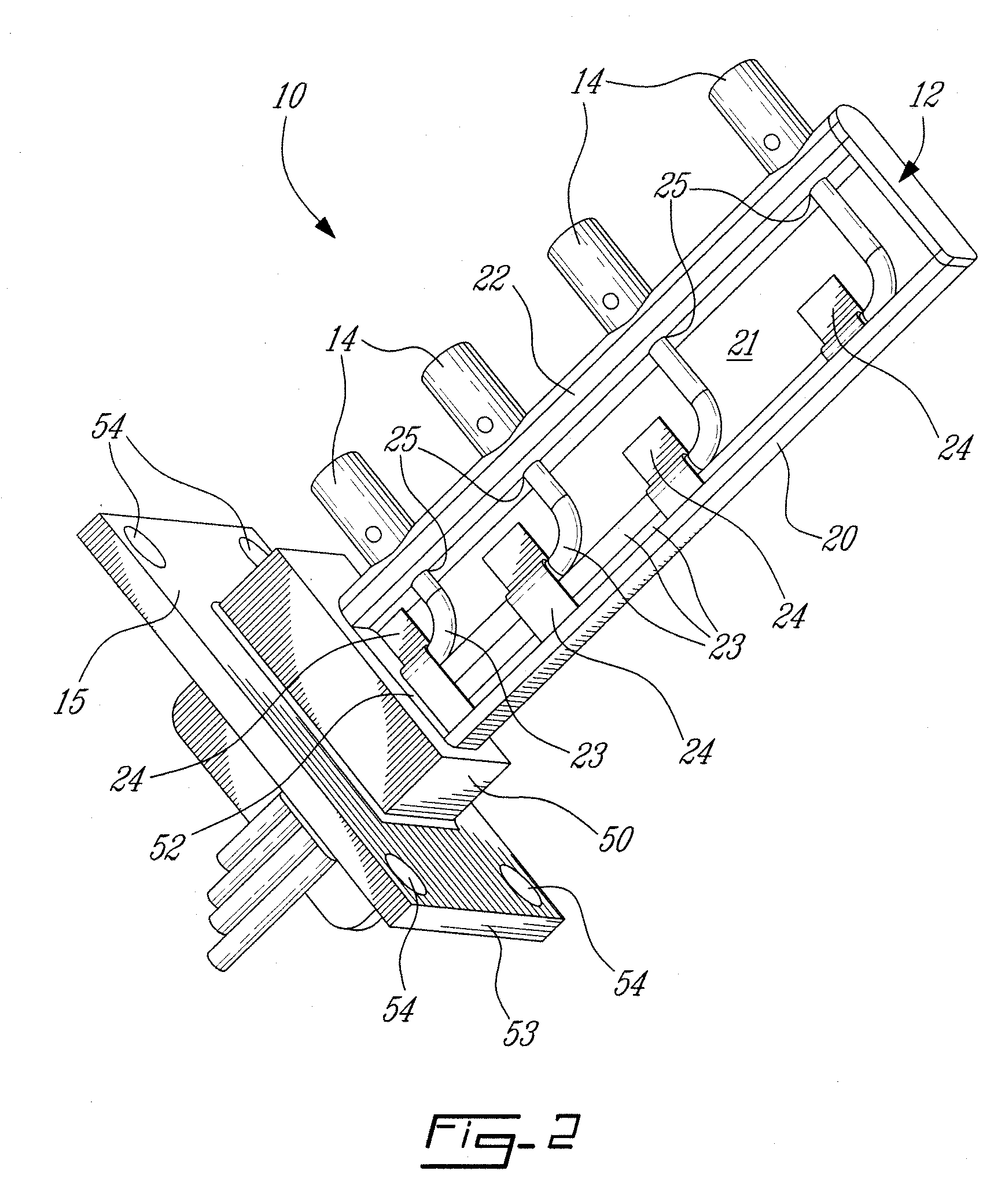

Multipoint probe assembly and method

A probe assembly in a gas path of a gas turbine engine comprises a support casing having a first wall with throughbores. The support casing has a base mounted to a gas turbine engine proximate the gas path. The first wall extends radially into the gas path. The throughbores are provided at positions corresponding to different gas path radii. Wire units each have an end directed to an own throughbore, and an end exiting through an outlet of the casing and connected to a processing unit. Retaining members in the casing constrain movement of the wire units. Probes for each of the throughbores are configured for measuring the temperature / pressure. The probes each have a connector end received in a non-integral relation in the throughbore and connected to an associated wire unit, whereby the probes in the non-integral relation with the support casing measure parameters in the gas path.

