Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce bubble defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

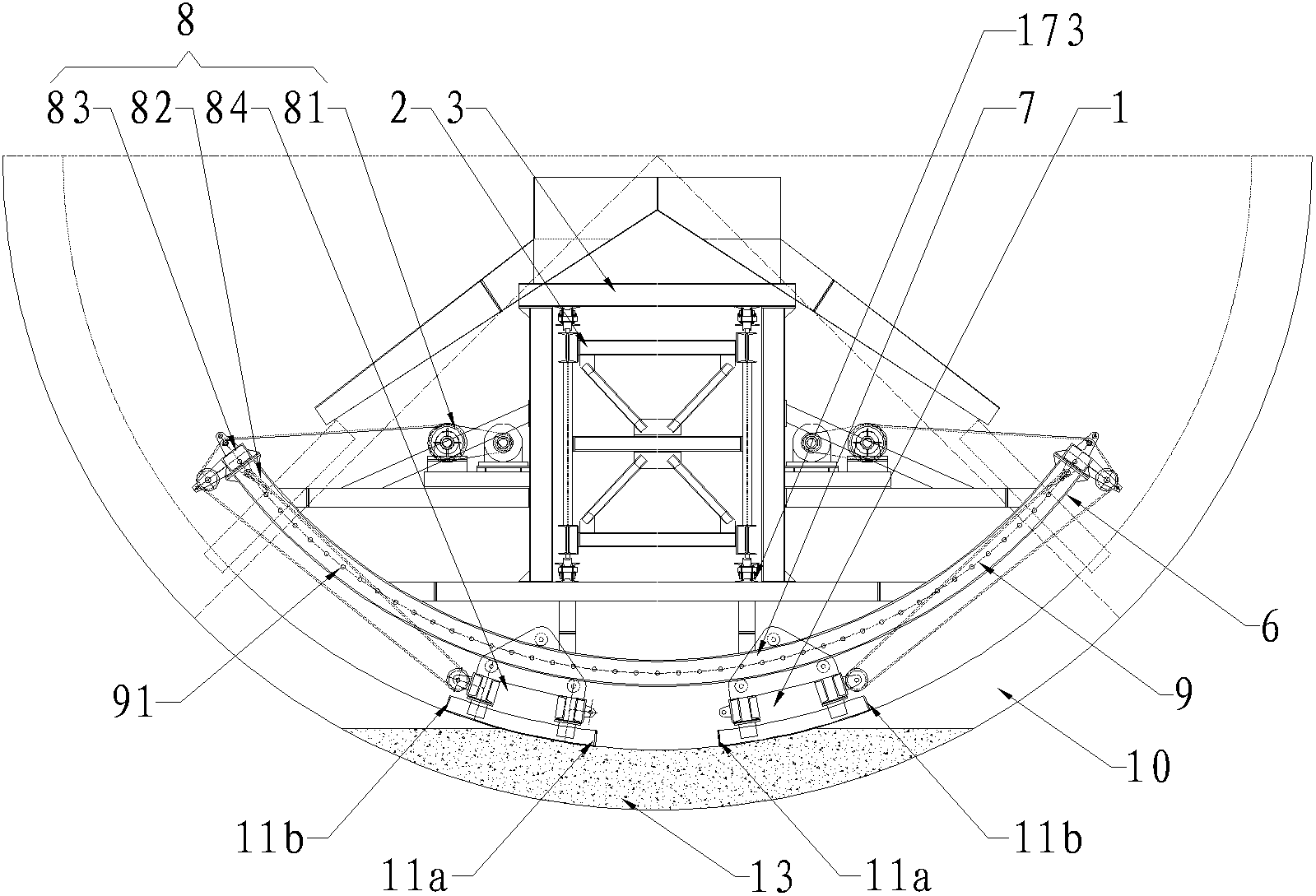

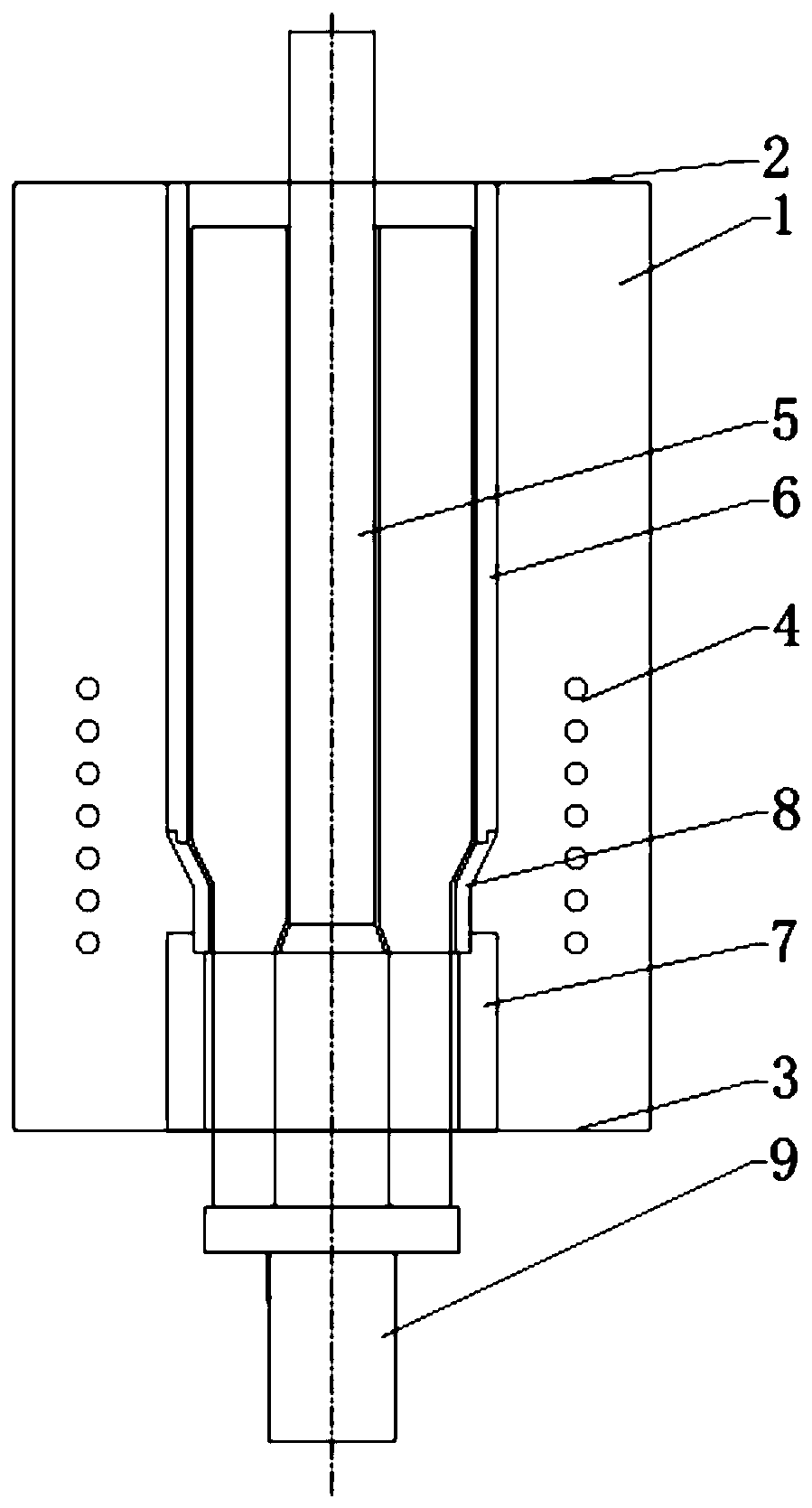

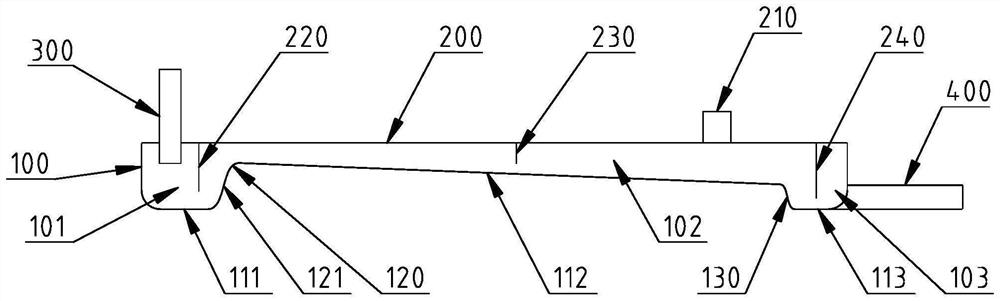

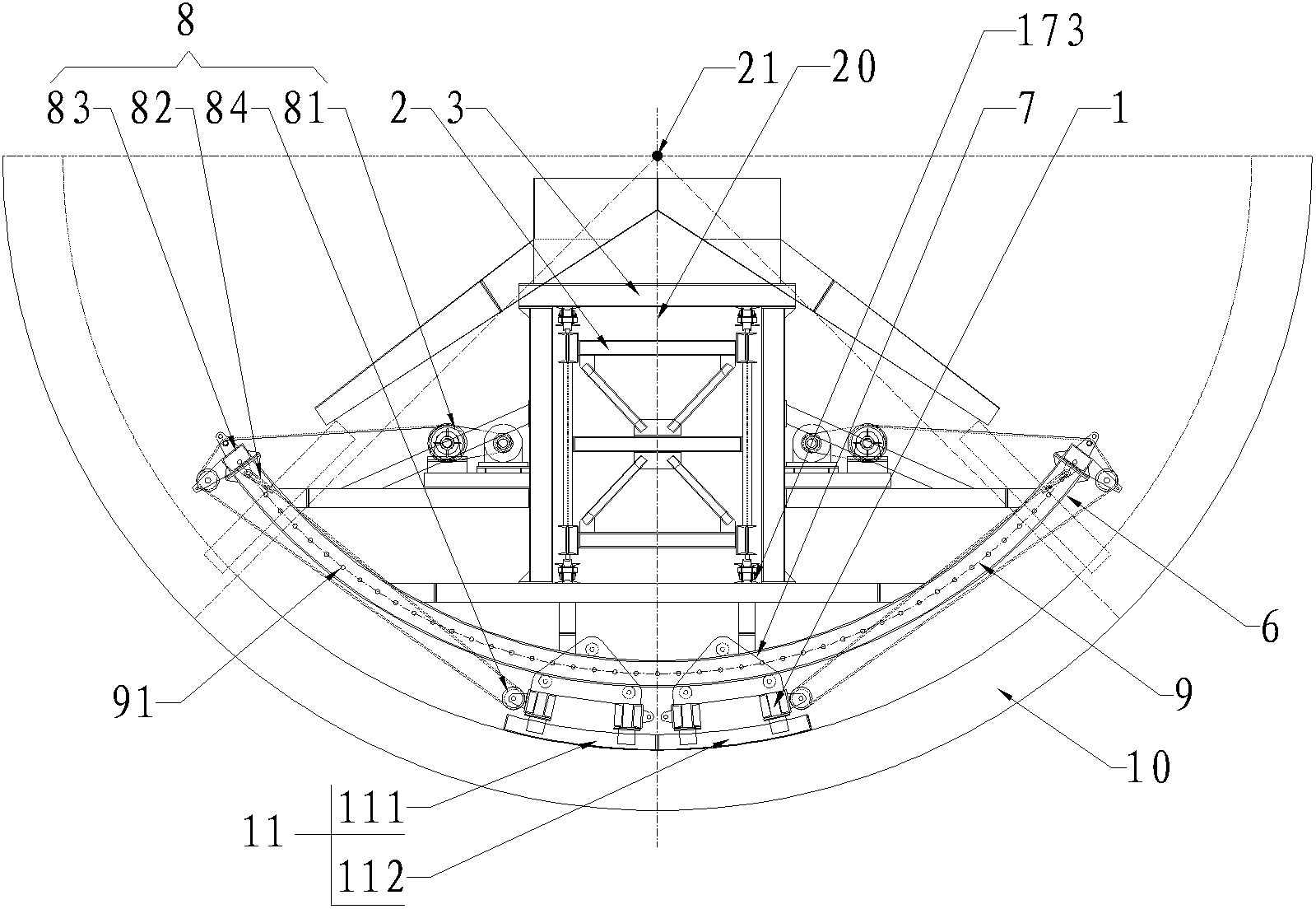

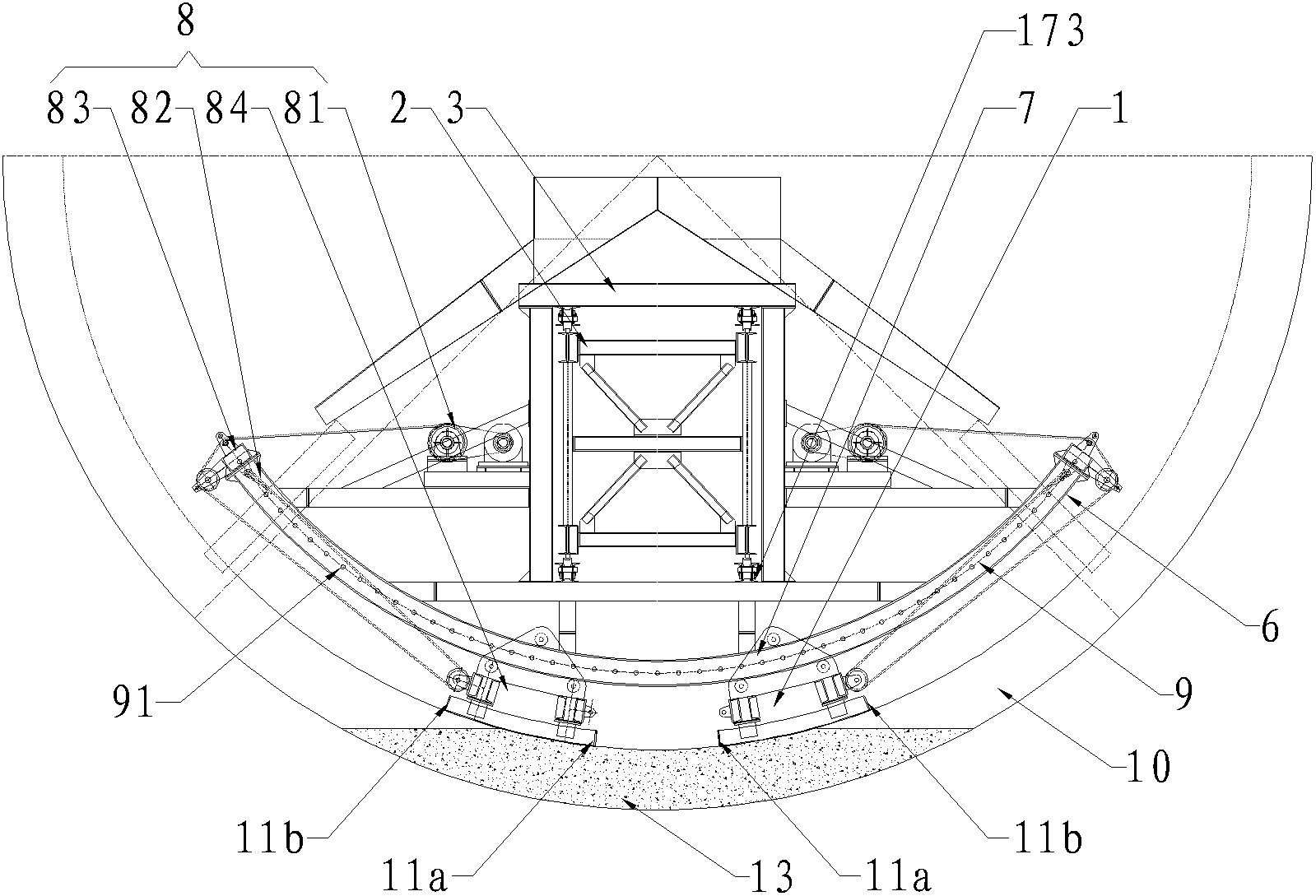

Tunnel bottom concrete side-slipping lining construction method and side-slipping needle beam bottom board trolley

