Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Avoid work environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

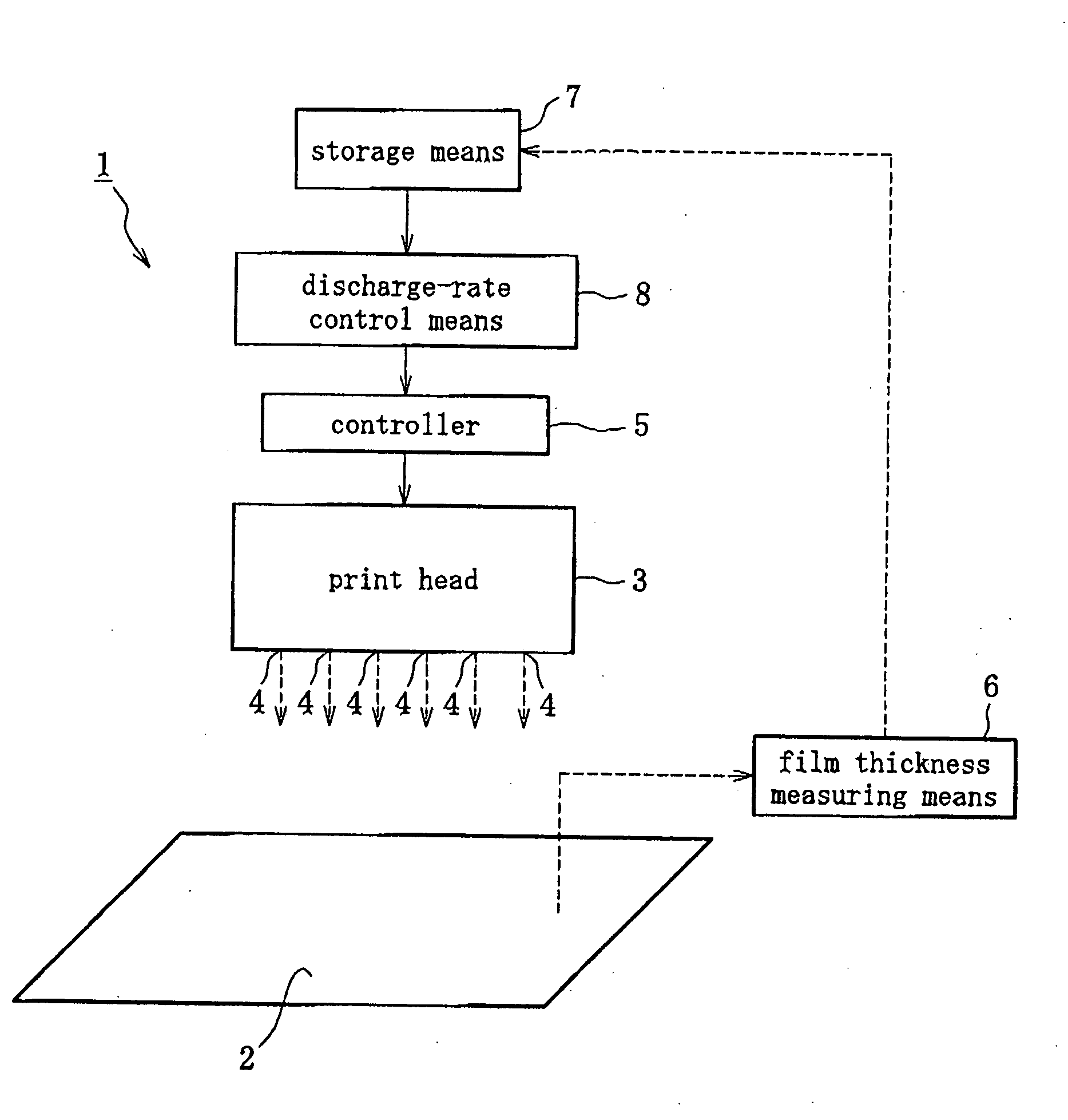

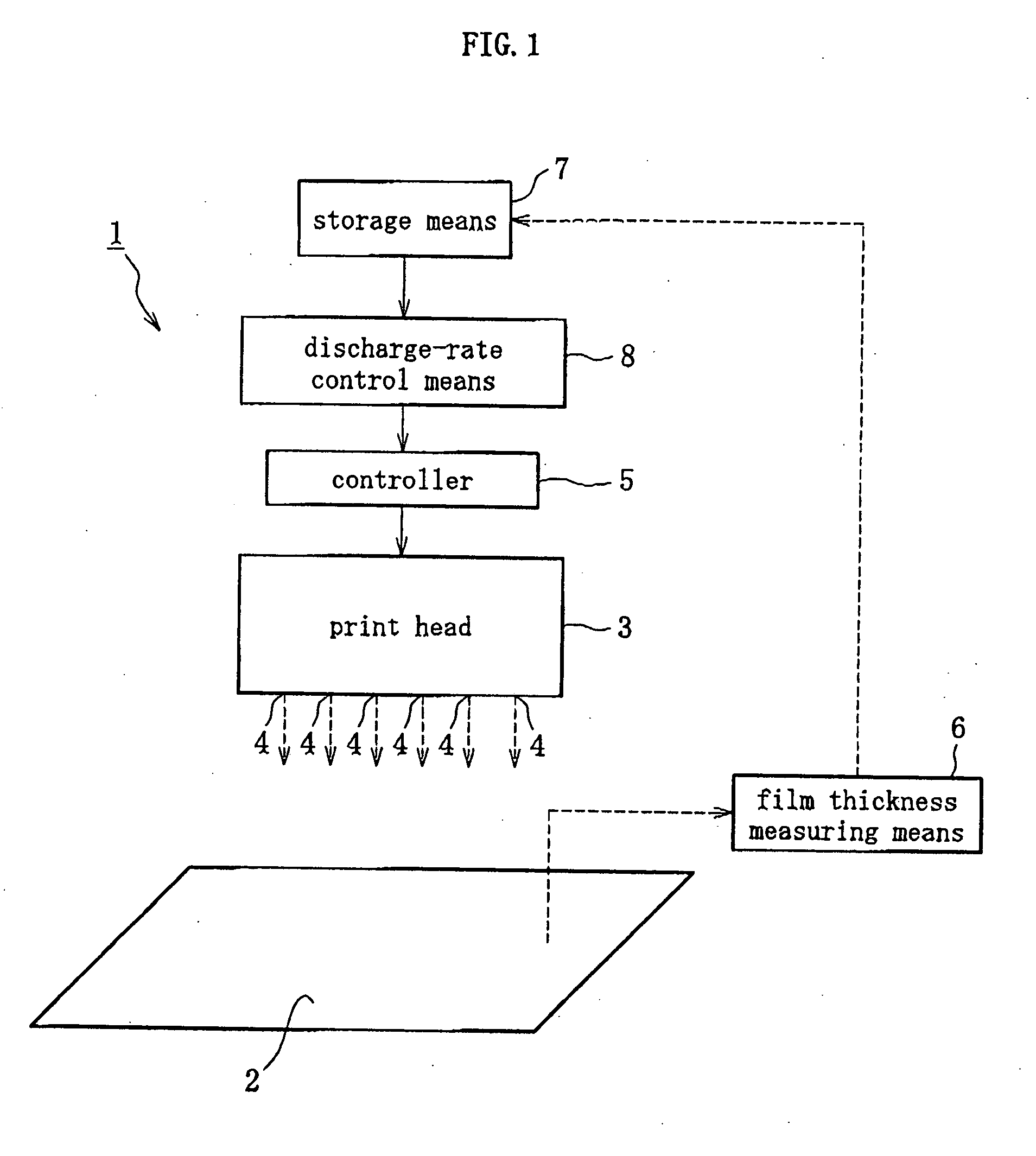

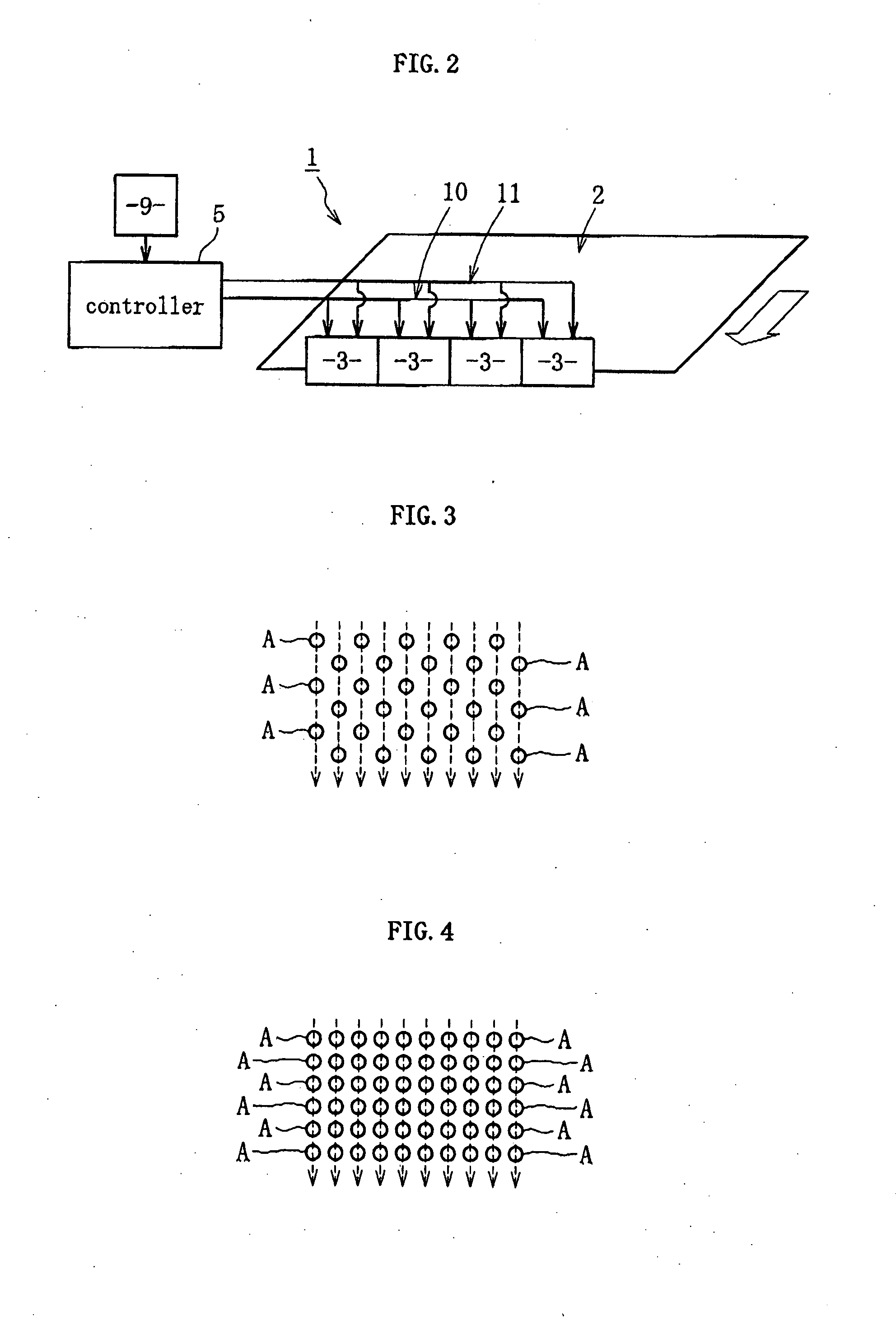

Discharge Rate Control Method for Ink-Jet Printer, Ink Spread Inspecting Method, and Oriented Film Forming Method

ActiveUS20080309698A1Unnecessary forming can be preventedAvoid work environmentLiquid surface applicatorsSpraying apparatusDischarge rateEngineering

Discharge rate control method for ink-jet printer 1 including film forming step forming film B on coating article 2 with non ink-absorbent characteristic by discharging ink on coating article 2 from a plurality of nozzles 4 of print head 3, film thickness measuring step measuring film thickness of film B, corresponding to ink discharge position of each nozzle 4, formed on coating article 2 in film forming step, and discharge rate correcting step correcting discharge rate of ink from each nozzle 4 by increasing or decreasing discharge rate based on difference between target film thickness Ba and film thickness at ink discharge position of each nozzle 4 measured in film thickness measuring step.

