Process for reclaiming chromium and aluminum by comprehensive treatment of sludge containing chromium-aluminium

A comprehensive processing and aluminum slime technology, applied in the direction of improving process efficiency, etc., can solve problems such as aluminum can not be recycled, high energy consumption, and resources can not be fully utilized, so as to achieve the effect of protecting the environment, realizing comprehensive utilization, and realizing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

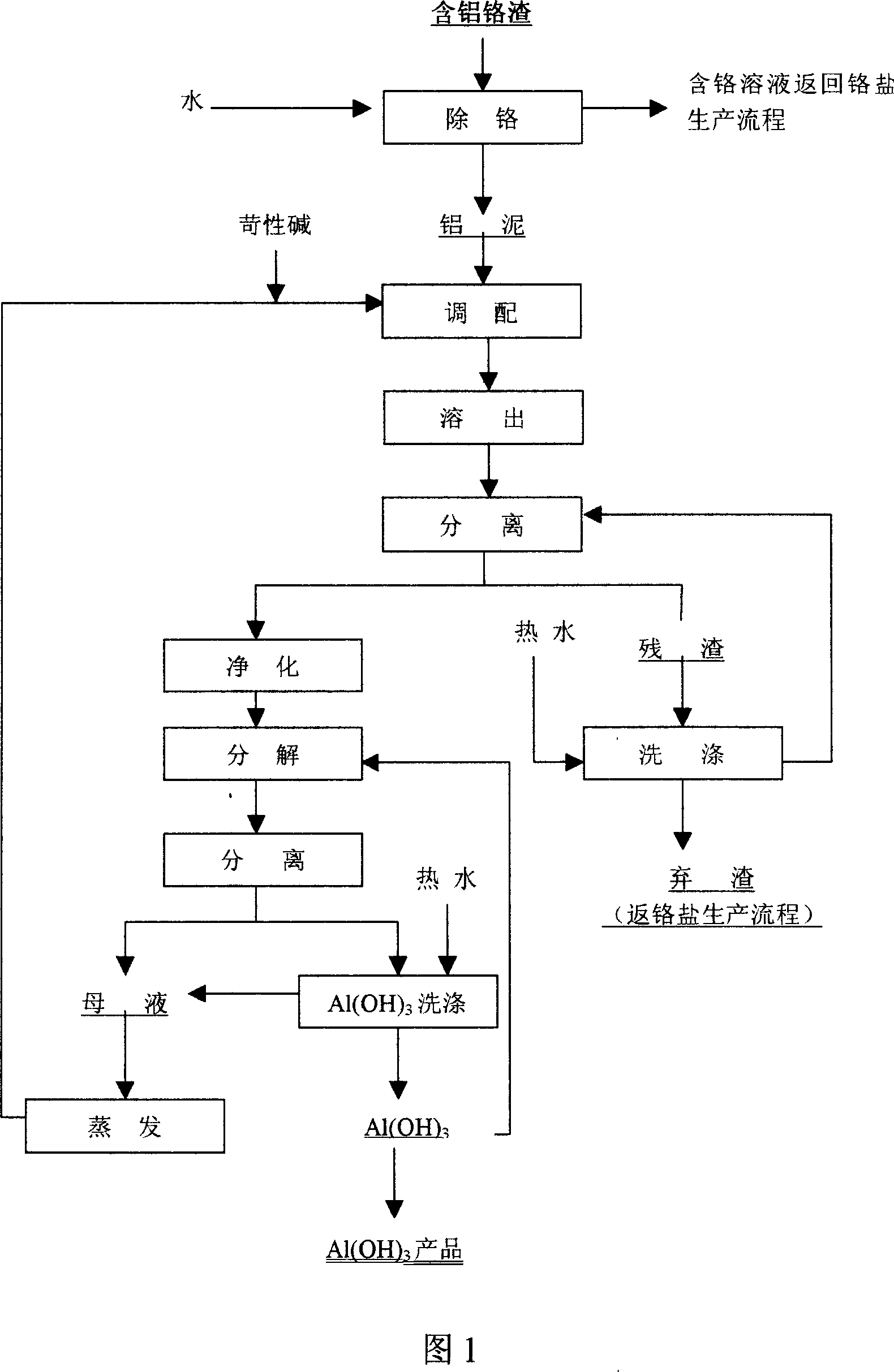

Image

Examples

Embodiment approach 2

[0013] Add a certain amount of chromium-removing lotion in the chromium-containing aluminum mud with a water content of about 70%, control its liquid-solid ratio to be 5.0, carry out liquid-solid separation after stirring at 70° C. for 4 hours, and the chromium concentration in the gained liquid phase ( Take Na 2 Cr 2 o 7 .2H 2 O) is 100g / L, the band loss of chromium in solid phase aluminum mud (water content is about 70%) is 0.5%, aluminum (as Al(OH) 3 (calculated) content of 23%; then, add industrial grade soda sulfide while dechroming and aluminum slurrying, and the addition amount is 3kg / m 3 Slurry, the resulting slurry solution is dissolved in a sodium aluminate solution with a caustic molecular ratio of 3.0, the dissolution temperature is 120°C, and the dissolution time is 30 minutes. The dissolved slurry is separated by sedimentation, and the obtained supernatant (crude liquid) is filtered through a leaf , and then decompose the seed crystals to precipitate aluminum...

Embodiment approach 3

[0015] Add a certain amount of chromium-removing lotion in the chromium-containing aluminum mud with a water content of about 70%, control its liquid-solid ratio to be 3.0, carry out liquid-solid separation after stirring at 50° C. for 6 hours, and the chromium concentration in the gained liquid phase ( Take Na 2 Cr 2 o 7 .2H 2 O) is 120g / L, the band loss of chromium in solid phase aluminum mud (water content is about 70%) is 1.0%, aluminum (as Al(OH) 3 ) content of 18%; then, add industrial grade sodium sulfide while dechroming and aluminum slurrying, the addition amount is 6kg / m 3 Slurry, the resulting slurry solution is dissolved in a sodium aluminate solution with a caustic molecular ratio of 2.8, the dissolution temperature is 80°C, and the dissolution time is 60 minutes. The dissolution slurry is separated by sedimentation, and the obtained supernatant (crude liquid) is filtered through a leaf , and then decompose the seed crystals to precipitate aluminum hydroxide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com