Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Reduce the amount of acid and alkali" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

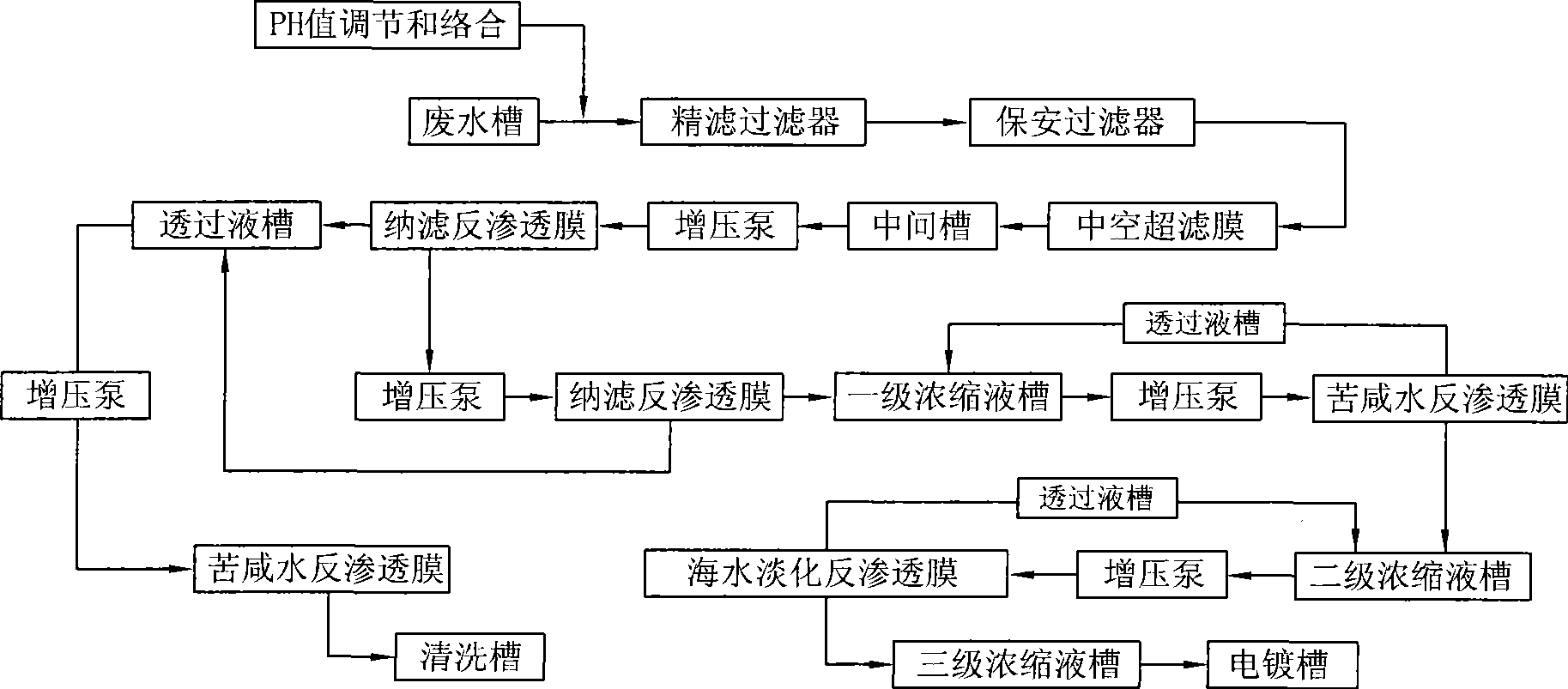

Process for advanced treatment of electroplating waste by integrated membrane

InactiveCN101481157AAchieving zero emissionsAvoid secondary pollutionCellsGeneral water supply conservationWater desalinationFiltration

The invention discloses an integrated film deep processing electroplating waste water technology which has the following technical procedures: complexation and pH value regulation are carried out to electroplating waste water; primary filtration is carried out to the electroplating waste water by a fine-filtration filter and a safety filter; the electroplating waste water enters a hollow super-filtration film; the electroplating waste water is pressurized and enters a nano-filtration reverse osmosis film to carry out first-stage concentration; permeating liquid enters a permeating liquid tank; after being pressurized, the electroplating waste water in the permeating liquid tank returns to a cleaning tank by an brackish water reverse osmosis film; after being pressurized, the concentrated liquid enters the permeating liquid tank, the permeating liquid enters the permeating liquid tank, and the concentrated liquid is further pressurized to enter the brackish water reverse osmosis film for second-stage concentration; the permeating liquid after the second-stage concentration returns to the inlet of the alkali reverse osmosis film, and after being further pressurized, the concentrated liquid enters a seawater desalting reverse osmosis film for third-stage concentration; the permeating liquid after the third-stage concentration returns to the inlet of the seawater desalting reverse osmosis film, and the concentrated liquid returns to the electroplating tank to be used as electroplating supplementary liquid. The invention avoids the second environmental pollution, and realizes the zero discharge of the electroplating waste water.

Owner:ZHEJIANG YUQUAN ENVIRONMENTAL ENG

Yeast glucans extraction process

InactiveCN101012468AReduce the amount of acid and alkaliLess extraction processMicroorganism based processesFermentationEnzymeChemistry

The invention discloses a manufacturing technique of yeast gluglucosan to decompose yeast cellar wall conjugase under high temperature, which compriss the following steps: adopting yeast cell wall as raw material; adding water with weight rate at 1:3-1:8 to make suspension; heating to 105-150 deg.c for 1-6h; cooling; diluting; centrifuging; washing for 2-3 times; removing sediment; adding water with rate at 1;15-1:25; heating to 30-40 deg.c; adjusting pH value to 9-11; stirring; adding proteinase; enzymolyzing 2-6h; neutralizing; centrifuging; washing; disposing through excessive ketone; filtering; washing residual for three times through ketone; freezing sediment at -70 deg.c for 22h; freezing sediment at -60 deg.c for 6-10h; obtaining the product.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

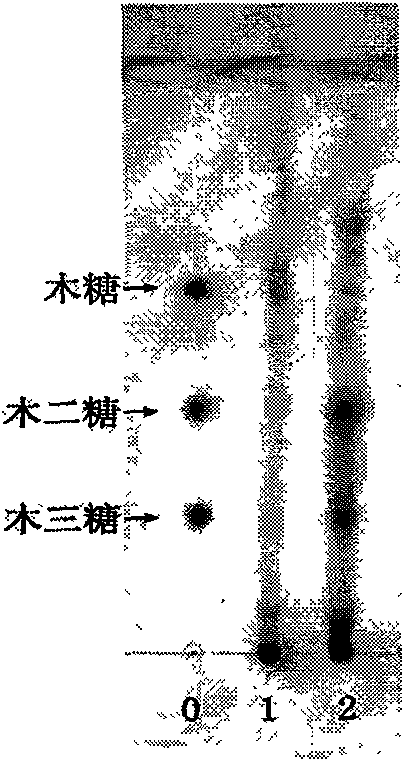

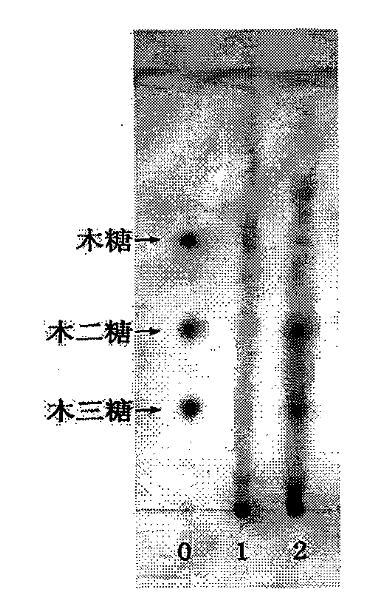

Production method for xylose by enzyme process

The technical scheme for xylose preparation with enzyme comprises: using CGMCC1476 as a Aspergillus niger strain to ferment and prepare excision xylanase that has high activity and needs mild reaction condition; enzymolyzing specially corn core and zylan in straw materail; refining to prepare single-xylose with purity more than 90%. This invention has no pollution to environment and conversion more than 80%.

