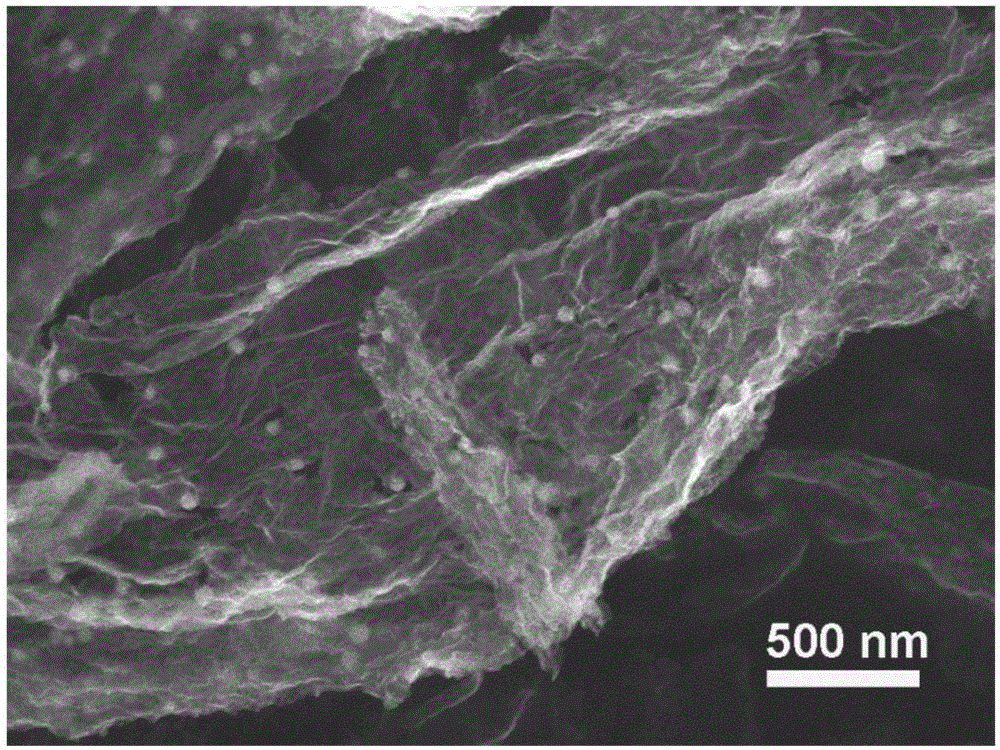

Nitrogen-doped graphene-iron-based nanoparticle composite catalyst and preparation method thereof