Owner:PRATT & WHITNEY CANADA CORP

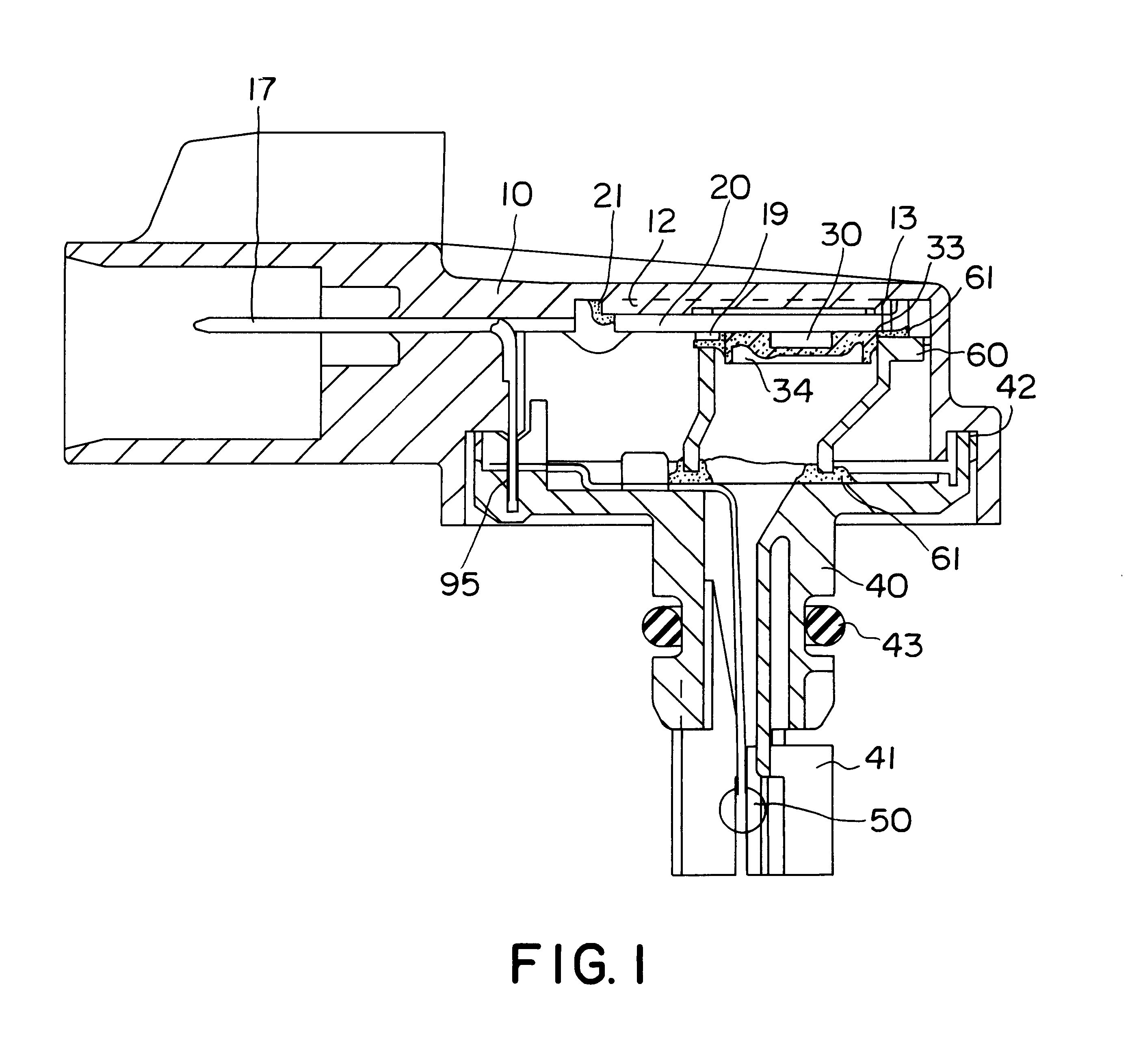

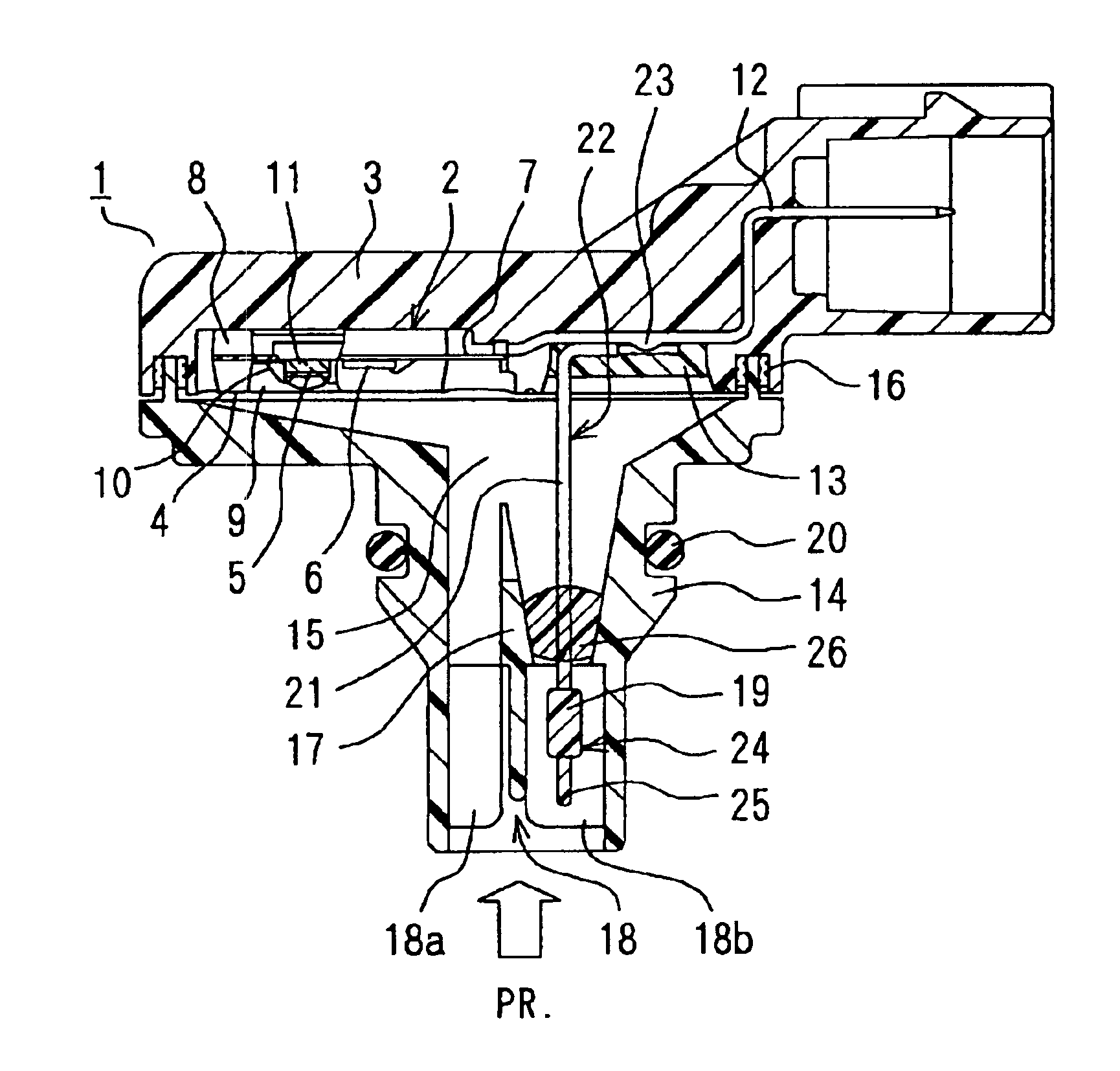

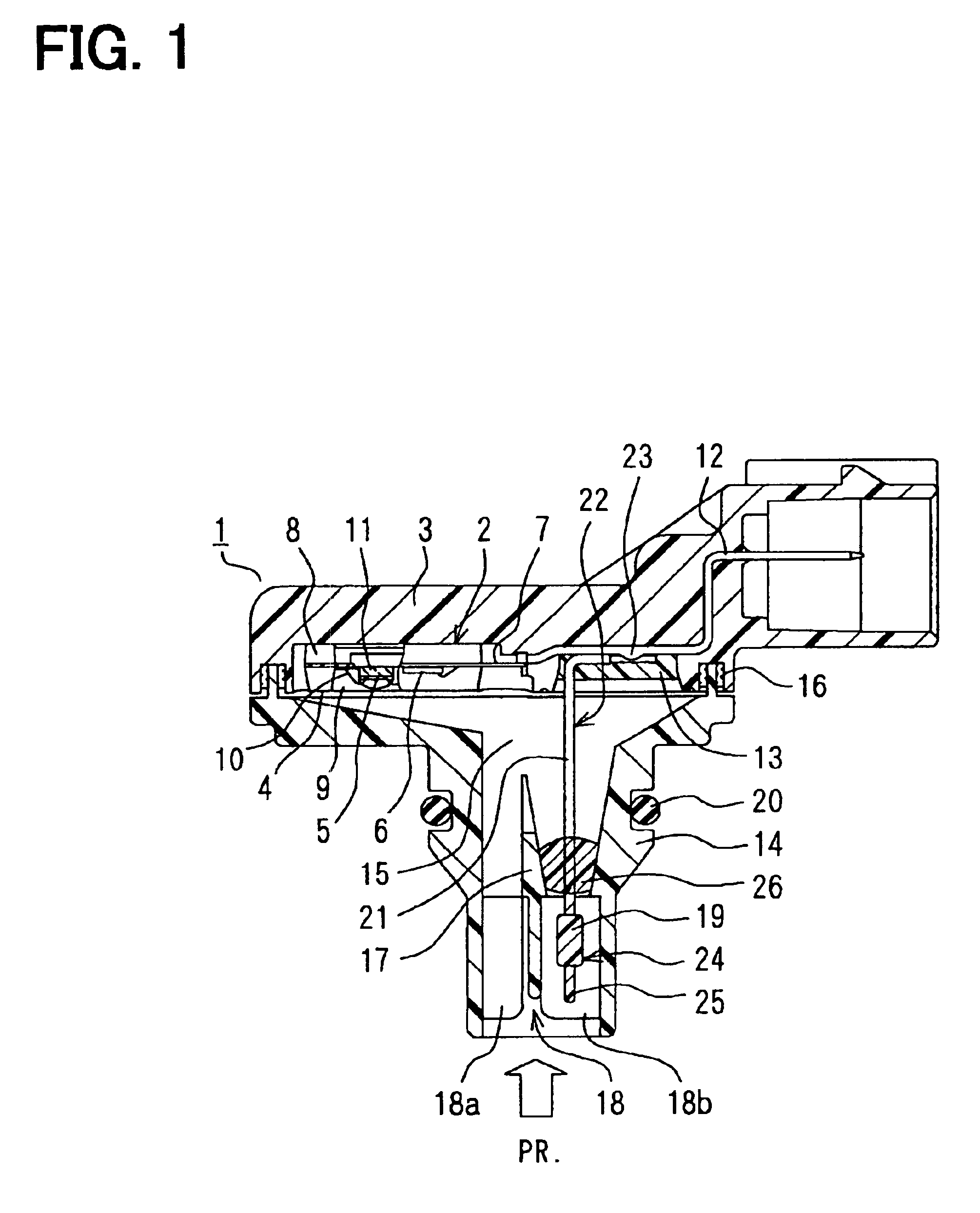

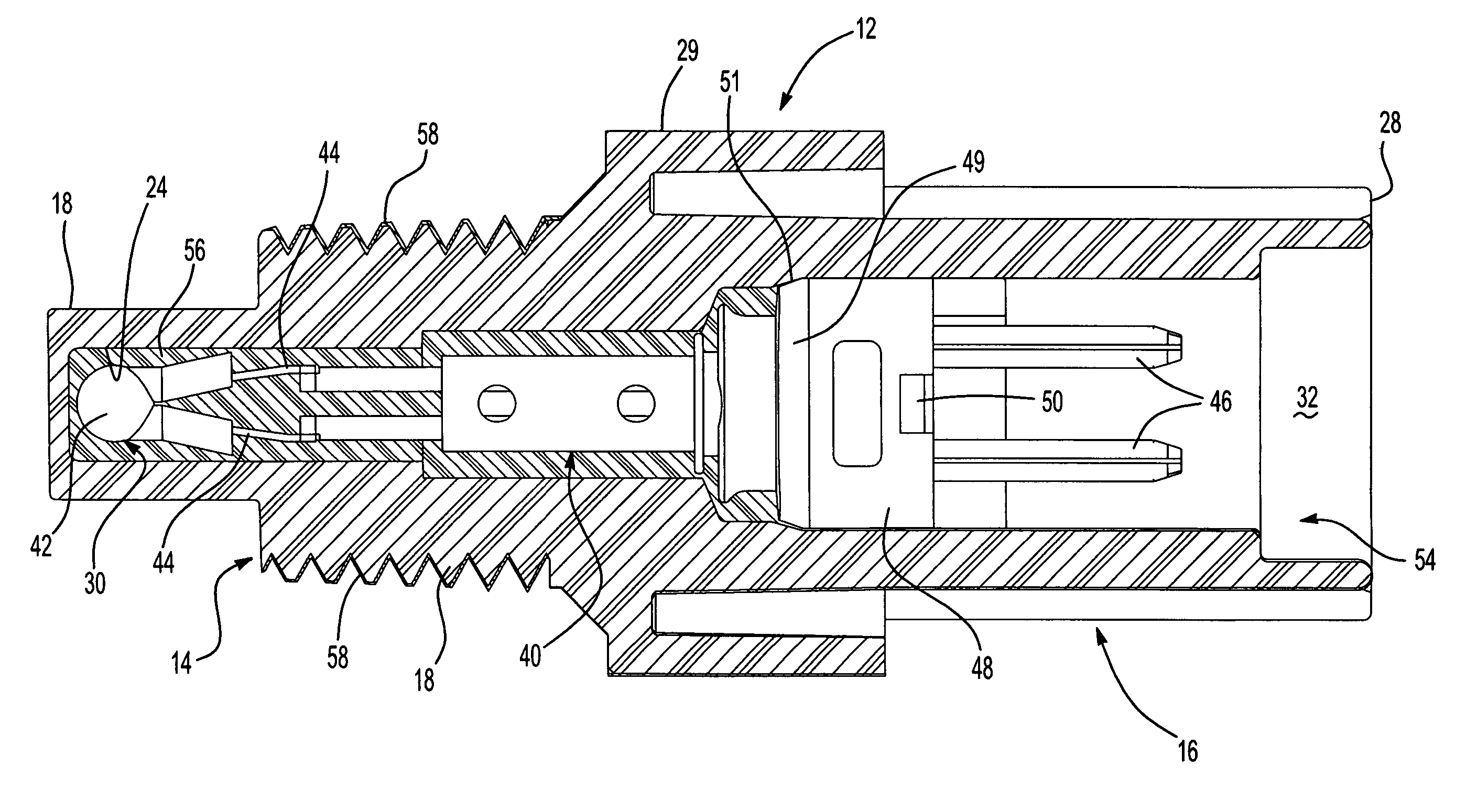

Pressure sensor device having temperature sensor

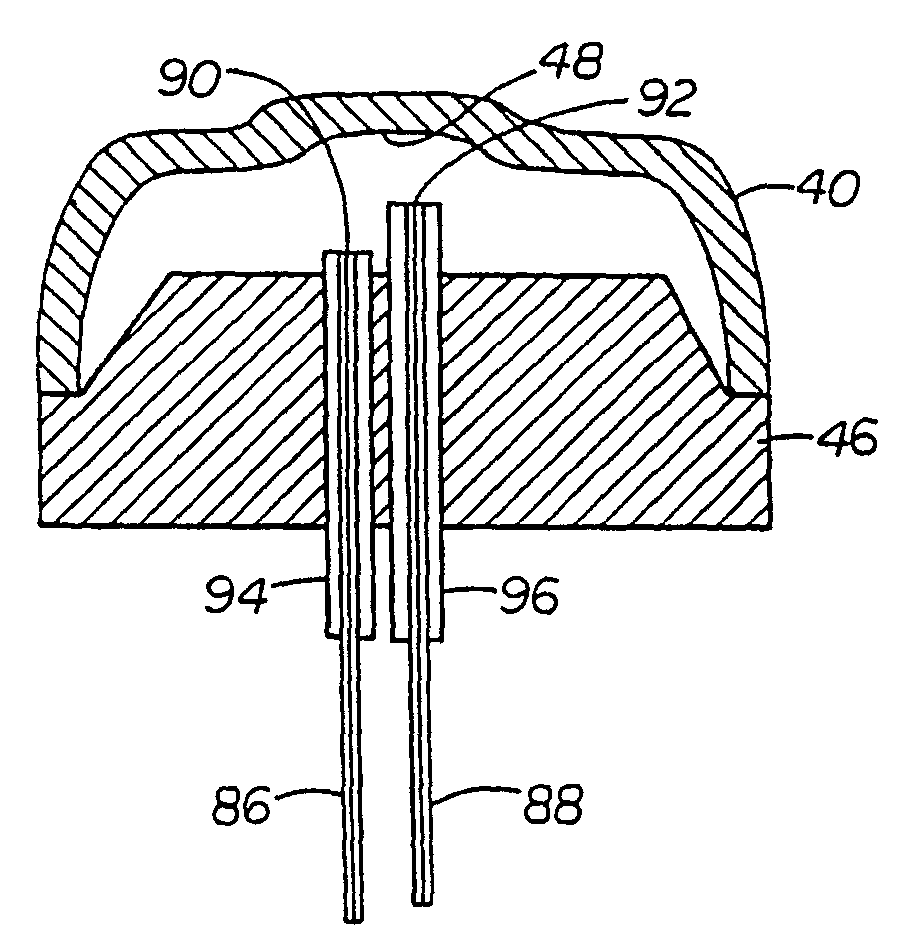

ActiveUS7043993B2Reduce vibrationLess chemical resistanceThermometer detailsTemperature measurement in motorsElectricityForce sensor

A pressure sensor device having a temperature sensor includes a pressure sensor, a temperature sensor, a sensor casing for accommodating the pressure sensor and a connector pin for electrically connecting the pressure sensor and an outside circuit, and a port mounted on the sensor casing and having a pressure introduction port for introducing a measuring object to the pressure sensor. The temperature sensor is disposed in the pressure introduction port, and electrically connects to the connector pin through a lead wire. The lead wire with the temperature sensor is supported by a connection portion disposed between the connector pin and the lead wire. The lead wire has a buffer disposed between the lead wire and a part of the pressure introduction port for reducing a vibration of both the temperature sensor and the lead wire.