InactiveCN102434171AEasy dischargeImprove construction conditionsUnderground chambersTunnel liningSlip lineTraction system

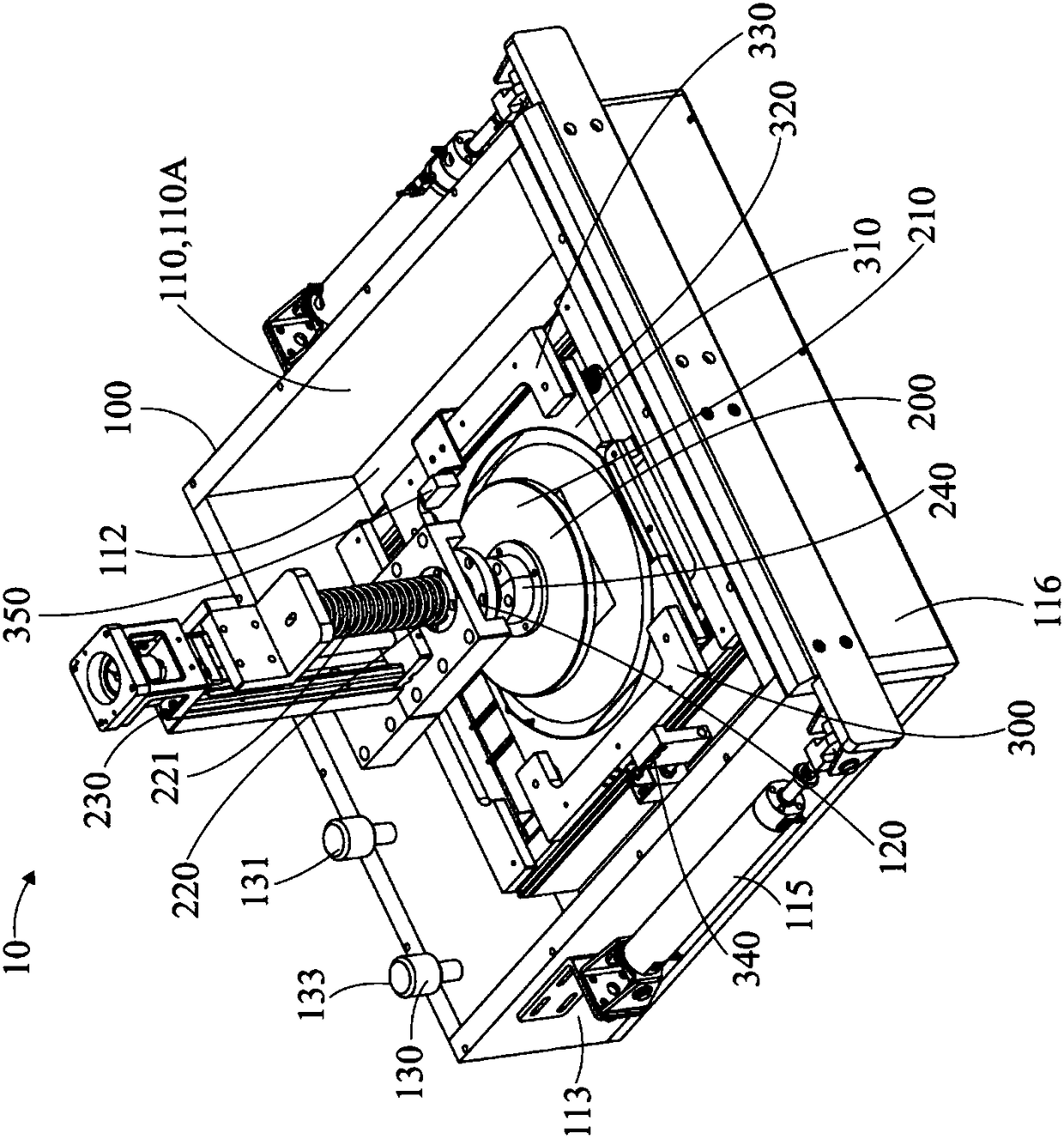

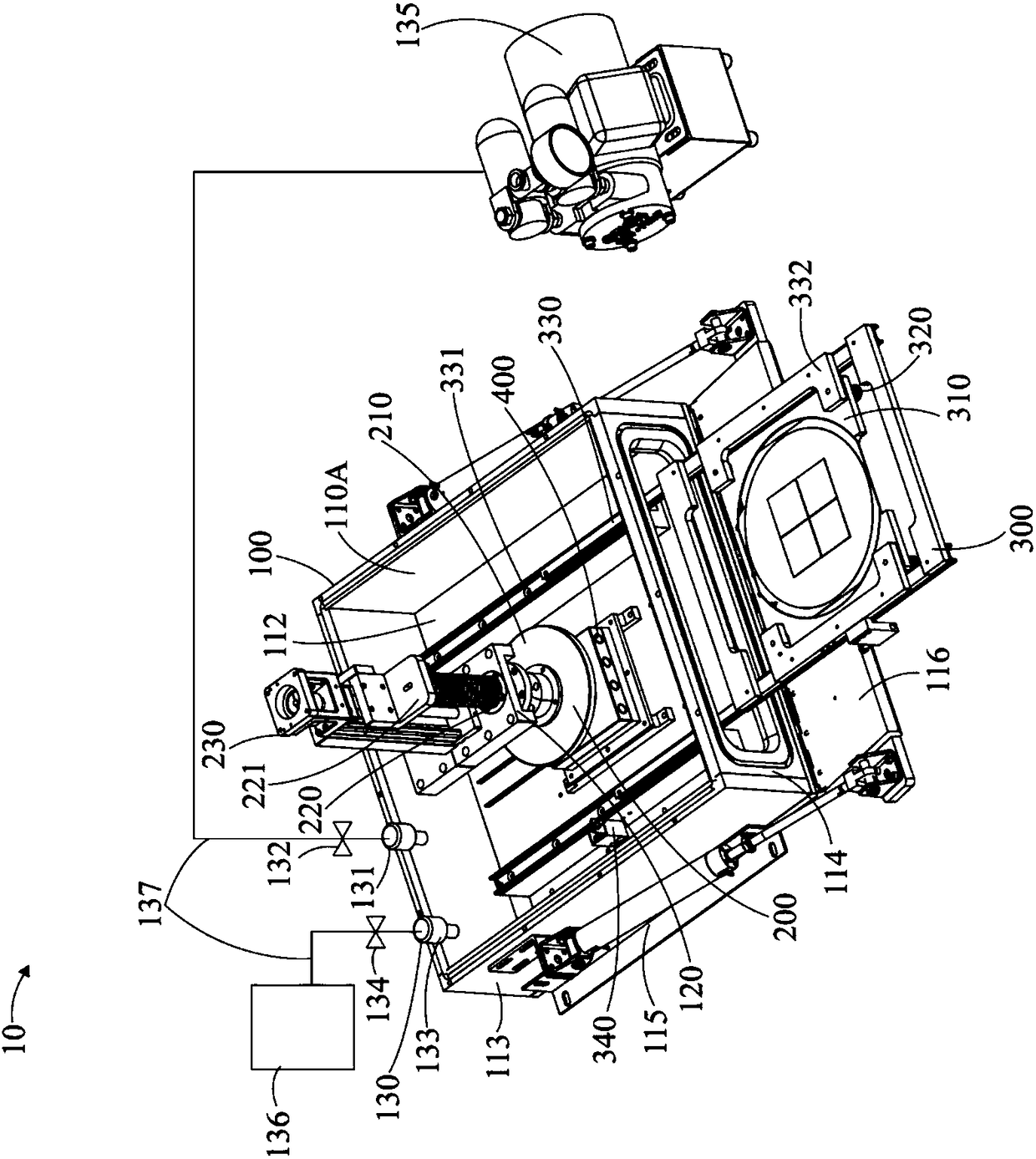

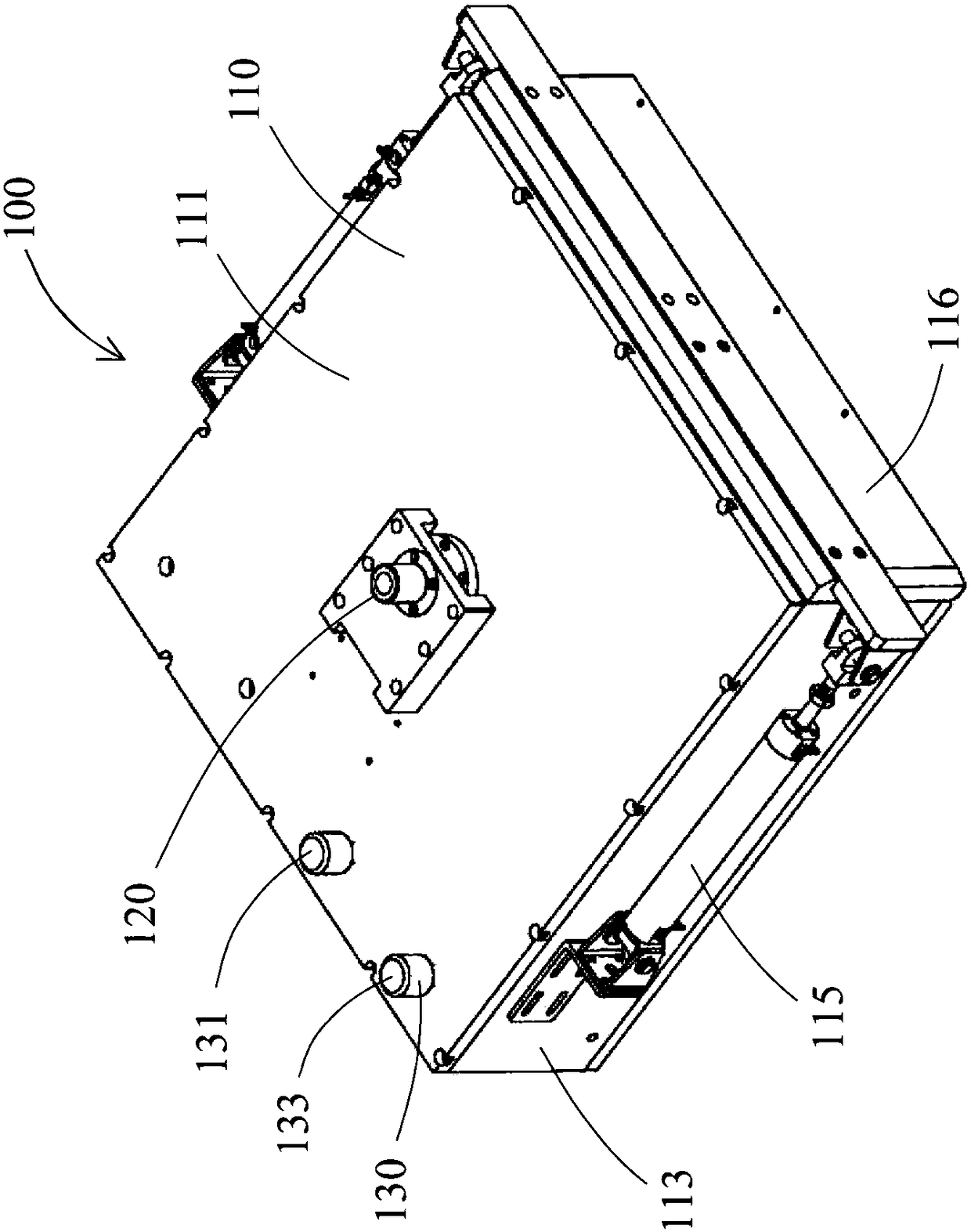

The invention discloses a tunnel bottom concrete side-slipping lining construction method capable of overcoming the bubble defect and a side-slipping needle beam bottom board trolley. The method sequentially comprises construction steps of in-position of a formwork group, side-slipping pouring of concrete and longitudinal movement of the trolley. Guiding tracks matched with designed linear dimension of a tunnel construction face are respectively and fixedly connected in front of and on the back of the lower portion of a beam frame assembly of the side-slipping needle beam bottom board trolley. The formwork group consists of a pair of slide formworks, the pair of slide formworks is symmetrical with a vertical face where the central line of a beam frame is located and is respectively connected with the guiding tracks through a sliding guide mechanism, and the sliding guide mechanism is connected with the beam frame assembly through a side-slipping traction system. The tunnel bottom concrete side-slipping lining construction method is capable of overcoming the defects of bubbles on the surface of concrete, overlap-joint slab staggering of new and old concrete, temperature cracking and the like, has the advantages of being reliable in structure, quick in lining speed, good in construction quality and safe in construction, reducing interference of construction conditions and the like, and is mainly used for side-slipping lining construction of tunnel bottom concrete.

