A gapless extrusion method of aluminum alloy seamless pipe

An extrusion method and seamless tube technology, which are applied in metal extrusion, metal containers to be extruded, metal processing equipment, etc., can solve the problem of uneven wall thickness of seamless aluminum alloy extrusion tubes, and improve the surface of the product. The effect of good quality, wall thickness and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

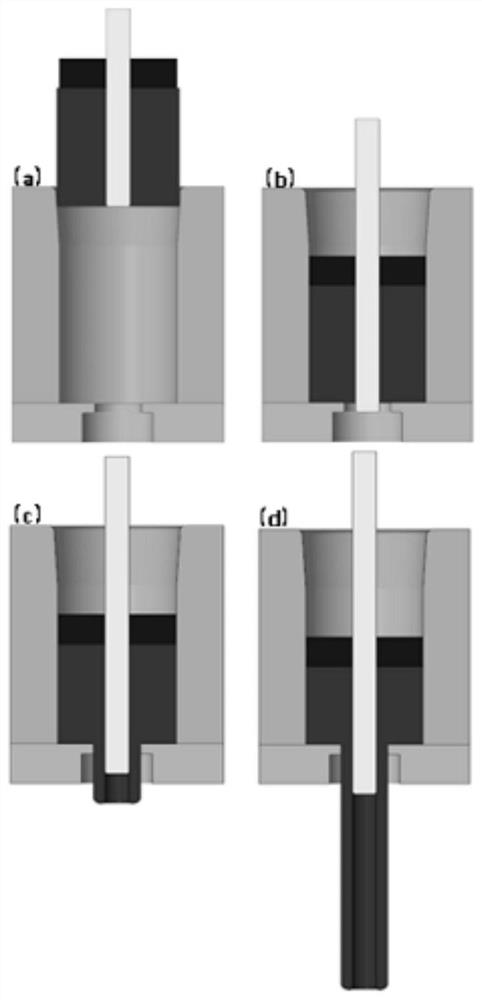

[0016] Such as figure 1 shown, using solid ingot extrusion 6061 aluminum alloy seamless pipe. First put The ingot is machined to its outer diameter to Change the inner diameter to The entrance section of the extrusion barrel lining is processed into a conical flare, the cone angle is controlled at 3-5°, the length of the conical section is controlled at 50mm; the entrance fillet is controlled at R5mm; the processed extrusion with a conical entrance The inner lining of the press cylinder is assembled with the outer casing of the extrusion cylinder by the conventional hot charging method, and preheated to 440°C by the conventional method; the extruded ingot is heated to 470°C by the conventional method; the heated extruded ingot is used The conventional method is to transfer from the heating furnace to the horizontal extruder, apply pressure through the extrusion rod and the extrusion pad, push the extruded ingot from the conical inlet into the extrusion cylinder to th...

Embodiment 2

[0018] Such as figure 2 shown, using an outer diameter of hollow ingot extrusion 7005 aluminum alloy seamless pipe. first to The solid ingot is machined to its outer diameter to the outer diameter And in the center of the ingot machine a diameter of The circular hole; the inner diameter is The entrance section of the extrusion cylinder lining is processed into a conical flare, the cone angle is controlled at 5°, the length of the conical section is controlled at 45mm; the entrance fillet is controlled at R5mm; the processed extrusion cylinder with a conical entrance The inner liner is assembled with the outer casing of the extrusion cylinder by the conventional hot-charging method, and preheated to 440°C by the conventional method; the extruded billet is heated to 475°C by the conventional method; the heated extruded billet is heated by the conventional method Transfer from the heating furnace to the horizontal extrusion machine, and then use the extrusion rod to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com