Owner:DENSO CORP

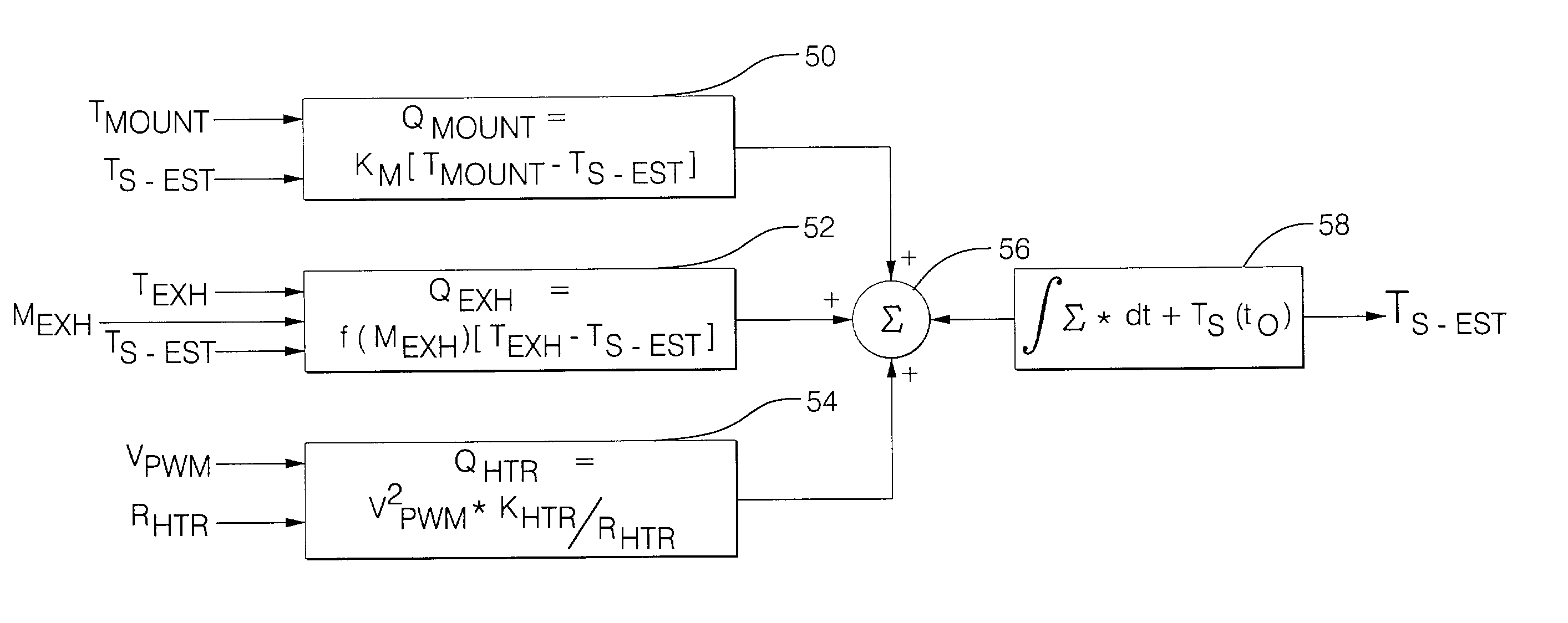

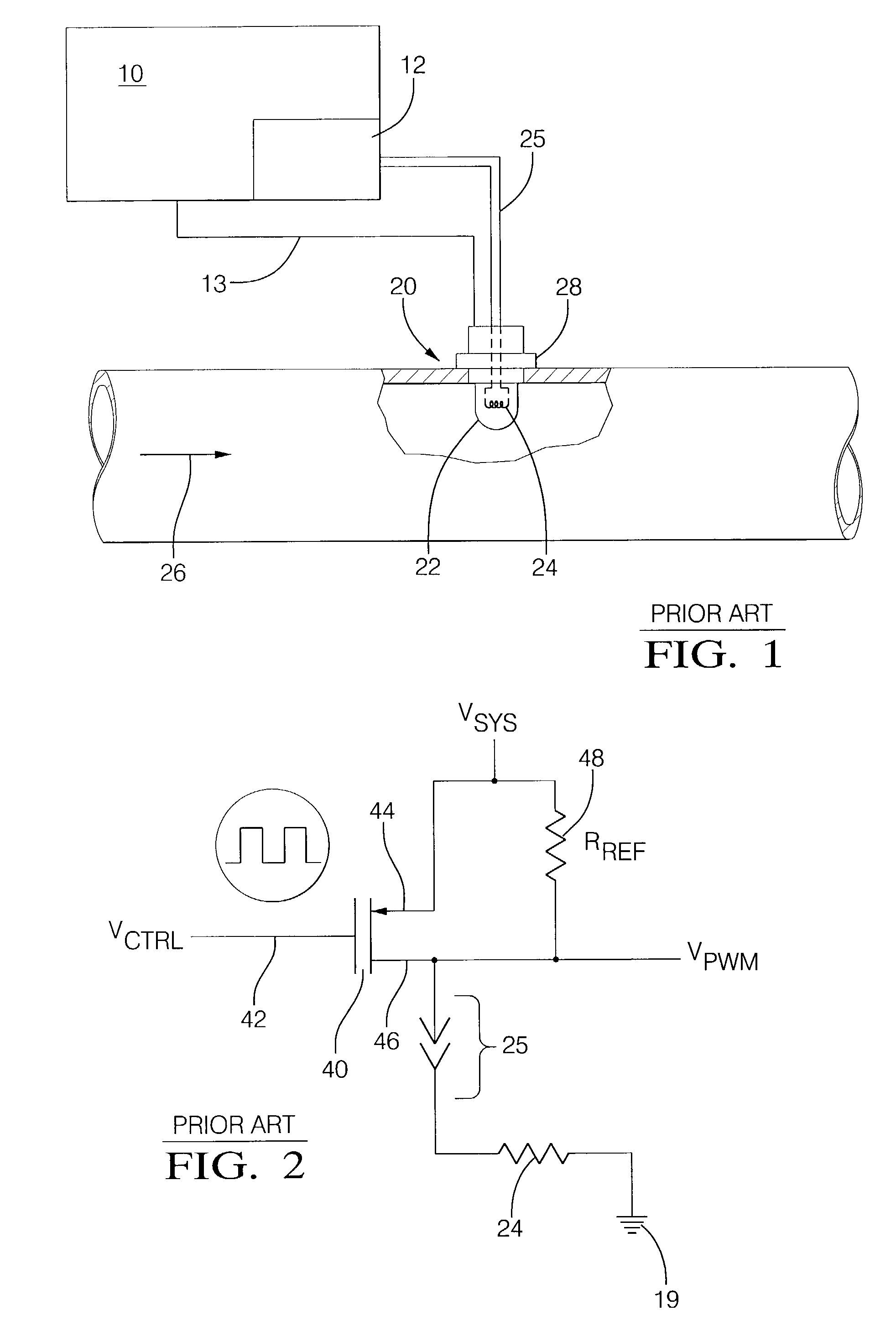

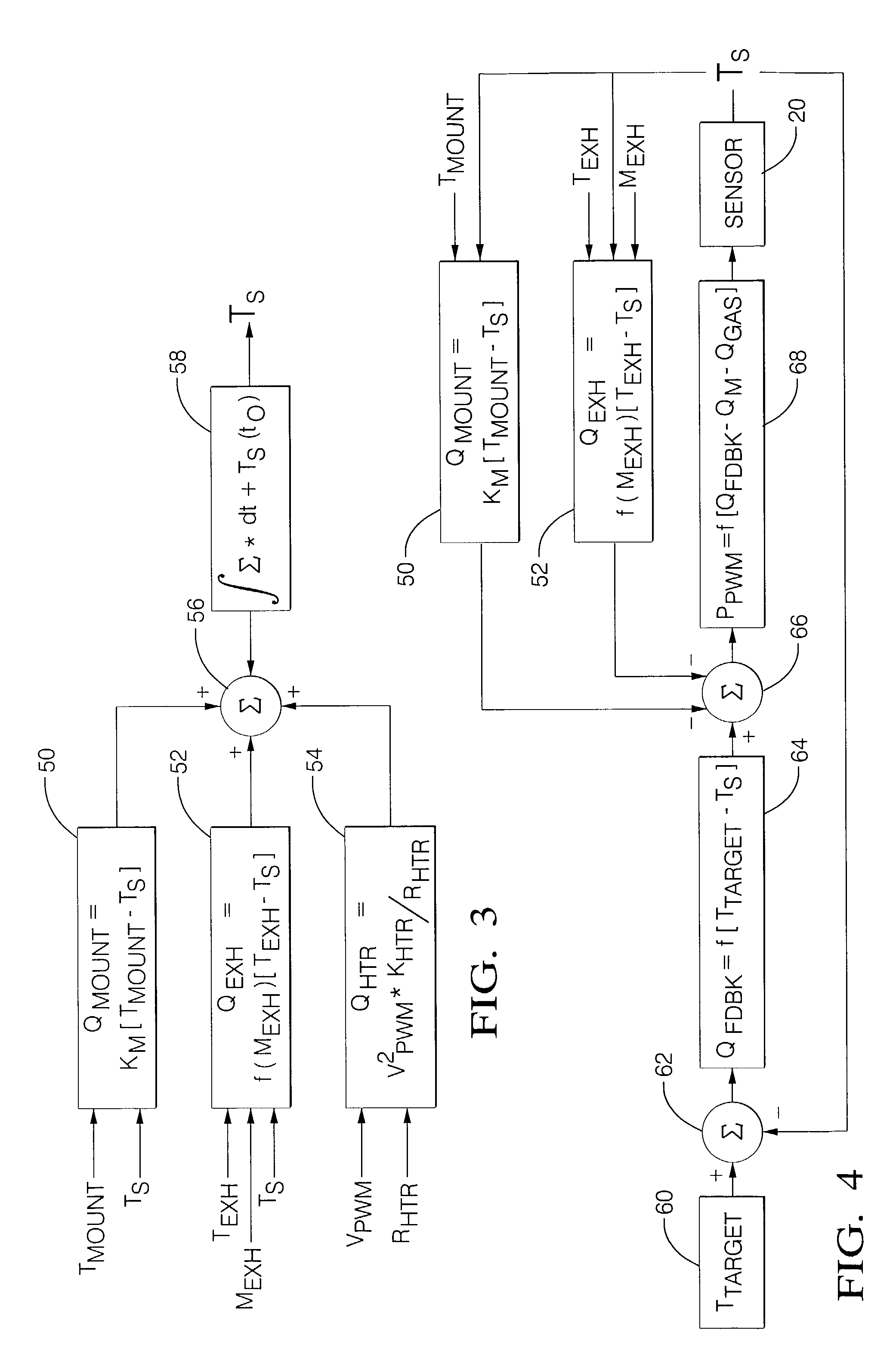

Method and apparatus to control an exhaust gas sensor to a predetermined termperature

InactiveUS7036982B2Accurate measurementImproved engine controlThermometer detailsTemperature measurement in motorsControl systemProcess engineering

The invention provides a control strategy and a control system to control a gas sensor to a target operating temperature. It relies upon both feedback and model-based feedforward control systems to achieve and then maintain the sensor at the target operating temperature. The mechanization includes a gas sensor with a heating element in a feedstream. The control strategy employs a control system for the heating element that is based upon the target operating temperature, the temperature of the heating element, and an effect of the feedstream and mounting structure on the temperature of the sensor. The control strategy enables the control system to optimize the heating of a sensor during warm-up and steady state operations.

Owner:DELPHI TECH IP LTD

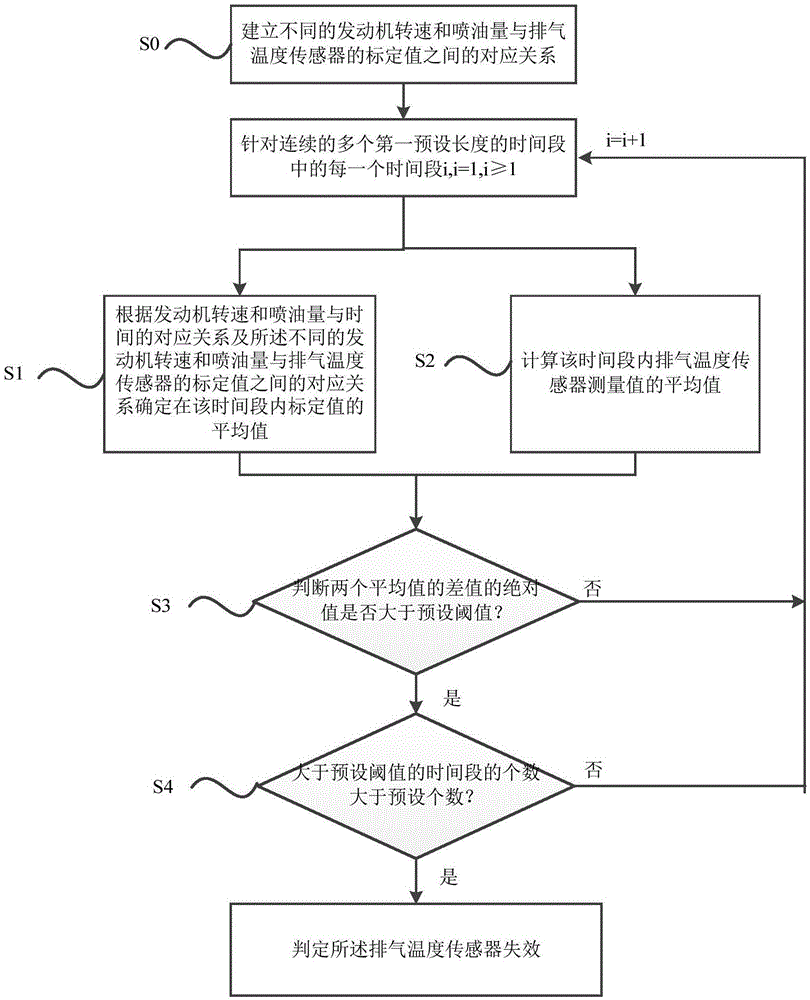

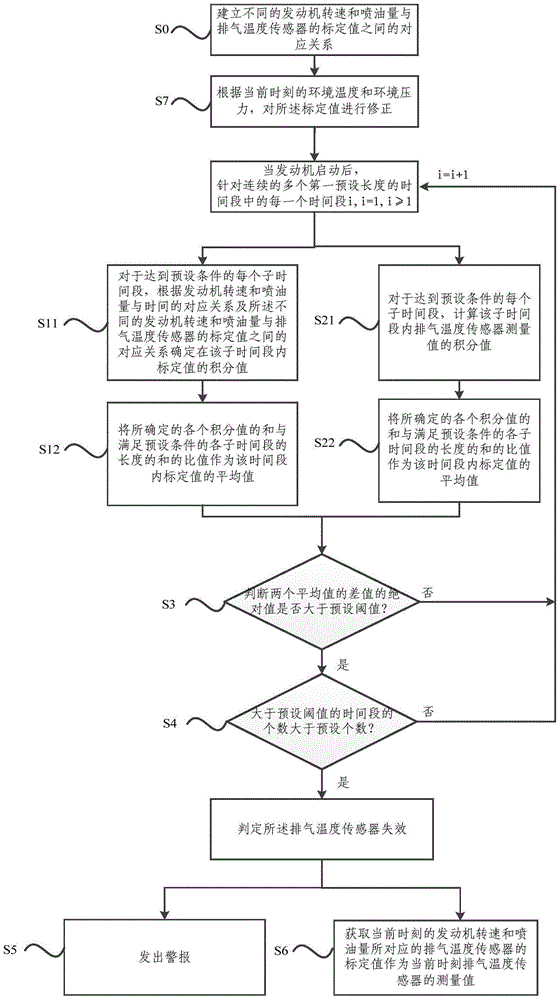

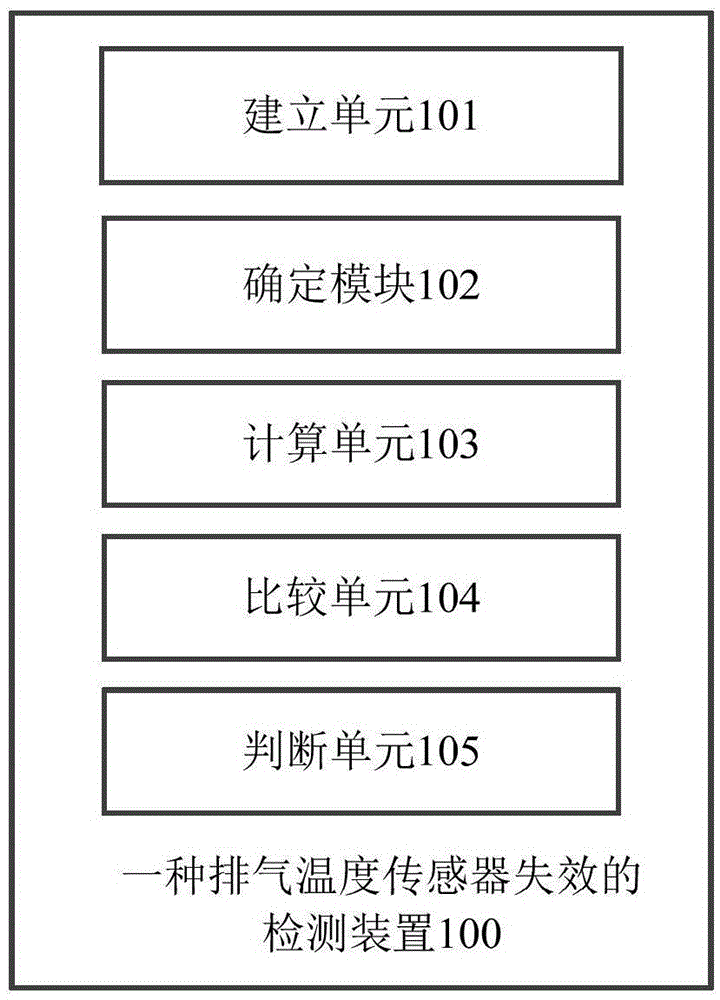

Method and device for detecting failure of exhaust temperature sensor

ActiveCN105628257ARealize measurement value error detectionTemperature measurement in motorsElectrical controlLower limitEngineering

The invention relates to a method and a device for detecting failure of an exhaust temperature sensor. The method comprises steps: a corresponding relation between different engine rotation speeds and fuel injection quantities and calibration values of the exhaust temperature sensor is built; as for each time period in continuous multiple time periods with first preset lengths, whether the absolute value of the difference between the average value of exhaust temperature sensor measurement values and the average value of the calibration values is larger than a preset threshold is judged, and when the number of time periods during which the absolute value is larger than the preset threshold is larger than a preset number, the exhaust temperature sensor is judged to fail. According to the technical scheme provided by the invention, error detection on the measurement values of the exhaust temperature sensor during the overall working process can be realized; and compared with the prior art, whether the measurement values have deviation when the measurement values of the exhaust temperature sensor do not exceed the upper limit and the lower limit of measurement can be judged.