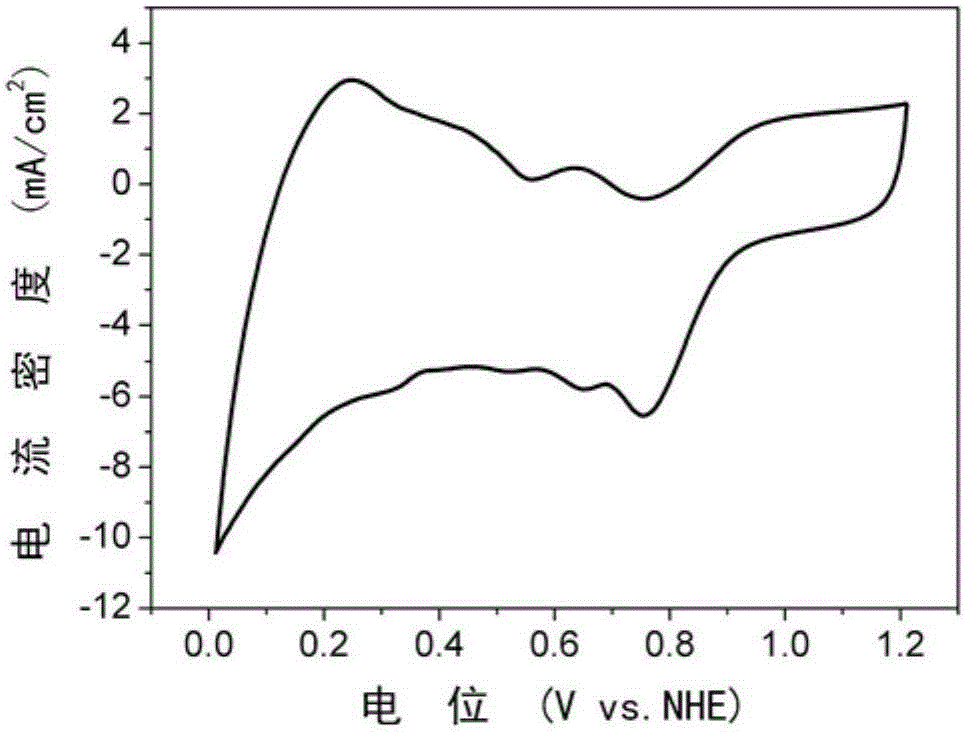

A nitrogen-doped graphene and nanoparticle technology is applied in the field of electrochemical catalysis to achieve the effects of good cycle stability, excellent methanol tolerance, and high oxygen reduction catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Weigh 80 mg of graphene oxide (Zhongke Times Nano, Chengdu Organic Chemical Co., Ltd.), ultrasonically disperse it in 400 mL of deionized water, and prepare a graphene oxide aqueous solution with a concentration of 0.2 mg / mL. The above graphene oxide aqueous solution was placed in a 1000 mL three-necked flask, 100 μL of hydrazine hydrate solution (80% by mass fraction) was added, and reacted in an oil bath at 95° C. for 1 hour (full magnetic stirring). After the solution was cooled, it was filtered to remove large pieces of reduced graphene oxide to obtain a black water dispersion of reduced graphene oxide (concentration was about 0.15 mg / mL).

[0028] Step 2: Weigh 25 mg of ferric chloride hexahydrate, add it to the above-mentioned reduced graphene oxide dispersion, and stir thoroughly for 12 hours to obtain a mixed solution (the mass ratio of iron content to reduced graphene oxide is about 1:12) , The airgel precursor was obtained after freeze-drying at -62°C....

Embodiment 2

[0032] Step 1: Weigh 200 mg of graphene oxide (Zhongke Times Nano, Chengdu Organic Chemical Co., Ltd.), ultrasonically disperse it in 200 mL of deionized water, and prepare a graphene oxide aqueous solution with a concentration of 1 mg / mL. The graphene oxide aqueous solution was placed in a 500 mL three-necked flask, 800 mg of sodium borohydride was added, and after fully magnetically stirred for 3 hours, it was reacted in a 95° C. oil bath for 1 hour (fully magnetically stirred). After the solution is cooled, filter to remove large pieces of reduced graphene oxide; rinse with a large amount of deionized water to remove residual ions. Finally, a black water dispersion of reduced graphene oxide (concentration about 0.5 mg / mL) was obtained.

[0033] Second step: take by weighing 84mg ferric oxalate pentahydrate, join in the above-mentioned reduced graphene oxide dispersion liquid, obtain mixed solution (the mass ratio of iron content and reduced graphene oxide is about 1:5) afte...

Embodiment 3

[0036] Step 1: Weigh 120 mg of graphene oxide (Zhongke Times Nano, Chengdu Organic Chemical Co., Ltd.), ultrasonically disperse it in 400 mL of deionized water, and prepare a graphene oxide aqueous solution with a concentration of 0.3 mg / mL. The above graphene oxide aqueous solution was placed in a 1000 mL three-necked flask, 150 μL of hydrazine hydrate solution (80% by mass fraction) was added, and reacted in an oil bath at 95°C for 1 hour (full magnetic stirring). After the solution was cooled, it was filtered to remove large pieces of reduced graphene oxide to obtain a black water dispersion of reduced graphene oxide (concentration was about 0.25 mg / mL).

[0037]Second step: take by weighing 90mg ferric nitrate nonahydrate, join in the above-mentioned reduced graphene oxide dispersion liquid, obtain mixed solution (the mass ratio of iron content and reduced graphene oxide is about 1:8) after fully stirring 12 hours, in Airgel precursors were obtained after freeze-drying at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com