method for estimating the junction temperature of an IGBT power module on line

A power module and junction temperature technology, applied in the fields of power electronics and electronic information science, can solve problems such as measurement errors affecting estimated values, difficult maintenance, and high failure rate of thermocouples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

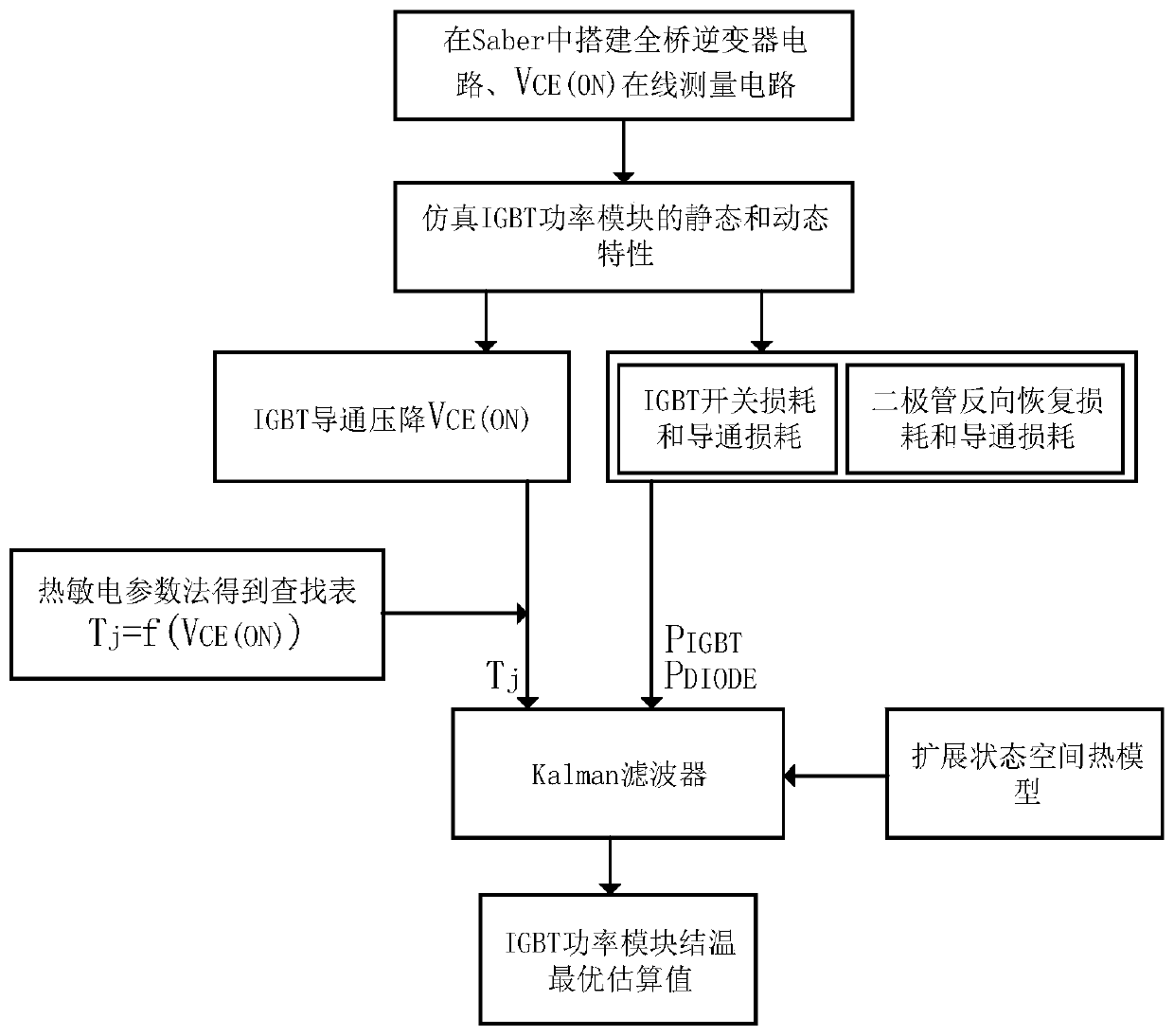

[0082] Such as figure 1 As shown, the present invention provides a method for online estimation of the junction temperature of an IGBT power module, as follows image 3 The shown full-bridge inverter circuit is taken as an example to introduce the implementation process of this method in detail. The specific implementation steps are as follows:

