Curved surface glass film attaching process

A curved glass and film coating technology, which is applied in the field of glass surface film coating, can solve problems such as low yield, low production capacity, and high requirements for manual skills of operators, and achieve the effects of reducing bubble defects, precise forming, and high forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the technical solution clearer, the technical solution will be further described in detail below in conjunction with specific embodiments. It should be understood that these descriptions are only exemplary, and are not intended to limit the scope of the technical solution.

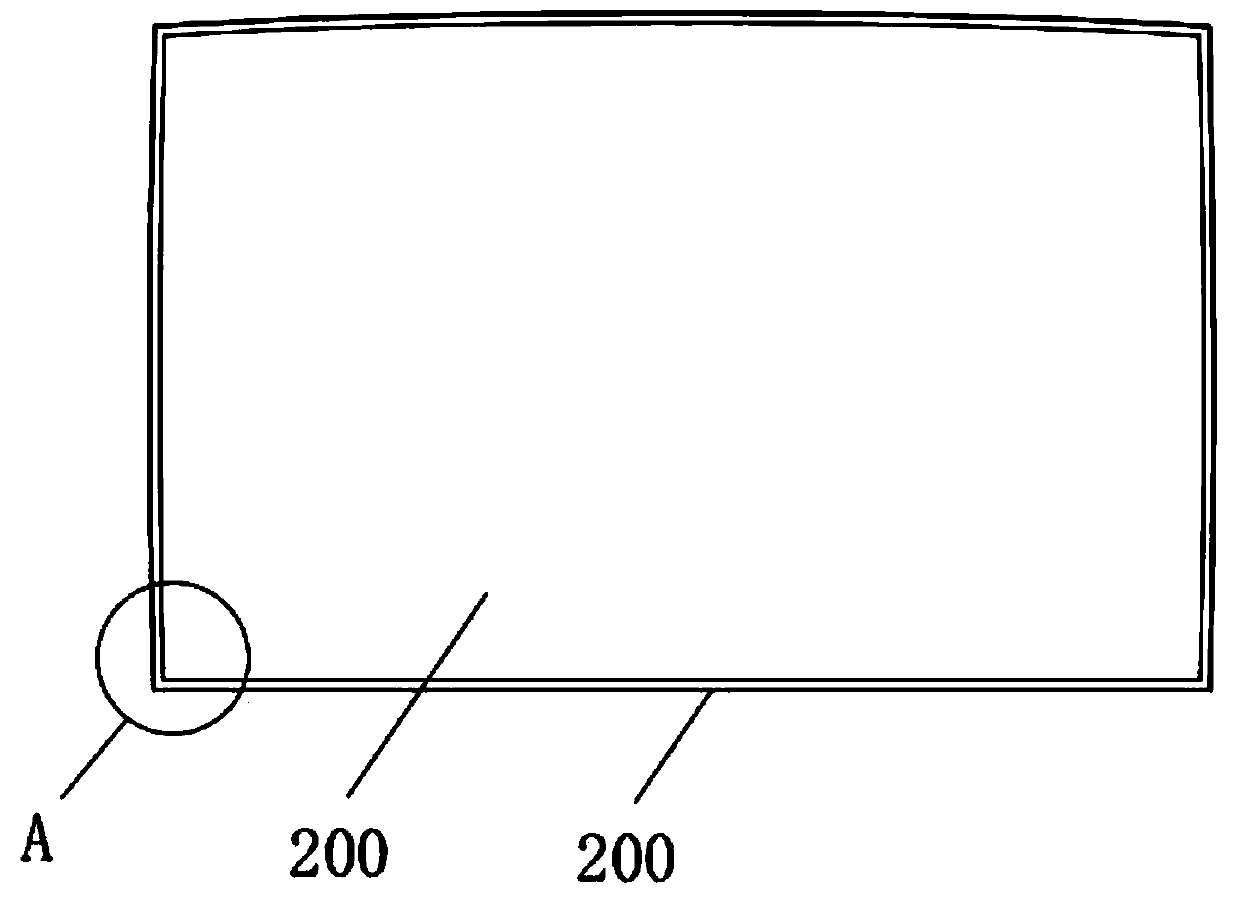

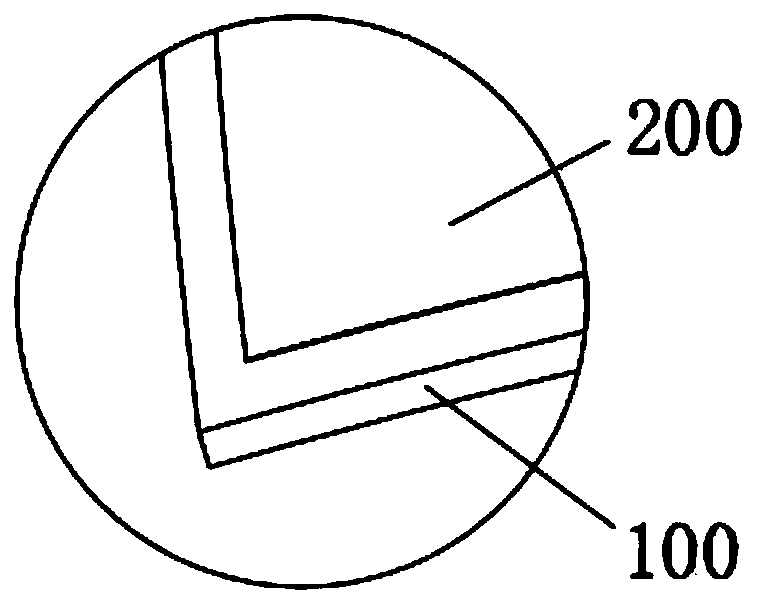