Owner:JINAN GUOLI BIOLOGICAL SCI & TECH

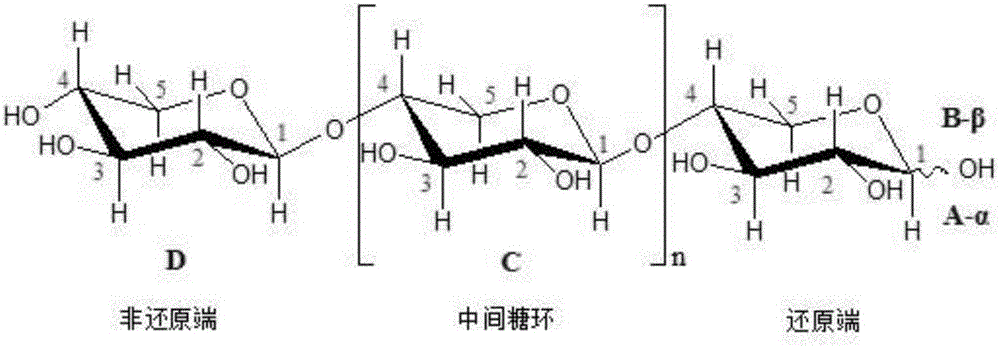

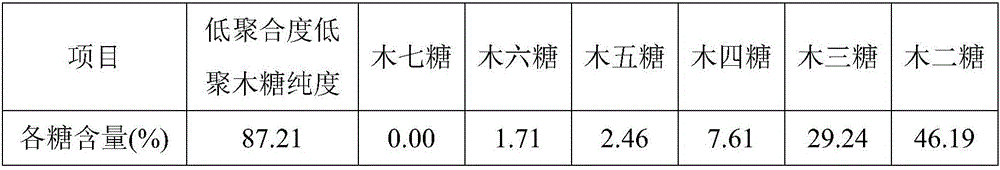

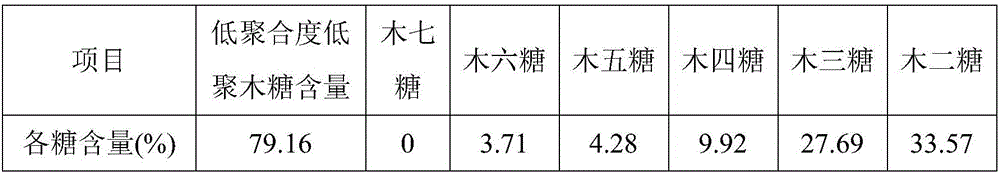

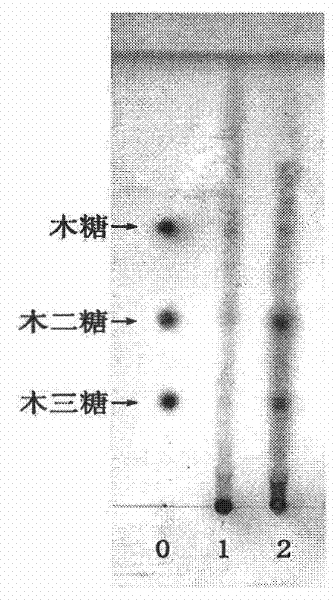

Xylooligosaccharide with low DP (degree of polymerization) as well as preparation method and application of xylooligosaccharide

PendingCN106636256AHigh dissolution ratePromote degradationBacteriaMicroorganism based processesFiberEnzymatic hydrolysis

The invention discloses a preparation method of xylooligosaccharide with low DP (degree of polymerization). The preparation method is characterized by comprising steps as follows: (1) wood fiber biomass is taken as a raw material and subjected to diluted acid / diluted base / hot water pretreatment, a liquid is filtered, a solid phase is treated in a high-temperature degrading or steam explosion pretreatment manner, and the wood fiber biomass is cooled for later use; (2) xylanase is added to a pretreatment solution in step (1) for an enzymatic hydrolysis reaction; (3) an enzymatic hydrolysis solution is treated through enzyme deactivation, purification, concentration and drying, and xylooligosaccharide with low DP is prepared. The DP of finally obtained xylooligosaccharide is low by reasonably optimizing each process step, and xylobiose, xylotriose and xylotetraose are taken as main components, so that the functionality of xylooligosaccharide as a bifidus factor is enhanced. Tests verify that prepared xylooligosaccharide has a good proliferative effect on bifidobacterium animalis and lactobacillus casei. The process is simplified, the product quality is improved, and xylooligosaccharide has good application prospect.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

Extraction method of deep-sea fish gelatin

ActiveCN103805071AAvoid it happening againAvoid yield reductionGlue/gelatin preparationCompound organicRoom temperature

The invention discloses an extraction method of deep-sea fish skin gelatin, and the method comprises the following steps of putting cleaned fish skin in conditioning fluid which is prepared from compound organic acid and stirring, cleaning the conditioned fish skin by water at room temperature, putting the cleaned fish skin in weakly acidic water solution at 30-60 DEG C for extraction, combining the extracting solution, filtering the extracting solution by 100-mesh filter cloth, and carrying out concentration and drying to obtain the gelatin. The method provided by the invention is gentler, and the prepared product is high in yield and purity, large in molecular weight, narrow in molecular weight distribution, shallow in color and light in fishy smell.

Owner:QINGDAO HUAKE BIOLOGICAL TECH CO LTD

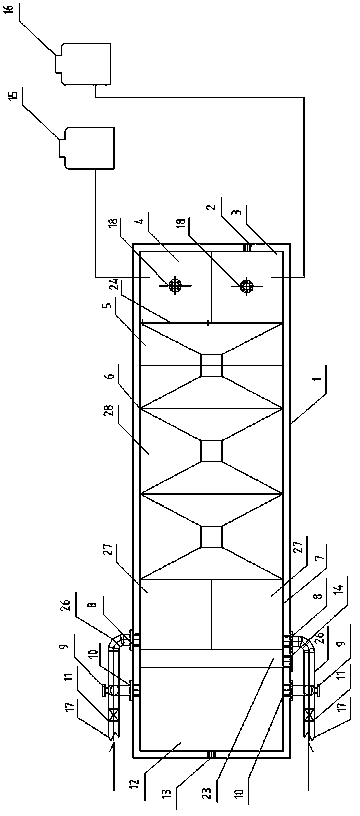

System and method for treating sewage

InactiveCN105884145AImprove processing effectReduce the amount of acid and alkaliWater/sewage treatment by centrifugal separationTreatment involving filtrationSewage treatmentSewage

The invention provides a system and a method for treating sewage. The system comprises a thick grid, a water collecting tank, a fine grid, a rotational flow sand settling tank, a regulating tank, an emergency tank, a coagulation sedimentation tank, gas flotation equipment, an intermediate water tank, ultra-filtration equipment, a concentrated water regulating tank, a multistage coagulation sediment, an A2O biochemical tank, an inclined-tube sedimentation tank, a fiber turntable filter tank, a sludge concentrated water tank, a sludge dewatering room, a disinfection tank and a water recycling tank. The system and the method have the advantages that diversified processes for treating the sewage are combined with one another to form the complete system for treating the sewage, accordingly, different stages of sewage can be assuredly effectively treated, and treatment effects can be improved; outlet water treated by the aid of the system is high in quality, requirements of national emission indexes can be met, the outlet water can be applied to life again, and accordingly water resources can be reused.

Owner:SICHUAN GERUISI ENVIRONMENT TECH CO LTD

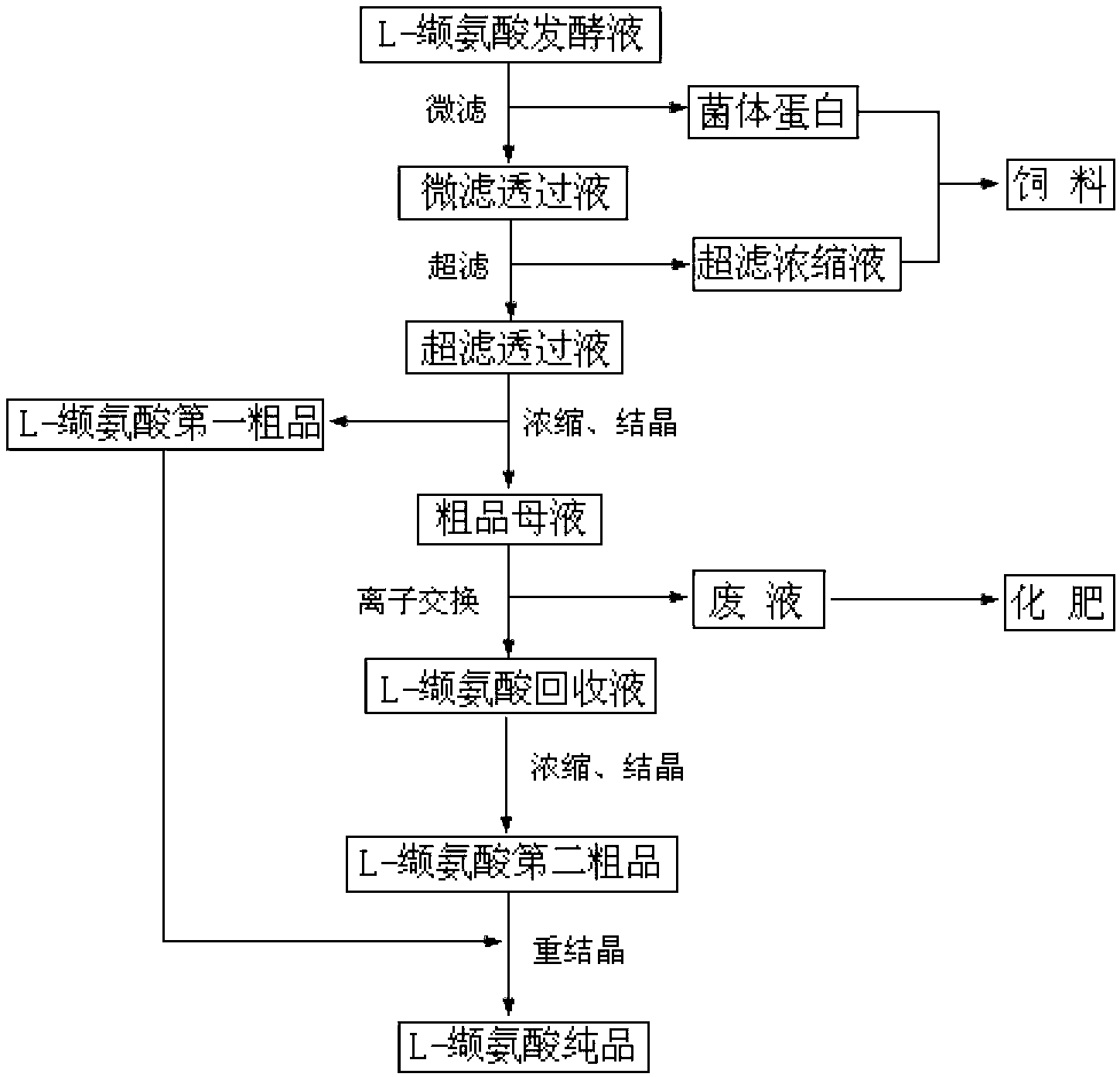

Method for separating and extracting L-valine from broth with high efficiency

InactiveCN103232353AHigh removal rateIncrease economic value addedOrganic compound preparationAmino-carboxyl compound preparationIon exchangeEconomic benefits

The invention discloses a method for separating and extracting L-valine from broth with high efficiency, and microfiltration for the L-valine broth, ultrafiltration, condensation and crystallization are carried out in order, and an L-valine first crude product and a crude product mother liquor are obtained, and an ion exchange treatment is carried out for the crude product mother liquor, and the L-valine in the crude product mother liquor is further recycled, and after concentration and crystallization, a L-valine second crude product is prepared. The method provided by the invention has the advantages of high overall yield and prepared L-valine with high purity, and thalline proteins separated from the extraction treatment can be used as feed additives, and the eluate in the ion exchange treatment can be used as fertilizer, thereby realizing zero discharge of the ammonium-containing waste water with environment protection, and in addition reducing production cost and improving economic benefit.