Owner:广汉金达隧道机械有限公司

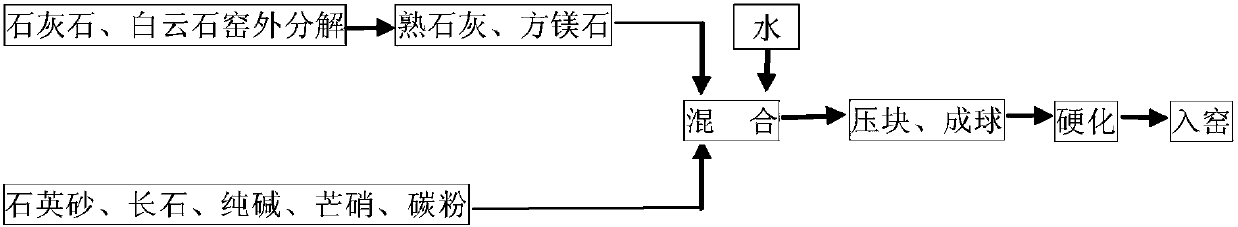

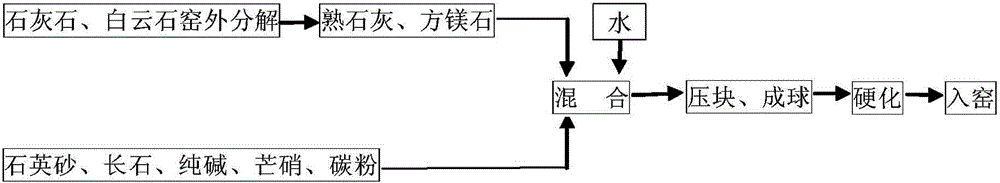

Preparation method of self-bonding and pre-decomposing glass batch

InactiveCN103102057AReduce bubble defectsEliminate potential hazardsGlass productionLower limitUltimate tensile strength

The invention provides a preparation method of a self-bonding and pre-decomposing glass batch. The method comprises the following steps of: pre-decomposing carbonate out of a kiln so as to obtain slaked lime and periclase, then mixing with other glass batch in a proper proportion in a mixing machinery, adding 8-20wt% of water during the mixing process, then pelletizing the mixed batch, standing for more than 72hours, and hardening by hydration to finally obtain the pelletized glass batch with a certain strength. According to the preparation method, the decomposing process of the carbonate is finished out of the kiln, thus the heat consumption can be greatly reduced; the lower limit of the grain size of the raw material is not required, and thus the resource can be used furthest; the cost of the raw material is reduced by adopting the light soda ash; and the pelletizing of the glass batch can be achieved without using an external bonding agent. Therefore, the preparation method has the advantages that the melting rate is improved, the melting temperature is reduced, the melting efficiency is high, and the like.

Owner:YANSHAN UNIV

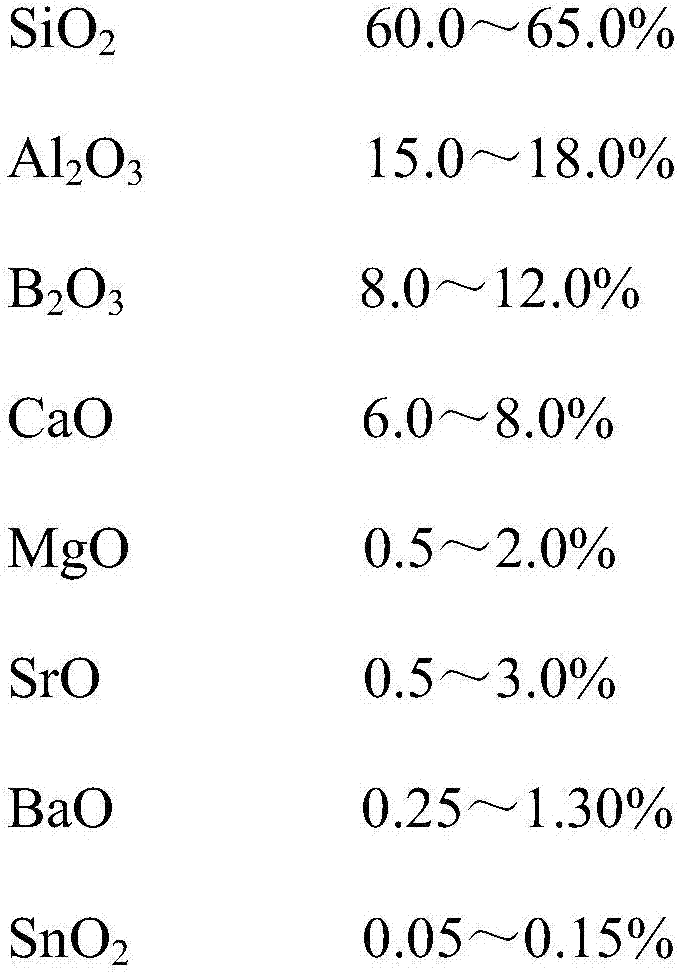

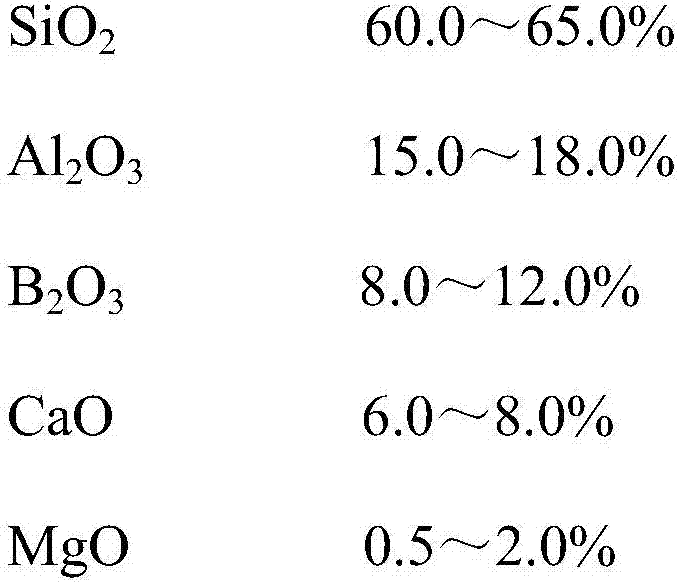

Liquid crystal substrate glass and preparation method thereof

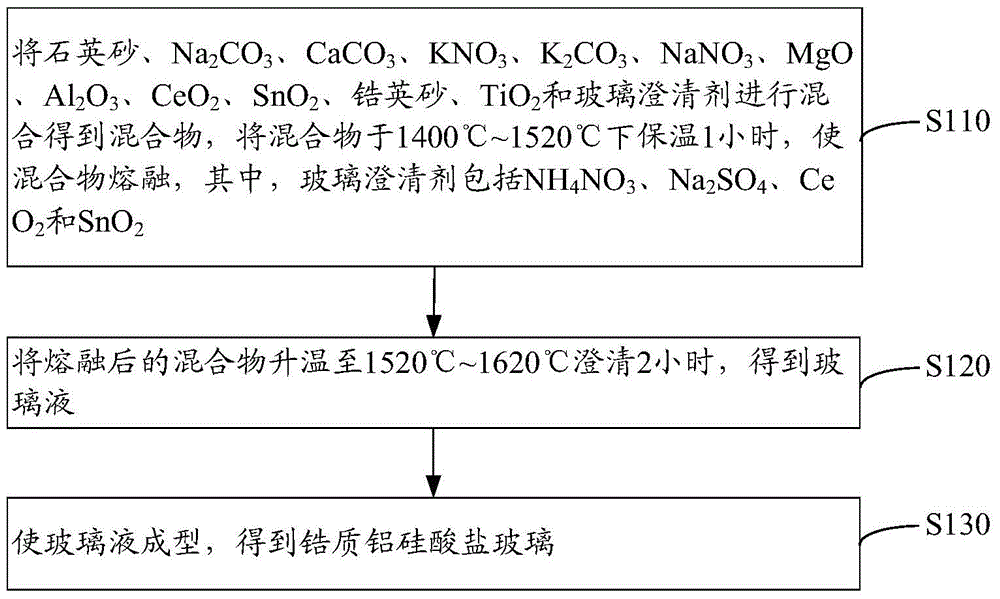

The invention provides liquid crystal substrate glass and a preparation method thereof. The liquid crystal substrate glass consists of the following oxides in percentages by mass: 60.0-65.0% of SiO2, 15.0-18.0% of Al2O3, 8.0-12.0% of B2O3, 6.0-8.0% of CaO, 0.5-2.0% of MgO, 0.5-3.0% of SrO, 0.25-1.30% of BaO, 0.05-0.15% of SnO2 and inevitable impurities. The preparation method comprises the following steps: uniformly mixing the raw materials; melting and clarifying the raw materials and then drawing the raw materials by overflowing to form the liquid crystal substrate glass. The environmentally friendly oxide SnO2 is used as a clarifying agent, alkali metal oxide is not added, and the purpose of eliminating air bubbles on the premise of not polluting the environment is achieved.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