Owner:WEICHAI POWER CO LTD

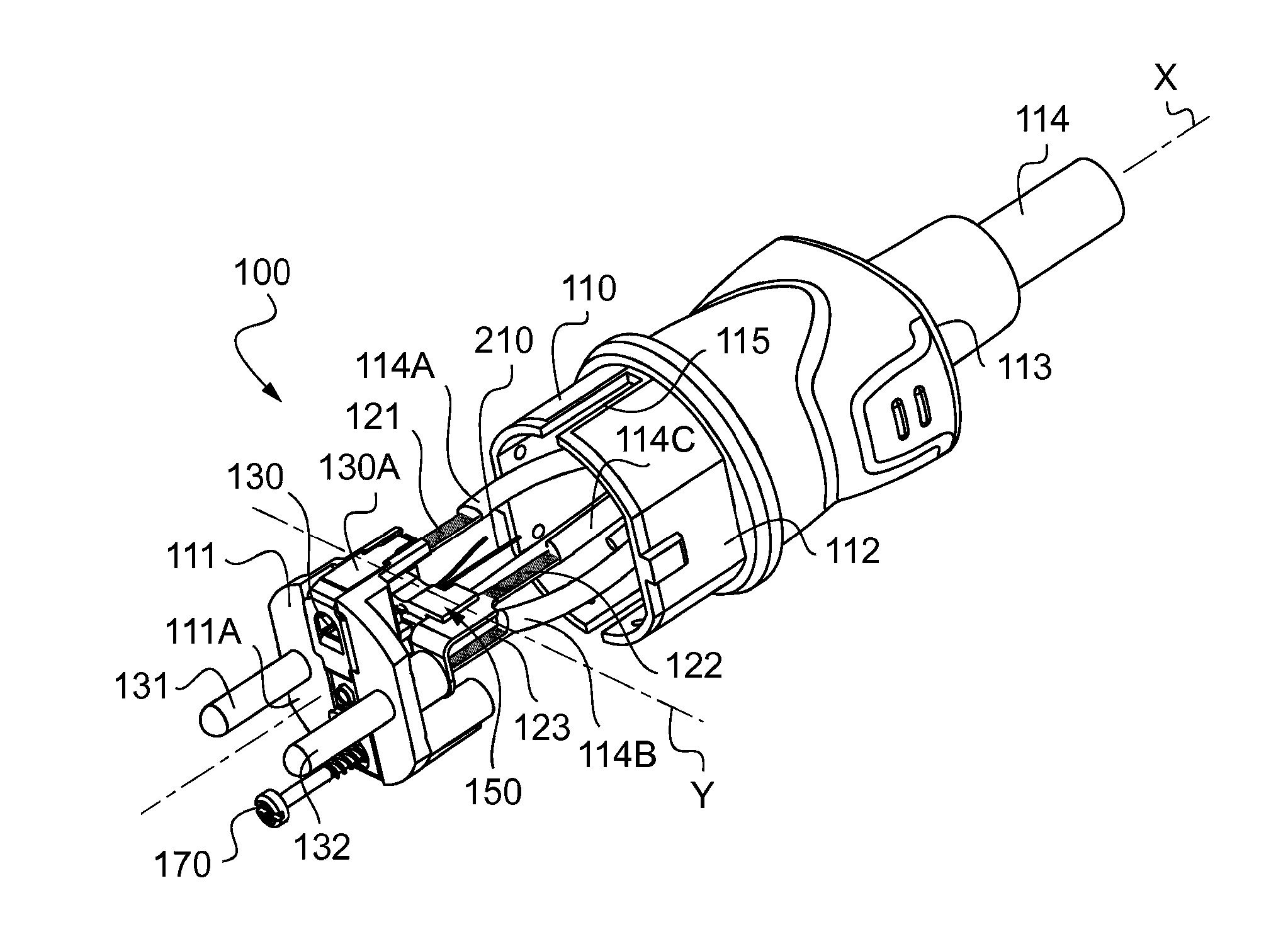

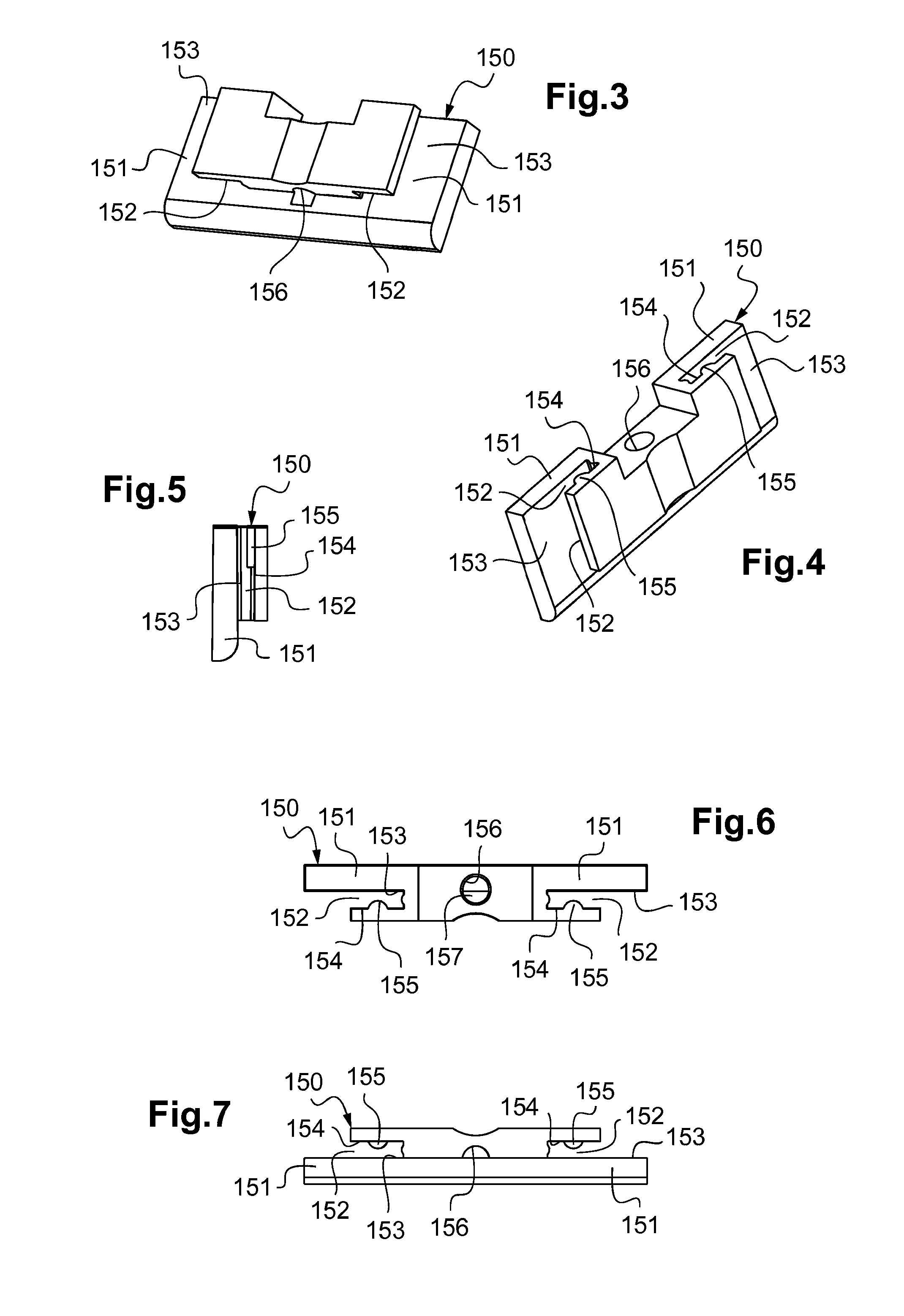

Electrical apparatus comprising a temperature sensor housed in a support element

ActiveUS20160104978A1Precise positioningEasily reproducibleThermometer detailsTemperature measurement in motorsElectricityElectrical connection

The invention relates to an electrical apparatus (100) comprising an electrically insulating body (110) housing at least two electrical connection elements (121, 122, 123), and a temperature sensor (200). According to the invention, the temperature sensor is received in a thermally conductive and electrically insulating support element (150) which is separate from said body and mounted inside said body, so as to extend between said electrical connection elements, set back from the outer faces of said body.