Owner:北京轻发生物技术中心 +2

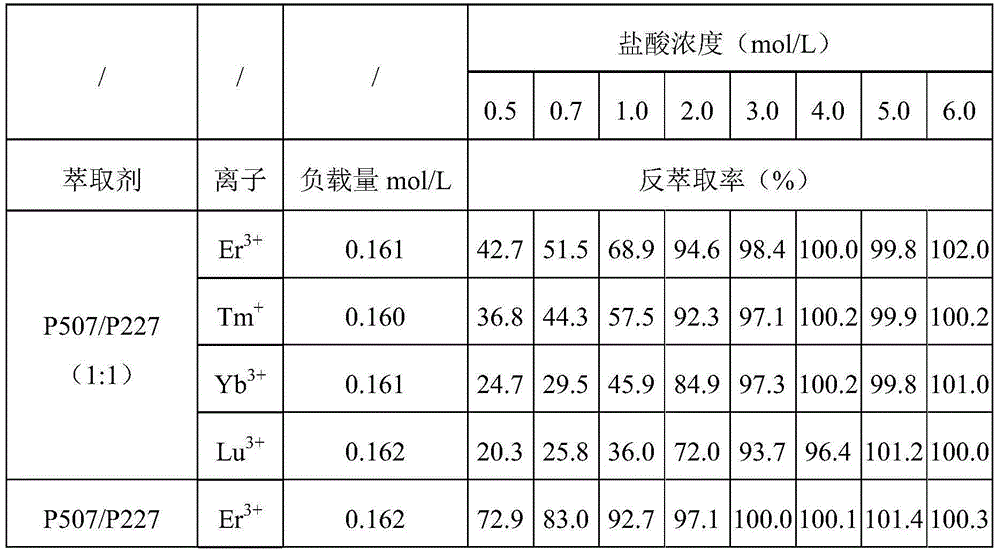

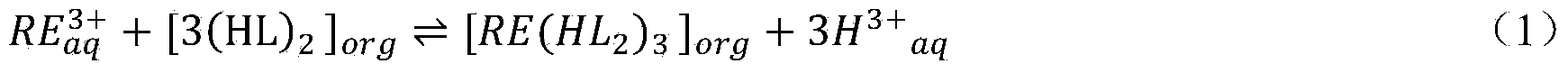

Extracting agent, extraction system and application

InactiveCN105177322AEfficient separationHigh saturation capacityProcess efficiency improvementETHYLHEXYL ACETATEChemistry

The invention discloses an extracting agent, an extraction system and an application. The extracting agent comprises 2-ethylhexyl phosphonic acid mono-ethylhexyl ester and di-(2-ethylhexyl) phosphinic acid. The extraction system comprises an organic phase and a water phase, wherein the organic phase comprises a diluent and the extracting agent; the water phase comprises rear-earth ions; and the pH value of the water phase is 1.0-3.0. The extraction system disclosed by the invention can effectively improve extraction and reverse extraction performances of a P507 extraction system, is good in separating capacity on heavy rear-earth elements, capable of carrying out extraction and reverse extraction under relatively low acidity and reducing dosage of acid and alkali, more green and environmentally-friendly, low in cost, high in saturation capacity, free of an emulsion phenomenon and more suitable for practical industrial production.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

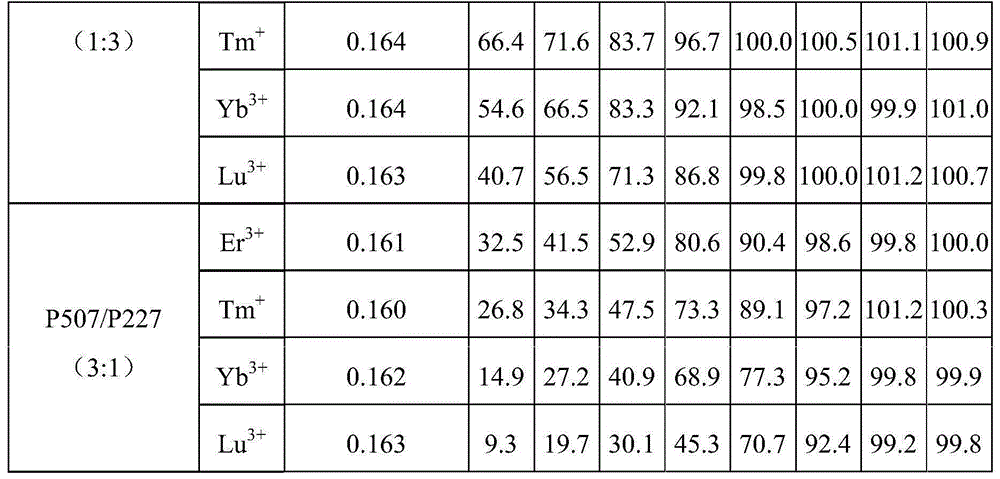

New technology for extracting L-glutamine

ActiveCN104745666AReduce dosageCompatibility is reasonableMicroorganism based processesFermentationFiltrationIon exchange

The invention belongs to the technical field of fermentation and discloses a new technology for extracting L-glutamine. The new technology for extracting the L-glutamine comprises the following steps: fermenting, carrying out micromembrane filtration, concentrating, crystallizing, carrying out ion exchange, recrystalizing, and preparing a fertilizer. The new technology for extracting the L-glutamine has the advantages that fermentation efficiency is high, an extraction technology is easy and feasible, environmental protection and no pollution are realized, and waste materials are changed into things of value.

Owner:XINJIANG FUFENG BIOTECH

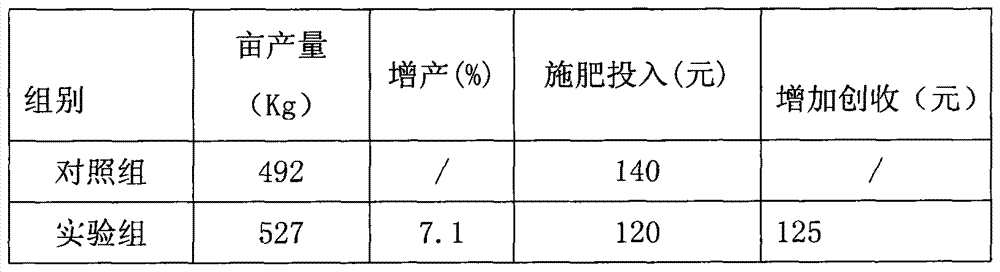

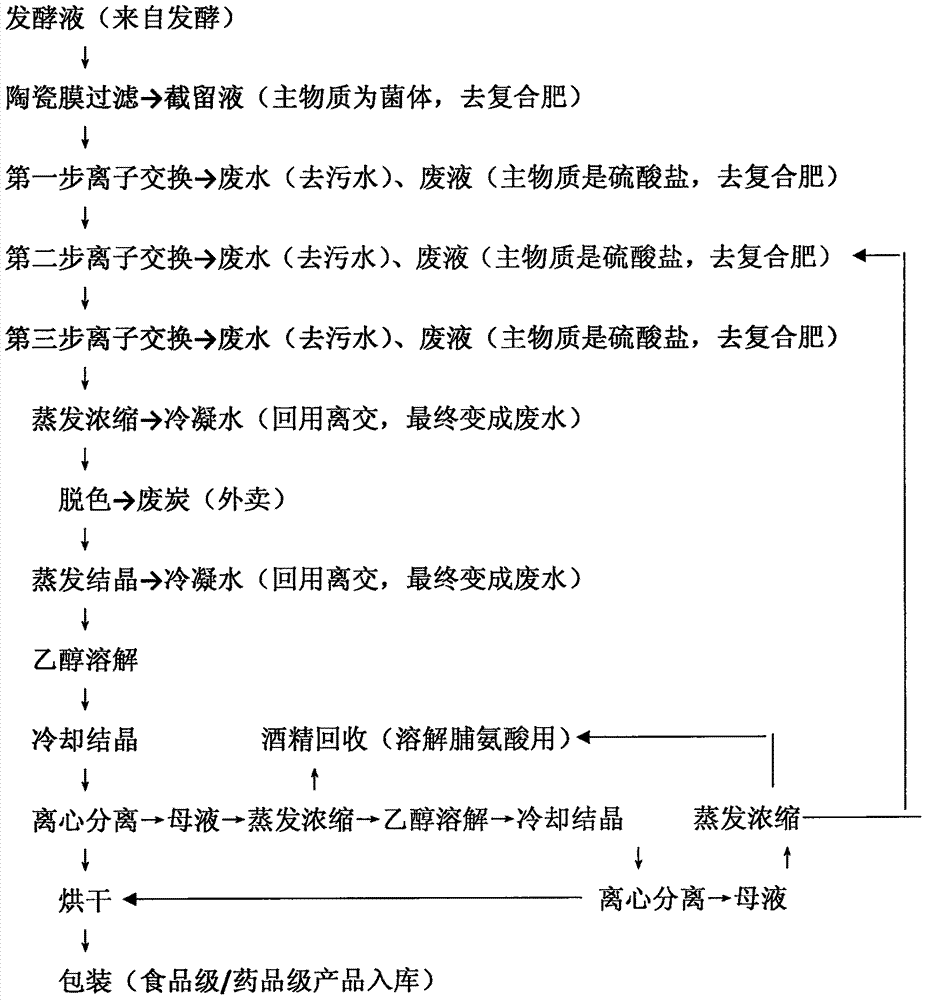

New extraction process of L-proline

InactiveCN106995398AHigh yieldQuality improvementOrganic chemistryChemical industryWater dischargeIon exchange