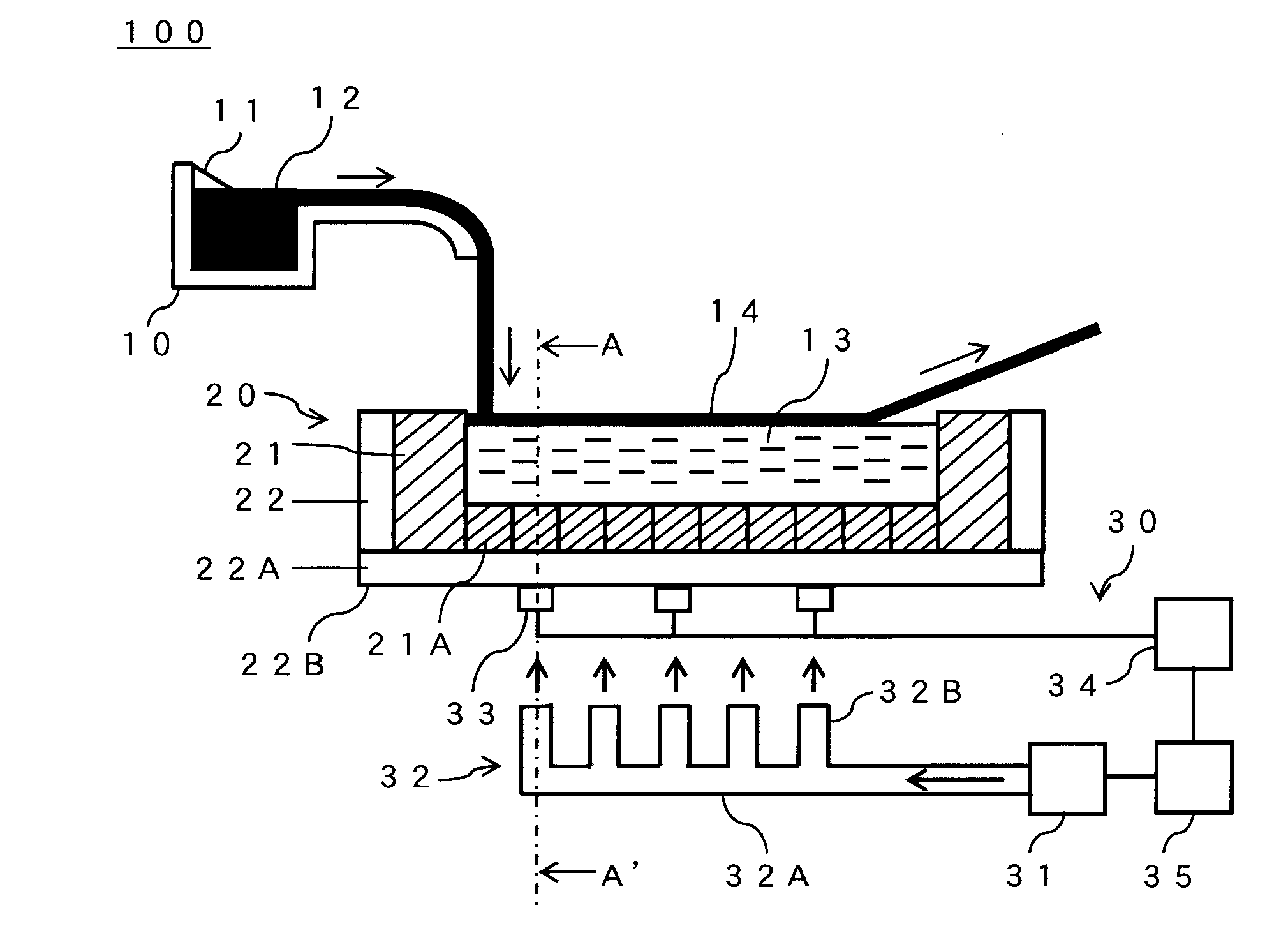

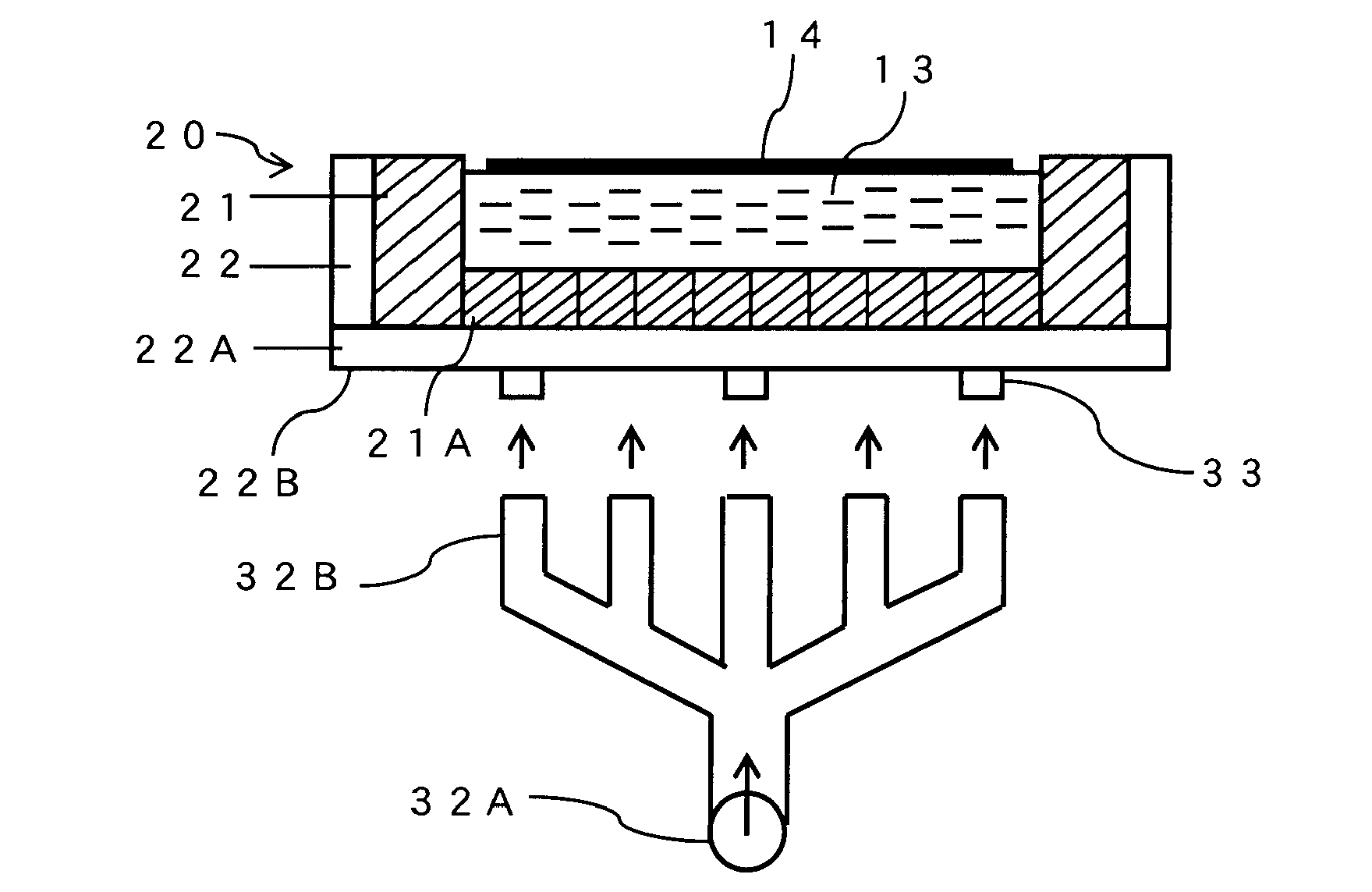

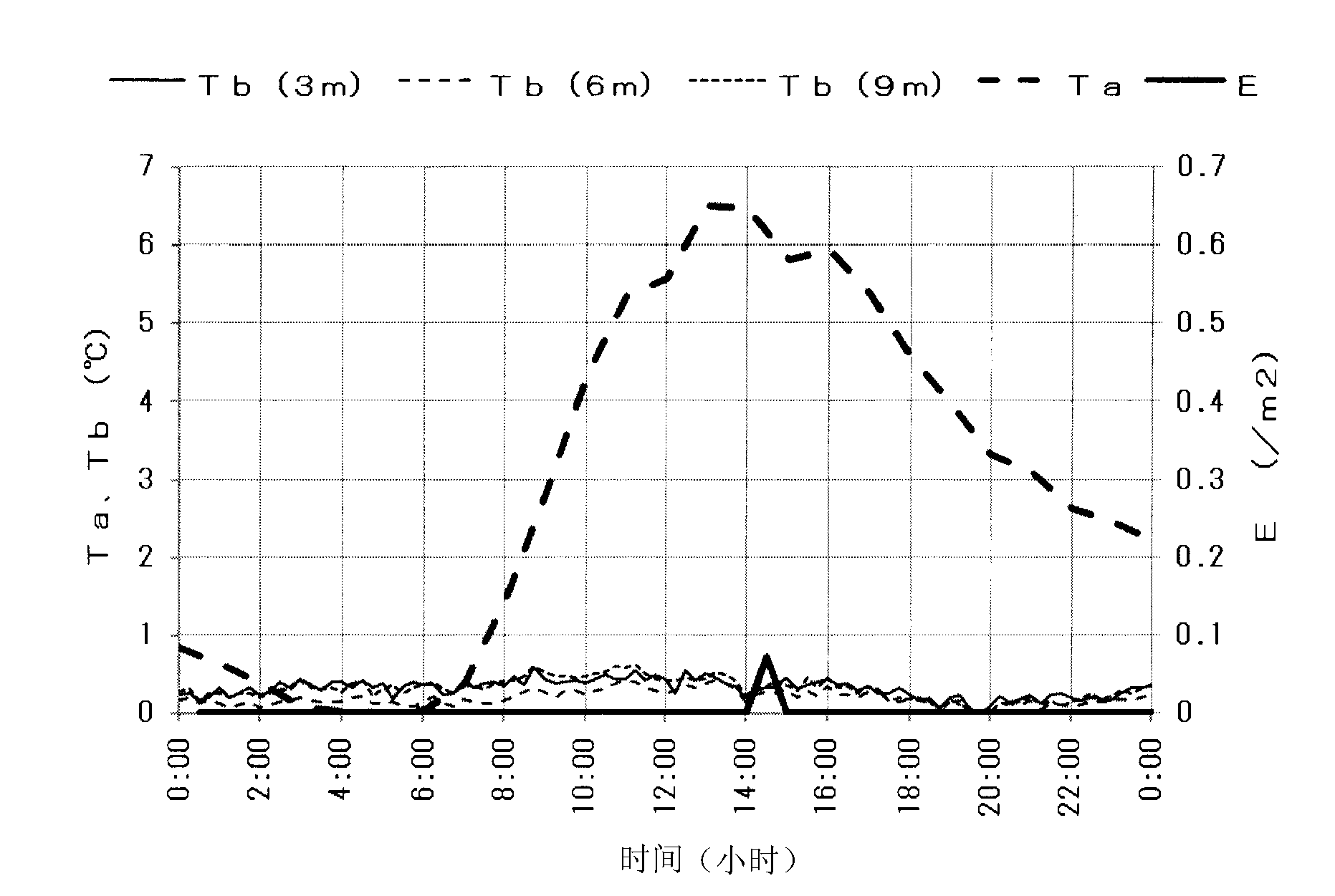

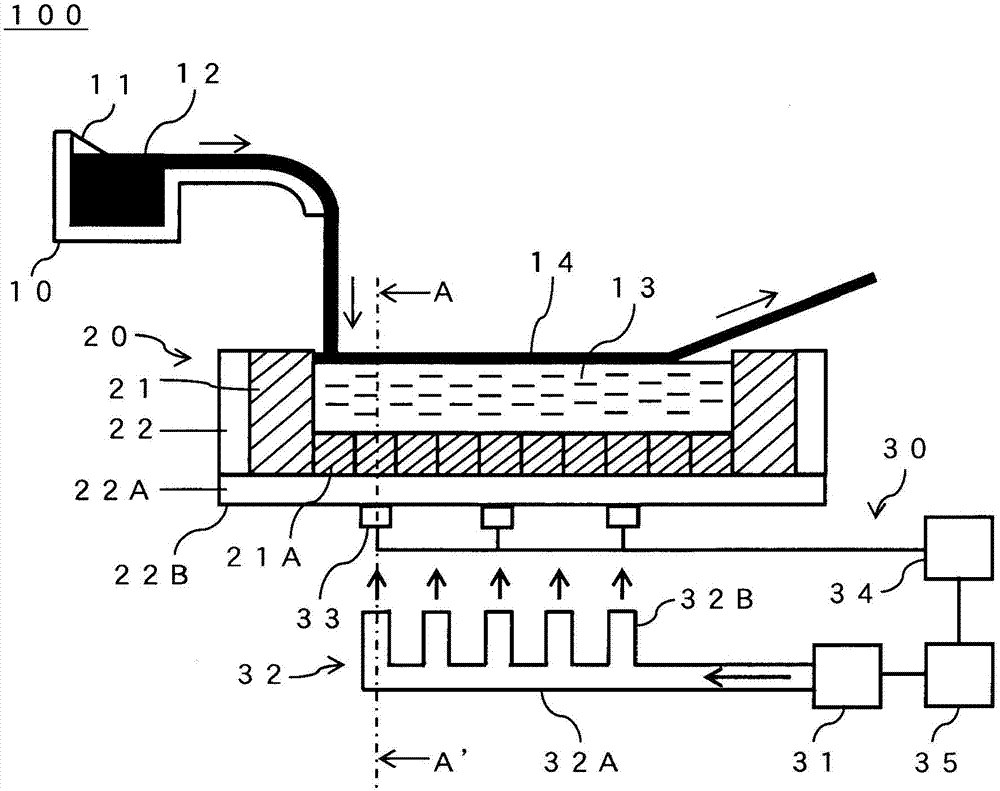

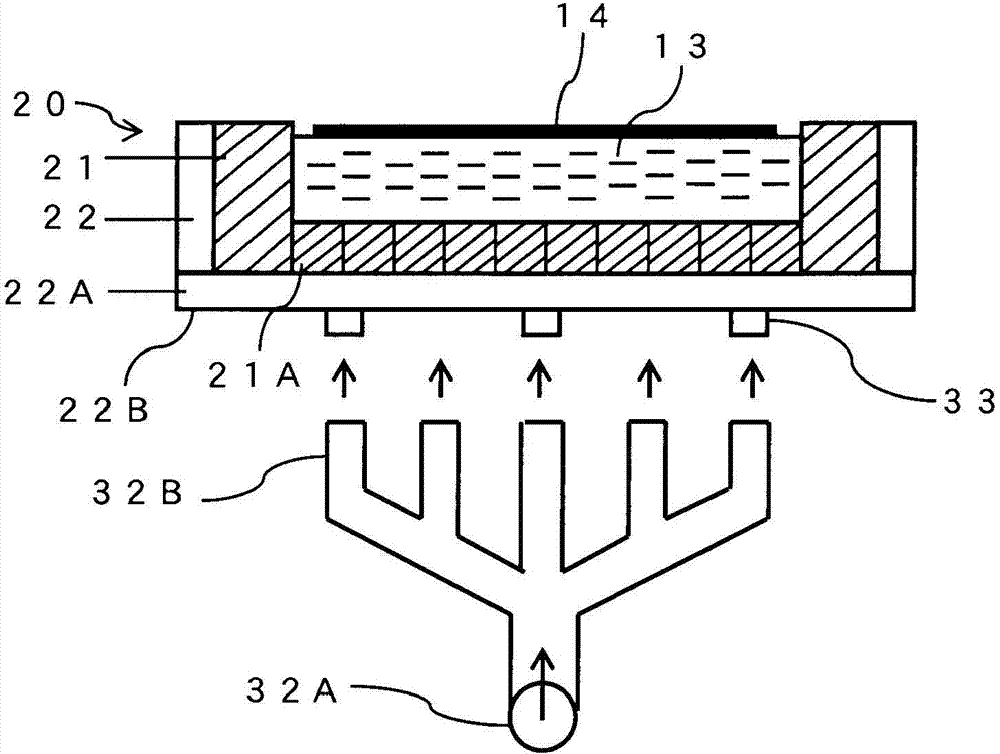

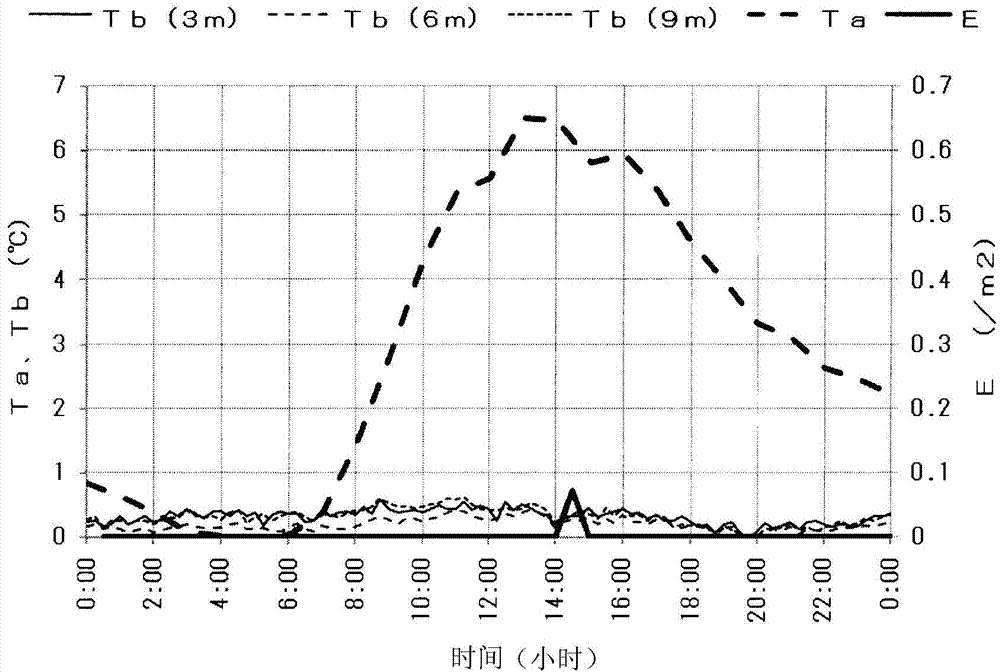

Method for producing float plate glass and apparatus for producing float plate glass

The present invention is related to a method for producing float plate glass, wherein: molten glass is produced by introducing a glass starting material into a melting tank; the molten glass is continuously supplied on the surface of a molten metal which is contained in a bath that is provided with bottom bricks and a bottom casing that covers the bottom bricks; and the molten glass is caused to flow along the surface of the molten metal in a predetermined direction, so that the molten glass is float-formed into a strip-shaped glass ribbon. In this method for producing float plate glass, the temperature fluctuation range of the outer surface of the bottom casing is controlled within 4 DEG C.

Owner:ASAHI GLASS CO LTD

Aviation titanium alloy 3D printing enhancement process

PendingCN112453426AImprove fatigue fracture strengthHigh mechanical strengthAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedLaser scanning

The invention discloses an aviation titanium alloy 3D printing enhancement process, which comprises the following steps: S1, outputting a to-be-laid powder raw material through a mixer, and flatly laying the to-be-laid powder raw material on a powder bed through a scraper strip and a powder leaking groove; S2, performing laser scanning on metal powder on the powder bed for the first time until thetemperature of the metal powder laid on the powder bed rises to a preset temperature; S3, planning a scanning path for a preheated metal powder layer according to a set scanning strategy, and performing laser scanning for the second time; S4, cooling and molding to obtain a solidified metal sheet; S5, performing laser scanning on the solidified metal sheet for the third time to obtain a semi-finished product; and S6, performing laser scanning on the surface of a metal cutting layer of a finished product for the fourth time, and then the aviation titanium alloy 3D printing enhancement processis completed. The process provided by the invention can reduce cracks and bubbles in the finished product, and the finished product is high in mechanical strength, dimensional precision and compactness and low in surface roughness Ra value.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

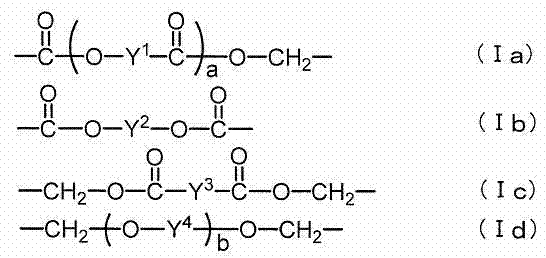

Polarizing plate using photocurable adhesive and laminate optical member

ActiveCN103597383AImprove applicabilityLow viscosityPolarising elementsEpoxy resin adhesivesTectorial membranePolyvinyl alcohol

Provided is a polarizing plate configured from a polyvinyl alcohol-based polarizer and a transparent protective film pasted onto the polarizer with an adhesive therebetween, wherein the adhesive contains 100 parts by weight of a photo cation curable component (A) and 1-10 parts by weight of a photo cation polymerization initiator (B), and the photo cation curable component (A) is formed from a photocurable adhesive containing the following (A1)-(A3) at the following quantities relative to the total quantity thereof: 30-85 wt% of an alicyclic diepoxy compound (A1) represented by formula (I); 1-69 wt% of a diglycidyl compound (A2) represented by formula (II), Z being a branch structure; and 1-69 wt% of a monofunctional epoxy compound (A3) represented by formula (III). The weight reduction of the protective film when the protective film is immersed at 23°C for two days in the photocurable adhesive is 0-30 wt%.