Owner:LEGRAND SNC

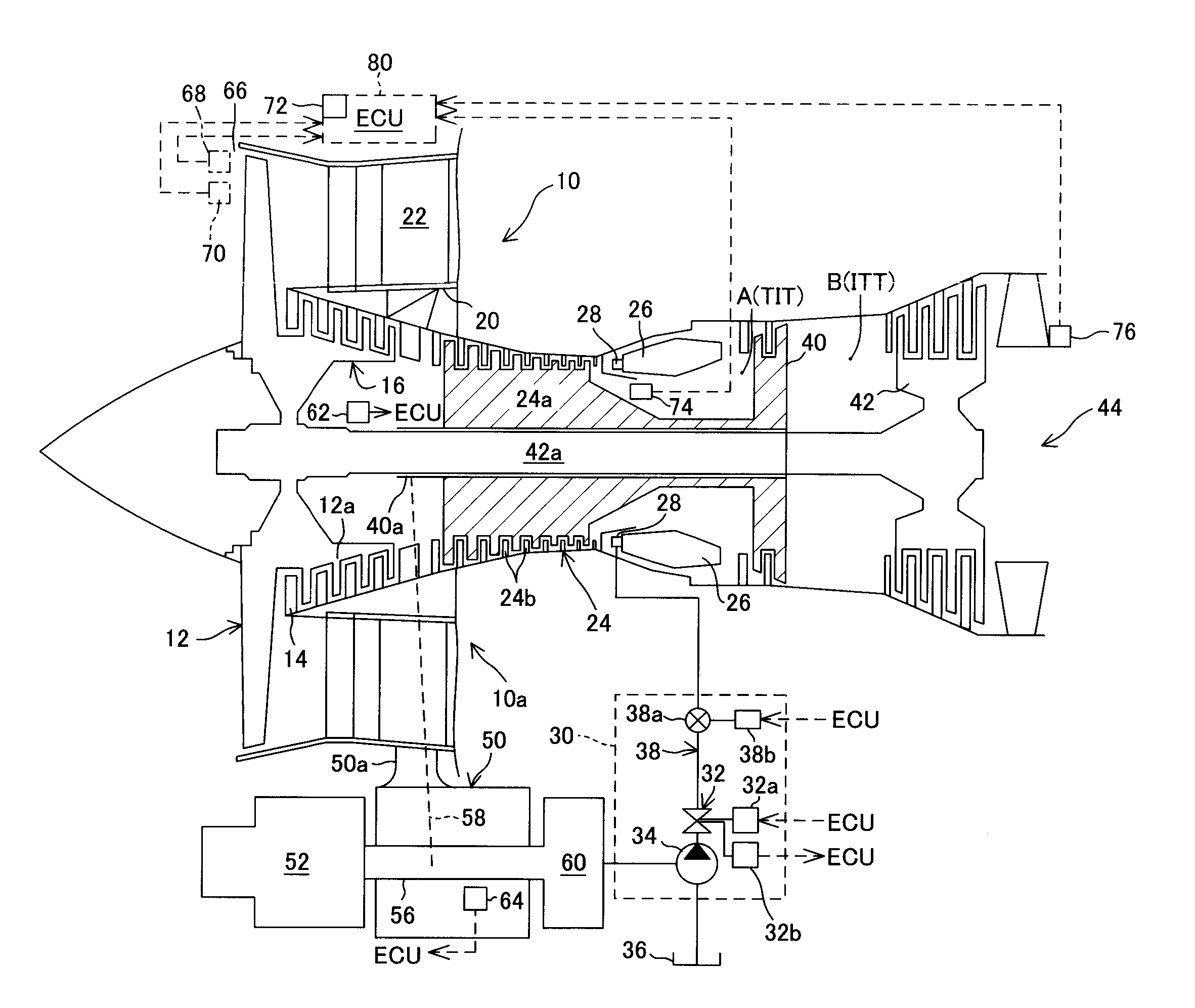

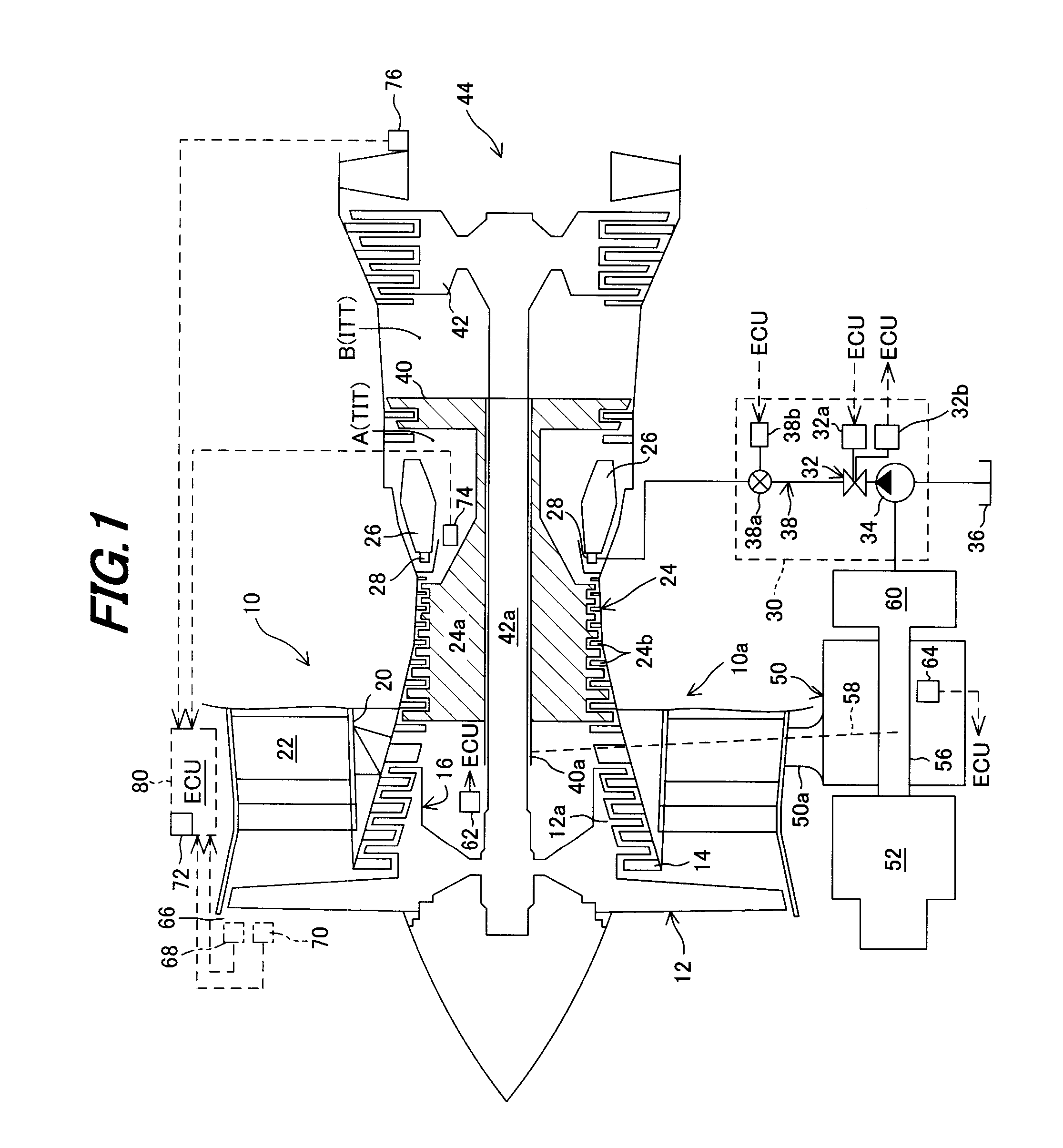

Temperature estimation apparatus for aeroplane gas turbine engine

ActiveUS20110077895A1Accurate estimateThermometer detailsAnalogue computers for vehiclesCombustion chamberHigh pressure

In a temperature estimation apparatus for an aeroplane gas turbine engine mounted on an aircraft and having a combustion chamber, a high-pressure turbine rotated by combustion gas exhausted from the combustion chamber, a low-pressure turbine located downstream of the high-pressure turbine to be rotated by low-pressure gas which has passed through the high-pressure turbine, a high-pressure turbine rotational speed sensor, a low-pressure turbine rotational speed sensor, and a temperature sensor, inlet temperature at an inlet of the high-pressure turbine is estimated based on the detected outlet temperature of the low-pressure turbine and the rotational speed of the low-pressure turbine and is corrected with the detected rotational speed of the high-pressure turbine.

Owner:HONDA MOTOR CO LTD

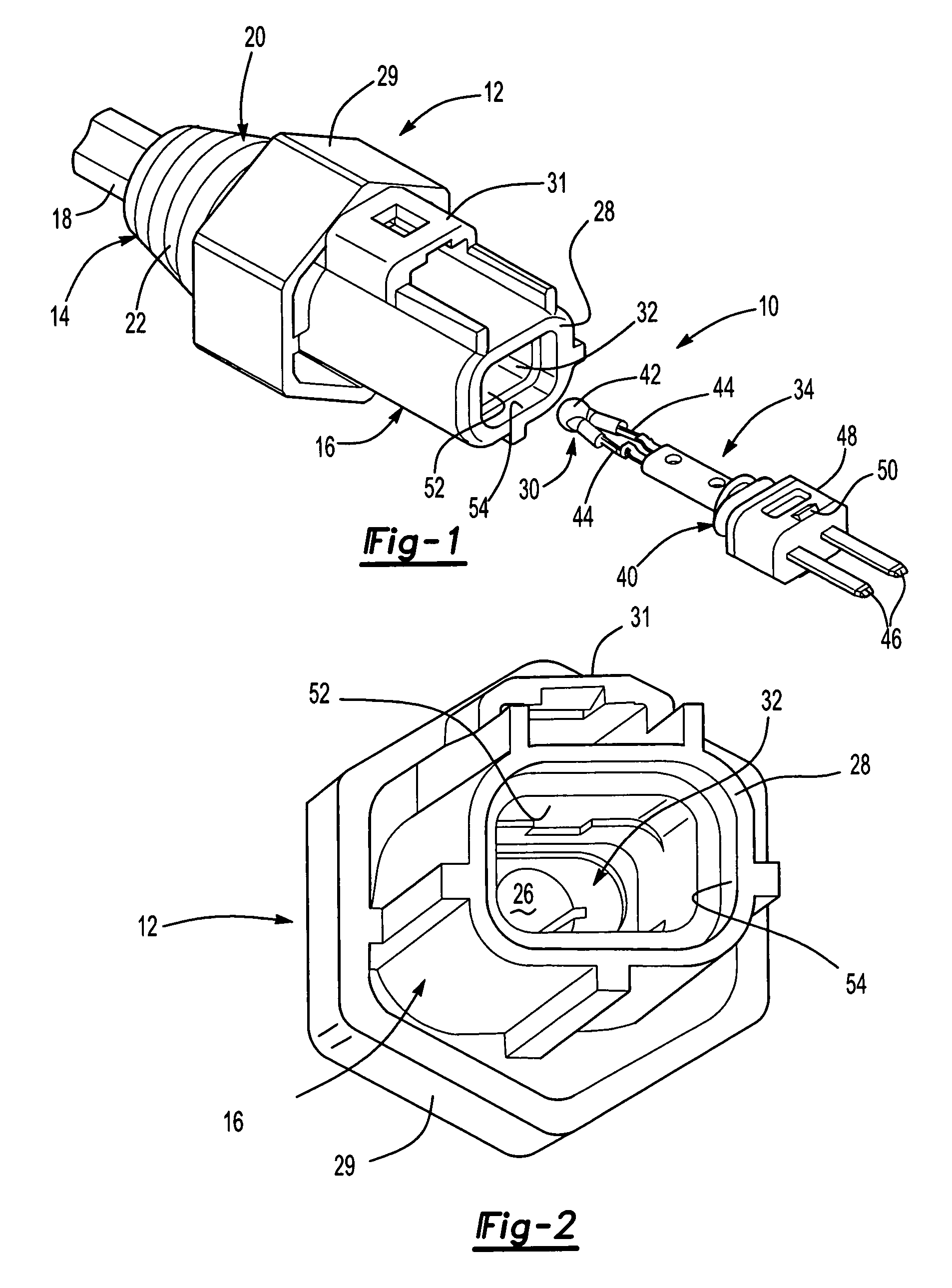

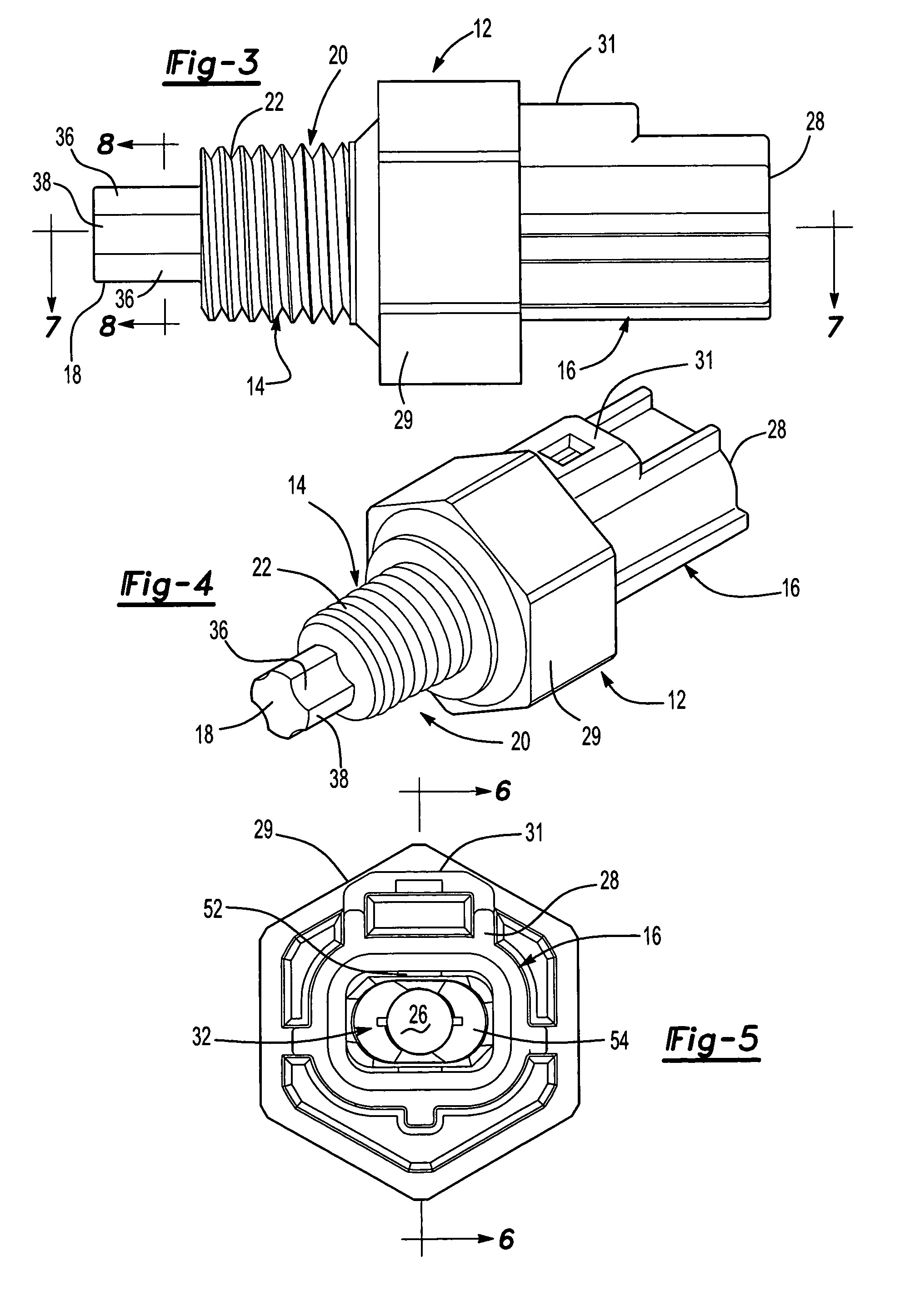

Temperature sensor

ActiveUS20060215731A1Speed up heat transferRaise transfer toThermometer detailsTemperature measurement in motorsEngineeringConductive materials

A temperature sensor used to monitor coolant and an automobile coolant system. The temperature sensor includes a one-piece housing having a sensor portion and a connector portion. A sensor assembly, including a sensor having a pair of terminals connected thereto is disposed within the housing. The sensor portion includes a sensor tip having a configuration conducive to improving thermal transfer from the coolant through the sensor tip to the sensor. A thermally conductive material may also be used to improve thermal or heat transfer to the sensor.

Owner:STONERIDGE INC

Flowing fluid conditioner

InactiveUS7171955B2Temperature measurement in motorsCoolant flow controlTemperature conditioningIntercooler

A method and system for temperature conditioning of engine intake air by use of controllable intercooler which consists of an active thermoelectric device and a controllable valve system which optimally directs the path of airflow through a plurality of chambers in response to signals from a controller in order to optimally provide temperature conditioned air to the engine. System features temperature storage isolated from heat soaked engine components allowing immediate and efficient conditioning of airflow into an internal combustion engine. Intelligent control of this device removes parasitic power drains during high demand situations.

