Preparation method for core-shell type carbon-coated iron nitride nano-composite particles and application of core-shell type carbon-coated iron nitride nano-composite particles

A composite particle, iron nanotechnology, applied in nanotechnology, electrical components, battery electrodes, etc., can solve problems such as the inability to reflect the advantages of carbon material cycle performance, the lack of carbon coating structure, and the deterioration of electrode cycle performance. The effects of pulverization and failure, simple preparation process and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

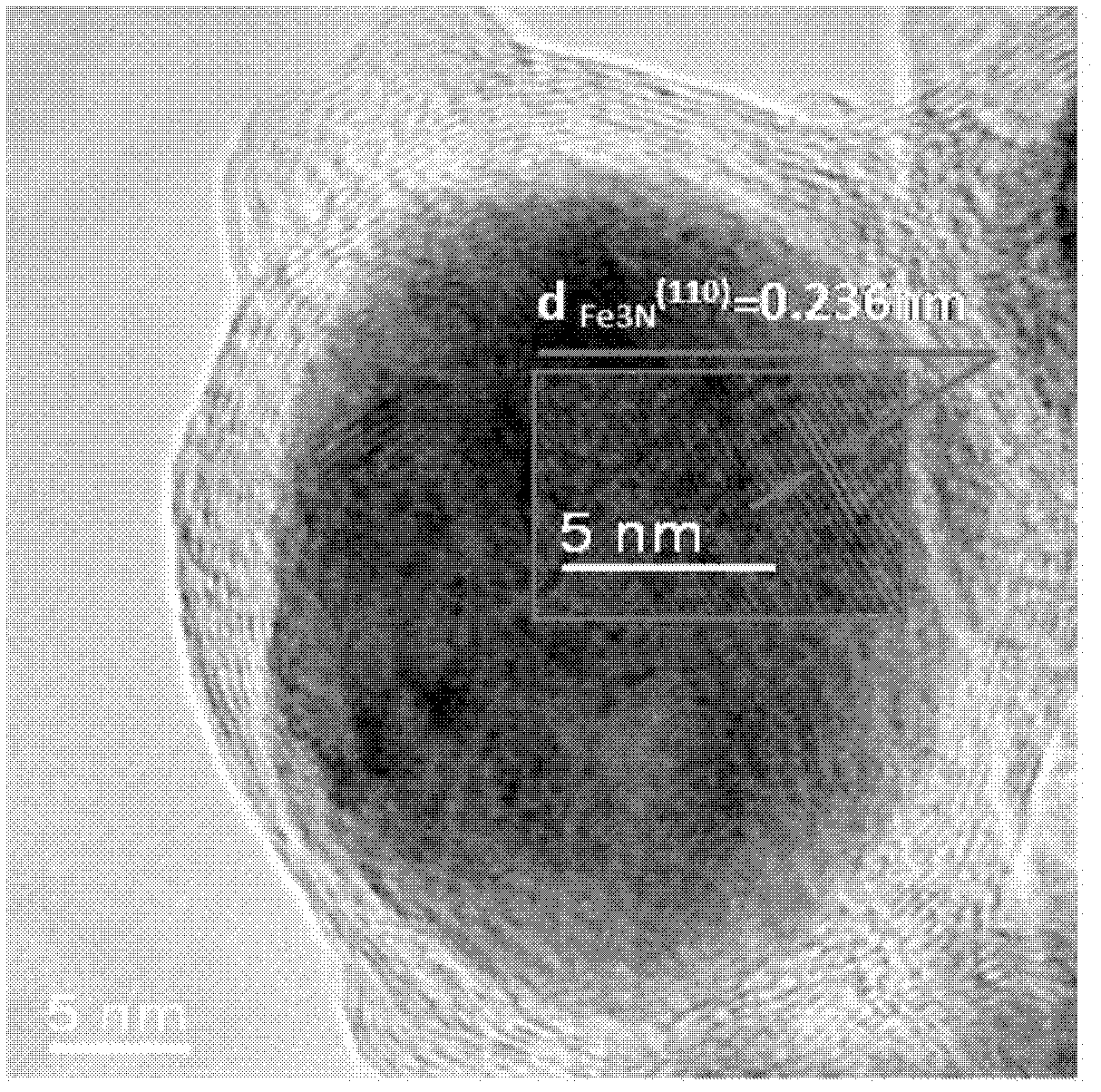

[0027] Take about 80g of iron block and put it into the automatic control DC arc hydrogen plasma equipment to evaporate, and at the same time, feed methane and argon with a ratio of 3:4 to obtain the precursor of carbon-coated iron nanoparticles; place this precursor at 400°C Heat treatment for 4 hours under a protective atmosphere, and then cooled to room temperature to obtain carbon-coated iron nitride nanocomposites.

[0028] The above-mentioned carbon-coated iron nitride nanocomposite material is made into a lithium-ion electrode sheet, and a battery is assembled in a glove box. The electrode sheet is composed of carbon-coated iron nitride nanocomposites with a mass ratio of 80%, 10% carbon black and 10% polytetrafluoroethylene binder; the electrolyte is 1mol / L LiPF 6 solution, and the counter electrode is a lithium sheet.

[0029] The invention prepares the negative electrode of the lithium ion battery with the carbon-coated iron nitride nanocomposite material as the act...

Embodiment 2

[0033] Get about 80g of iron block and put it into the automatic control DC arc hydrogen plasma equipment to evaporate, and feed the methane and argon gas with a ratio of 1:3 at the same time to obtain the carbon-coated iron nanocomposite particle precursor; put this precursor at 400 Heat treatment for 4 hours in a protective atmosphere at about ℃, and cool to room temperature to obtain carbon-coated iron nitride nanocomposite particles.

[0034] The carbon-coated iron nitride nanocomposite material obtained in this embodiment, the electrode made therefrom and the test conditions thereof are all the same as those in Example 1.

[0035] In the second embodiment, image 3 and Figure 4 They are charge and discharge curves and cycle stability performance curves at room temperature and in the range of 2-0.01V at a current density of 100mA / g, respectively. It can be seen from the figure that when the carbon-coated iron nanocomposite material prepared by the present invention is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com