Owner:SUMITOMO CHEM CO LTD +1

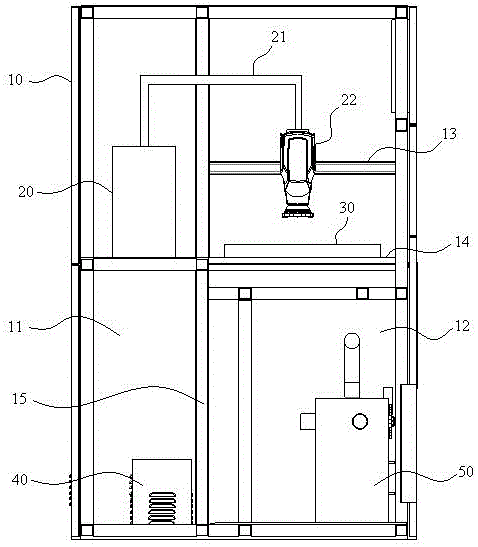

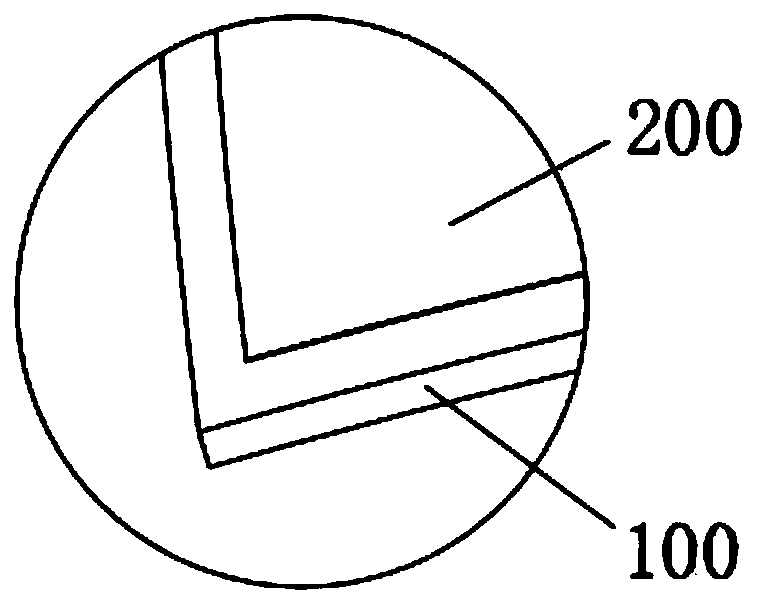

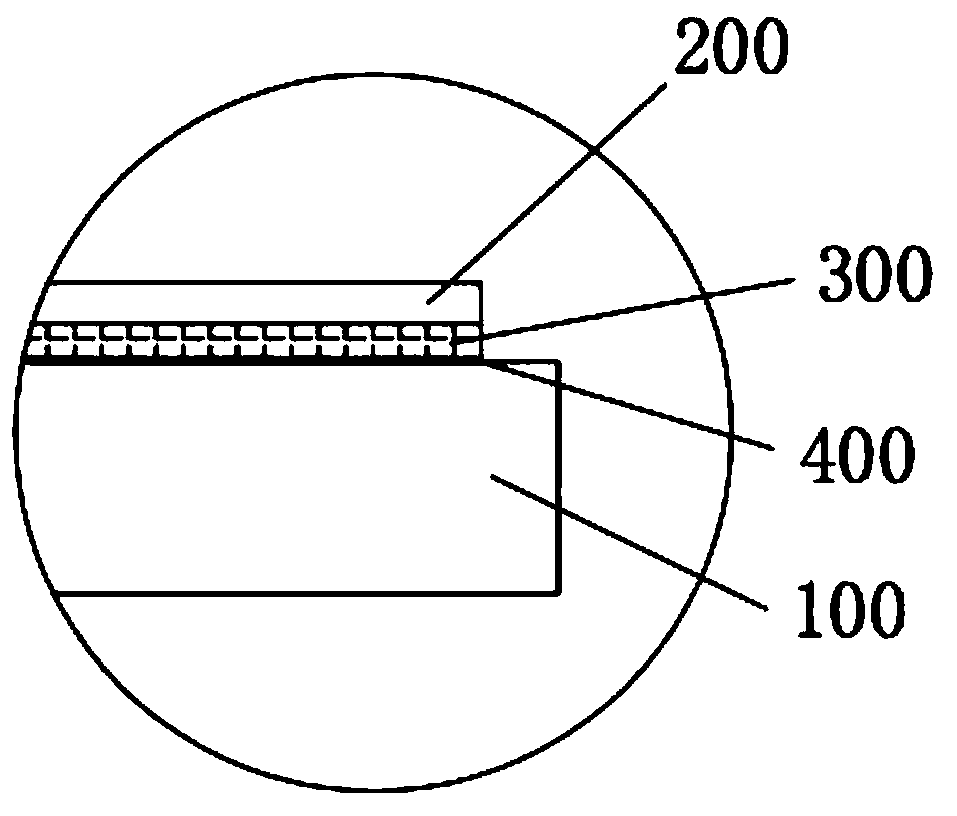

Vacuum film pasting apparatus and method

ActiveCN108321097AReduce bubble defectsImprove yieldSemiconductor/solid-state device manufacturingSemiconductor devicesAdhesiveEngineering

The invention provides a vacuum film pasting apparatus. The vacuum film pasting apparatus comprises a vacuum cavity module, a film pressing module, a bearing module and a heating platform, wherein thefilm pressing module comprises a film pressing plate; and the bearing module comprises a bearing plate and a spring device. When the vacuum film pasting apparatus acts, the film pressing plate presses a film downwards to drive the bearing plate to move to the heating platform so as to heat the film sheet to enable jointing adhesive to be cured and laminated; after heating is completed, the film pressing plate moves upwards, and the spring device can release the spring potential energy pre-stored in lamination, and drives the bearing plate to move upwards to recover to the initial position. The invention also provides a vacuum film pasting method; and by virtue of the vacuum film pasting apparatus and method, lamination shortcoming caused by air bubbles between the film sheet and the to-be-pasted film part can be reduced, and the combination force between the film sheet and the to-be-pasted film part can be improved.

Owner:MAVEN OPTRONICS CO LTD

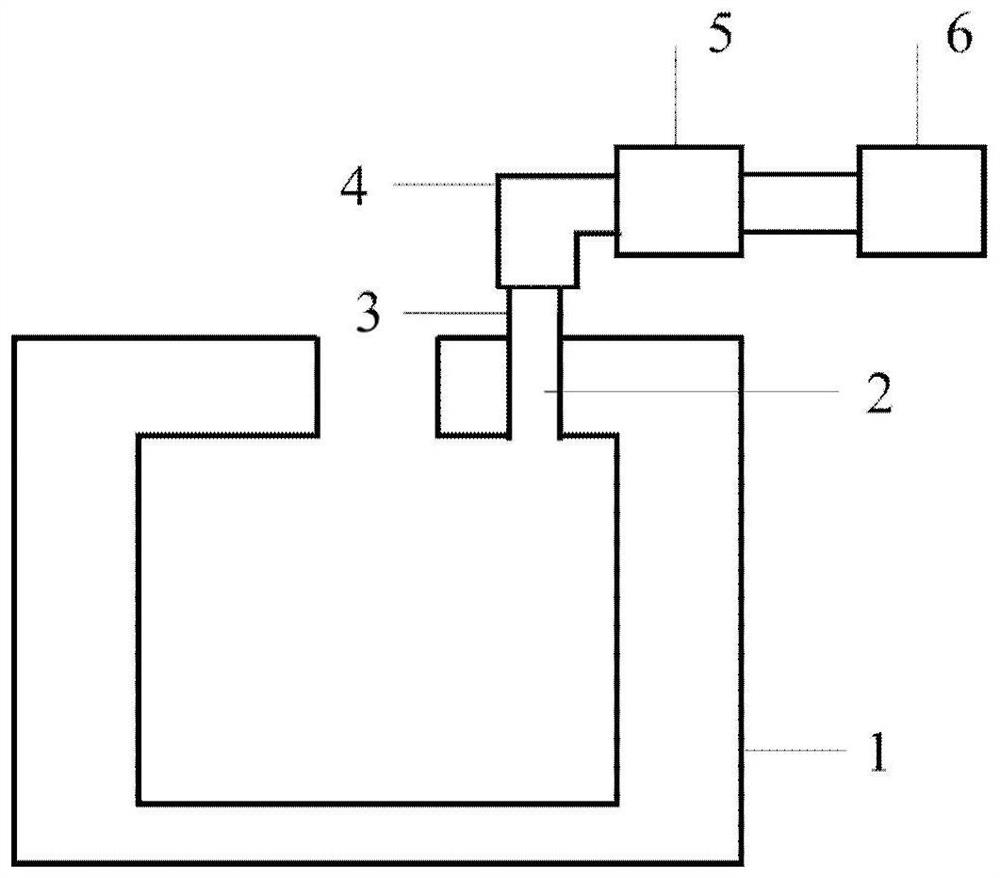

Method for forming waterproof coating in negative pressure environment

ActiveCN106622829AAccelerated escape velocityReduce the generation of coating bubble defectsLiquid surface applicatorsCoatingsMaterials scienceCoating

The invention relates to a method for forming a waterproof coating in a negative pressure environment, and belongs to the technical field of spraying equipment. The method comprises the following steps: step 1, stirring the coating, namely, stirring the coating in a storing tank; and step 2, coating under negative pressure, namely, starting a vacuum pump to create the negative pressure environment for a negative pressure space, and coating the coating on a test part through a spraying mechanism. According to the technical scheme, the method has the advantages that the coating is stored in the storing tank and is stirred all the time so as to ensure uniform mixing; the vacuum pump can provide the negative pressure state to the negative pressure space, so that the escape speed of bubbles in a coating layer on the surface of the test part is increased, and as a result, the deflect of bubbles in the coating can be reduced. The method is beneficial in technological effect and obvious in practical value.

Owner:ANHUI BUILDING ENG QUALITY SUPERVISION & TESTING STATION

Process for the preparation of self-adhesive and pre-disintegrated glass batches

InactiveCN103102057BReduce bubble defectsEliminate potential hazardsGlass productionLower limitPericlase

The invention provides a preparation method of a self-bonding and pre-decomposing glass batch. The method comprises the following steps of: pre-decomposing carbonate out of a kiln so as to obtain slaked lime and periclase, then mixing with other glass batch in a proper proportion in a mixing machinery, adding 8-20wt% of water during the mixing process, then pelletizing the mixed batch, standing for more than 72hours, and hardening by hydration to finally obtain the pelletized glass batch with a certain strength. According to the preparation method, the decomposing process of the carbonate is finished out of the kiln, thus the heat consumption can be greatly reduced; the lower limit of the grain size of the raw material is not required, and thus the resource can be used furthest; the cost of the raw material is reduced by adopting the light soda ash; and the pelletizing of the glass batch can be achieved without using an external bonding agent. Therefore, the preparation method has the advantages that the melting rate is improved, the melting temperature is reduced, the melting efficiency is high, and the like.