The invention relates to a chemical process, which is a new extraction process of L-proline, and provides the new extraction technology of the L-proline. The new extraction technology of the L-proline comprises the step of filtering a fermentation liquor through a ceramic membrane to obtain filter clogging liquid, and is characterized by decoloring the filter clogging liquid, and obtaining a finished product through ion exchange for less than or equal to two times. The new extraction technology of the L-proline has the beneficial effects that the acid-base dosage and the water discharge are reduced, energy conservation, consumption reduction and emission reduction are realized, the cost is greatly reduced, the finished product yield is high, and the quality is good.

Owner:TONGLIAO MEIHUA BIOLOGICAL SCI TECH CO LTD

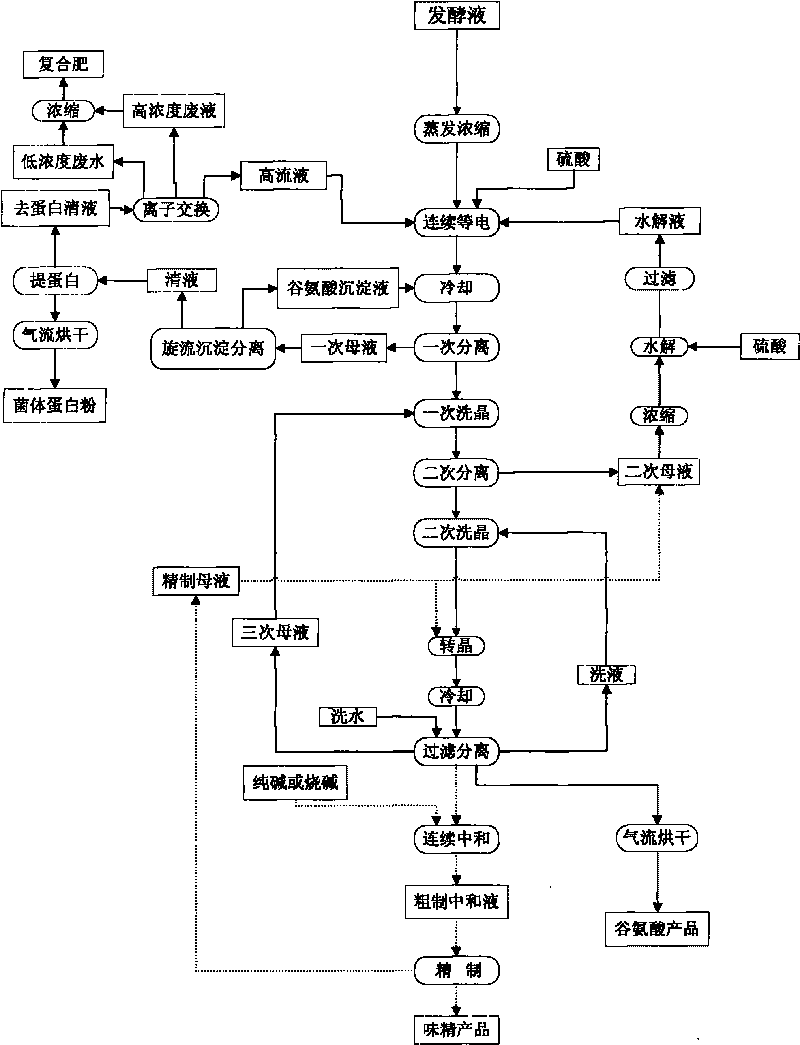

Production process of glutamic acid and monosodium glutamate

InactiveCN101735088AReduce dosageTemperature controlOrganic compound preparationAmino-carboxyl compound preparationMonosodium glutamateFiltration

The invention discloses a production process of glutamic acid and monosodium glutamate, which comprises the following steps: firstly, evaporating and concentrating fermentation liquid; after concentrated sulfuric acid is added for isoelectric operation, cooling to 5-15 DEG C; obtaining an alpha-crystalline glutamic acid crystal suspension after primary separation, primary crystal washing, secondary separation and secondary crystal washing; regulating the pH value to be 4.0-5.0 at 80-90 DEG C, cooling to 35 DEG C, and obtaining a beta-crystalline glutamic acid crystal through filtration and separation, wherein the beta-crystalline glutamic acid crystal can be dried by air flow to obtain glutamic acid products, and the beta-crystalline glutamic acid crystal can be continuously neutralized and refined to obtain monosodium glutamate products; carrying out cyclone precipitation on primary mother liquid after primary separation, removing protein in supernatant liquid by flocculation air flotation process, and drying the protein to obtain bacterial protein powder; and carrying out ion exchange on the deproteinized clear liquid to prepare compound fertilizer. The extraction method of the glutamic acid provided by the invention fundamentally reduces the generation of waste water, improves the extraction yield and the product quality, reduces the amount of water for exchanging ions and washing columns to the minimum, and has higher production efficiency and lower production cost.

Owner:BEIJING PIHUA BIOLOGICAL TECH

Zirconium-aluminum composite inorganic surface treatment method of titanium dioxide

ActiveCN103756369AReduce the amount of acid and alkaliSave washing waterPigment physical treatmentPigment treatment with non-polymer organic compoundsSlurryAluminum composites

The invention provides a zirconium-aluminum composite inorganic surface treatment method of titanium dioxide. The zirconium-aluminum composite inorganic surface treatment method comprises the following steps: beating titanium dioxide into slurry with the pH value of 9.0-10; adding a dispersing agent; grinding; stirring, and heating to 45-60 DEG C; stirring, adding an acidic zirconium salt, carrying out heat preservation, and curing, wherein the addition amount of the acidic zirconium salt accounts for 0.3-5.5% of the weight of titanium dioxide in the slurry based on zirconium oxide; heating the slurry to 55-65 DEG C; stirring, slowly adding an alkaline aluminum salt, when the pH value of the slurry system reaches 9.3-10.0, adding a first acidic aluminum salt to the slurry system so as to maintain the pH value at 9.3-10.0, carrying out heat preservation, and curing, wherein the total addition amount of the alkaline aluminum salt, and the first acidic aluminum salt accounts for 1.5-10% of the weight of titanium dioxide in the slurry based on aluminum oxide; adding a second acidic aluminum salt so as to control the pH value at 6.5-7.8; filtering and washing, thus obtaining treated titanium dioxide. The zirconium-aluminum composite inorganic surface treatment method has the advantages that the using amount of acid and base can be reduced, washing water is saved, and the purpose of saving cost is achieved.

Owner:四川金雅汇科技有限公司

Method for preparing high-purity lithium carbonate by using fractional crystallization technology

ActiveCN111252788AControl concentrationControl flowLithium carbonates/bicarbonatesLithium chlorideLithium carbonate

The invention relates to a method for preparing high-purity lithium carbonate by using a fractional crystallization technology. The method comprises the following steps: carrying out process treatmenton salt lake brine by adopting one or more of means selected from a group consisting of, but not limited to, electrodialysis, adsorption, nanofiltration, extraction, precipitation, reverse osmosis, ion exchange and evaporation to obtain a refined lithium chloride solution 1; introducing a sodium carbonate solution into the refined lithium chloride solution 1, carrying out a primary lithium precipitation reaction to obtain a wet lithium carbonate crystal 1, and then washing, drying, crushing and packaging the wet lithium carbonate crystal 1 to obtain a high-purity lithium carbonate product; introducing mother liquor of the primary lithium precipitation reaction into crystallization evaporation equipment, separating out saturated sodium chloride in the evaporation process, and filtering outa sodium chloride crystal to obtain a high-concentration lithium chloride solution 2; introducing a sodium carbonate solution for a secondary lithium precipitation reaction to obtain a wet lithium carbonate crystal 2; and dissolving the wet lithium carbonate crystal 2 with hydrochloric acid to obtain a lithium chloride solution 3, and combining the lithium chloride solution 3 with the refined lithium chloride solution 1.