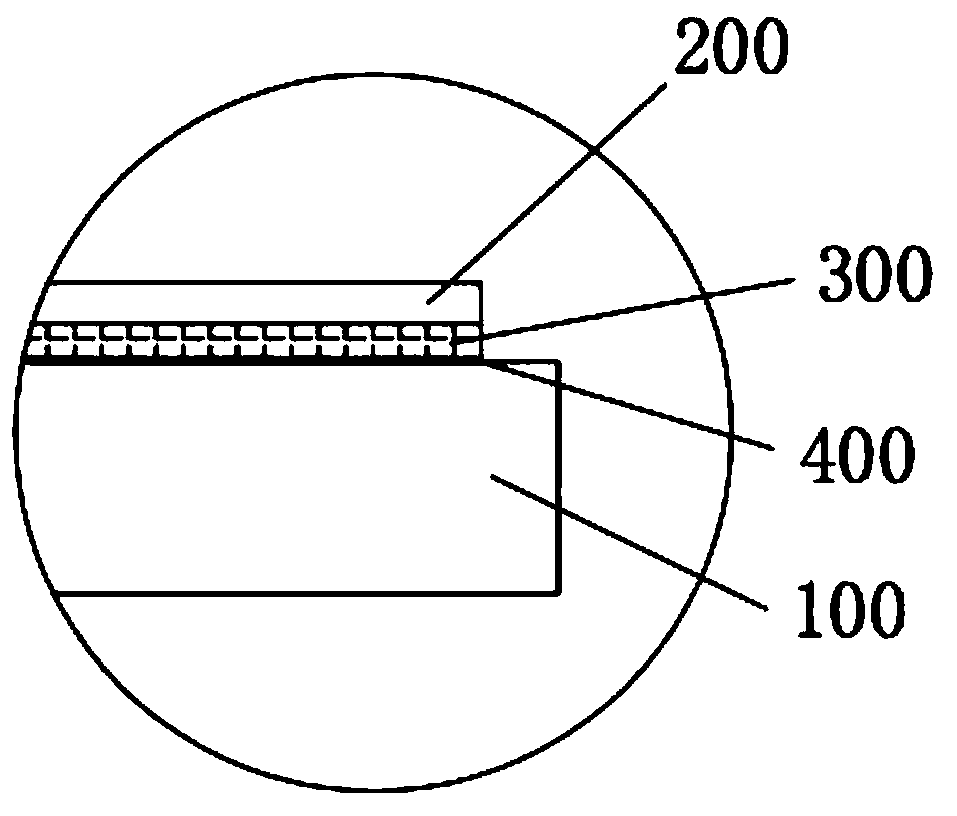

[0029] Such as Figure 1-Figure 3 As shown, this embodiment proposes a coating process for curved glass 100, which includes the following steps:

[0030] Step 1. Cut the explosion-proof film 200 into the same shape as the glass 100 to be filmed, and attach the edge of the cut explosion-proof film 200 to the surface of the glass 100 in alignment. At this time, the release film is not removed from the explosion-proof film 200;

[0031] Step 2. Send the glass 100 with the explosion-proof film 200 produced in step 1 into a heating device for baking and heating at a temperature of 120°C, so that the release film becomes soft and graduall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com