Preparation method of solar ultrawhite ultrathin glass and product thereof

A technology of ultra-thin glass and solar energy, which is applied in glass manufacturing equipment, glass furnace equipment, glass forming, etc. It can solve the problems of section whiteness and glass light transmittance that need to be improved, does not conform to industrial production, and arsenic environmental pollution. Achieve strong chemical decolorization performance, improve chemical stability and reduce absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The weight percent composition of each component of the solar ultra-white ultra-thin glass is as follows:

[0028] Si0 2 73.6%, R 2 O 14.05%, CaO 9.10%, MgO 0.91%, Al 2 o 3 1.43%, Fe 2 o 3 0.0088%, Sb 2 o 5 0.1%, CeO 2 0.1%, Er 2 o 3 0.08%, ZnO 0.5%.

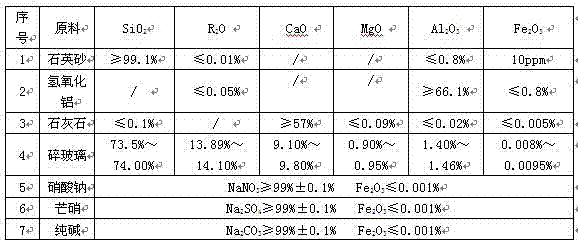

[0029] Its preparation method is: according to the weight ratio of each component and the conventional loss in the production process, calculate the weight of various raw materials such as quartz sand, soda ash, aluminum hydroxide, sodium nitrate, mirabilite, limestone and broken glass, and accurately weigh them. Each raw material. The control and requirements for the content of various effective oxides and harmful impurities in the chemical composition of raw materials are as follows:

[0030]

[0031] Control the secondary pollution of trace iron in raw material transportation and cullet crushing: the hopper elevator for the silica sand of the raw material in the transportation adopts a high-strengt...

Embodiment 2

[0041] The weight percent composition of each component of the solar ultra-white ultra-thin glass is as follows:

[0042] Si0 2 73.8%, R 2 O 14%, CaO 9.80%, MgO 0.9%, Al 2 o 3 1.40%, Fe 2 o 3 0.008%, Sb 2 o 5 0.01%, CeO 2 0.01%, Er 2 o 3 0.01%, ZnO 0.02%.

[0043] Its preparation method is: according to the weight ratio of each component and the conventional loss in the production process, calculate the weight of various raw materials such as quartz sand, soda ash, aluminum hydroxide, sodium nitrate, mirabilite, limestone and broken glass, and accurately weigh them. Each raw material. The cullet is common ultra-white cullet, and the components in the cullet may be slightly different from those in Example 1. The control and requirements of the content of various effective oxides and harmful impurities in the chemical composition of raw materials are the same as in Example 1, except that the Fe in the quartz sand 2 o 3 The content is 25ppm.

[0044] Control ...

Embodiment 3

[0054] The weight percent composition of each component of the solar ultra-white ultra-thin glass is as follows:

[0055] Si0 2 74%, R 2 O 13.89%, CaO 9.20%, MgO 0.93%, Al 2 o 3 1.46%, Fe 2 o 3 0.0095%, Sb 2 o 5 0.08%, CeO 2 0.15%, Er 2 o 3 0.05%, ZnO 0.2%.

[0056] Its preparation method is: according to the weight ratio of each component and the conventional loss in the production process, calculate the weight of various raw materials such as quartz sand, soda ash, aluminum hydroxide, sodium nitrate, mirabilite, limestone and broken glass, and accurately weigh them. Each raw material. The control and requirements of the content of various effective oxides and harmful impurities in the chemical composition of raw materials are the same as in Example 1, except that the Fe in the quartz sand 2 o 3 The content is 40ppm.

[0057] Control the secondary pollution of trace iron in raw material transportation and cullet crushing: the hopper elevator for the silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com