Owner:BEIJING QINGYUAN POWERISE TECH CO LTD +1

Method for producing xylo-oligosaccharide by utilizing cotton seed hulls

The invention discloses a method for producing xylo-oligosaccharide by utilizing cotton seed hulls, which adopts the cotton seed hulls as raw materials and comprises the steps: the cotton seed hulls are dipped in a dilute sulphuric acid solution according to a solid-to-liquid ratio of 1 to 10, pretreated at room temperature for 20-24 hours, treated in high pressure steam at temperature of 180-190 DEG C for 7-15 minutes, cooled down by water to 50 DEG C and then added with 1.0-2.5% xylanase for enzymolysis for 24-36 hours in slow stirring or vibration manner, after being boiled for 10 minutes to remove enzyme, enzymatic hydrolyzate is filtered and concentrated in a vacuum manner till sugar concentration is more than 75 percent to obtain the xylo-oligosaccharide syrup. The method is characterized in that the cotton seed hulls with more xylose content of xylan is adopted as raw materials; pretreatment is conducted to effectively remove coloring matters; high pressure processing can greatly shorten time; the technological process of xylo-oligosaccharide production is simple and practical, with relatively low production cost; and the production technique and method of xylo-oligosaccharide have good industrialized application prospect.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Clean production technology and method for lithium sulfate

InactiveCN108383140AImprove conversion rateImprove leaching rateLithium sulfates/sulfitesLithium sulphatePregnant leach solution

The invention provides a clean production technology and method for lithium sulfate. A technique and a roasting additive are used. The production process comprises the steps of sieving, mixing, granulating, roasting, soaking, impurity deposition, crystalizing, drying and the like, and the roasting additive comprises components including Na2SO4, K2SO4, CaCO3, CaO and the like. By the clean production technology and method for lithium sulfate, the roasting conversion rate and leaching rate of lithium can be increased, moreover, acid is not used, types and contents of impurities in leaching liquid are less, a follow-up impurity removal process is simple, and acid and alkali consumption is low. The production process is simple, the lithium extracting rate is high, energy and materials are reused, and thus, the clean production technology and method are suitable for large-scale production.

Owner:天津二八科技股份有限公司

Iron-carbon micro-electrolysis process for introducing ozone and treating waste water

InactiveCN108033520AReduce processing costsEnsure no color returnWater/sewage treatment apparatusElectrolysisSludge

The invention discloses an iron-carbon micro-electrolysis process for introducing ozone and treating waste water. The iron-carbon micro-electrolysis process comprises the following steps: S1, adjusting the pH of the waste water to 2 to 9 by utilizing an acid solution / alkali solution; S2, filtering the waste water with the pH of 2 to 9 in S1, outputting the waste water into an iron-carbon micro-electrolysis reactor, introducing ozone into the iron-carbon micro-electrolysis reactor, reacting for 1h to 3h, and discharging the waste water out of the iron-carbon micro-electrolysis reactor; and S3,transporting the waste water outputted from the iron-carbon micro-electrolysis reactor into a neutralizing precipitating pond to be precipitated. Compared with the prior art, the iron-carbon micro-electrolysis process has the beneficial effects that the treatment capacity for organic matters in the waste water can be improved, the color reversion phenomenon can be well overcome, the pH range of the waste water entering the iron-carbon micro-electrolysis reactor can be enlarged, the consumption of acid and alkali can be reduced, the generation amount of the neutralized precipitated sludge is reduced, and the comprehensive treatment cost of the waste water can be reduced.

