Pressure sensor device having temperature sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First Embodiment)

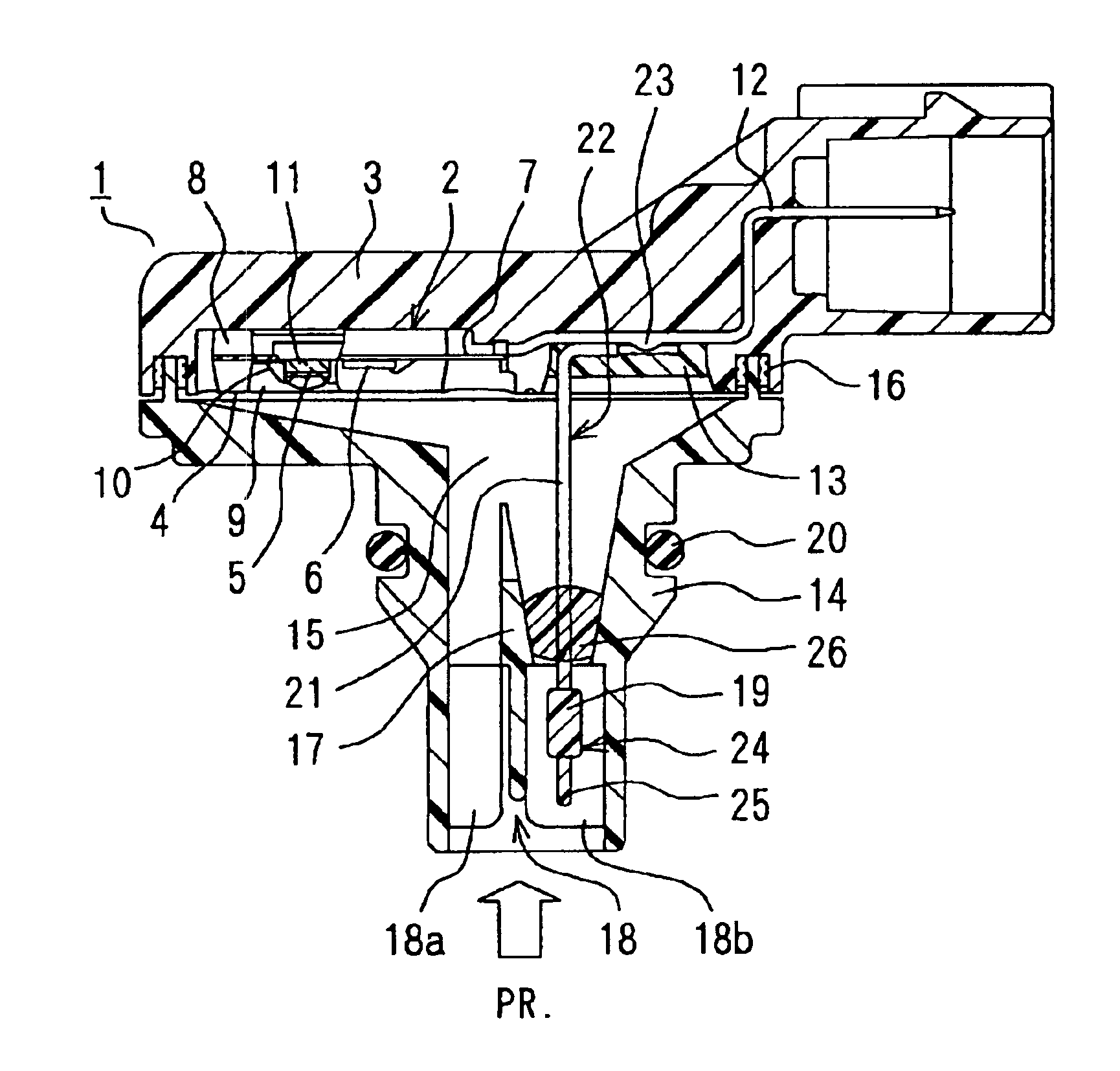

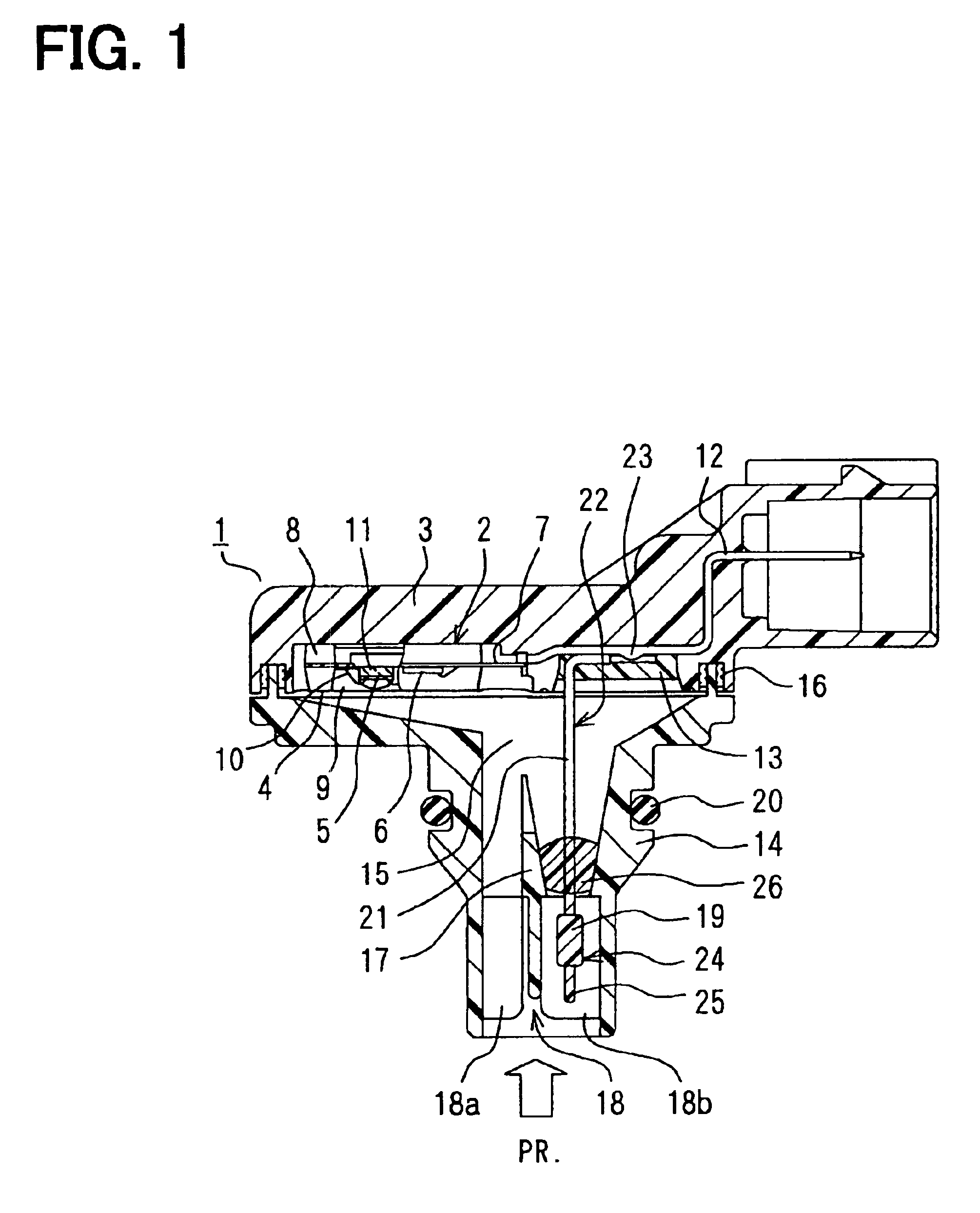

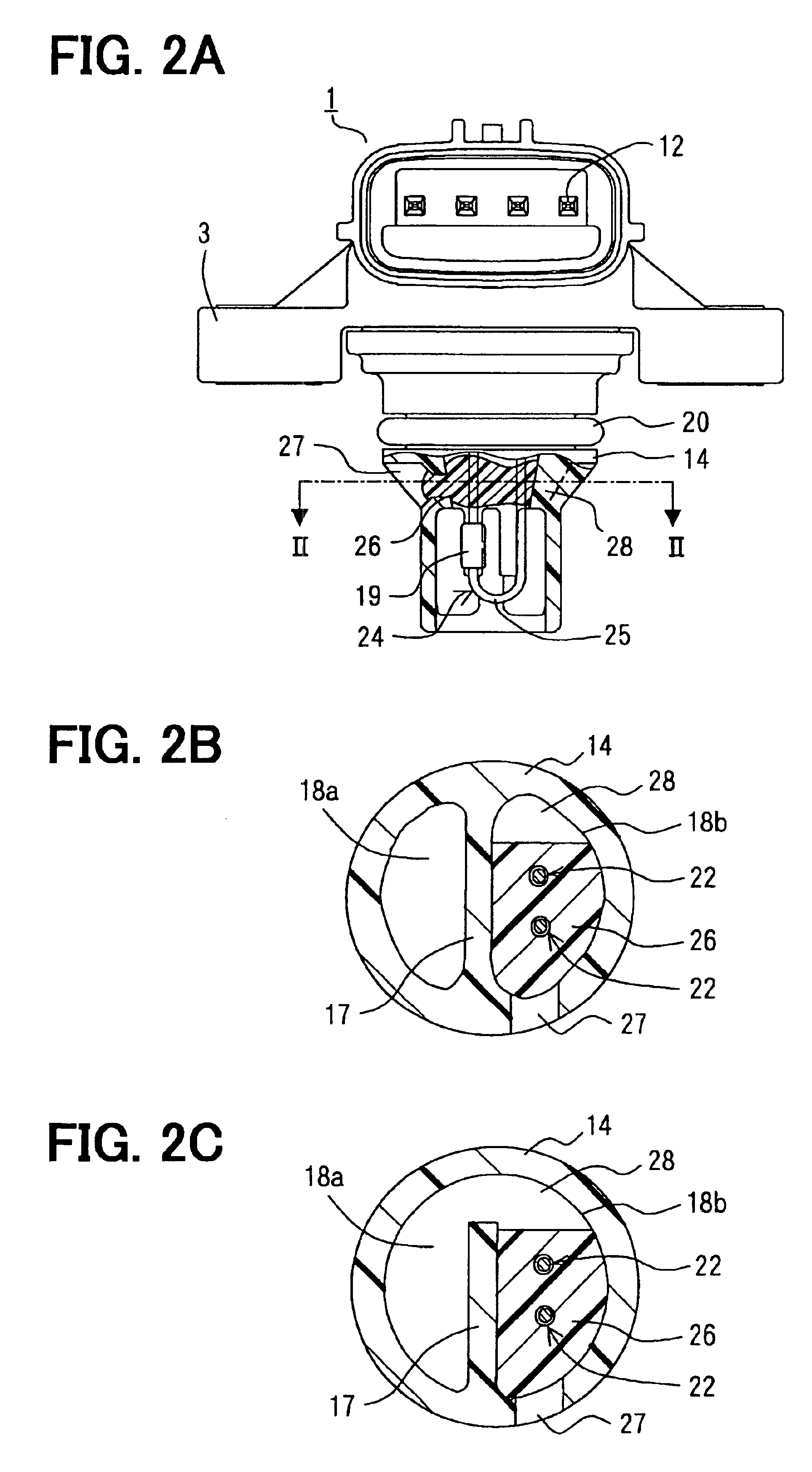

[0022]A pressure sensor device 1 having a temperature sensor according to a first embodiment of the present invention is shown in FIG. 1. The pressure sensor device 1 detects, for example, both pressure and temperature of intake air as a measuring object in an intake manifold of a vehicle. The device 1 includes a sensor casing 3. A mold IC (i.e., integrated circuit) 2 as a pressure detection element having a pressure sensor chip 5 is disposed in the sensor casing 3. The mold IC 2 includes a fixation portion 4 having a concavity, in which the pressure sensor chip 5 is mounted. The pressure sensor chip 5 detects the pressure of the measuring object. The mold IC 2 further includes a signal processor IC 6 and a lead frame 7.

[0023]The signal processor IC 6 magnifies a measurement signal outputted from the pressure sensor chip 5. The lead frame 7 outputs a magnified measurement signal from the signal processor IC 6. The signal processor IC 6 and the lead frame 7 are mold...

