Method for treating heavy-metal sewage by using multistage chemical precipitation

A chemical precipitation and heavy metal technology, which is applied in the direction of precipitation treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of complicated sewage treatment technical solutions and less heavy metal sewage, so as to save the amount of acid and alkali, and simplify the process. Realize and improve the effect of sedimentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

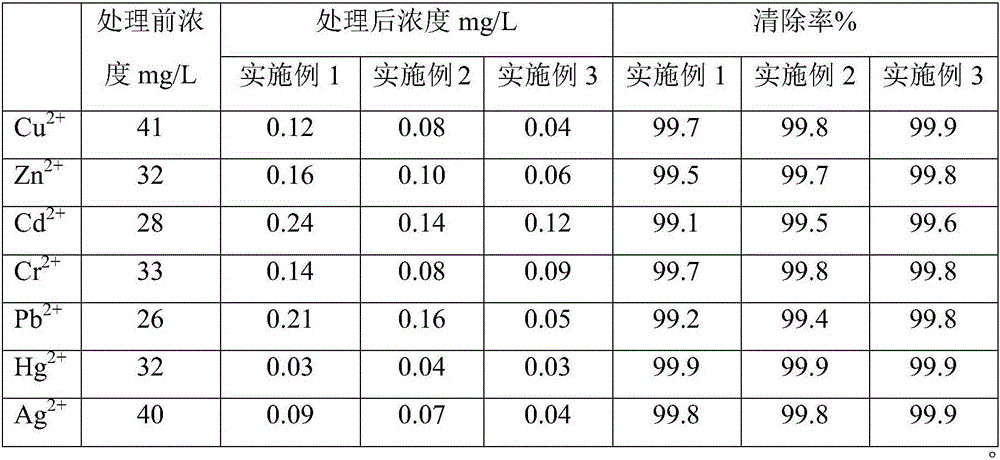

Examples

Embodiment 1

[0030] A method for treating heavy metal sewage by using multi-stage chemical precipitation:

[0031] (1) Introduce the heavy metal sewage into the acid adjustment tank, add hydrochloric acid and ferrous sulfate, adjust the pH to 2.0, and the residence time is 1.5h to obtain sewage 1;

[0032] (2) Sewage 1 is introduced into the first-level pH adjustment tank again, and sodium hydroxide and sodium sulfide are added to adjust the pH to 6.0, and the residence time is 1h, and then pass through the first-level coagulation inclined tube sedimentation tank to obtain sewage 2;

[0033] (3) After sewage 2 is introduced into the secondary pH adjustment tank, sodium hydroxide and calcium hydroxide are added to adjust the pH to 8.5, and the residence time is 0.5h, and then pass through the secondary coagulation inclined tube sedimentation tank to obtain sewage 3;

[0034] (4) After the sewage 3 is introduced into the three-stage pH adjustment tank, sodium hydroxide is added to adjust the...

Embodiment 2

[0037] A method for treating heavy metal sewage by using multi-stage chemical precipitation:

[0038] (1) Introduce the heavy metal sewage into the acid adjustment tank, add hydrochloric acid and ferrous sulfate, adjust the pH to 3.0, and the residence time is 2.5h to obtain sewage 1;

[0039] (2) Sewage 1 is introduced into the first-level pH adjustment tank again, and sodium hydroxide and sodium sulfide are added to adjust the pH to 7.0, and the residence time is 2h, and then pass through the first-level coagulation inclined tube sedimentation tank to obtain sewage 2;

[0040] (3) After the sewage 2 is introduced into the secondary pH adjustment tank, sodium hydroxide and calcium hydroxide are added to adjust the pH to 9.5, and the residence time is 1h, and then the sewage 3 is obtained through the secondary coagulation inclined tube sedimentation tank;

[0041] (4) After the sewage 3 is introduced into the three-stage pH adjustment tank, sodium hydroxide is added to adjust ...

Embodiment 3

[0044] A method for treating heavy metal sewage by using multi-stage chemical precipitation:

[0045] (1) Introduce the heavy metal sewage into the acid adjustment tank, add hydrochloric acid and ferrous sulfate, adjust the pH to 2.5, and the residence time is 2h to obtain sewage 1;

[0046] (2) Introduce sewage 1 into a primary pH adjustment tank, add sodium hydroxide and sodium sulfide, adjust the pH to 6.5, and stay for 1.5 hours, then pass through a primary coagulation inclined tube sedimentation tank to obtain sewage 2;

[0047] (3) After the sewage 2 is introduced into the secondary pH adjustment tank, sodium hydroxide and calcium hydroxide are added to adjust the pH to 9, the residence time is 0.8h, and then the sewage 3 is obtained through the secondary coagulation inclined tube sedimentation tank;

[0048] (4) After the sewage 3 is introduced into the three-stage pH adjustment tank, sodium hydroxide is added to adjust the pH to 10, and the residence time is 60 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com