Owner:江苏森博环保科技发展有限公司

Method for cleaning comprehensive utilization of shrimp and crab shell waste

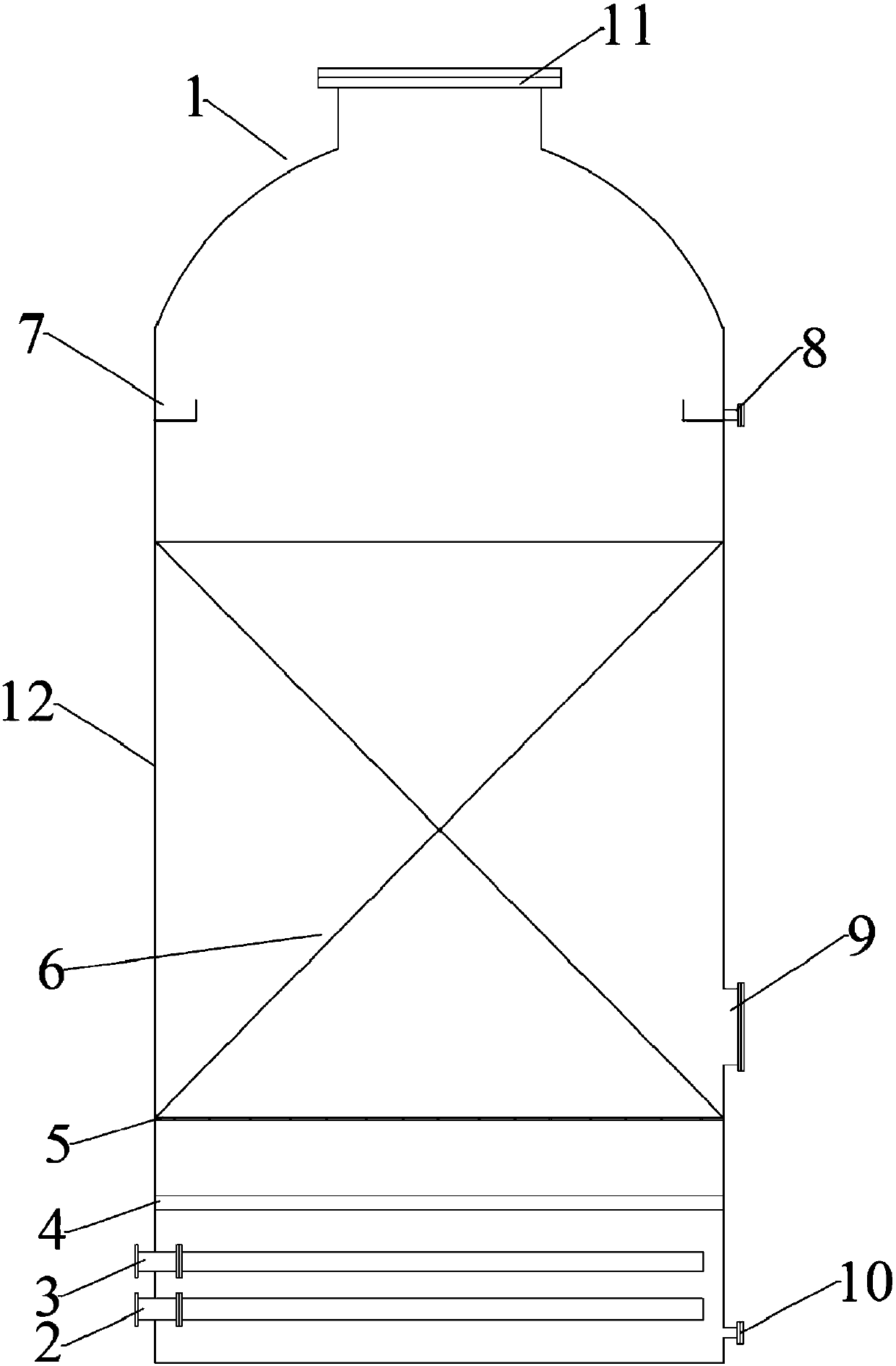

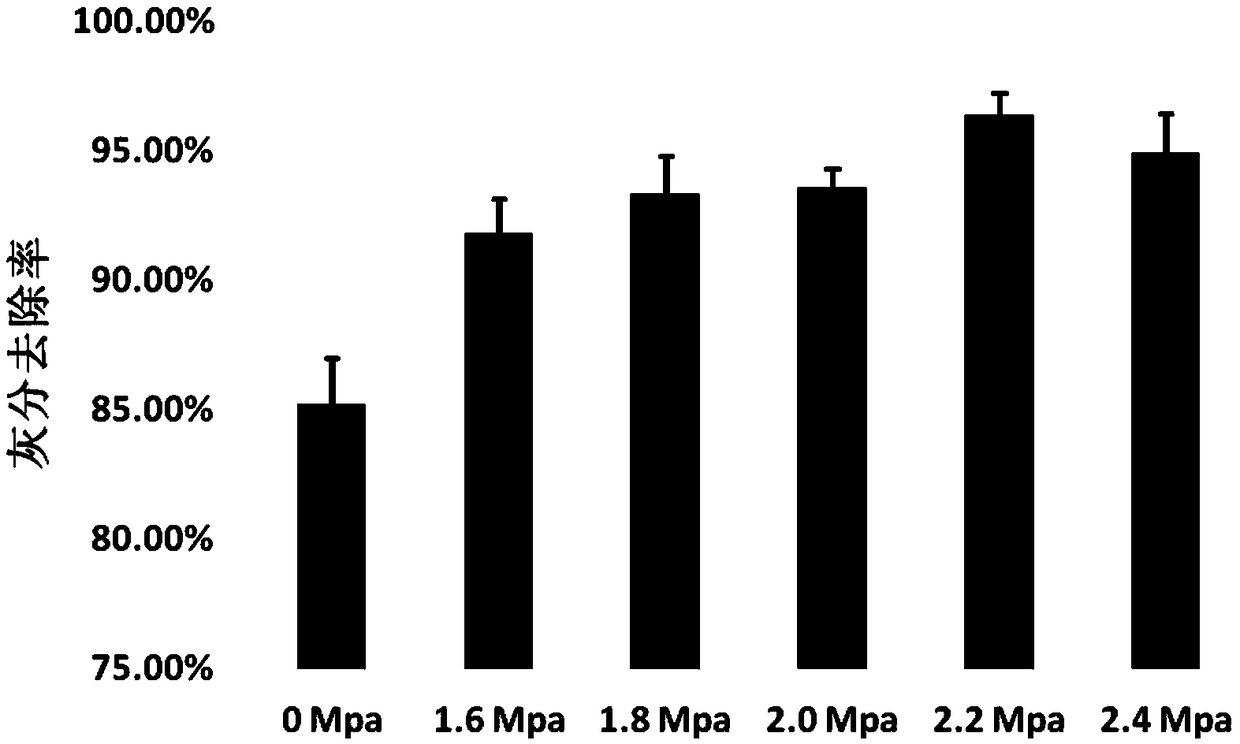

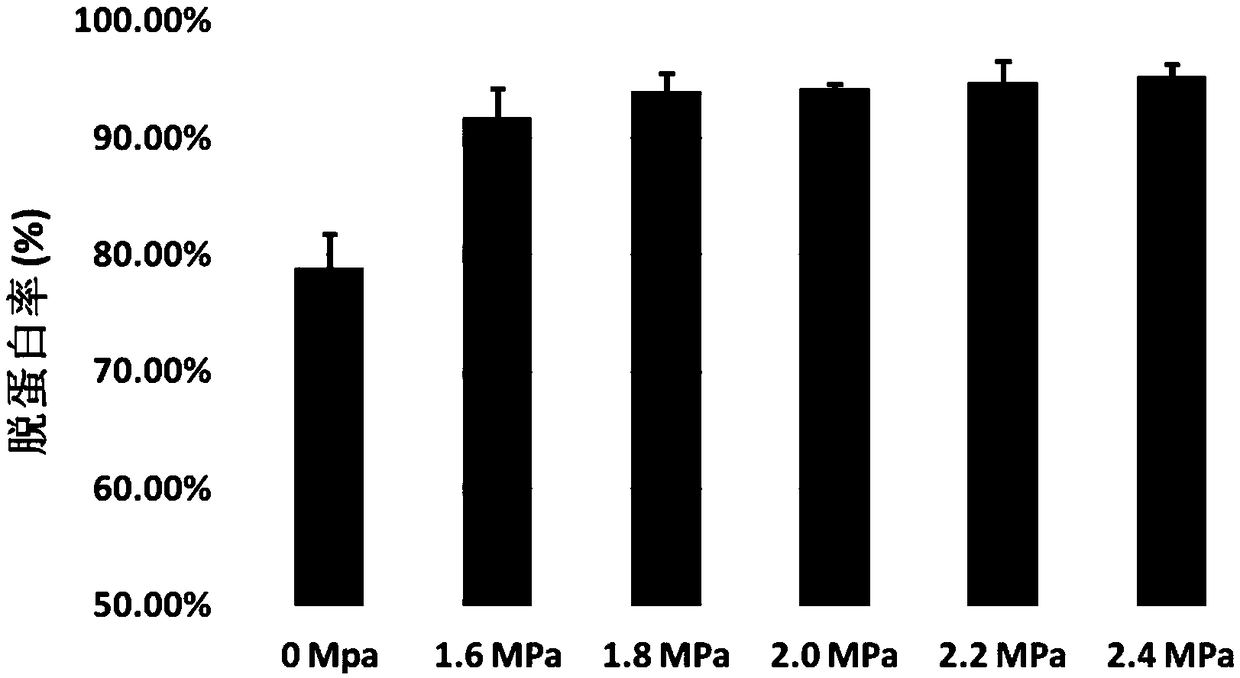

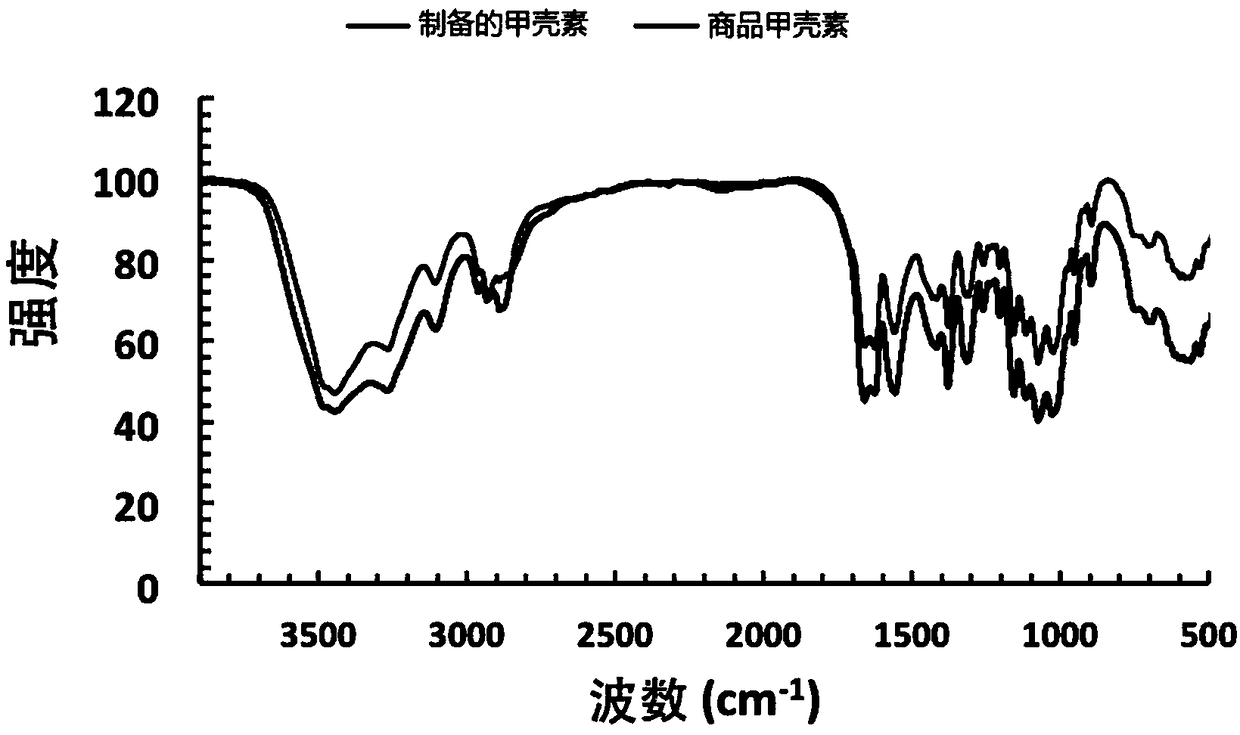

InactiveCN109134703AReduce the amount of acid and alkaliLow costAnimal corpse fertilisersClimate change adaptationChitin formationChemistry

The invention relates to chitin extraction, in particular to a method for cleaning comprehensive utilization of shrimp and crab shell waste. The method includes the steps of steam explosion, wherein shrimp shells and / or crab shells are soaked in water, placed in steam explosion equipment, treated at 1.4MPa-2.4MPa for 60-600s, dried and crushed; decalcification, wherein shrimp shell and / or crabshell powder is treated with a decalcifying agent at 20-80 DEG C for 60-300min, filtering is conducted, a filtrate A is obtained, a solid material is washed with water, and drying is conducted; deproteinization, wherein the shrimp shell and / or crab shell powder is treated with a lye at 60-100 DEG C for 90-300min, filtering is conducted to obtain a filtrate B, the solid material is washed with water, and drying is conducted; the shrimp shells and / or the crab shells are treated according to the sequence of the steam explosion, the decalcification and the deproteinization or the steam explosion, the deproteinization and the decalcification to obtain the chitin. The method improves the separation efficiency of the chitin and reduces the amount of acid and alkali and waste discharge.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Post-extraction method for fermentation-process epsilon-polylysine production

ActiveCN110396188AReduce the amount of acid and alkaliConserve waterLiquid productSeparation technology

A post-extraction method for fermentation-process epsilon-polylysine production is provided, belonging to the technical field of extraction and separation. The method mainly includes extracting epsilon-polylysine in a fermentation solution by utilizing an electrodialysis technique and a membrane separation technique. The method specifically includes: subjecting the fermentation solution to solid liquid separation through ceramic membrane filtration after the fermentation solution is subjected to thermal flocculation; then removing soluble macromolecule substances through filtration with an ultrafiltration membrane; performing decoloration with activated carbon; performing filtration to obtain a decolorized solution; subjecting the decolorized solution to electrodialysis treatment; pumpinga dialysis liquid product to a nanofiltration membrane device and performing cyclic concentration; subjecting the concentrate to spray drying or vacuum freeze drying to obtain an epsilon-polylysine product. Compared with traditional ion exchange extraction methods, the method when being used for epsilon-polylysine extraction enables a product recovery rate of 80% or above, and product purity of 98% or above; and the method can save water by 60% and reduce the environment protection cost by 50% for products per ton after the electrodialysis technique is adopted to replace a traditional ion exchange technique. The method has advantages of capability of reducing wastewater generation, a high degree of automation, a high extraction and recovery rate and high purity of extract products, and issuitable for industrial production.

Owner:山东惠仕莱生物科技有限公司

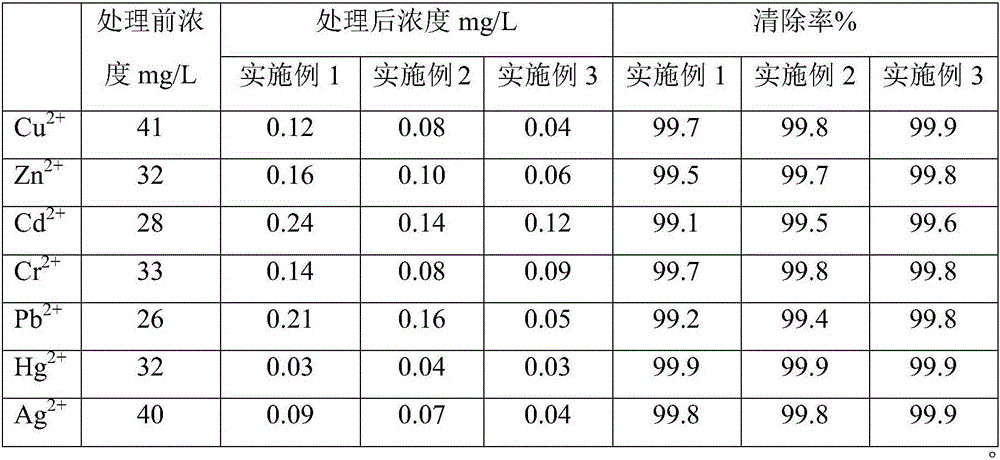

Method for treating heavy-metal sewage by using multistage chemical precipitation

InactiveCN105923841AEfficient and fine controlReduce the amount of acid and alkaliWater contaminantsMultistage water/sewage treatmentAutomatic controlPh regulation

The invention provides a method for treating heavy-metal sewage by using multistage chemical precipitation. The method comprises the following treatment step: sequentially introducing the heavy-metal sewage into an acid regulation pool, a first-stage pH regulation pool, a first-stage coagulative inclined-tube precipitation tank, a second-stage pH regulation pool, a second-stage coagulative inclined-tube precipitation tank, a third-stage pH regulation pool, a third-stage coagulative inclined-tube precipitation tank and a pH adjusting tank. Multistage step-by-step pH regulation is carried out, corresponding reaction drugs are added in different pH ranges in an auxiliary manner so as to remove different heavy-metal ions, and the efficient and fine control on a pH value is achieved; meanwhile, the pH ranges are regulated step by step, so that the consumption of acids / bases can be lowered, and whether automatic control or manual control can be achieved simply; the precipitation tanks are the inclined-tube precipitation tanks, so that the efficiency of precipitation is increased.

