Liquid crystal substrate glass and preparation method thereof

A liquid crystal substrate and glass technology, which is applied in the field of environment-friendly liquid crystal substrate glass and its preparation, can solve the problems of difficult discharge of air bubbles, high viscosity at high temperature, unfavorable glass clarification, etc., and achieves the effect of improving effect, uniform quality and sufficient mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] A method for preparing an environmentally friendly liquid crystal substrate glass, comprising the following steps:

[0068] Step (1), take by weighing the raw material that comprises quartz powder, aluminum oxide powder, boric acid, calcium carbonate, strontium nitrate, magnesium carbonate, barium nitrate and tin dioxide, mix uniformly, obtain mixed material, will mixed material income material tank (per 450 kg for each material tank), transported to the melting pool furnace;

[0069] Preferably, the quartz powder has a particle size of 0.020-0.150mm, and the purity is not less than 99.5%; the impurity content of tin dioxide is not more than 0.3%;

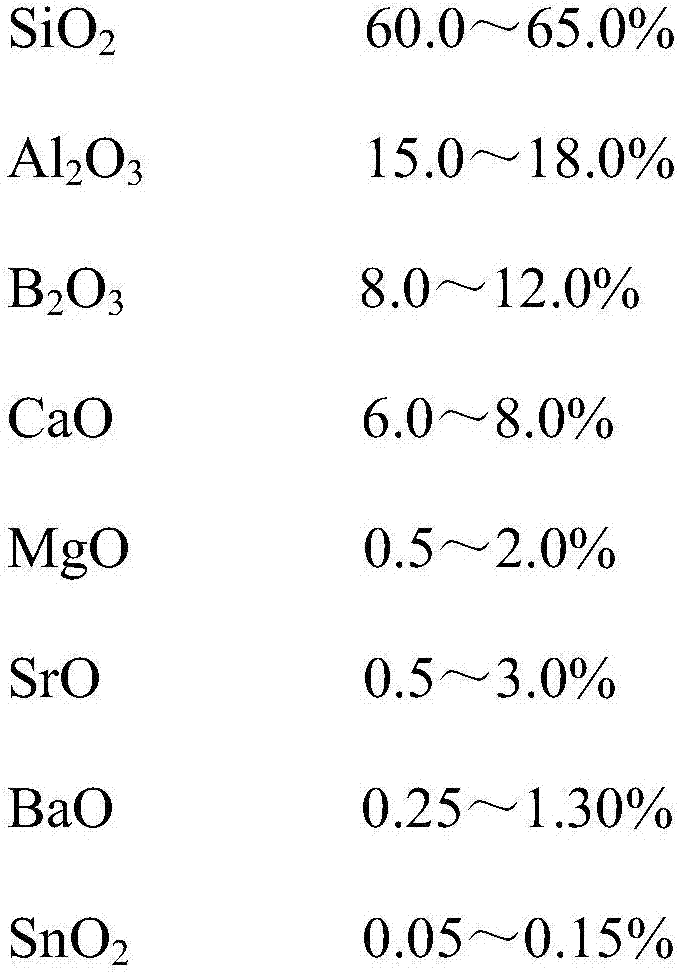

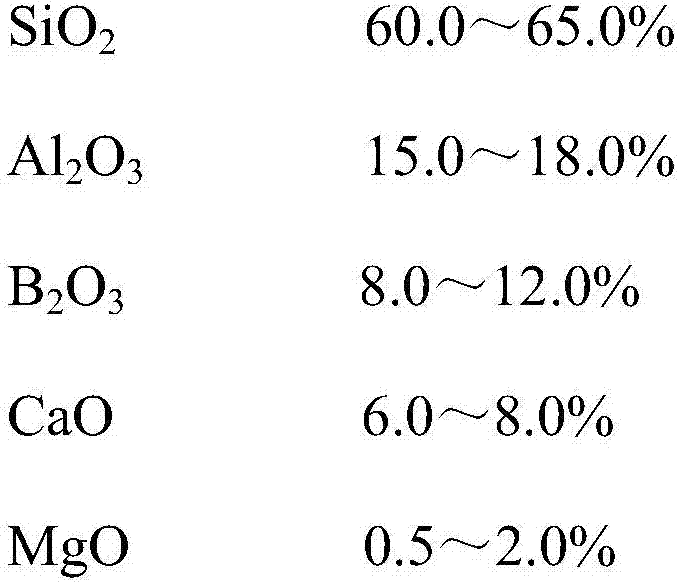

[0070] In step (2), the above mixture is melted and clarified at 1500-1650° C., and then overflow-drawn to make liquid crystal substrate glass, so that the liquid crystal substrate glass is composed of the following components based on the mass percentage of oxides:

[0071]

[0072]

[0073] and the impurities that a...

Embodiment 1

[0080] Step (1), take by weighing the raw material of quartz powder, aluminum oxide powder, boric acid, magnesium carbonate, calcium carbonate, strontium nitrate, barium nitrate and tin dioxide by the formula of table 1; At first tin dioxide and part quartz powder are according to 1: Add the mass ratio of 9 to the premix system for premixing for 20 minutes, then feed the uniformly mixed premix into the mixer, and mix with the rest of quartz powder, alumina powder, boric acid, magnesium carbonate, calcium carbonate, strontium nitrate, Barium nitrate is added to the mixing system according to the formula ratio, and after 25 minutes of mixing, the mixture is collected into the feed tank (each feed tank has a loading capacity of 450 kg), and is transported to the melting tank furnace;

[0081] In step (2), the mixed material is fed into the pool furnace, and after being melted and clarified at 1600° C., the liquid crystal substrate glass is made by overflow drawing.

Embodiment 2

[0083] The formula is shown in Table 1, the melting and clarification temperature is 1550°C, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com