Measuring and determining method for spall strength of quasi-brittle material at high strain rate

A technology for brittle materials and spalling strength, used in measuring devices, analyzing materials, strength properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

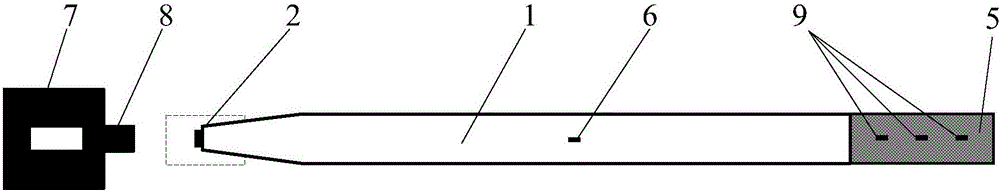

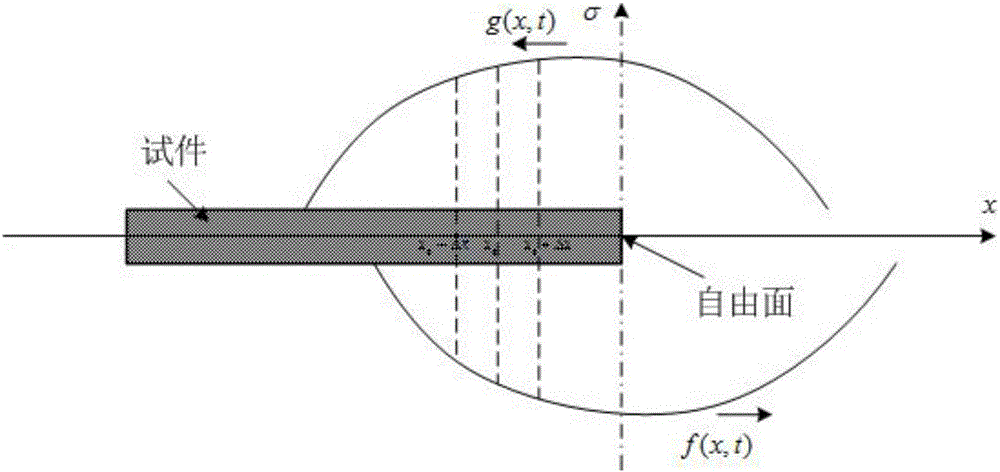

[0020] Such as figure 1 with 2 Shown, a kind of concrete axial dynamic tensile fracture test method based on Hopkinson's principle is characterized in that, comprises the following steps:

[0021] (1) A composite pulse shaper 2 prepared by superimposing a polytetrafluoroethylene disk 3 on an annealed copper disk 4 is installed at the impact end of the incident rod 1, and the vertical end face of the other end of the incident rod 1 is connected to the cylindrical concrete specimen 5 The vertical end face at one end fits closely;

[0022] (2) Paste the strain gauge 6 in the middle of the incident rod 1, and paste the strain gauge 9 on the concrete specimen 5, respectively pasting at the 4 point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com