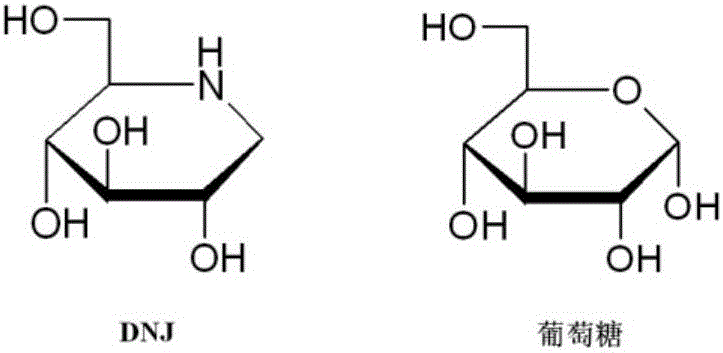

Method for preparing DNJ nanosuspension

A nano-suspension and surfactant technology, which is applied in the field of natural medicinal chemistry, can solve the problems of restricting the practical and large-scale development of natural DNJ, the simple and low efficiency of separation technology, and the small investment in DNJ market, so as to improve the purification yield. High efficiency, obvious feasibility and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This implementation prepares the method for DNJ nano-suspension, comprises the following steps:

[0061] (1), preparation contains the extraction extractum of DNJ: can adopt one or more in following 3 kinds of methods:

[0062] Method 1: After the mulberry material is dried and pulverized, use 70% ethanol solution to extract ultrasonically (420W, 30min), wherein the ratio of liquid to solid is 40mL / g, and the number of extractions is 4 times. The extract is filtered and concentrated under reduced pressure to obtain the extract . 5kg of dried mulberry bark powder was used to obtain 0.50kg of extract, in which the purity of DNJ was 0.104%.

[0063] Method 2: After the mulberry material is dried and crushed, it is extracted by boiling in pure water (100°C, 30 min), the ratio of liquid to solid is 40 mL / g, and the number of extractions is 4 times. The extract is filtered and concentrated under reduced pressure to obtain the extract. 5kg mulberry bark dry powder obtained 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com