Owner:ISHII HYOKI

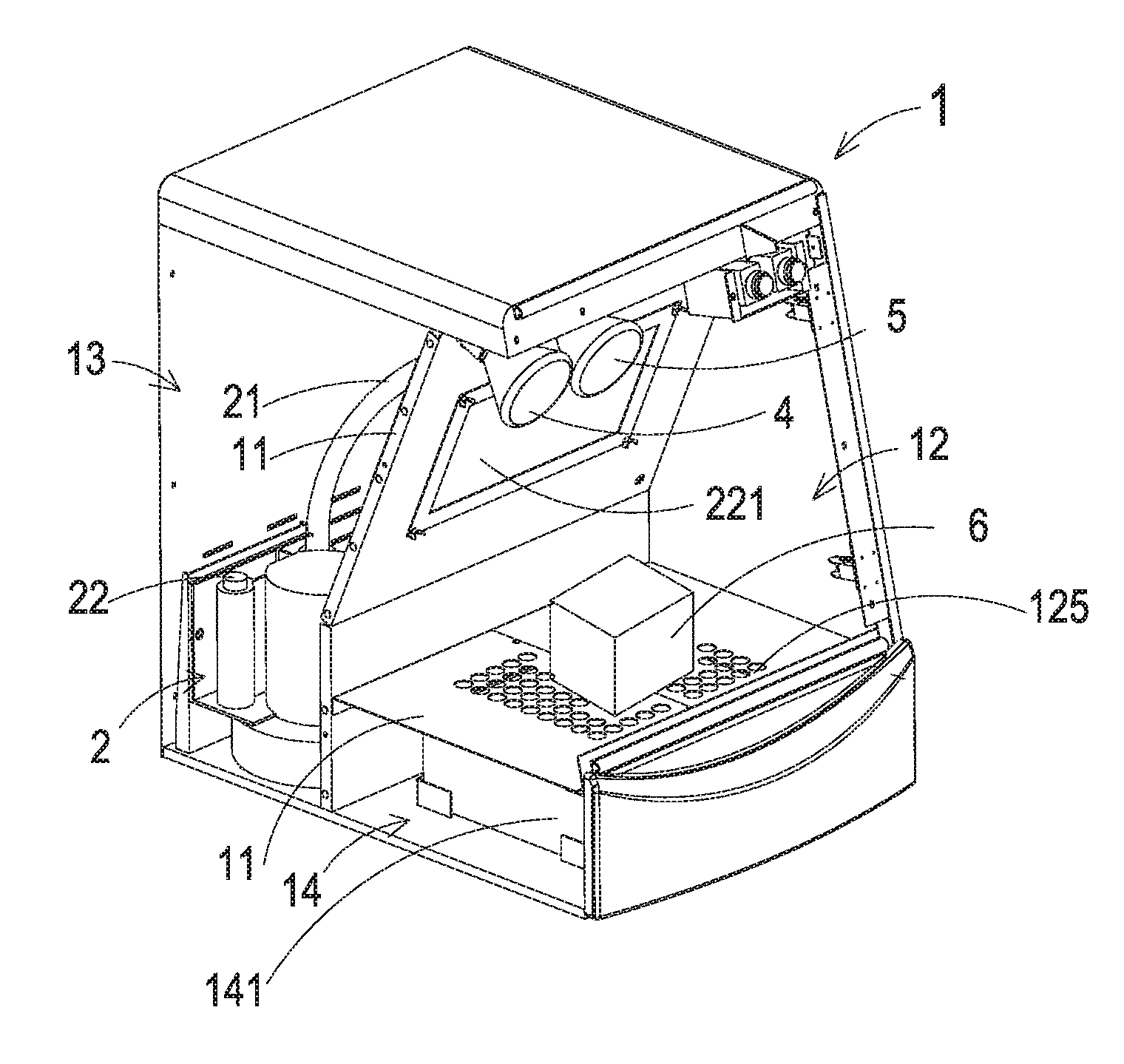