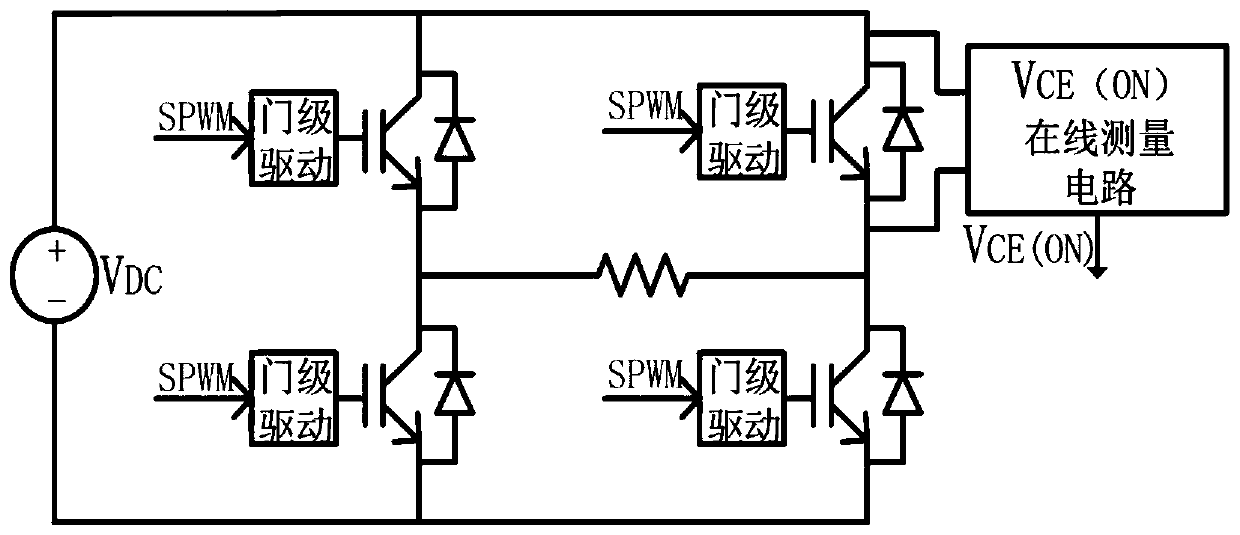

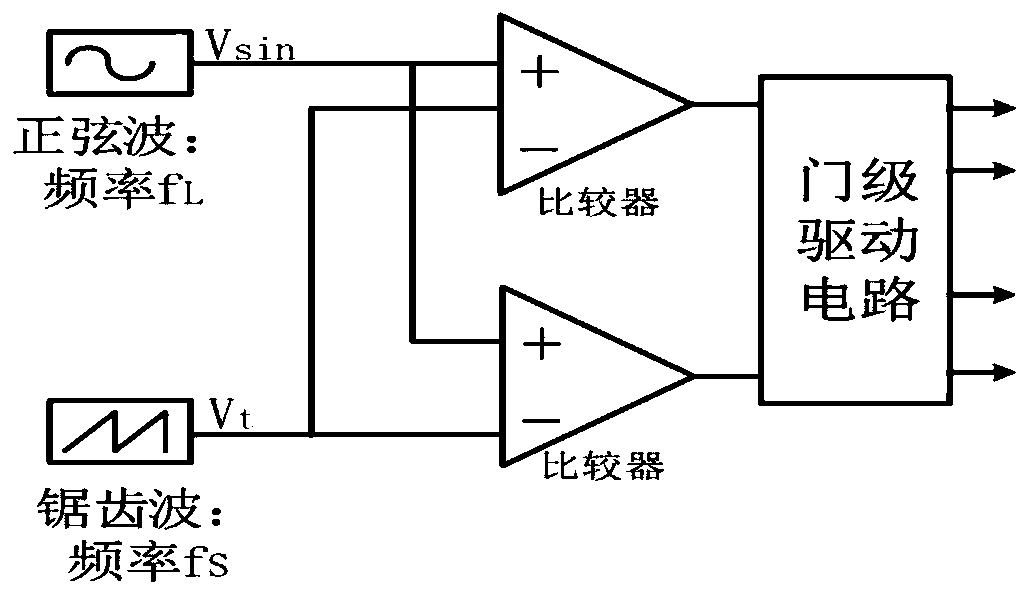

[0083] Step 1. Build a full-bridge inverter circuit in Saber, V CE(ON) On-line measurement circuit, SPWM control circuit and gate-level drive circuit, V CE(ON) The two input terminals of the online measurement circuit are connected to the collector and emitter of the IGBT of the full-bridge inverter circuit to realize the connection between the full-bridge inverter circuit and V CE(ON) Connection of in-line measurement circuits such as figure 2 shown.

[0084] Step 1 in the embodiment specifically inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com