Neutralization device for preparation of vanadium catalyst for EPDM rubber

A technology of EPDM rubber and catalyst, which is applied in the direction of chemical/physical/physical chemical fixed reactors, etc. It can solve the uncontrollable acid-base amount of the neutralization device, prolong the total time of vanadium-based catalysts, and cannot remove vanadium-based catalysts Problems such as insoluble impurities can be eliminated to achieve the effect of reducing production cost and precise feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

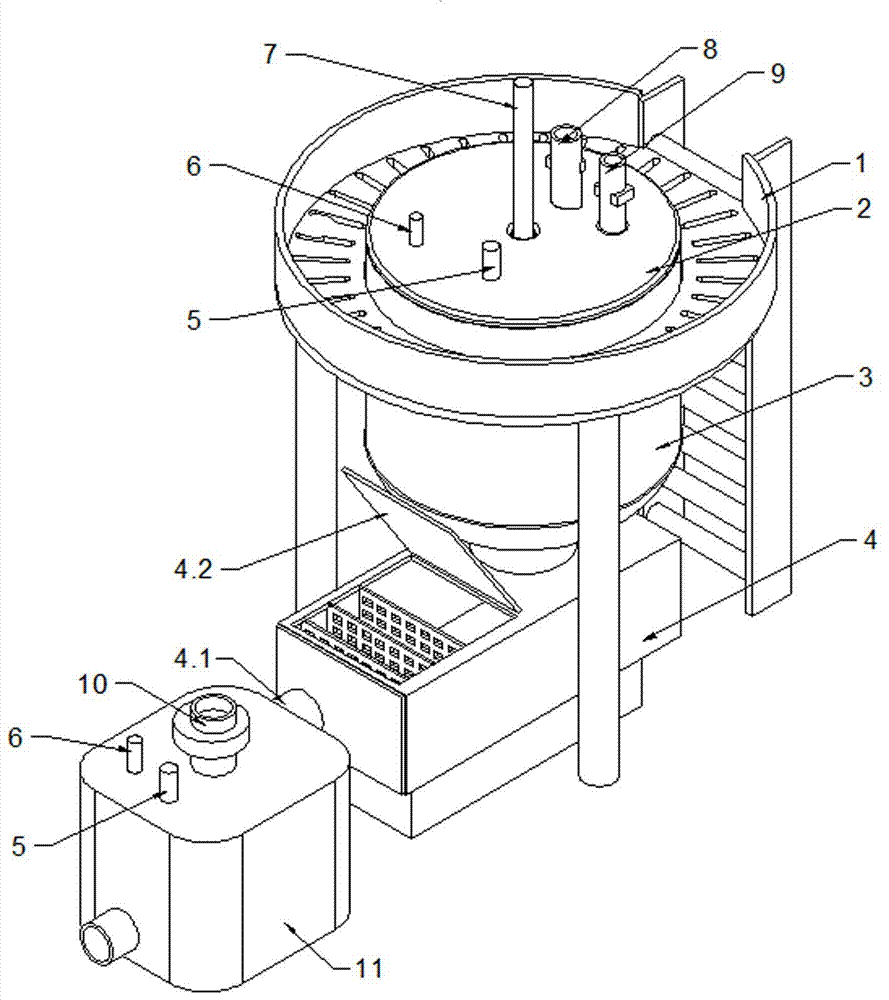

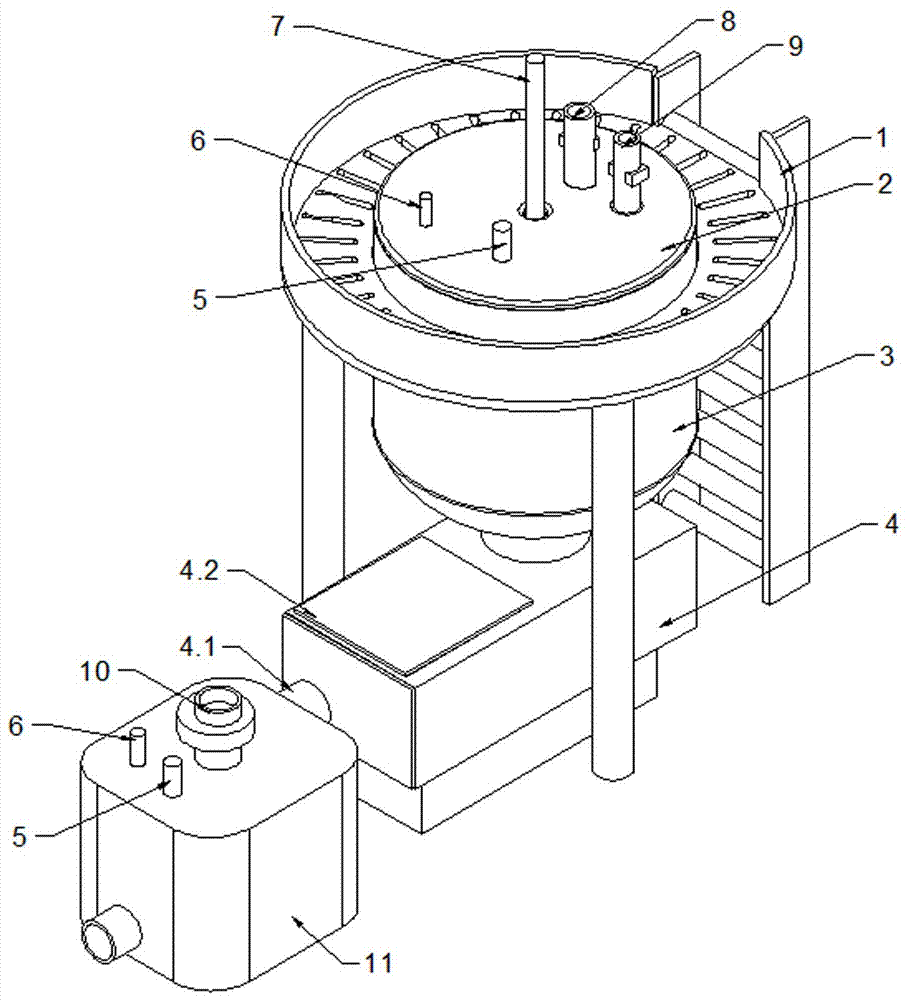

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0024] Such as Figure 1-3 As shown, the neutralization device for the preparation of vanadium-based