second embodiment

(Second Embodiment)

[0044]A pressure sensor device 200 having a temperature sensor according to a second embodiment of the present invention is shown in FIG. 3. The lead wire 22 of the temperature sensor 24 follows the inner wall of the temperature sensor chamber 18b. An elastic member 29 having a ball shape is disposed in the temperature sensor chamber 18b so that the elastic member 29 suppresses the vibration of the lead wire 22. The elastic member 29 is inserted into the temperature sensor chamber 18b through the introduction port 27. At this time, the elastic member 29 deforms so as to be inserted into the temperature sensor chamber 18b. The elastic member 29 is disposed between the lead wire 22 and the inside end of the introduction port 27, so that the lead wire 22 is press-contacted to the inner wall of the temperature sensor chamber 18b. Thus, the vibration of the temperature sensor 24 is reduced. The elastic member 29 does not have fluidity such as the resin material, so tha...

third embodiment

(Third Embodiment)

[0049]A pressure sensor device 300 having a temperature sensor according to a third embodiment is shown in FIG. 4. At least one of the temperature sensor chip 19 or the lead wire 22 is insert-molded into the inlet port 14. Therefore, the temperature sensor 24 is supported by both the inlet port 14 and the connection portion 23, so that the vibration of the temperature sensor 24 is reduced. Accordingly, the endurance of the temperature sensor 24 is increased.

[0050]Although the lead wire 22 of the temperature sensor 24 is inserted into the inlet port 14, both the temperature sensor chip 19 and the lead wire 22 are inserted into the inlet port 14. In this case, since the temperature sensor chip 19 detects the temperature through the inner wall of the inlet port 14, the response of the temperature sensor chip 19 is reduced. Therefore, it is preferred that the temperature sensor 24 is inserted into the inlet port 14 so as to detect the temperature directly by the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com