Hybrid amorphous metal alloy stent

a metal alloy and hybrid technology, applied in the field of stents, can solve the problems of inability to acceptably smooth, uniform surfaces of metal devices, limited fatigue resistance of current metals, etc., and achieve the effects of reducing restenosis, promoting neo-intima growth, and reducing fatigue resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

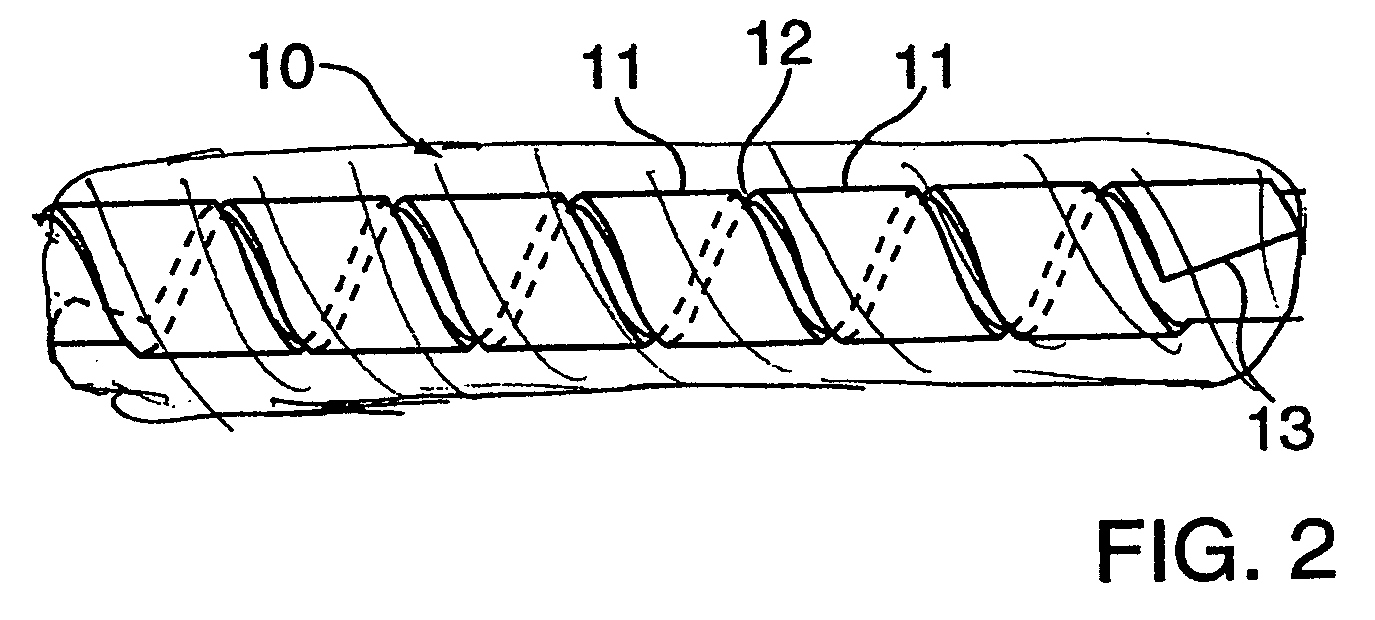

Image

Examples

example 1

Methods of Making Amorphous Metal Alloys

[0062] Many different methods may be employed to form amorphous metal alloys. A preferred method of producing medical devices according to the present invention uses a process generally known as heat extrusion, with the typical product being a continuous article such as a wire or a strip. The process does not involve additives commonly used in the bulk process that can render the amorphous metal alloy non-biocompatible and even toxic. Thus, the process can produce highly biocompatible materials. In preferred embodiments, the continuous amorphous metal alloy articles are fabricated by a type of heat extrusion known in the art as chill block melt spinning. Two common chill block melt spinning techniques that produce amorphous metal alloy articles suitable for the medical devices of the present invention are free jet melt-spinning and planar flow casting. In the free jet process, molten alloy is ejected under gas pressure from a nozzle to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com