catalysts for EPDM rubber includes, from high to low, an alkalization reaction kettle for providing alkalization reactions, a filter pool 4 for filtering insoluble impurities in alkalization reactions, and A neutralization tank 11 for providing a neutralization reaction place. This design can rely on the gravity potential energy to successfully complete the liquid delivery work without adding additional delivery pumps, so this setting is more energy-saving and environmentally friendly.

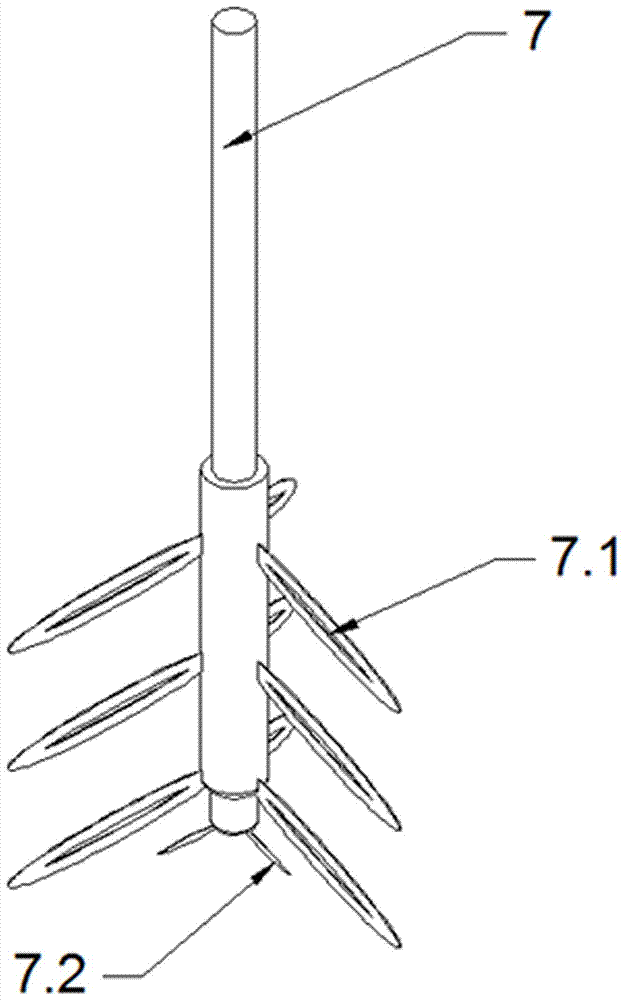

[0025] The alkalization reactor includes a reactor body 3 and a reactor cover 2 fixed to the reactor body 3 through a flange connection. The bottom of the reactor main body 3 is connected to the filter tank 4 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com