Owner:YANSHAN UNIV

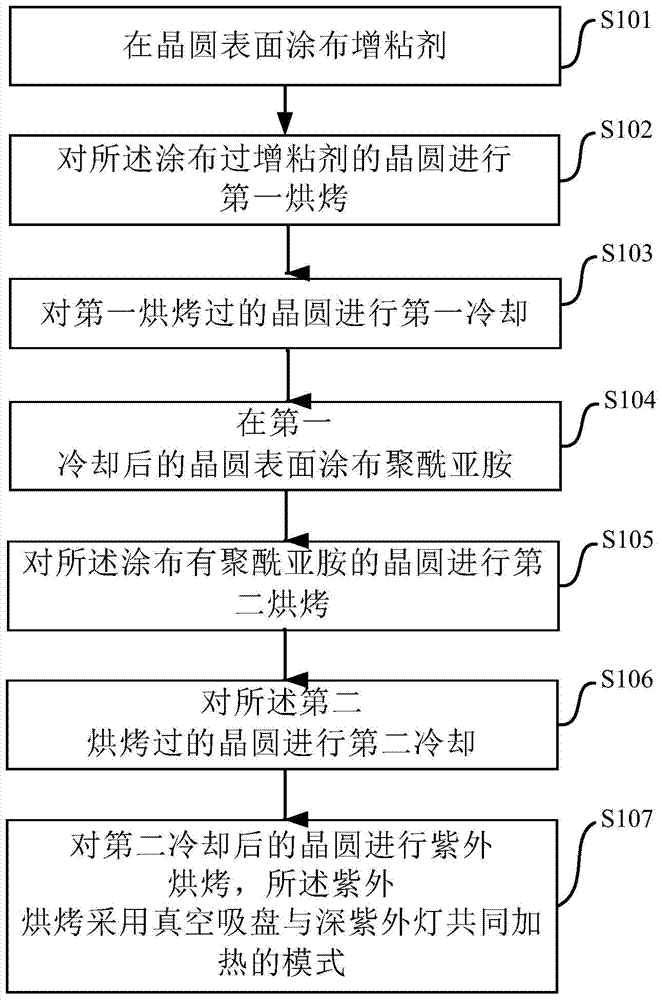

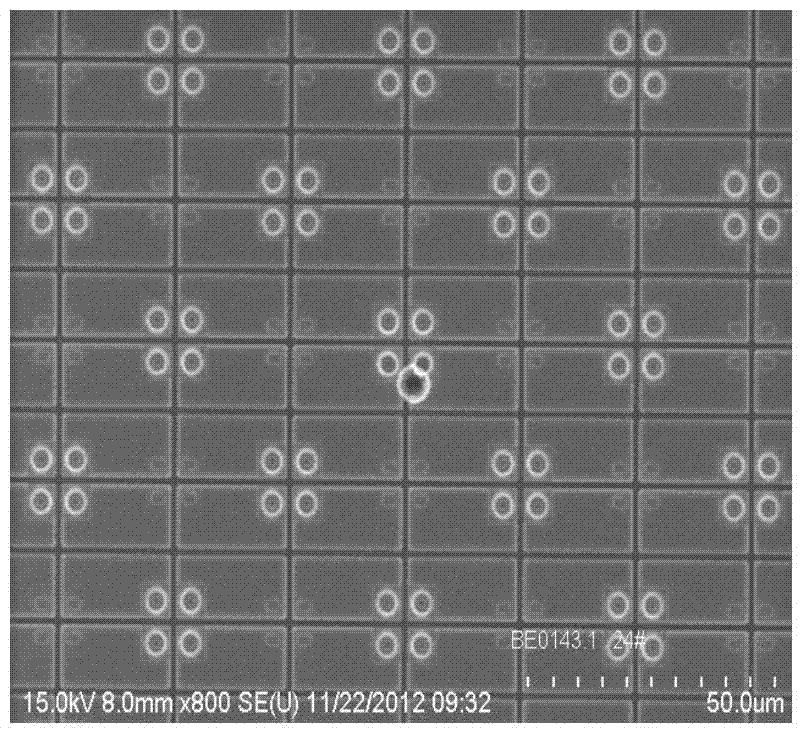

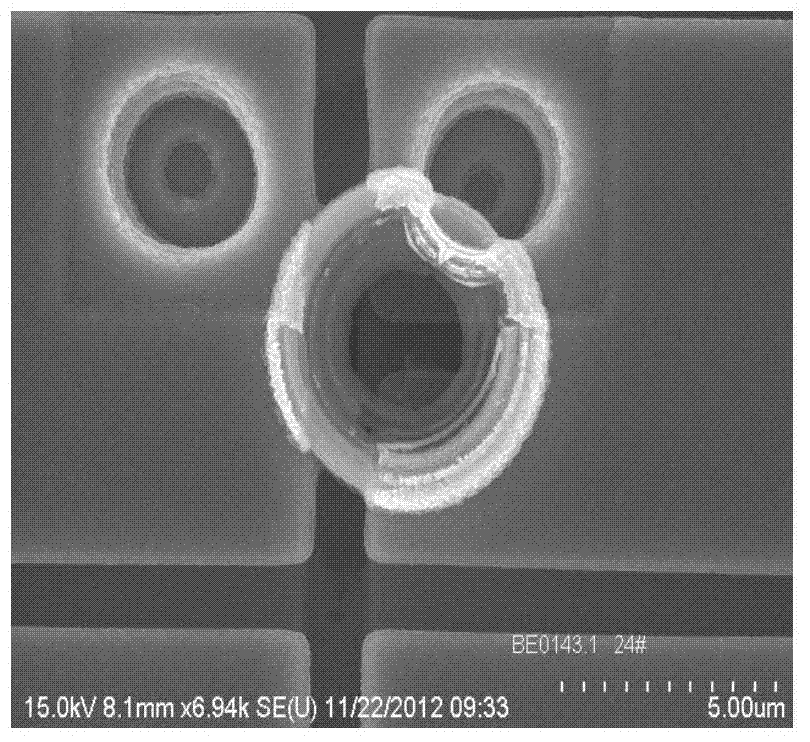

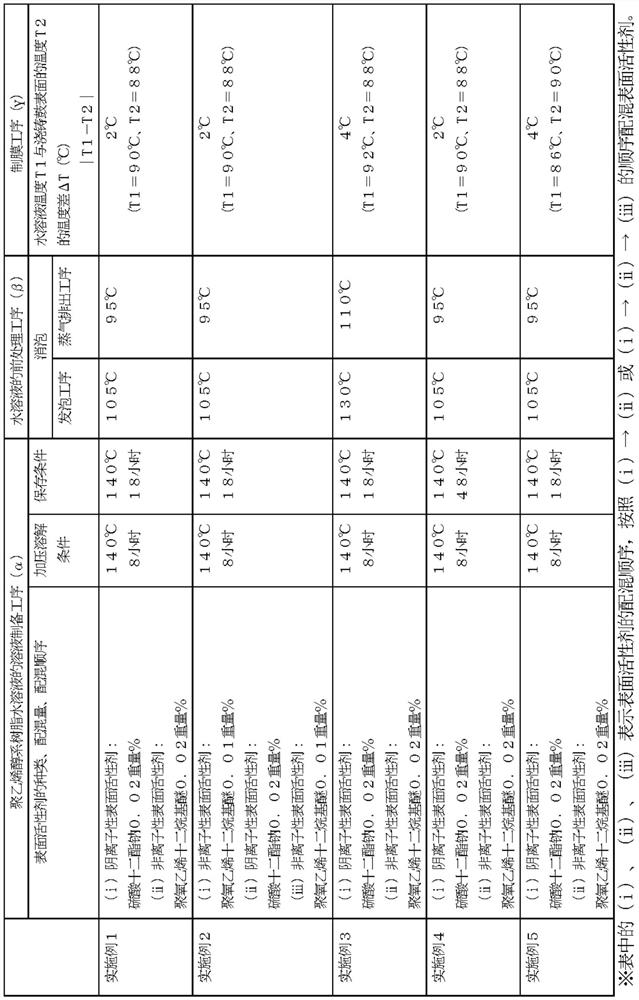

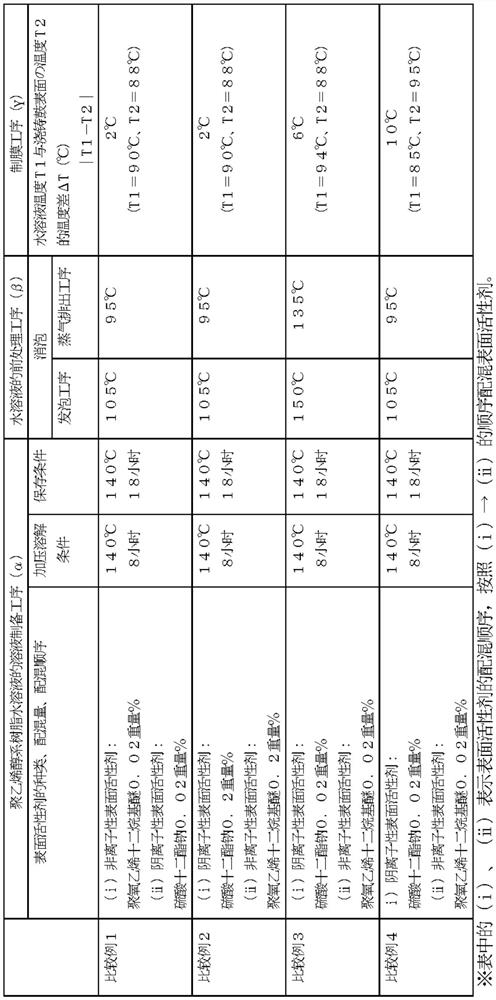

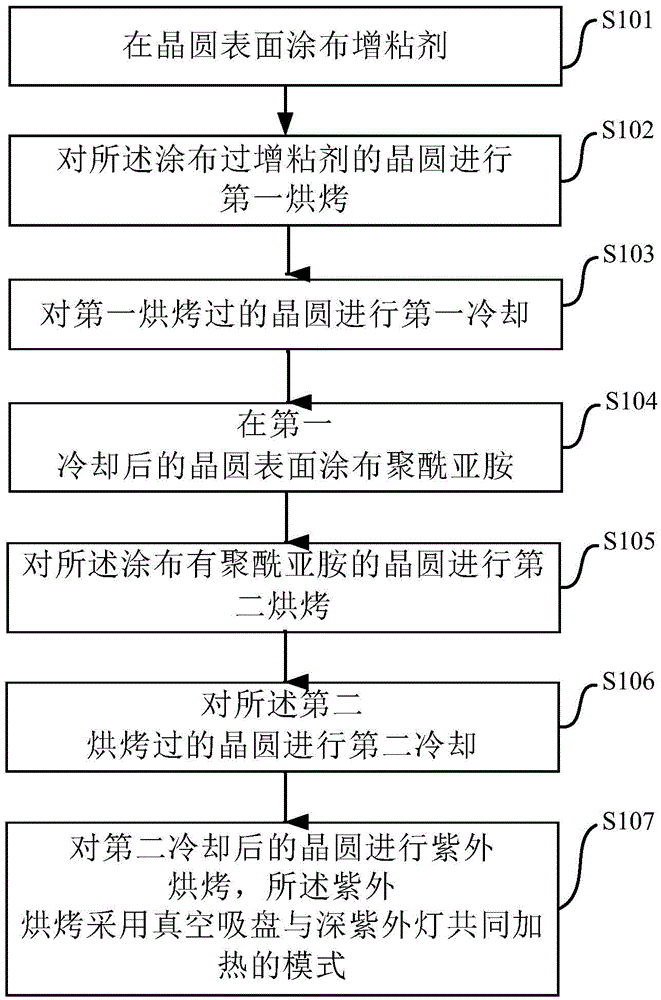

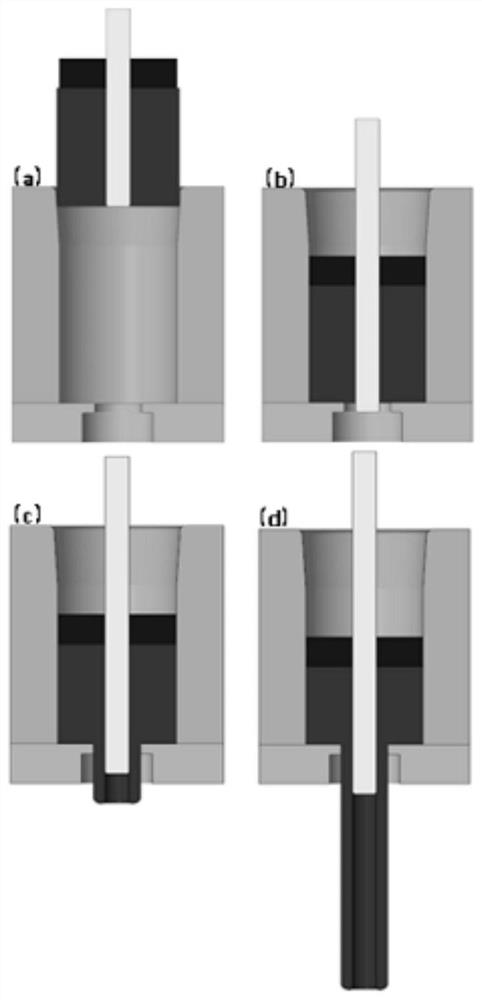

Polyimide (PI) coating and baking method

ActiveCN104261344AReduce bubble defectsReduce bubble defect problemsDecorative surface effectsPretreated surfacesPolyimideAir bubble

The invention provides a high-viscosity polyimide (PI) coating and baking method, which has the advantages of low cost and low defect density. The method comprises the following steps in sequence: coating the surface of a wafer with a tackifier; performing first baking on the wafer coated with the tackifier; performing first cooling on the wafer which is subjected to first baking; coating the surface of the wafer which is subjected to first cooling with PI; performing second baking on the wafer coated with the PI; performing second cooling on the wafer which is subjected to second baking; and performing ultraviolet baking on the wafer which is subjected to second cooling, wherein a common heating mode for heating through a vacuum sucking disk and a deep ultraviolet lamp is adopted in the ultraviolet baking. According to the embodiment of the invention, the problem of generation of bubble defect due to high viscosity of PI glue is solved, the product yield is increased, and the imaging quality is enhanced.

Owner:北方广微科技有限公司

Method for solving blister generated in die-casting piece

The invention relates to an aluminum alloy die-casting improving method, in particular to a method which is suitable for solving blister generated in a die-casting piece. By adopting the following methods: mould temperature is controlled, injection speed is reduced, coating material with low gas evolution is selected, an overflow well is additionally arranged, pressure holding time and mould staying time are adjusted and smelting technology finishing is carried out, the generation of blister defect of the aluminum alloy die-casting piece is effectively improved.

Owner:WUJIANG TIANLONG MACHINERY

Flexible glass and preparation method thereof

PendingCN114656142AHigh strain point temperatureHigh Young's modulusGlass forming apparatusGlass productionLaser cuttingSilicon dioxide

The invention discloses flexible glass and a preparation method thereof. The flexible glass is prepared from the following raw materials in parts by weight: 60.04 to 63.01 parts by weight of silicon dioxide, 16.7 to 21.5 parts by weight of aluminum oxide, 12.93 to 19.85 parts by weight of boric oxide, 2.43 to 14.19 parts by weight of calcium carbonate, 0.16 to 2.07 parts by weight of magnesium oxide, 0.5 to 2.74 parts by weight of strontium carbonate and 0.12 to 4.16 parts by weight of barium nitrate. The method comprises the following steps: 1, pouring raw materials into a mixer, and uniformly mixing to form a mixture; step 2, adding the mixture in the step 1 into a glass kiln through a batch feeder, heating to melt glass, clarifying the molten glass in a platinum feeding channel, and flowing the clarified glass into a stay tube tunnel; 3, drawing the molten glass into a long glass tube in a tube drawing tunnel by a traction tube drawing machine, wherein the interior of the tube drawing tunnel is in a polar atmosphere; step 4, transversely and longitudinally cutting the glass tube by using a laser cutting machine according to specification requirements to form a glass sheet; and step 5, inspecting the glass sheet to prepare a flexible glass product.

Owner:IRICO DISPLAY DEVICES

Optical polyvinyl alcohol-based film, method for producing the same, and polarizing film using the optical polyvinyl alcohol-based film

ActiveCN109154692BImprove polarization performanceReduce bubble defectsPolarising elementsFlat articlesPolyvinyl alcoholThin membrane

The present invention is an optical polyvinyl alcohol-based film, which is a polyvinyl alcohol-based film with a width of more than 2m and a length of more than 4km. The number of bubbles with a diameter of 50 μm or more contained in ≥4km) is 0.01 / m 2 the following. Therefore, the polarizing film obtained using this optical polyvinyl alcohol-type film has few display defects and is high quality.

Owner:MITSUBISHI CHEM CORP

Forming method of waterproof coating under negative pressure environment

ActiveCN106622829BIncrease escape velocityReduce bubble defectsSpray boothsVacuum pumpMaterials science

The invention relates to a method for forming a waterproof coating in a negative pressure environment, and belongs to the technical field of spraying equipment. The method comprises the following steps: step 1, stirring the coating, namely, stirring the coating in a storing tank; and step 2, coating under negative pressure, namely, starting a vacuum pump to create the negative pressure environment for a negative pressure space, and coating the coating on a test part through a spraying mechanism. According to the technical scheme, the method has the advantages that the coating is stored in the storing tank and is stirred all the time so as to ensure uniform mixing; the vacuum pump can provide the negative pressure state to the negative pressure space, so that the escape speed of bubbles in a coating layer on the surface of the test part is increased, and as a result, the deflect of bubbles in the coating can be reduced. The method is beneficial in technological effect and obvious in practical value.