Owner:SICHUAN GERUISI ENVIRONMENT TECH CO LTD

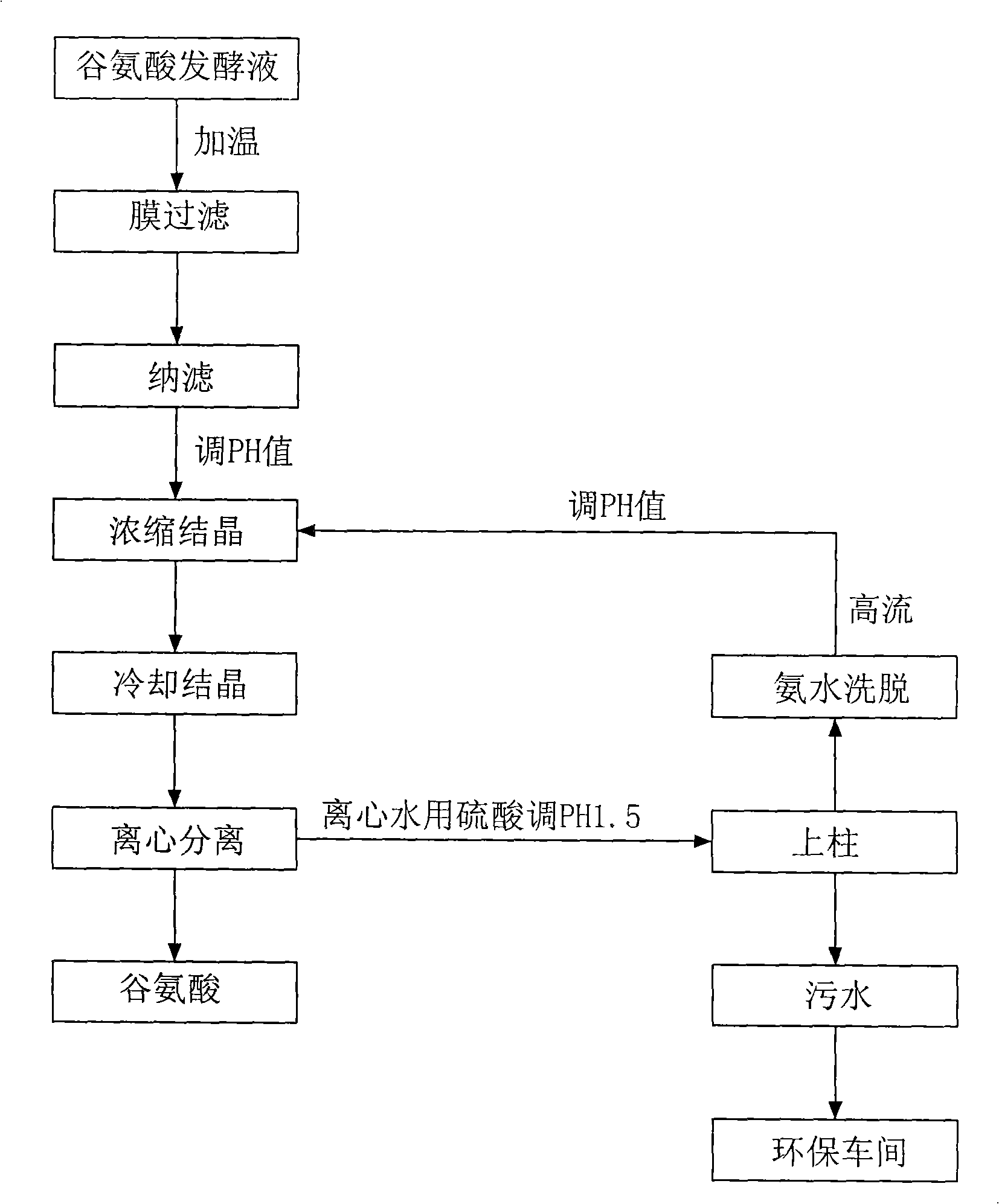

Glutamic acid extracting technique

InactiveCN101293848ALess waste waterReduce the amount of acid and alkaliOrganic compound preparationAmino-carboxyl compound preparationFilter systemEvaporation

The invention discloses a glutamic acid extraction process, which comprises heating glutamic acid fermenting liquor, ultra-filtering, and filtering with a nano-filter system, heating the fermenting liquid, adjusting the pH value to 3.0-4.0 with sulfuric acid, concentrating by evaporation in a crystallizer pan; and discharging to a crystallization promoting tank when 50%-80% of water is evaporated off, slowly cooling to a temperature below 60 DEC C, and centrifugally separating glutamic acid. The glutamic acid extraction process has small usage amount of acid and alkali, less waste water amount, and higher extraction efficiency of the glutamic acid. The obtained glutamic acid is ensured that the product quality reaches the national standard.

Owner:MAIDAN BIOLOGICAL GROUP FUJIAN

Equipment for removing lead in wastewater of lead storage battery

ActiveCN104003553AMake sure the effluent contains leadEfficient removalMultistage water/sewage treatmentWater dischargeWastewater

The invention discloses equipment for removing lead in wastewater of a lead storage battery. The equipment is characterized by comprising a first-stage reaction zone, a second-stage reaction zone, a settling zone, a filtering zone and an effluent zone, wherein a water inlet is formed in the upper end of the side wall of the first-stage reaction zone; the first-stage reaction zone is connected with the second-stage reaction zone by virtue of a first-stage reaction zone water outlet in the lower end of the first-stage reaction zone; the second-stage reaction zone is connected with the settling zone by virtue of a second-stage reaction zone water outlet; the settling zone is connected with the filtering zone and is used for distributing water in an overflowing water discharge mode; the filtering zone is connected with two sides of the effluent zone by virtue of filtering zone water outlet tubes at bottoms on two sides of the filtering zone; the first-stage reaction zone is further connected with a lead removing agent adding device; the second-stage reaction zone is connected with a coagulation aid agent adding device. The equipment is simple to operate, high in treatment efficiency and small in occupied area, an efficient lead removing technique, a settlement technique and a filtration technique are integrated, and the problems that lead-containing wastewater of the conventional lead storage battery industry cannot stably meet the standard after being treated and a great amount of hazardous wastes are generated are solved.

Owner:NANJING GW ENVIRONMENT ENG

Extraction system, extraction method and reextraction method

The invention discloses an extraction system, an extraction method and a reextraction method. The extraction system disclosed in the invention comprises an organic phase and an aqueous phase, wherein the organic phase comprises a diluent and an extraction agent shown as a formula I; the aqueous phase comprises rare earth ions; the pH value in the aqueous phase is 2.5-4.5; M is hydrogen, alkali metal ions or positive ammonium ions. The extraction method disclosed in the invention comprises the following steps: oscillating and balancing the extraction system. The reextraction method disclosed in the invention comprises the following steps: (1) saponifying the organic phase of the extraction system, mixing with the aqueous phase containing the rare earth ions, and obtaining an organic phase loaded with the rare earth ions; and (2) mixing the organic phase loaded with the rare earth ions with an aqueous solution of acid. According to the extraction system, the rare earth ions can be efficiently separated under low acidity, the extraction system is high in saturation capacity and difficult in emulsification, realizes reextraction of the rare earth ions under low acidity and is suitable for actual production.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