Owner:PERKINS MICHAEL T

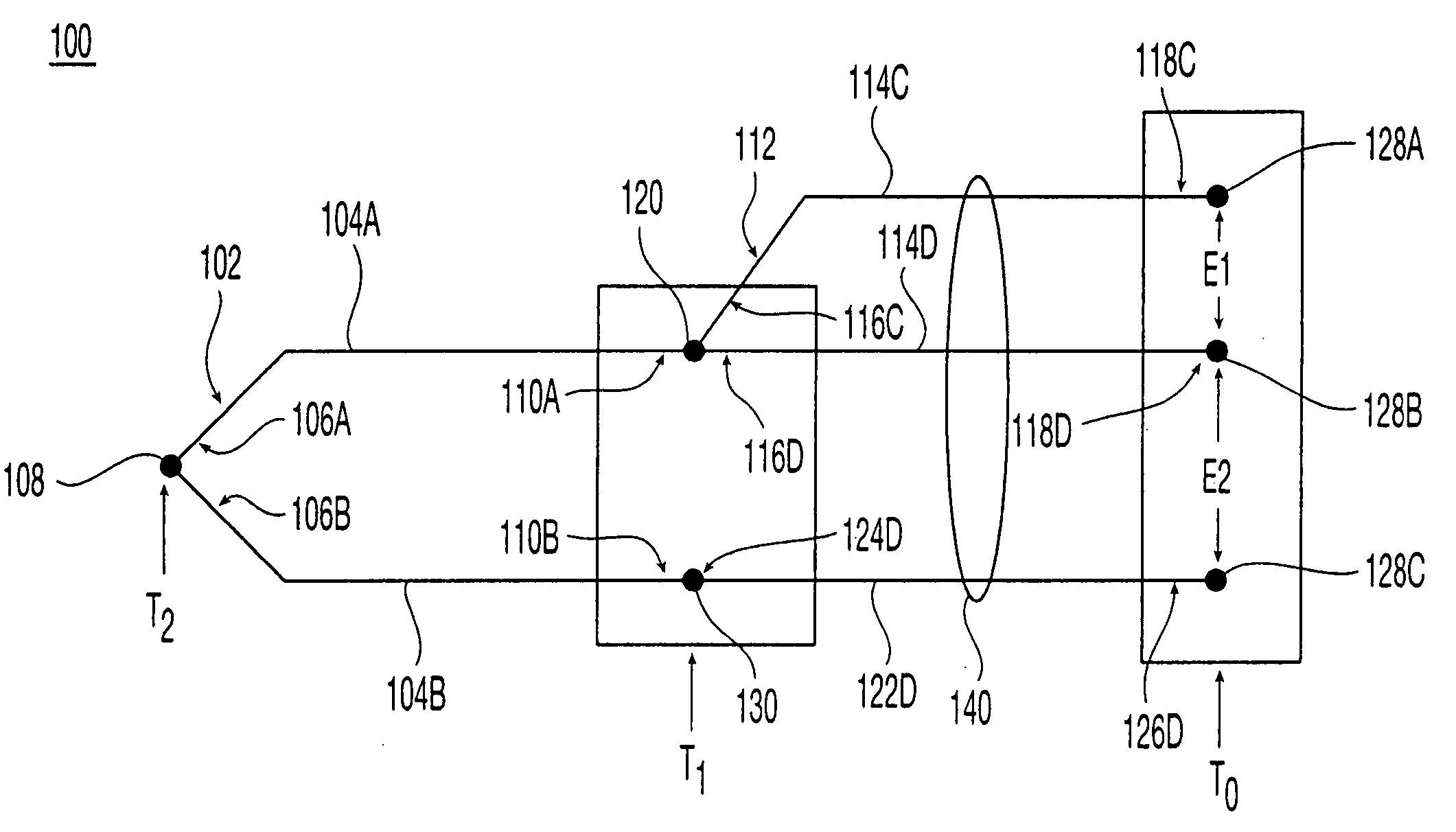

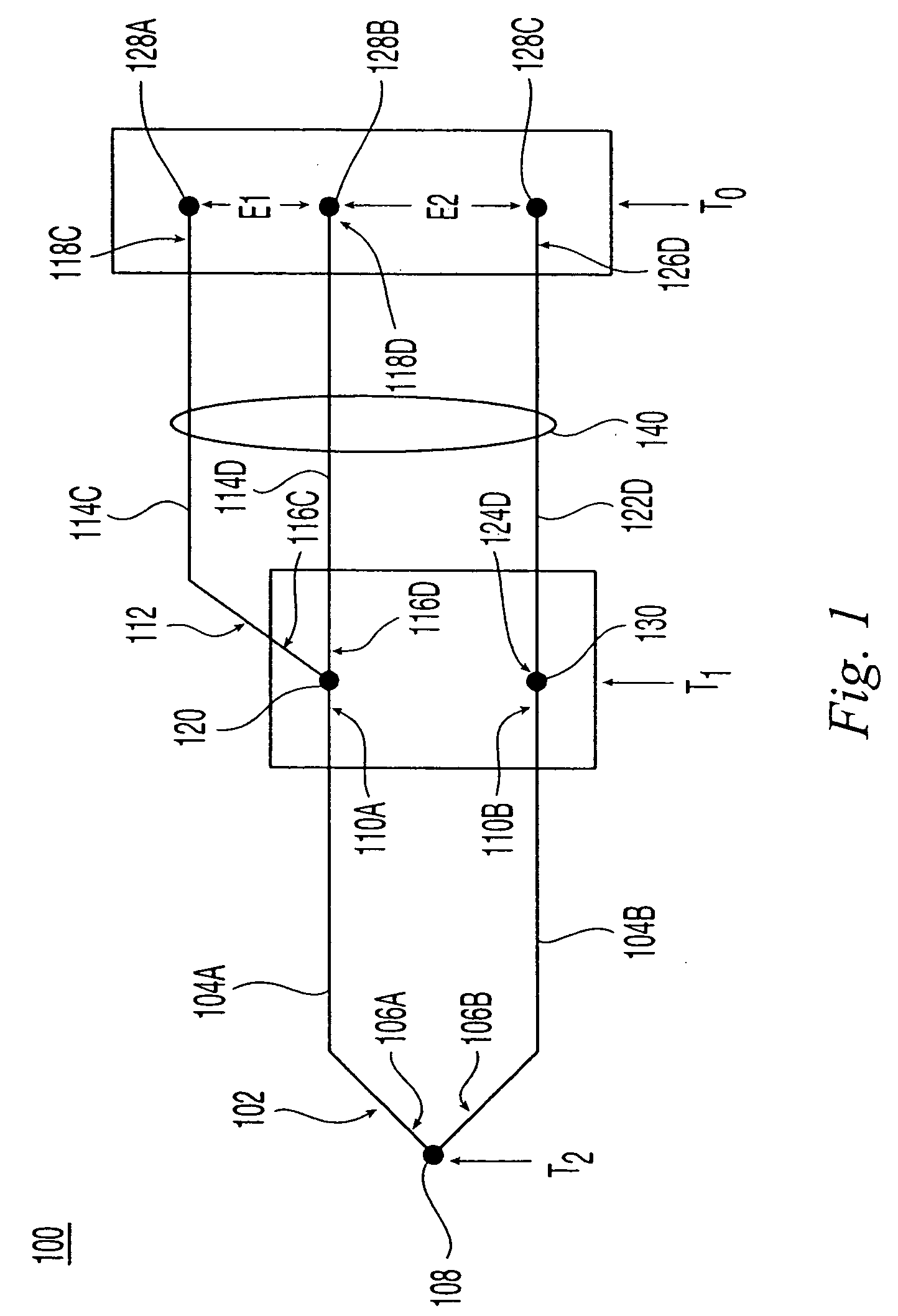

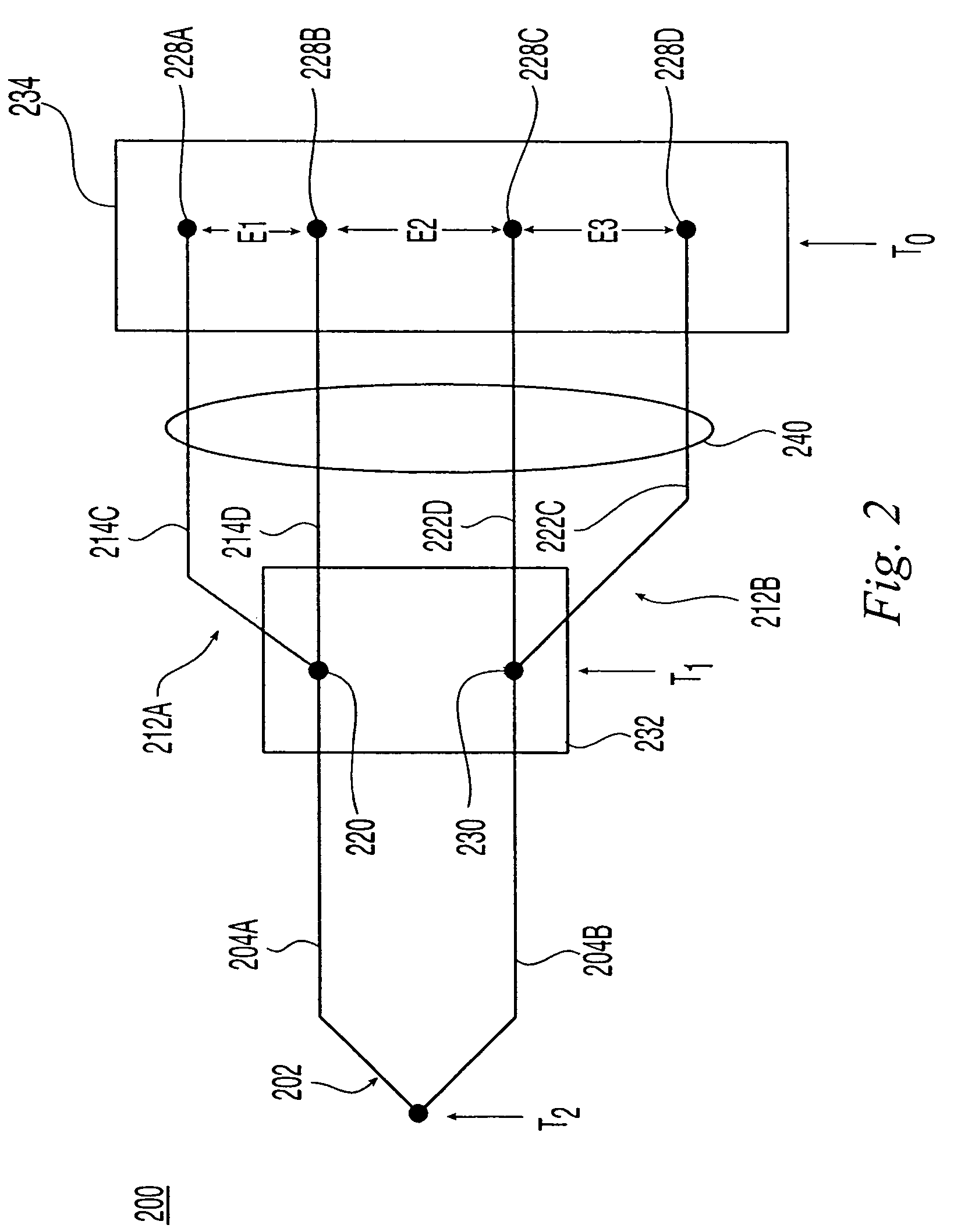

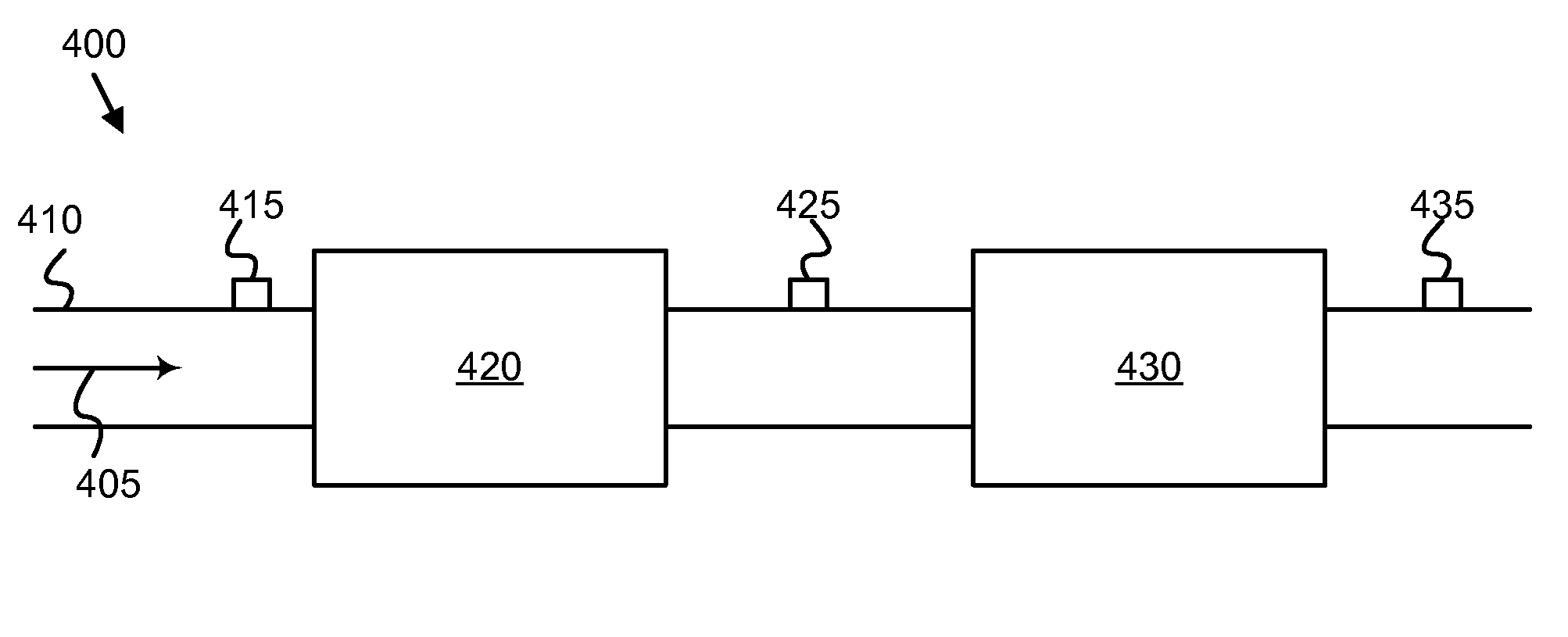

Sensor rationality diagnostic

A sensor diagnostic method, such as to determine rationality of one of three temperature sensors used in an exhaust aftertreatment system, includes determining the temperature difference between the first and second sensor, determining the temperature difference between the second and third sensor, determining whether the temperature differences are within an acceptable threshold range and comparing the two temperature differences to determine which sensor is in error, if any.