Owner:ANHUI BUILDING ENG QUALITY SUPERVISION & TESTING STATION

Polarizing plate and laminated optical member using photocurable adhesive

ActiveCN103597383BImprove applicabilityLow viscosityPolarising elementsEpoxy resin adhesivesPolymer sciencePolyvinyl alcohol

Provided is a polarizing plate configured from a polyvinyl alcohol-based polarizer and a transparent protective film pasted onto the polarizer with an adhesive therebetween, wherein the adhesive contains 100 parts by weight of a photo cation curable component (A) and 1-10 parts by weight of a photo cation polymerization initiator (B), and the photo cation curable component (A) is formed from a photocurable adhesive containing the following (A1)-(A3) at the following quantities relative to the total quantity thereof: 30-85 wt% of an alicyclic diepoxy compound (A1) represented by formula (I); 1-69 wt% of a diglycidyl compound (A2) represented by formula (II), Z being a branch structure; and 1-69 wt% of a monofunctional epoxy compound (A3) represented by formula (III). The weight reduction of the protective film when the protective film is immersed at 23°C for two days in the photocurable adhesive is 0-30 wt%.

Owner:SUMITOMO CHEM CO LTD +1

Polyimide coating and baking method

ActiveCN104261344BReduce bubble defect problemsAdd UV baking stepDecorative surface effectsPretreated surfacesUV curingImaging quality

The invention provides a low-cost, low-defect-density high-viscosity polyimide coating and baking method, which comprises the following steps in sequence: coating a tackifier on the surface of a wafer; Carry out the first baking to the wafer of sticky agent; Carry out the first cooling to the wafer of described first baking; Coating polyimide on the wafer surface after described first cooling; To described coating The wafer with polyimide is subjected to the second baking; the second baked wafer is subjected to the second cooling; the second cooled wafer is subjected to ultraviolet baking, and the ultraviolet baking The mode of co-heating with vacuum suction cup and deep ultraviolet lamp is adopted. The embodiment of the present invention solves the problem of bubble defects caused by the high viscosity of PI glue, thereby improving the product yield and imaging quality.

Owner:北方广微科技有限公司

Zirconium aluminosilicate glass and preparation method thereof

ActiveCN104986954BLower melting temperatureHigh clarityGlass tempering apparatusAluminum silicateZircon

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD

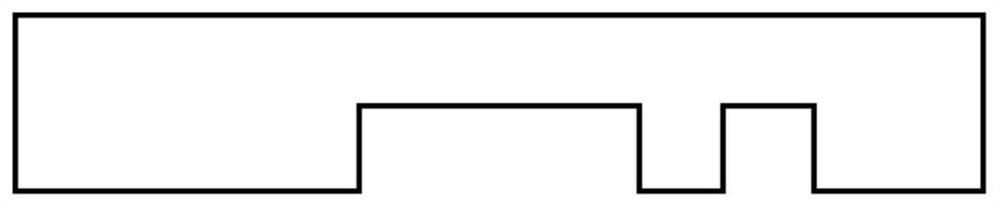

Gapless extrusion method for aluminum alloy seamless tube

ActiveCN111014329ALeave no gapsImproves wall thickness uniformityExtrusion containersIngotAluminium alloy

The invention discloses a gapless extrusion method for an aluminum alloy seamless tube. An inlet segment of a liner of an extrusion barrel in the extrusion method is processed into a cone-shaped flaring, and the inner diameter of an extrusion segment from a flaring segment is slightly smaller than the outer diameter of an extrusion ingot. The innovative point of the invention is primarily adoptingan extrusion ingot blank, the outer diameter of which is slightly smaller than the inner diameter of the liner of the extrusion barrel. In order to push the extrusion ingot into the extrusion barrelsmoothly, the inlet end of the liner of the extrusion barrel is processed into a cone-shaped horn mouth. When extrusion is started, a certain pressure is applied by an extrusion bar and an extrusion pad to push the heated extrusion ingot blank from a cone-shaped inlet to the extrusion barrel till the bottom. As the outer diameter of the extrusion ingot blank is slightly greater than the inner diameter of the extrusion barrel, the ingot blank deforms plastically to a certain extent in the pushed process and extrude all air in the extrusion barrel, and the extrusion barrel is filled fully without any gaps. Therefore, threading and extrusion forming are carried out directly without upset-extruding thereafter.

Owner:广东华昌集团有限公司

Curved surface glass film attaching process

The invention relates to the technical field of glass surface film coating, in particular to a curved surface glass film attaching process. The curved surface glass film attaching process comprises the following steps: 1, cutting explosion-proof film into the same shape as the glass to be attached, and attaching the edge of the cut explosion-proof film on the surface of the glass in alignment, wherein release film is not removed from the explosion-proof film at the moment; and 2, feeding the glass with the explosion-proof film prepared in the step 1 into a heating device for baking and heatingunder the heating temperature of 120 DEG C so as to enable the release film to be soft, gradually adhere to the surface of the glass and form a curve shape consistent with the curvature of the glass,and then attaching the explosion-proof film on the surface of the glass, heating, pressurizing and curing to accomplish attachment of the explosion-proof film. According to the process, the explosion-proof film and the glass can be perfectly attached, the yield is high, and batch production can be achieved.

Owner:沈阳市辽河特种玻璃厂

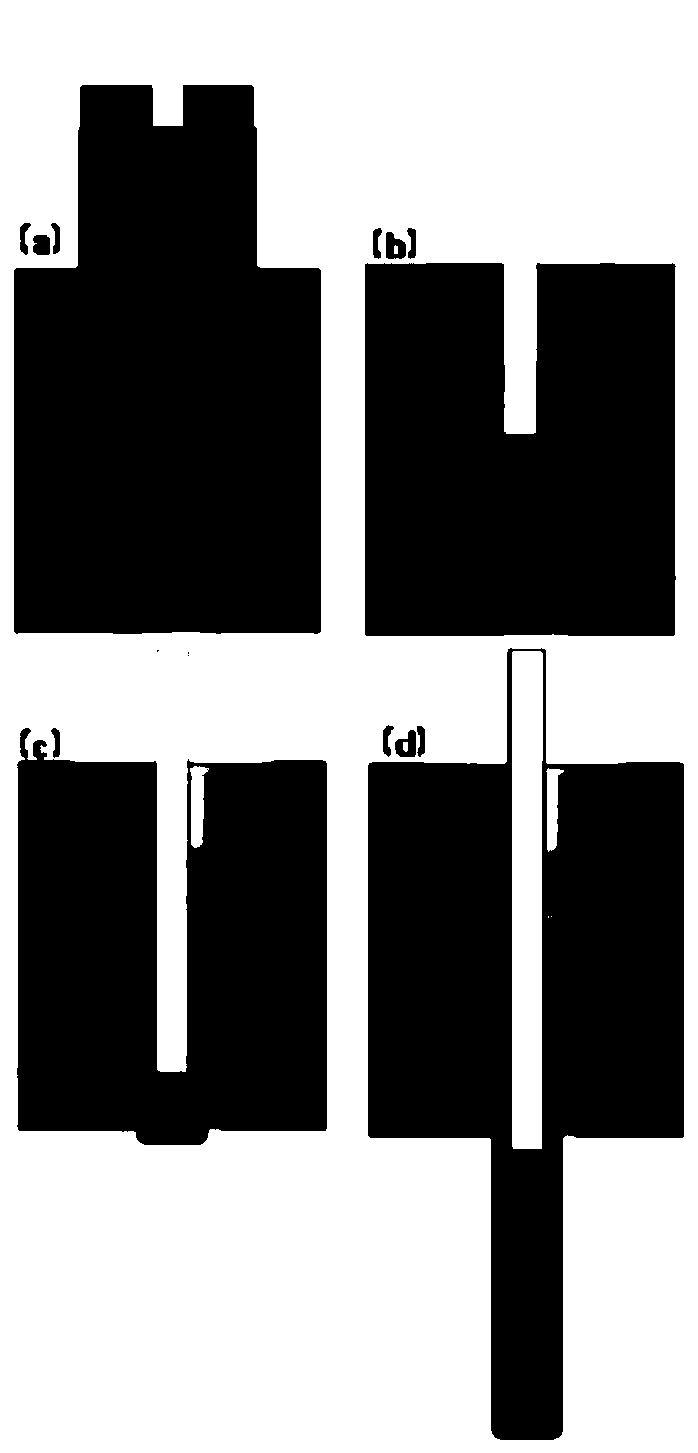

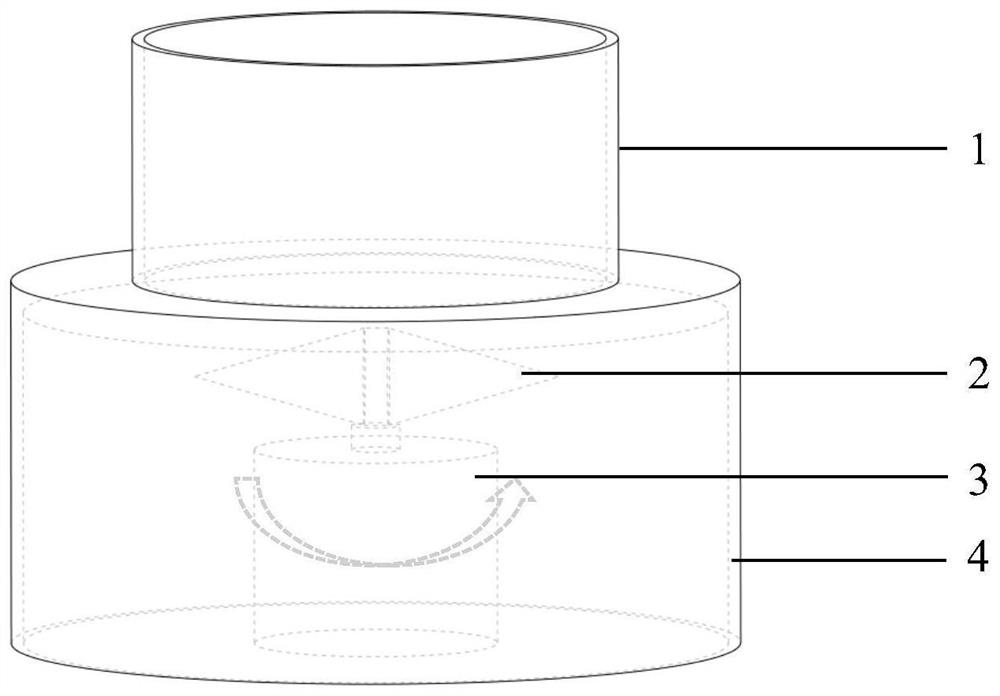

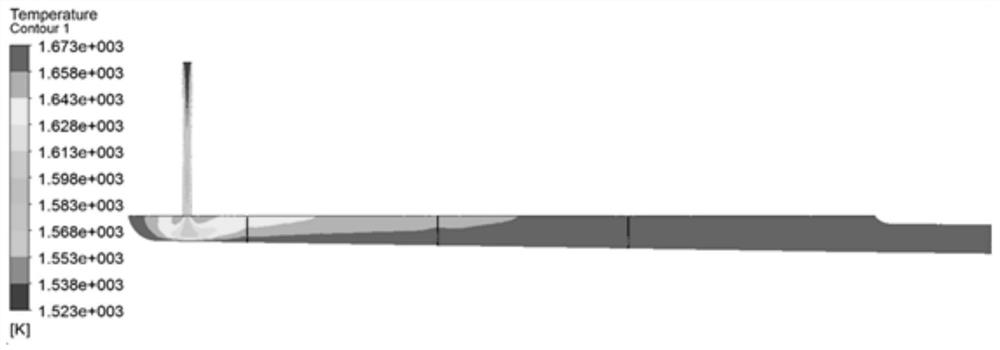

Quartz thick-walled tube secondary moulding device, and moulding method

ActiveCN110498595AReduce bubble defectsQuality improvementGlass reforming apparatusGlass productionThermal insulationThick wall

The invention discloses a quartz thick-walled tube secondary moulding device. The quartz thick-walled tube secondary moulding device comprises a furnace body and a traction mechanism; the furnace bodycomprises a furnace shell, an upper end cover, a lower bottom plate, an induction heating coil, an upper induction heating member, a center pole, a lower thermal insulation member, and a moulding platform; a furnace chamber penetrating the furnace body is arranged in the furnace shell; the upper end cover and the lower bottom plate are arranged on the upper end and the lower end of the furnace shell respectively; the upper end cover is provided with a locating groove and a nitrogen gas hole; the lower bottom plate is provided with a feeding port and a nitrogen gas hole; the induction heatingcoil is arranged in the furnace shell; the upper induction heating member is a hollow cylindrical structure member, is arranged in the furnace chamber, and is suspended on the upper wall of the furnace shell; the center pole is arranged in the furnace chamber, and is located using the locating groove, and is provided with a through hole; the lower end of the upper induction heating member is connected with the moulding platform; the moulding platform is provided with a tapered throat; the lower end of the moulding platform is provided with the lower thermal insulation member. The invention also discloses a secondary moulding method using the quartz thick-walled tube secondary moulding device. The quartz thick-walled tube secondary moulding device is capable of realizing a second time of moulding of thick-walled tubes with a thickness higher than a tolerance, and saving raw materials effectively.

Owner:江苏亨芯石英科技有限公司

A steelmaking process for controlling porosity defects in continuous casting slabs

ActiveCN112496287BReduce bubble defectsIntelligent adjustment of blowing volumeCasting parameters measurement/indication devicesSteelmakingIndustrial engineering

The invention relates to a steelmaking process for controlling the pore defects of continuous casting slabs, which is characterized in that it includes: step 1, transporting the ladle containing the molten steel for refining to the turntable, and turning the turntable to the casting position, and turning the steel The liquid is injected into the tundish; step 2, detect the height of the molten steel liquid level in the tundish, adjust the opening of the nozzle of the tundish according to the height of the liquid steel level, and the tundish distributes the molten steel to several crystallizers through the nozzle. The crystallizer is provided with a submerged nozzle, and argon gas is passed into the submerged nozzle to seal the nozzle; step 3, the molten steel is preliminarily formed into a billet in the crystallizer, and the mold lowers the billet to In the pipeline, the steel billet is subjected to secondary water cooling in the pipeline; step 4, pulling and straightening rollers pull the steel billet after secondary water cooling out of the pipeline; step 5, the cutting device cuts the steel billet according to the required length of the casting billet. The invention intelligently adjusts the amount of argon blowing through the control module, thereby reducing bubble defects in the continuous casting slab.