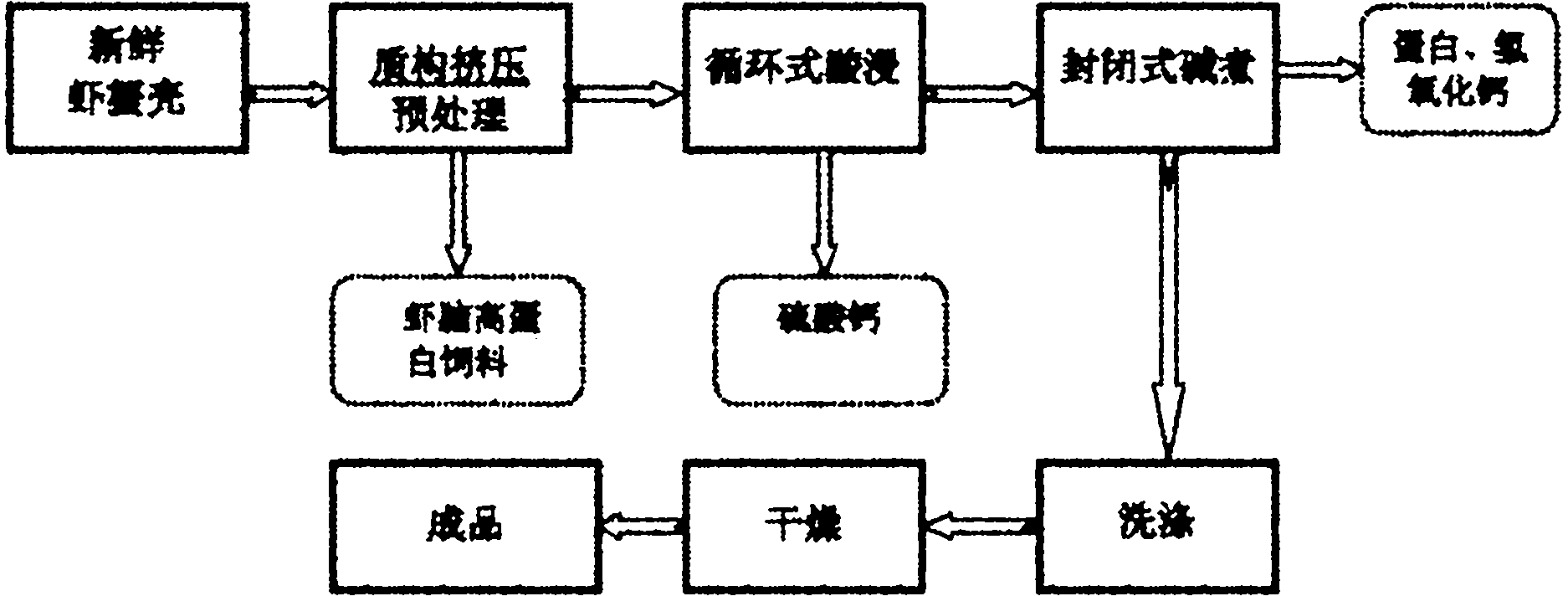

Chitin clean production process

InactiveCN101974103AAdjust and improve production processReduce acid and alkali consumptionShrimpSulfate

The invention belongs to the field of processing of chitin and discloses a chitin clean production process. The process comprises the steps of taking fresh shrimp and crab shells as raw materials, carrying out texture extrusion pretreatment, dynamic cyclic pickling, closed alkali boiling and washing, drying, and obtaining a chitin finished product. The process adjusts and improves the production process flow of the chitin and can carry out comprehensive utilization and treatment on the shrimp and crab shells, reduce the consumption of acid and alkali, recover calcium sulfate, proteins and other useful materials, recycle washing water, solve the problems of serious pollution and waste of resources of the conventional process and have obvious environmental and economic benefits.

Owner:YANGZHOU RIXING BIO TECH

Sucralose wastewater advanced treatment and desalination method

InactiveCN111646638AReduce colorReduce the amount of acid and alkaliWater treatment parameter controlGeneral water supply conservationSucroseDesalination

The invention relates to a sucralose wastewater advanced treatment and desalination method. The method is characterized by comprising the following steps of: (1) adding ammonia water into wastewater to adjust the pH value to 6-7; (2) adding 10% of a composite settling agent, controlling the volume ratio of the settling agent to the wastewater at 1:18-23, and performing depositing for 1.5-2.5h to obtain a supernatant; (3) carrying out wet oxidation treatment on the wastewater at a temperature of 200DEG C-250DEG C under a pressure of 2.0-3.0Mpa, and remaining the state for 4-5h; (4) feeding thewastewater into MVR for evaporation and concentration, wherein the concentration ratio is 70-75%; (5) pumping a mother liquor into an evaporation kettle, performing evaporating and concentrating to obtain mother liquor, adding butanol or octanol, controlling the volume ratio of the mother liquor to the butanol or octanol at 1:1-4, and carrying out aerobic biochemical treatment on the supernatant;(6) cooling and crystallizing the mother liquor, and performing filtering to obtain a salt and alcohol; and (7) rectifying the alcohol to obtain a pure product. The method has the advantages that theuse amount of acid and alkali is greatly reduced; a relatively pure ammonium chloride salt is obtained; the mother liquor amount after alcohol extraction is reduced by 40 times compared with that of raw water, and the environmental protection pressure is greatly reduced.

Owner:ANHUI JINGHE IND

A method for producing xylooligosaccharides from cottonseed hulls

A method for producing xylooligosaccharides by using cottonseed hulls, using cottonseed hulls as raw materials, soaking in dilute sulfuric acid solution with a solid-to-liquid ratio of 1:10, pretreating at room temperature for 20-24 hours, and then passing through high-pressure steam at 180-190°C Treat for 7-15 minutes, add 1.0-2.5% xylanase after the water is cooled to 50°C, and enzymolyze 24-36 hours under the conditions of temperature 45-50°C and pH4.0-pH5.5 under slow stirring or shaking conditions Hour. The enzymolysis solution is boiled for 10 minutes to kill enzymes, and then filtered and concentrated in vacuum until the sugar concentration is above 75% to obtain the xylooligosaccharide syrup. The present invention is characterized in that: Cottonseed hulls with more xylose content in raw xylan are used as raw materials; pretreatment effectively removes pigment substances; high pressure treatment can significantly shorten the time; the production process of xylooligosaccharides is simple and practical, and the production cost is relatively low. Low; the xylo-oligosaccharide production process and method of the present invention have good industrial application prospects.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preparing gallic acid with tara powder

InactiveCN108003012AIncrease profitReduce the amount of acid and alkaliCarboxylic compound separation/purificationGallic acid esterOrganic fertilizer

The invention discloses a method for preparing gallic acid with tara powder. The method comprises the following steps that the tara powder is extracted with water, and water extract is collected; water extract concentration is conducted; concentrated solution hydrolysis is conducted; gallic acid is refined. According to the method, by changing the original technology, the acid and alkali dosage islowered, and meanwhile tara powder residues discarded before can be used for preparing organic fertilizer, and the comprehensive utilization efficiency of resources is improved.

Owner:JIURUI BIOLOGY & CHEM CO LTD

Application of graded lignin in preparation of phenolic foam thermal-insulation materials

The invention discloses application of graded lignin in preparation of phenolic foam thermal-insulation materials. Compared with the prior art, the phenolic foam thermal-insulation materials are prepared by directly blending the graded lignin with foamable phenolic resin through control of the molecular weight of the graded lignin, so that tedious modification steps in a process for preparing phenolic resin from lignin are avoided, using amount of acids and alkalis is saved, and energy consumption in a modification process is reduced, and at the same time, the lignin content in the final phenolic foam thermal-insulation material products can be greatly improved, and the products are economical and more environmentally friendly. The phenolic foam thermal-insulation materials filled with thegraded lignin have better mechanical properties, thermal stability, anti-ultraviolet aging properties and better fineness, and the product quality meets national standards, and can meet a market demand.

Owner:NANJING UNIV OF TECH

PH regulation method in high fructose corn syrup production process

ActiveCN103540690AReduce the introductionReduce ionFructose productionGlucose productionHigh-fructose corn syrupIon exchange

The invention belongs to the field of food processing and in particular relates to a pH regulation method in a high fructose corn syrup production process. The pH regulation method in the high fructose corn syrup production process is characterized by comprising the following steps: conveying a material of which the pH value is to be adjusted to a pH regulation front tank, pumping the material into an ion exchange column I and an ion exchange column II which are connected in parallel, and allowing the material to be subjected to ion exchange in the two ion exchange columns, wherein sampling valves are respectively arranged on the lower parts of the two ion exchange columns, and a pH value is monitored through the valves; continuously conveying the material of which the pH value is adjusted to a required pH value to a regulation rear tank after the material reaches the pH value required to be adjusted through a regulation column, sampling and detecting through the sampling valves at fixed time intervals, and determining that the regulation column is ineffective after the pH value is unqualified; converting the material to a standby ion exchange column for continuous feeding.

Owner:SHANDONG XIWANG SUGAR

Titanium dioxide aluminum coating technology with cost advantage

ActiveCN108587244AReduce the amount of acid and alkaliLow costInorganic pigment treatmentSlurryAluminum coating

The invention discloses a titanium dioxide aluminum coating technology with the cost advantage. The technology comprises the following steps: 1) adjusting the pH value of a titanium dioxide slurry to8-11 by using a metaaluminate solution; 2) adding the metaaluminate solution and an acidic aluminum salt solution to the titanium dioxide slurry in a cocurrent flow manner to control the pH value of the slurry to 8-11; 3) adding an acid solution and a metaaluminate solution to the slurry obtained in the step 2) in a cocurrent flow manner to control the pH value of the slurry to 8-11; and 4) adjusting the pH value of the slurry obtained in step 3) to 6-8 by using the acid solution. The aluminum coating technology of titanium dioxide is improved, the use amount of acids and alkalis for adjustingthe pH value is reduced, the cost is saved, and obtained coated titanium dioxide still can keep excellent glossiness and product compactness.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Extraction method of deep-sea fish gelatin

ActiveCN103805071BAvoid it happening againHigh yieldGlue/gelatin preparationCompound organicRoom temperature

The invention discloses an extraction method of deep-sea fish skin gelatin, and the method comprises the following steps of putting cleaned fish skin in conditioning fluid which is prepared from compound organic acid and stirring, cleaning the conditioned fish skin by water at room temperature, putting the cleaned fish skin in weakly acidic water solution at 30-60 DEG C for extraction, combining the extracting solution, filtering the extracting solution by 100-mesh filter cloth, and carrying out concentration and drying to obtain the gelatin. The method provided by the invention is gentler, and the prepared product is high in yield and purity, large in molecular weight, narrow in molecular weight distribution, shallow in color and light in fishy smell.

Owner:QINGDAO HUAKE BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com