Nanocrystal iron nitride thin-film material and functions thereof

An iron nitride and nanocrystalline technology, applied in the application of magnetic film to substrate, metal material coating process, cathode sputtering application, etc., can solve the problems of large size, poor conductivity and low operating temperature of Hall devices , to achieve the effect of small size, good linearity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of active layer pattern. Form a "cross" pattern on a quartz substrate for depositing an iron nitride film by using a mask method, such as figure 1 (a) shown. There is no photoresist in the shaded part of the figure, the side length of the central square of the pattern is 1.0 μm, and the length of the protruding part on the four sides of the central square is 0.2 μm;

[0033] 2. Admit argon gas at room temperature. The DPS-III type ultra-high vacuum magnetron sputtering coating machine (built-in computer control software) of the Shenyang Keyi Center of the Chinese Academy of Sciences is adopted, and the vacuum degree of the back and the bottom is less than 3.0×10 -5 Pa, the high-purity Ar gas and N 2 The gas mixture is passed into the vacuum chamber. Where the Ar gas flow rate is 10sccm, N 2 The air flow is 2 sccm. When the vacuum degree drops to about 0.1Pa, use the computer control software that comes with the equipment to set the opening degree of...

Embodiment 2

[0042] 1. The preparation of the active layer pattern is the same as step 1 of Example 1;

[0043] 2. Adopt the DPS-III type ultra-high vacuum magnetron sputtering coating machine (built-in computer control software) of the Shenyang Keyi Center of the Chinese Academy of Sciences, and the vacuum degree at the back and the bottom is better than 3.0×10 -5 Pa, the high-purity Ar gas and N 2 The gas mixture is passed into the vacuum chamber. Where the Ar gas flow rate is 6 sccm, N 2 The air flow is 1 sccm. When the vacuum degree drops to about 0.1Pa, use the computer control software that comes with the equipment to set the opening degree of the ultra-high vacuum gate valve to 20%;

[0044] 3. Apply a radio frequency power of 50W to the iron target with a purity of 99.99%, and pre-sputter for 10 minutes;

[0045] 4. Open the baffle of the quartz substrate, the substrate rotates at a constant speed of 20 rpm, and the sputtering time is controlled at 30 minutes;

[0046] 5, the ...

Embodiment 3

[0053] 1. The preparation of the active layer pattern is the same as step 1 of Example 1;

[0054] 2, feed argon gas at room temperature with step 2 of embodiment 1;

[0055] 3, pre-sputtering is the same as step 3 of embodiment 1;

[0056]4. Sputtering film formation. Open the baffle of the quartz substrate, the substrate rotates at a constant speed of 20 rpm, and the sputtering time is controlled to be 1 minute, 10 minutes and 30 minutes respectively, and samples I, II and III are obtained;

[0057] 5, the preparation method of electrode is the same as embodiment 1 step 5;

[0058] 6, the preparation method of protective layer is the same as embodiment 1 step 6;

[0059] Dektak3 surface topography instrument was used to measure the thickness of the active layer of the iron nitride film of Hall element I, II and III respectively, and the measurement results are listed in Table 1;

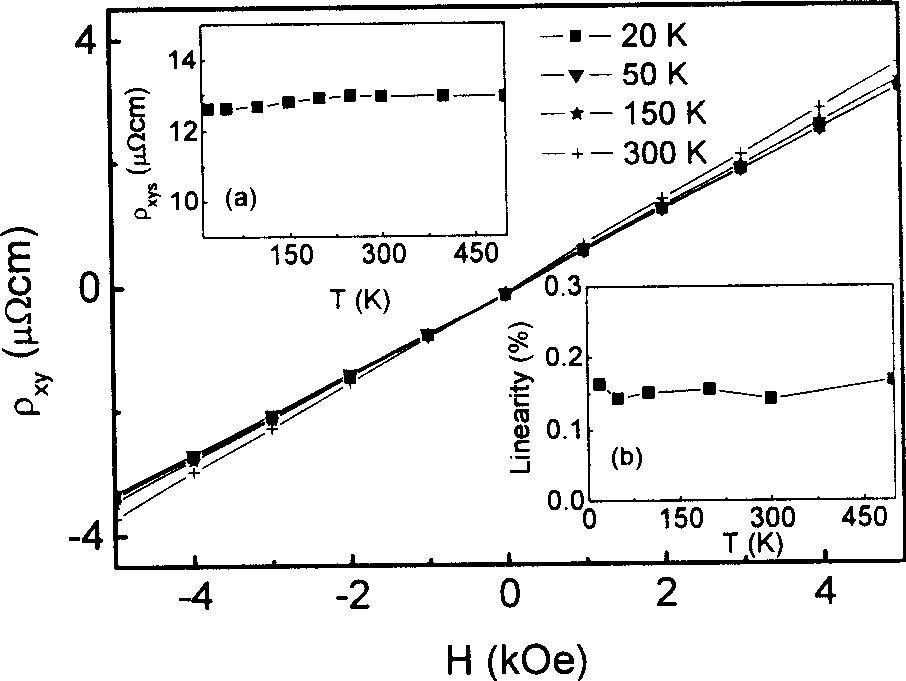

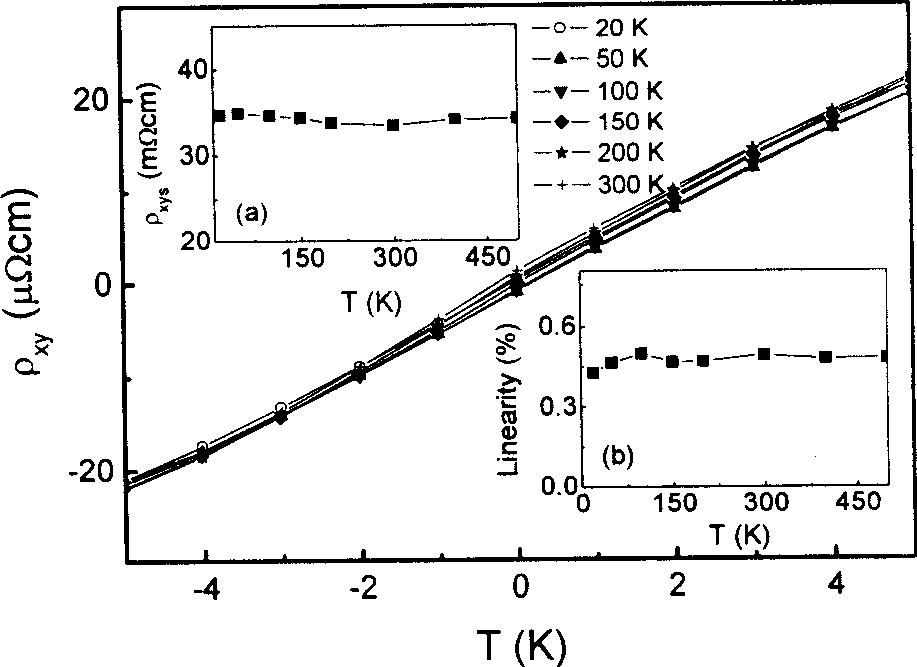

[0060] Using the physical property measuring instrument PPMS-9 produced by Quantum Design C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com