Owner:福建三宝钢铁有限公司

A magnetically reinforced phase-modified composite material and its preparation method

ActiveCN110354313BEnhance physiological defenseGood osteoinductivityTissue regenerationProsthesisBiodegradable polymerCompatibilization

The invention discloses a magnetically enhanced phase-modified composite material and a preparation method thereof. The composite material comprises the following components according to weight percentage: 1% to 25% of a magnesium-iron bimetallic composite oxide, and 75% to 25% of a biodegradable polymer material. 99%. The preparation method comprises the following steps: 1) preparation of layered magnesium-iron bimetallic composite oxide; 2) blending of magnesium-iron bimetallic composite oxide and biodegradable polymer solution; 3) forming of magnetically enhanced phase-modified composite material . The invention adopts composite reinforcement to prepare biodegradable magnetically reinforced phase-modified polymer-based composite materials, and utilizes the magnetic characteristics of layered magnesium-iron bimetallic composite oxides to introduce a rotating magnetic field to realize the reinforcement phase in the biodegradable polymer matrix Anisotropic distribution, the composite material has the advantages of controllable degradation rate, good biocompatibility and excellent mechanical properties.

Owner:SOUTHEAST UNIV

Epoxy resin composite material pouring mold

The invention discloses an epoxy resin composite material pouring mold. The pouring mold is a hollow cavity with a pouring opening, an air hole penetrates through one side of the hollow cavity, an air guide pipe penetrates through the air hole, and an air valve is connected with the air guide pipe to connect and disconnect the air guide pipe. The vacuum pump is connected with the air guide pipe so as to exhaust air from the hollow cavity.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Method for manufacturing float sheet glass and apparatus for manufacturing float sheet glass

The present invention relates to a method for producing a float sheet glass, the method including: producing a molten glass by supplying a glass raw material into a melting bath; supplying continuously the molten glass onto a surface of a molten metal held in a bath including bottom bricks and a bottom casing which covers the bottom bricks; and causing the molten glass to flow in a predetermined direction along the surface of the molten metal, and then float-forming the molten glass into a band plate-shaped glass ribbon, in which a fluctuation range of a temperature of an external surface of the bottom casing is controlled to fall within 4°C.

Owner:AGC INC

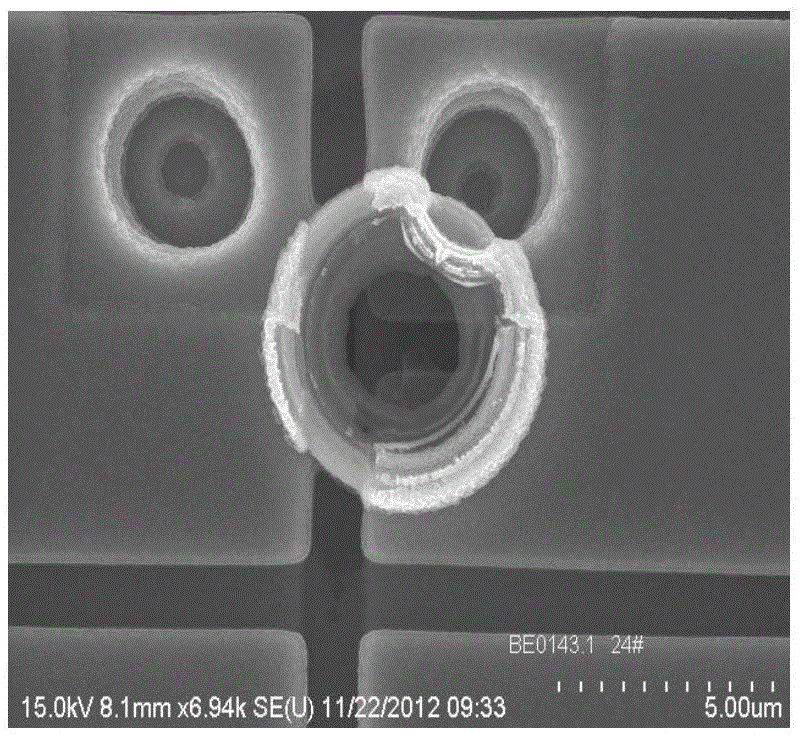

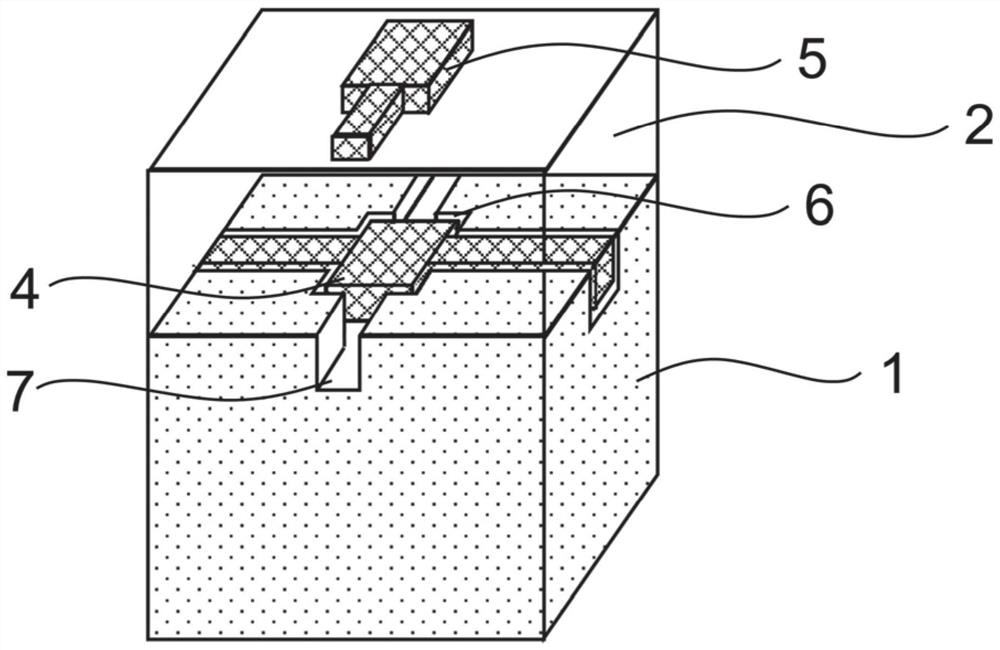

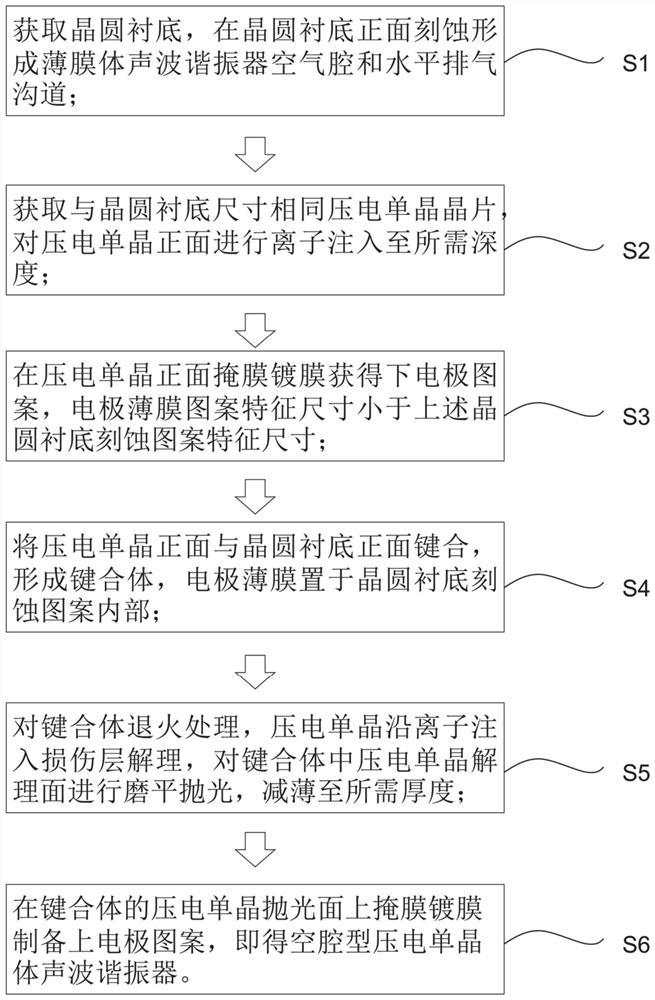

Cavity type piezoelectric single crystal acoustic resonator and preparation method thereof

PendingCN114301406AAvoid Crystal DefectsReduce manufacturing difficultyImpedence networksBonding processThin membrane

The invention discloses a cavity type piezoelectric single crystal acoustic resonator and a preparation method thereof. The cavity type piezoelectric single crystal acoustic resonator comprises a substrate and a piezoelectric single crystal film, the piezoelectric single crystal film is provided with a first surface and a second surface which are opposite to each other, the first surface and the second surface are respectively provided with a first electrode and a second electrode, the first surface is combined with the surface of the substrate, and the second surface is combined with the surface of the substrate. Air cavities and exhaust channels which are communicated with each other are formed in the surface of the substrate, the first electrodes are arranged in the corresponding air cavities, and the exhaust channels are communicated with openings formed in the surfaces of the acoustic resonators. Compared with the prior art, the method has the advantages that the piezoelectric single crystal film with stable chemical properties is prevented from being directly etched, the preparation difficulty of the cavity type piezoelectric single crystal acoustic resonator is reduced, meanwhile, the exhaust channel is arranged to assist the bonding process, the bubble defect in the bonding process can be reduced, and the practicability is very high.

Owner:苏州达波新材科技有限公司

Preparation process of curtain wall glass and curtain wall glass

The invention relates to the field of curtain wall glass, and discloses a curtain wall glass preparation process and curtain wall glass. The preparation process comprises the following steps: weighing silica sand, dolomite, borax, limestone, mica powder, zirconium dioxide, sodium carbonate, mirabilite, carbon powder and titanium dioxide coated and modified ferric oxide; mixing all the raw materials, and grinding into powder; melting, clarifying and homogenizing the powder at 1500-1550 DEG C, heating to 1860-1880 DEG C, stirring for 20-30 minutes, cooling to 1500-1550 DEG C, and stirring for 1.5-2.5 hours to obtain molten glass; feeding the molten glass into a tin bath for molding to obtain molded glass; and annealing the formed glass to obtain the curtain wall glass. According to the invention, while the curtain wall glass is ensured to have relatively high strength, the bubble defect in the curtain wall glass can be effectively reduced by adding the titanium dioxide coated and modified ferric oxide into the raw materials and carrying out heating treatment after clarification.

Owner:长兴旗滨玻璃有限公司

Glass clarification device and glass clarification method

PendingCN114477721ALow clarification temperatureReduce bubble defectsGlass furnace apparatusGlass productionMolten glassGlass manufacturing

The invention belongs to the technical field of glass manufacturing, particularly discloses a glass clarifying device and method, and aims to solve the problem of how to ensure a clarifying effect under a low-temperature clarifying condition. According to the glass clarifying device, the inclined plane is arranged in the middle of the bottom surface of the clarifying tank, the front end of the inclined plane is connected with the front-section bottom surface through the overflow weir structure, and the rear end of the inclined plane is connected with the rear-section bottom surface through the flow guide structure. Therefore, under the overflow action of the overflow weir structure, the molten glass can be uniformly distributed on the inclined plane in the transverse direction when the molten glass is controlled to be shallow; meanwhile, the inclined plane can control the depth of the molten glass at the inclined plane to be very shallow, so that the overall temperature of the molten glass is rapidly increased, rapid growth and accelerated floating of bubbles are facilitated, and the bubbles can be rapidly eliminated at a lower clarification temperature under the same clarification capability; in addition, under the flow guide effect of the flow guide structure, the glass liquid on the inclined plane can be collected, so that the glass liquid is mixed up and down and the liquid level is kept stable.

Owner:CDGM OPTICAL GLASS

Tunnel bottom concrete side-slipping lining construction method and side-slipping needle beam bottom board trolley

InactiveCN102434171BEasy dischargeImprove construction conditionsUnderground chambersTunnel liningTraction systemLinear dimension

The invention discloses a tunnel bottom concrete side-slipping lining construction method capable of overcoming the bubble defect and a side-slipping needle beam bottom board trolley. The method sequentially comprises construction steps of in-position of a formwork group, side-slipping pouring of concrete and longitudinal movement of the trolley. Guiding tracks matched with designed linear dimension of a tunnel construction face are respectively and fixedly connected in front of and on the back of the lower portion of a beam frame assembly of the side-slipping needle beam bottom board trolley. The formwork group consists of a pair of slide formworks, the pair of slide formworks is symmetrical with a vertical face where the central line of a beam frame is located and is respectively connected with the guiding tracks through a sliding guide mechanism, and the sliding guide mechanism is connected with the beam frame assembly through a side-slipping traction system. The tunnel bottom concrete side-slipping lining construction method is capable of overcoming the defects of bubbles on the surface of concrete, overlap-joint slab staggering of new and old concrete, temperature cracking and the like, has the advantages of being reliable in structure, quick in lining speed, good in construction quality and safe in construction, reducing interference of construction conditions and the like, and is mainly used for side-slipping lining construction of tunnel bottom concrete.

Owner:广汉金达隧道机械有限公司

A gapless extrusion method of aluminum alloy seamless pipe

ActiveCN111014329BLeave no gapsImproves wall thickness uniformityExtrusion containersIngotAluminium alloy

The invention discloses a gapless extrusion method for an aluminum alloy seamless pipe. In the extrusion method, the inlet section of the inner lining of the extrusion cylinder is processed into a conical flaring, and the inner diameter of the extruding section where the flaring section goes inward is Slightly smaller than the outer diameter of the extruded ingot. The innovation of the present invention is mainly that the extruded ingot whose outer diameter is slightly larger than the inner diameter of the extrusion cylinder liner is used. When the extrusion starts, a certain pressure is applied through the extrusion rod and the extrusion pad, and the heated extrusion billet is pushed into the extrusion cylinder from the tapered inlet to the bottom. Since the outer diameter of the extruded ingot is slightly larger than the inner diameter of the extrusion cylinder, the ingot will undergo a certain plastic deformation during the pushing process, and all the air in the extrusion cylinder will be squeezed out, and the extrusion cylinder will be completely filled without leaving any gaps . Therefore, there is no need for upsetting afterwards, and the piercing and extrusion are directly carried out.

Owner:广东华昌集团有限公司

High-strength touch screen glass substrate and preparation method thereof

PendingCN114180829AHigh mechanical strengthReduce bubble defectsGlass productionComposite materialTouchscreen

The invention relates to the technical field of touch screen glass substrates, and discloses a high-strength touch screen glass substrate and a preparation method thereof. The touch screen glass substrate is prepared from the following components in parts by weight on the basis of oxides: 70 to 80 parts of SiO2, 14 to 18 parts of Al2O3, 13 to 16 parts of Na2O, 2 to 3 parts of K2O, 2.7 to 3.5 parts of CaO, 3.8 to 4.6 parts of MgO, 0.1 to 0.3 part of SnO2 and 0.05 to 0.1 part of ZrO2. By adopting the formula, the mechanical strength of the touch screen glass substrate can be effectively improved, and meanwhile, the bubble defect in the touch screen glass substrate is reduced.

Owner:长兴旗滨玻璃有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com