Spall liners in combination with blast mitigation materials for vehicles

a technology of vehicle shells and liners, applied in protective equipment, transportation and packaging, paper/cardboard containers, etc., can solve the problems of vehicle casualties, unrealistic construction, and no space available to separate the spall resistant liner from the hull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-5

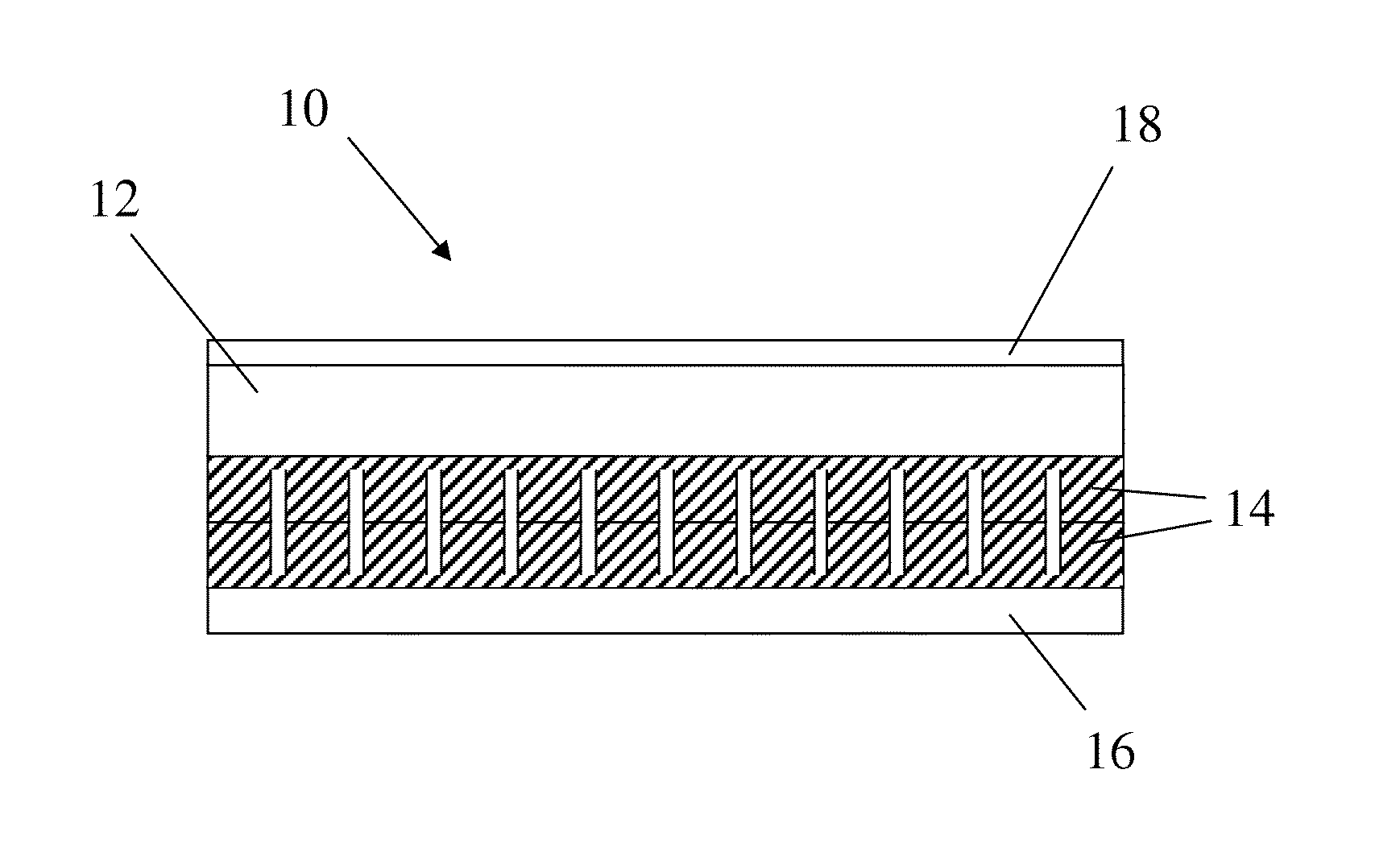

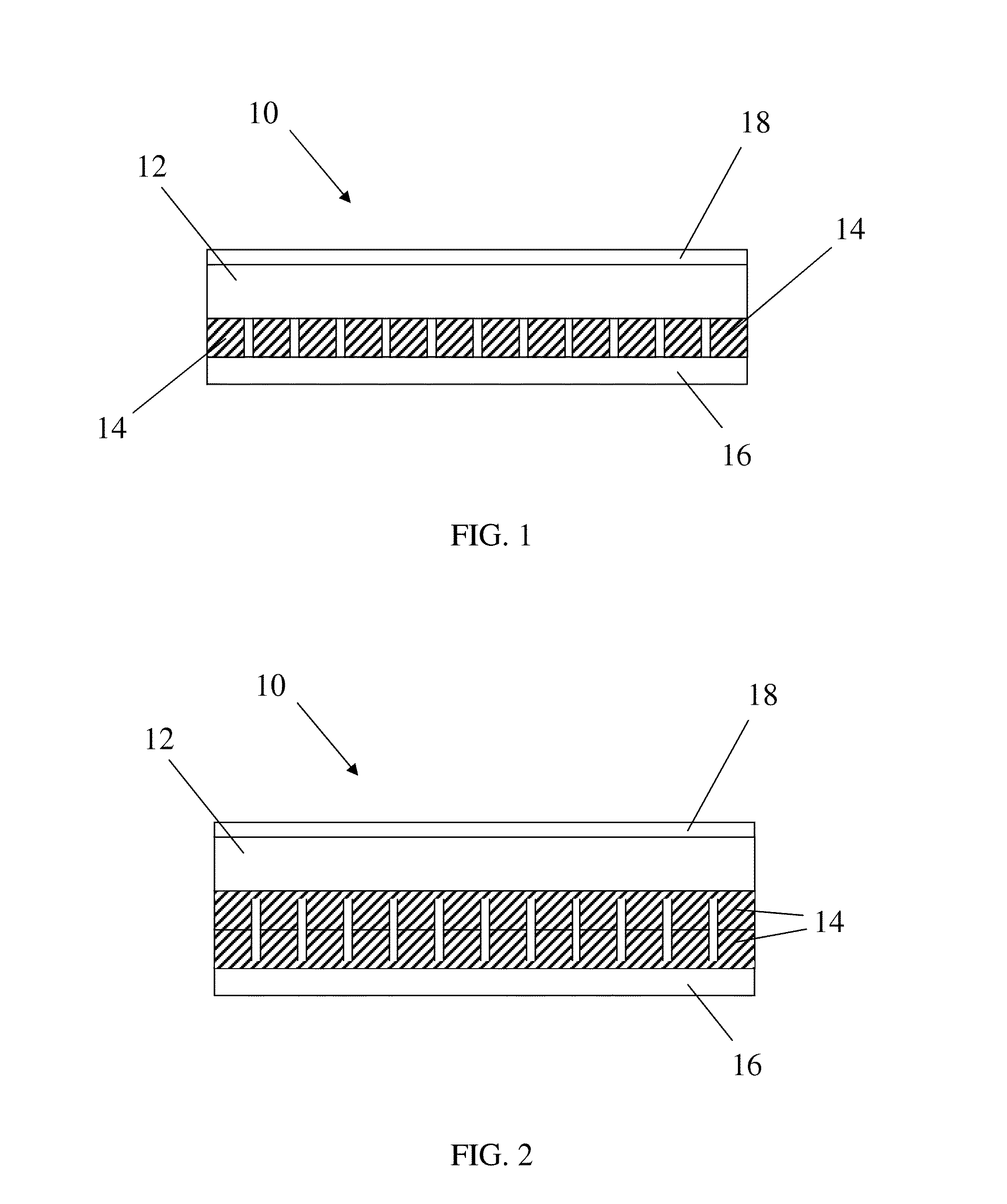

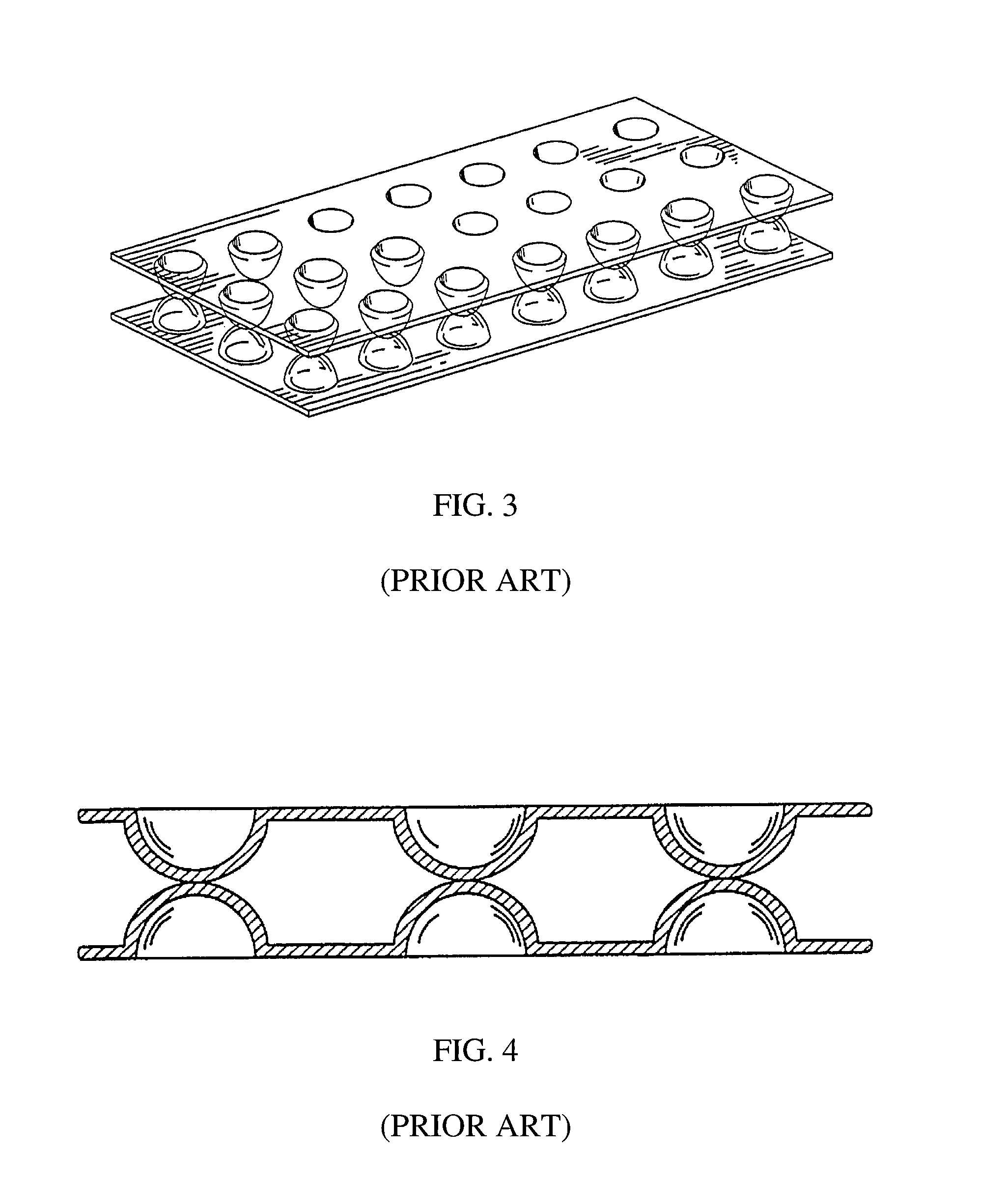

[0080]Overmatch testing was conducted to measure the performance of a spall resistant liner with and without a blast mitigating material attached to one of its surfaces. A strike face of high hard steel (15 mm of ARMOX® 440T steel commercially available from SSAB Technology AB of Stockholm, Sweden) was used as representative of