Owner:CUMMINS EMISSION SOLUTIONS

Detection device

InactiveUS20120237402A1Improve accuracyImprove operational reliabilityThermometer detailsInternal-combustion engine testingCombustionEngineering

Owner:ELTEK

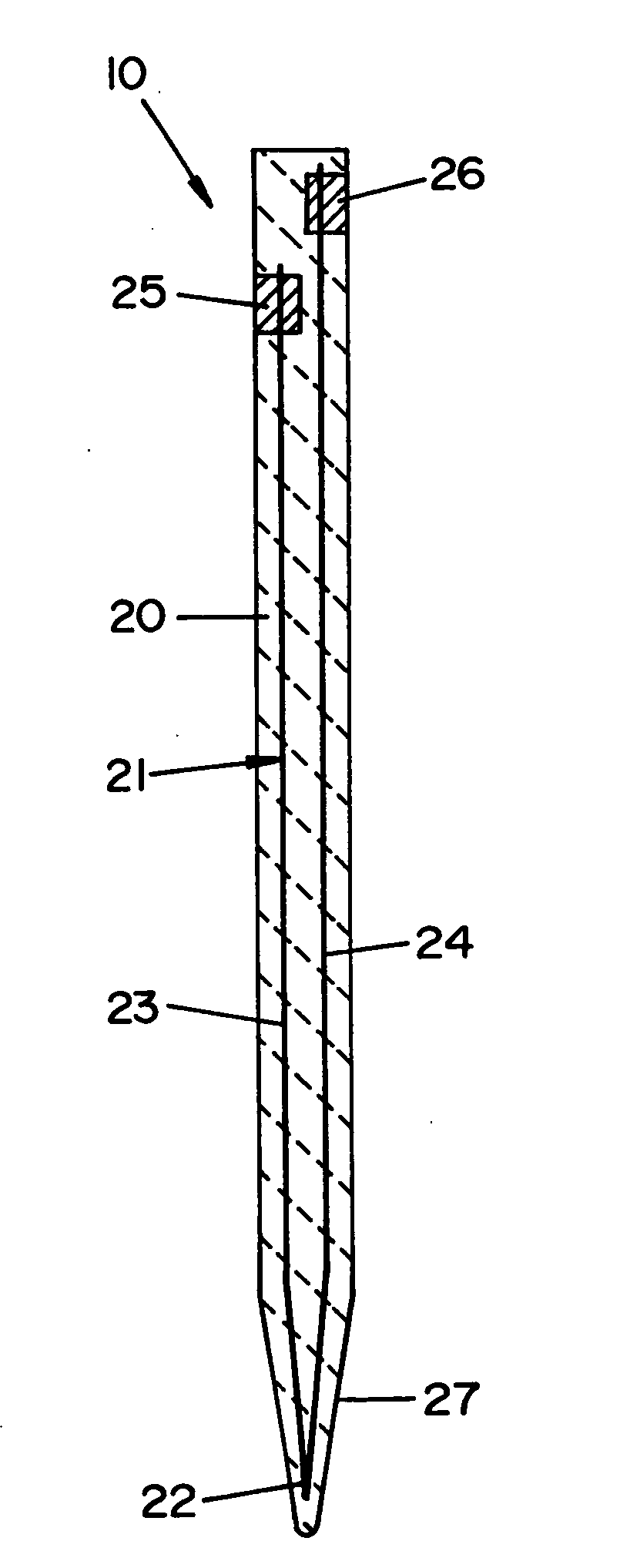

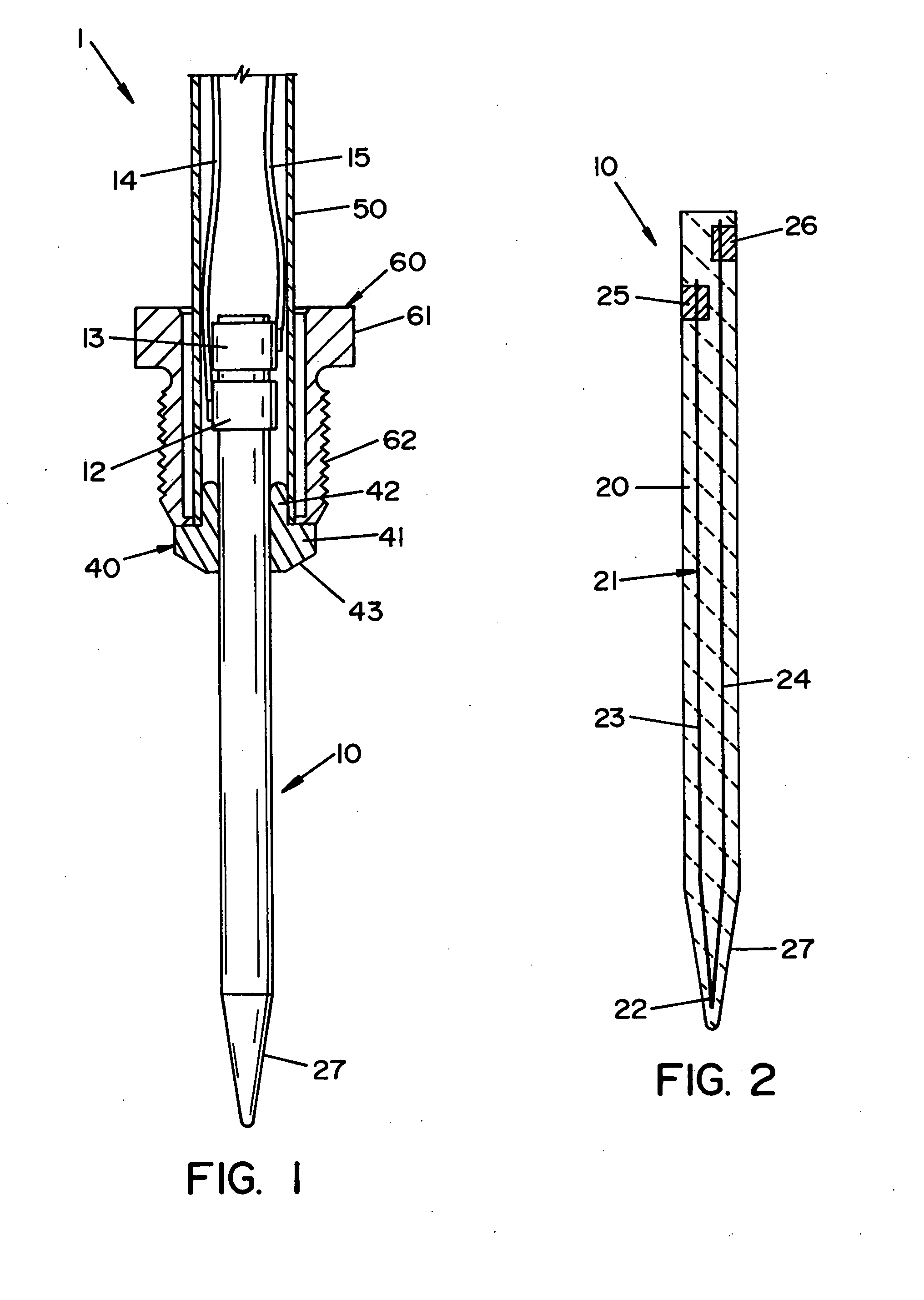

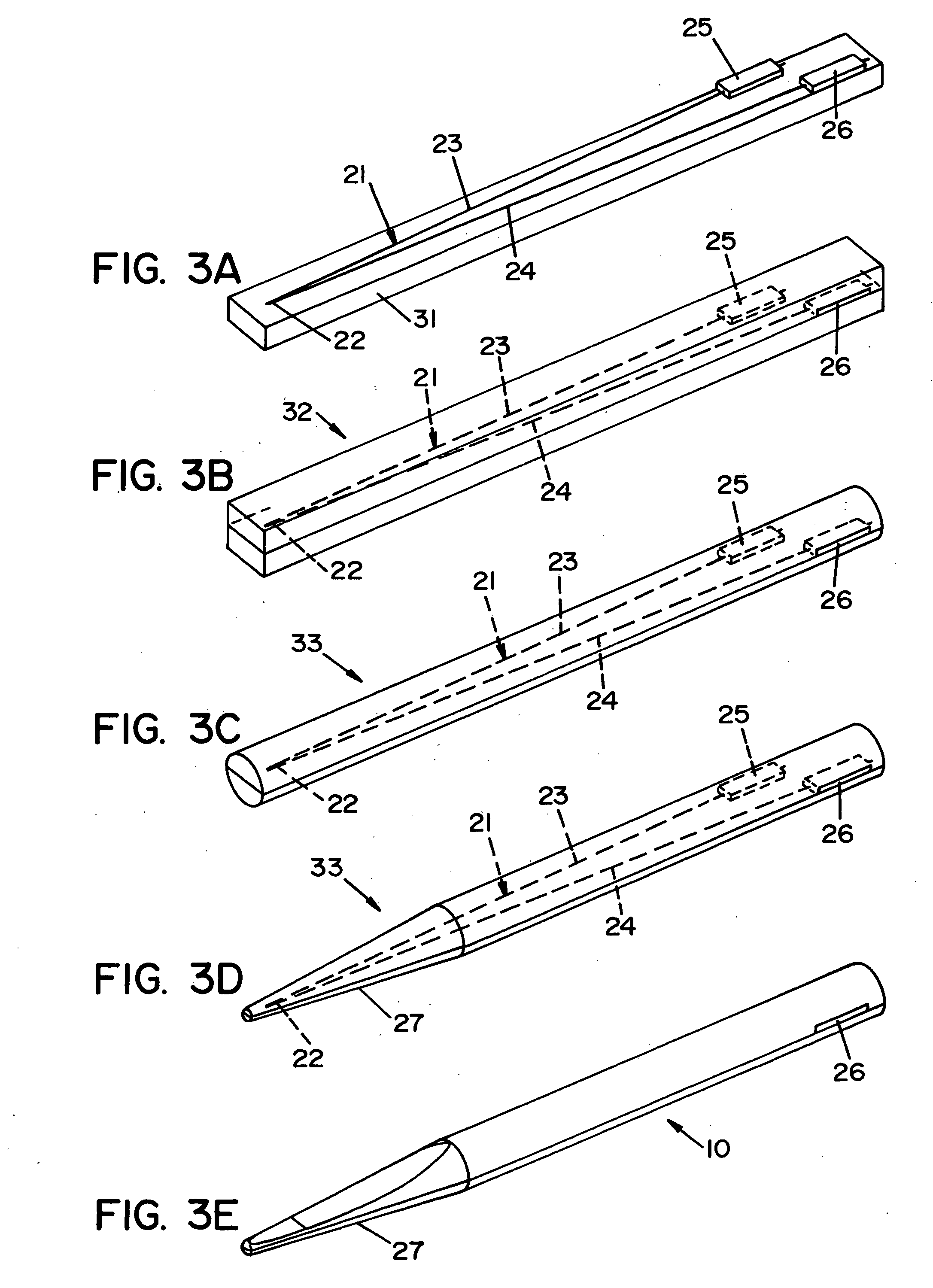

Temperature sensor element and method of manufacturing the same

InactiveUS20090268779A1Improve thermal conductivityImprove responseThermometer detailsTemperature measurement in motorsThermocoupleMaterials science

A temperature sensor element 10 has a reduced thermal conduction path from a measurement object to a sensitive end portion 22 of a thermocouple 21 and a high-dense insulating ceramic base body 20. Since the temperature sensor element 10 has excellent thermal conductivity from the measurement object to the sensitive end portion 22 of the thermocouple 21, it is also excellent in responsiveness at the time of temperature detection. Further, corrosion and material deterioration of the thermocouple 21 is unlikely to occur because the thermocouple 21 does not directly contact the measurement object (exhaust gas). As a result, the temperature sensor element 10 exhibits excellent durability. Therefore, the temperature sensor element 10 exhibits a good responsiveness at the time of temperature detection as well as excellent durability.

Owner:NGK SPARK PLUG CO LTD

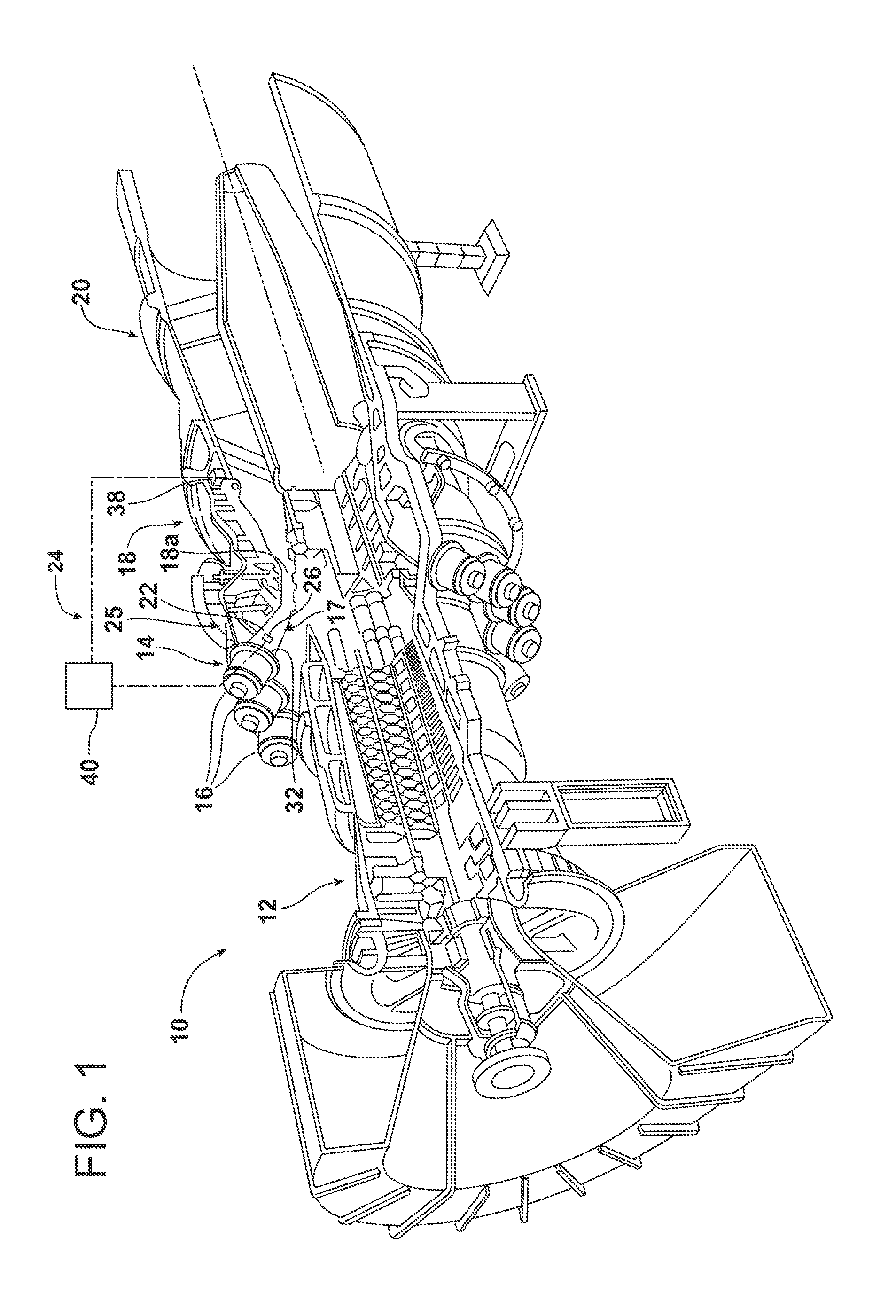

Motor control device, control method, and control program

InactiveUS8013565B2Accurate estimateEasy to controlHybrid vehiclesTemperature measurement in motorsAudio power amplifierRotor magnets

The temperature of a stator coil is measured by a temperature sensor (14), amplified by a stator coil temperature amplifier (21), and transmitted to a vehicle control section (23). Further, motor cooling oil (17) for cooling the outer periphery of the stator cools the stator coil (16) along an end coil section of the stator coil (16). The temperature of the motor cooling oil raised by the stator coil (16) is measured by a temperature sensor (15) and transmitted also to the vehicle control section (23) via a motor cooling oil temperature amplifier (22). The vehicle control section (23) estimates the temperature of a rotor magnet based on a thermal model (relationship between temperature, a heat production amount, and heat resistance) of the motor cooling oil, the stator coil, and the rotor magnet by using the motor cooling oil temperature and the stator coil temperature as input values and sends a control instruction to a motor control section (24).

