Production method and production device of condiments

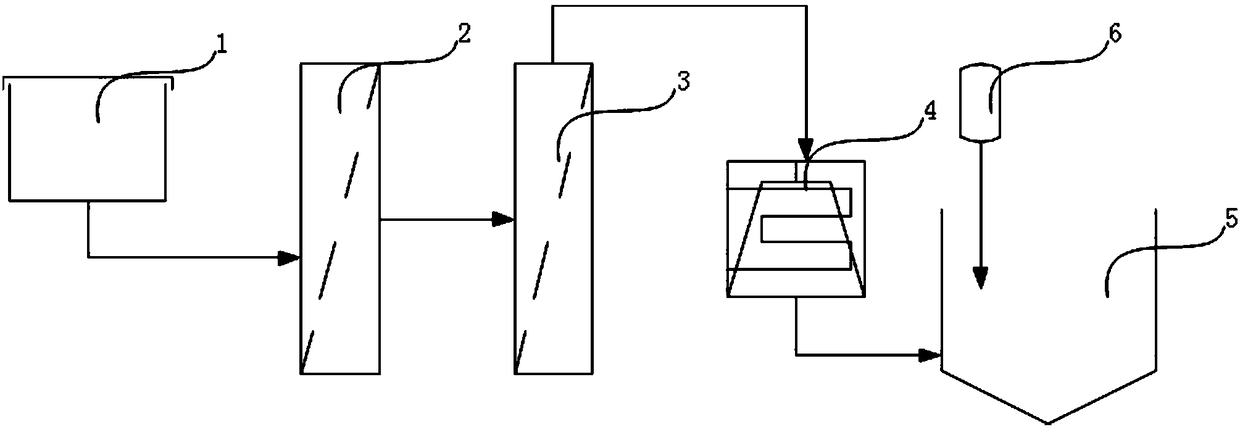

A production method and production device technology, applied in the field of condiment production methods and devices based on membrane integration technology, can solve the problems of high energy consumption and low production capacity, and achieve the effects of reducing concentration time, energy consumption, and clarification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

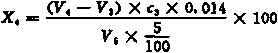

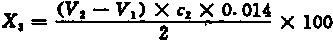

Embodiment 1

[0084] Collect 1000 kg of razor clam juice obtained by continuous steam cooking of razor clam in a dried razor clam processing factory, and use an inorganic microfiltration membrane process with a pore size of 0.05 μm to clarify to obtain 870 kg of clarified razor clam juice. The clarified razor clam juice obtained in the above steps is concentrated and dehydrated by nanofiltration. The molecular weight cut-off of the nanofiltration membrane is 200Da. The amino acid nitrogen content in the concentrated razor clam juice is 0.99g / 100ml. Concentrate the razor clam juice concentrated by nanofiltration in vacuum to obtain 48kg of razor clam juice concentrate. The content of amino acid nitrogen in the vacuum concentrated razor clam juice concentrate is 1.2g / 100ml. Edible salt is added to the concentrated juice of razor clam juice after vacuum concentration until the edible salt content in the concentrated juice reaches 20 wt%, and after thorough stirring, the finished product of raz...

Embodiment 2

[0086]Collect 1000 kg of razor clam juice obtained by continuous steam cooking of razor clam in a dried razor clam processing factory, and use an inorganic microfiltration membrane process with a pore size of 0.2 μm for clarification to obtain 920 kg of clarified razor juice. The clarified razor clam juice obtained in the above steps is concentrated and dehydrated by nanofiltration. The molecular weight cut-off of the nanofiltration membrane is 300Da. The amino acid nitrogen content in the concentrated razor clam juice is 1.12g / 100ml. Concentrate the razor clam juice concentrate after nanofiltration to obtain 34kg razor clam juice concentrate. The content of amino acid nitrogen in the vacuum concentrated razor clam juice concentrate is 1.34g / 100ml. Edible salt is added to the concentrated juice of razor clam juice after vacuum concentration until the edible salt content in the concentrated juice reaches 20 wt%, and after thorough stirring, the finished product of razor clam se...

Embodiment 3

[0088] Collect 1000 kg of razor clam juice obtained by continuous steam cooking of razor clam in a dried razor clam processing factory, and use an inorganic microfiltration membrane process with a pore size of 0.5 μm to clarify to obtain 910 kg of clarified razor juice. The clarified razor clam juice obtained in the above steps is concentrated and dehydrated by nanofiltration. The molecular weight cut-off of the nanofiltration membrane is 400Da. Amino acid nitrogen content in the clam juice after filtering and concentrating is 0.95g / 100ml. Concentrate the razor clam juice concentrated by nanofiltration in vacuum to obtain 36.4kg of razor clam juice concentrate. The amino acid nitrogen content in the vacuum concentrated razor clam juice concentrate is 1.12g / 100ml. Edible salt is added to the concentrated juice of razor clam juice after vacuum concentration until the edible salt content in the concentrated juice reaches 20 wt%, and after thorough stirring, the finished product o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com