a vehicle hull. In all examples, the spall resistant liner was constructed from the same material, comprising 19 consolidated layers of a 4-ply, non-woven aramid-fiber based composite fabric identified herein as GV-2018. THE GV-2018 composite included a polyurethane binder material with a total binder content of 13% by weight of the layer. In each example, the spall resistant liner had an areal density of 2.0 lb / ft2 (psf). In Example 1 (Comparative), the spall resistant liner tested was placed directly behind the strike face hull and clamped in place. In Example 2 (Comparative), the spall resistant liner tested was spaced apart from the strike face hull by 13...

examples 7-12

[0083]In Examples 6-11 the testing described for Comparative Example 1 was repeated where the test was performed with the spall resistant liner placed directly behind the strike face hull and clamped in place, but in these Examples the performance of spall resistant liners having varying areal densities were compared. Example 6 (Comparative) and Example 7 (Comparative) are duplicates of Example 1 (Comparative), testing a spall resistant liner having an areal density of 2.0 psf. In Examples 8 and 9, the spall resistant liner had an areal density of 3.5 psf. In Examples 10 and 11, the spall resistant liner had an areal density of 5.0 psf. Inventive Example 12 is a duplicate of Inventive Example 4, where a 2.0 psf spall resistant liner was adhered to one article of SKYDEX® blast mitigating material having a thickness of approximately 30 mm. In all examples, the spall resistant liner was constructed from the same materials and comprised GV-2018 as per Examples 1-5. The results are summa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com