Xylooligosaccharide with low DP (degree of polymerization) as well as preparation method and application of xylooligosaccharide

A technology of xylo-oligosaccharide and low polymerization degree, which is applied in the field of xylo-oligosaccharide with low polymerization degree and its preparation, can solve problems such as limiting the scope of application, improve product purity, reduce chromaticity and by-product generation, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

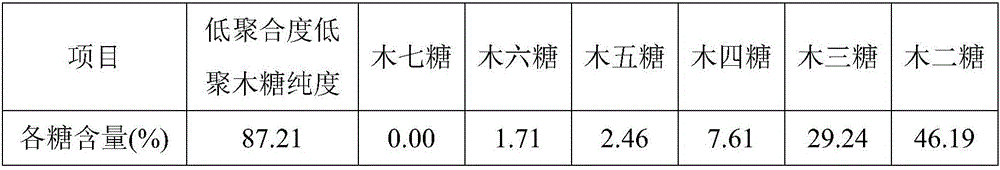

Embodiment 1

[0038] Take 450g of cottonseed hulls, mix it with 0.05% sodium hydroxide solution at a mass ratio of 1:7, heat up to 60 degrees Celsius and keep it warm for 30 minutes, filter out the liquid; wash it with water until the pH value is neutral; mix it with process water at a ratio of 1:3 The mass ratio is mixed, and the weak acid catalyst (acetic acid) of 0.7% cottonseed hull dry weight percentage is added, steam explosion treatment, processing pressure 1.5-2.5MPa, time 120s; The xylose content in the steam explosion liquid is 5.85%, cooling for stand-by. Add 0.8g xylanase to the cooking liquid, enzymolysis reaction temperature is 60°C, enzymolysis time is 8h, enzymolysis solution is deenzyme, activated carbon decolorization, electrodialysis desalination, concentration to prepare xylooligosaccharides with low polymerization degree. The decolorization temperature used for the decolorization of activated carbon is 50-90°C, the amount of activated carbon added is 0.1-2%, the decolori...

Embodiment 2

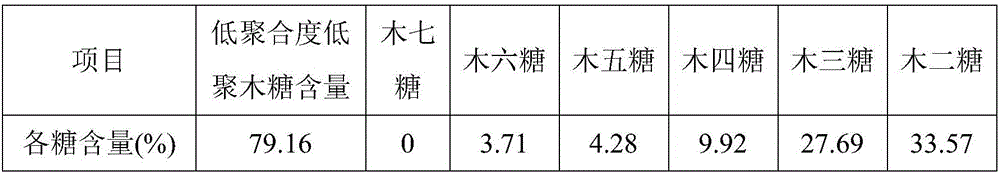

[0043] Take 450g of corncobs, mix them with process water at a mass ratio of 1:6 and heat up to 80 degrees Celsius for 40 minutes, filter out the liquid; add acetic acid with a percentage of dry weight of corncobs of 0.8%, and cook at high temperature. The treatment conditions are: cooking temperature 165 ℃, the cooking time is 50min, the xylan in the corn cob is dissolved, and the xylose content in the cooking liquid is 15.75%, and the temperature is lowered for later use. Add 0.1g xylanase to the cooking liquid, enzymolysis reaction temperature is 80°C, enzymolysis time is 8h, enzymolysis solution is deenzyme, activated carbon decolorization, electrodialysis desalination, concentration to prepare xylooligosaccharides with low polymerization degree. The decolorization temperature used for the decolorization of activated carbon is 50-90°C, the amount of activated carbon added is 0.1-2%, the decolorization time is 20-90min, and the decolorization is completed after plate and fra...

Embodiment 3

[0048] Get 450g of wheat straw, mix it with process water in a mass ratio of 1:10 and heat up to 90 degrees centigrade for 60 minutes, filter out the liquid; mix it with process water in a mass ratio of 1:8, add wheat straw dry weight percentage of 1.2% acetic acid, high temperature Cooking treatment, the treatment conditions are: cooking temperature 165 ° C, cooking time 60 minutes, xylan in the wheat straw is dissolved, and the content of xylose in the cooking liquid is 19.96%, and the temperature is lowered for use. Add 0.4g xylanase to the cooking liquid, enzymolysis reaction temperature is 80°C, enzymolysis time is 8h, enzymolysis solution is deenzyme, activated carbon decolorization, electrodialysis desalination, concentration to prepare xylooligosaccharides with low polymerization degree. The decolorization temperature used for the decolorization of activated carbon is 50-90°C, the amount of activated carbon added is 0.1-2%, the decolorization time is 20-90min, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com