Process for the preparation of self-adhesive and pre-disintegrated glass batches

A glass batching and pre-decomposition technology, applied in glass production and other directions, can solve the problems of ineffective utilization of resources, increase energy consumption, block regenerators, etc., so as to improve the effective utilization rate, eliminate potential hazards, and reduce air bubbles. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

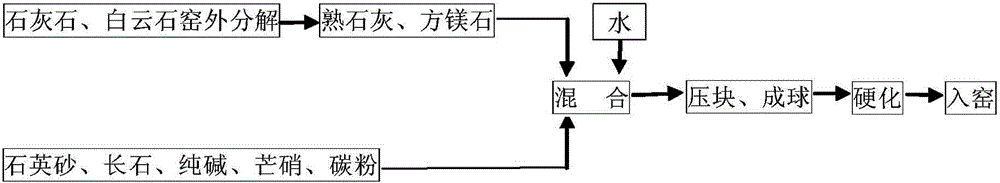

Image

Examples

Embodiment 1

[0034] Quartz sand, feldspar, limestone, dolomite, light soda ash, and Glauber's salt are mixed according to the ingredients in Table 1; then the calcium carbonate and magnesium carbonate in it are calcined in advance to form hydrated lime and periclase; hydrated lime and periclase are formed by adding water Ca(OH) 2 and Mg(OH) 2 ; The powdered Ca(OH) that has been obtained 2 and Mg(OH) 2 Mix with quartz sand, feldspar, dolomite, soda ash, and thenardite in a forced mixer for 15 minutes, add 10wt% water during the mixing process; spray the final powder with water and press it into a Φ32mm×16mm block. After testing, after being placed for 3 days, the compressive strength reaches 17.3MPa, which can meet the requirements of feeding. After X-ray diffraction analysis, it was proved that calcium silicate hydrate and calcium hydroxide appeared. The pressed blocks were melted and observed with a high-temperature microscope, which proved that the temperature at which the liquid pha...

Embodiment 2

[0038] On the rolling glass production line with a daily melting capacity of 150 tons, the ingredients are prepared according to the design composition in Table 2. The raw materials used are quartz sand, feldspar, limestone, dolomite, light soda ash, and Glauber's salt. The particle size of the raw material is less than 1mm, and there is no requirement for the lower limit of the particle size. According to the amount of molten glass per ton (dry basis), weigh 696.2kg of quartz sand, 45.1kg of feldspar, 46.1kg of limestone, 184.9kg of dolomite, 3.53kg of soda ash, 11.04kg of mirabilite, and 0.45kg of carbon powder. The limestone and dolomite are crushed and ball-milled to 80μm, and then fed into the suspension preheater and precalciner for predecomposition to become slaked lime and periclase. The temperature of the precalcining kiln is 900°C.

[0039] Table 2 Design composition of glass (wt%)

[0040] chemical components SiO 2 al 2 o 3 Fe 2 o 3 K 2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com