Owner:TOYOTA JIDOSHA KK

Temperature sensor that achieves a fast response in an exhaust gas environment

InactiveUS7458718B2Fast response timeImprove accuracyThermometer detailsTemperature measurement in motorsConvection heatHot Temperature

A temperature sensor and method of forming the same includes a temperature sensing portion having a metal housing configured with at least one circular fin on a surface of the metal housing. A temperature sensing element is generally associated with the temperature sensing portion, wherein a potting is located within a gap formed between the temperature sensing element and the metal housing and joined with a ceramic tube for carrying a plurality of high temperature metal lead wires to and from the temperature sensing portion, thereby forming a temperature sensor utilized in an exhaust gas environment to measure temperature and improve a response time and accuracy of the temperature sensor due to an increase in surface area of the sensor tip for a given thermal mass for convection heat transfer.

Owner:HONEYWELL INT INC

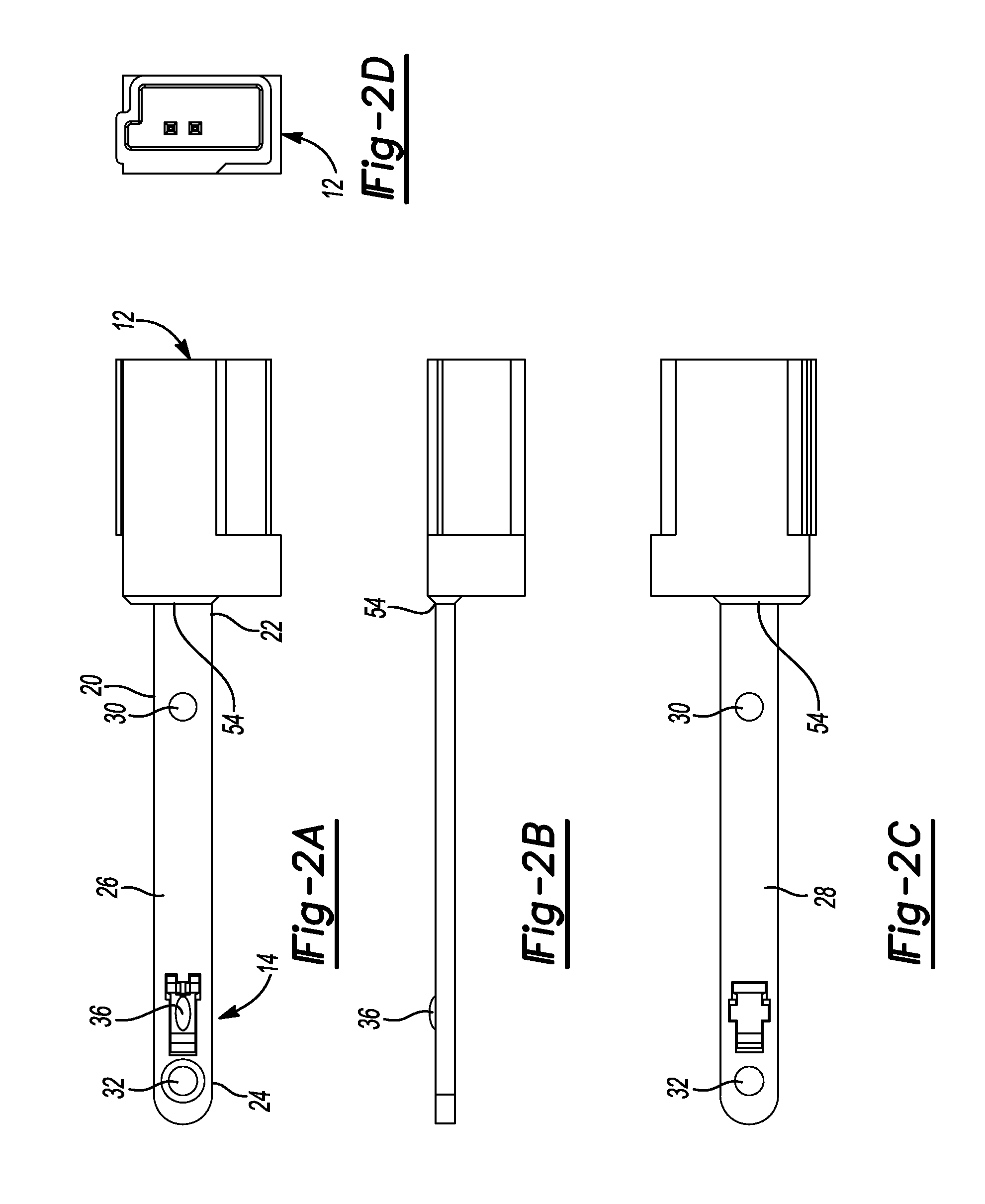

Low-profile temperature sensor probe

InactiveUS20130182745A1Thermometer detailsTemperature measurement in motorsElectricityElectrical resistance and conductance

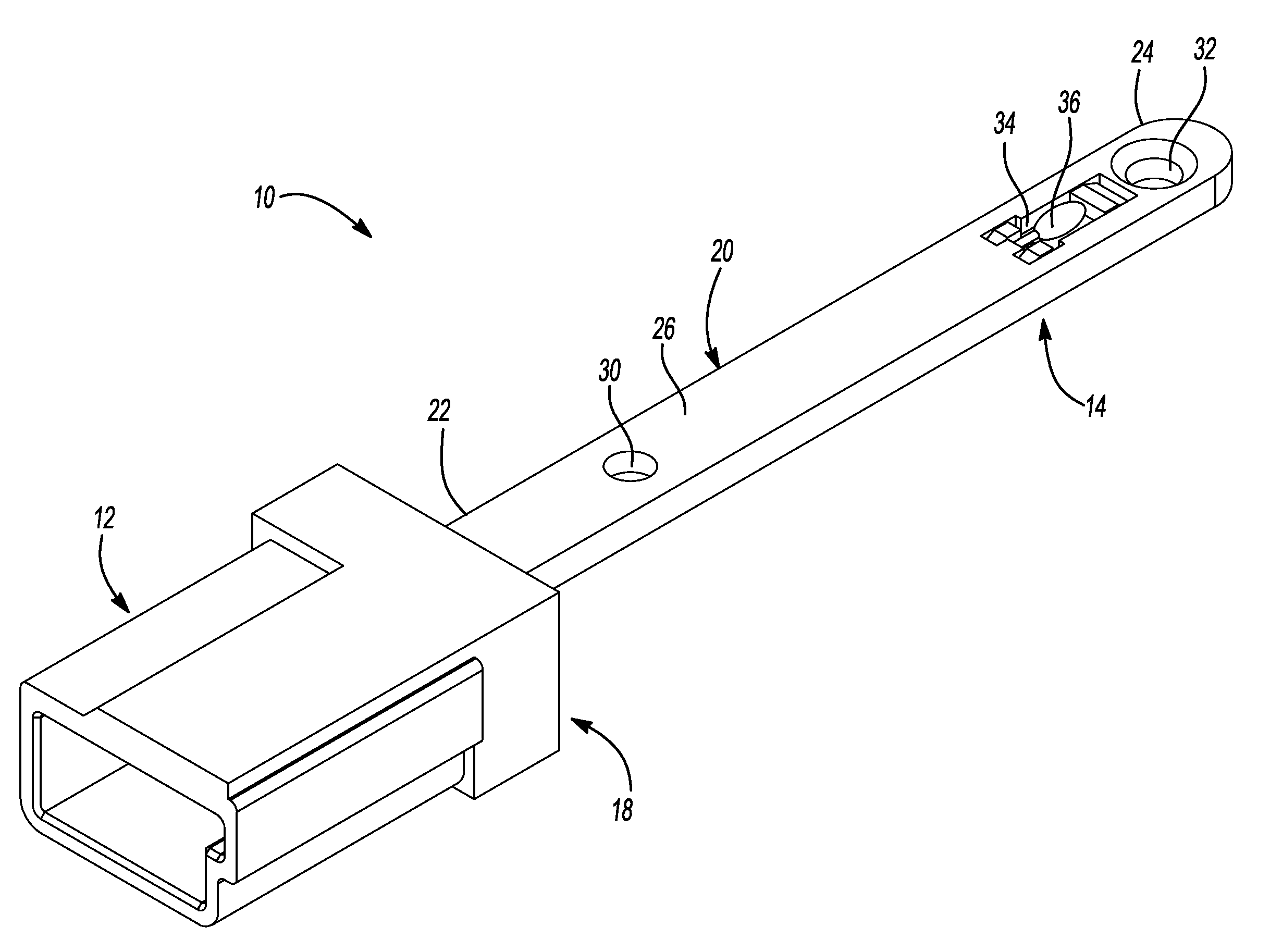

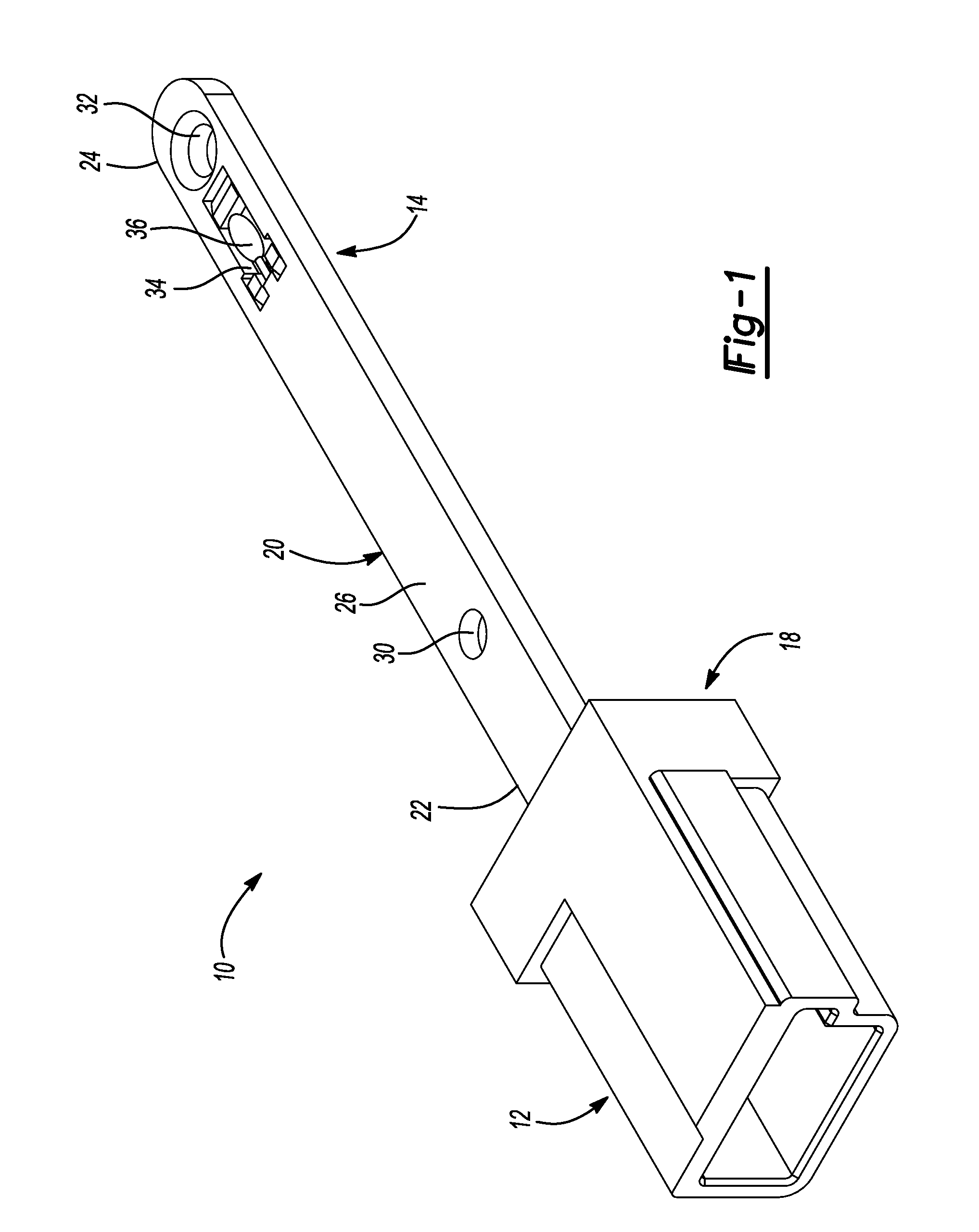

A low-profile temperature sensor probe is disclosed as including a probe circuit subassembly having a temperature sensing thermistor, the subassembly being overmolded with a durable insulating material to form the probe body. The probe body forms a connector block portion and a flexible extension portion. The flexible extension portion enables the sensor probe to conform to the surface of the object to be sensed without undue strain on the components. The thermistor element is located in a protective pocket and positioned relative the probe body to ensure direct contact with the object to be sensed. The connector block is configured to accommodate a standard plug-in type electrical connector.

Owner:THERM O DISC

Popular searches

Thermometers using electric/magnetic elements Using electrical means Temperature measurement of flowing materials Vehicles Fluid pressure measurement by electric/magnetic elements Material analysis by optical means Thermometers using physical/chemical changes Machines/engines Photometry using electric radiation detectors Rapid change measurement

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com