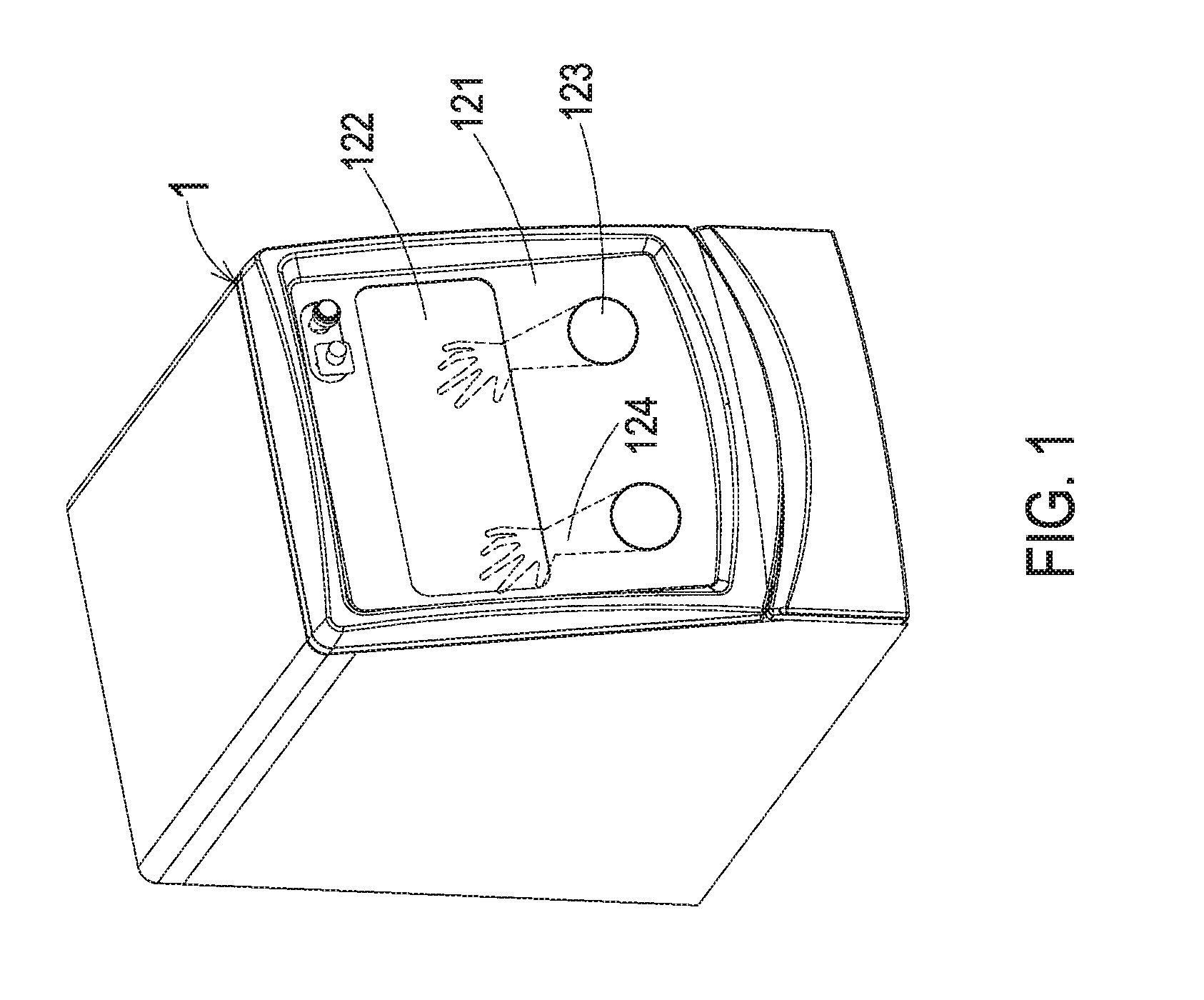

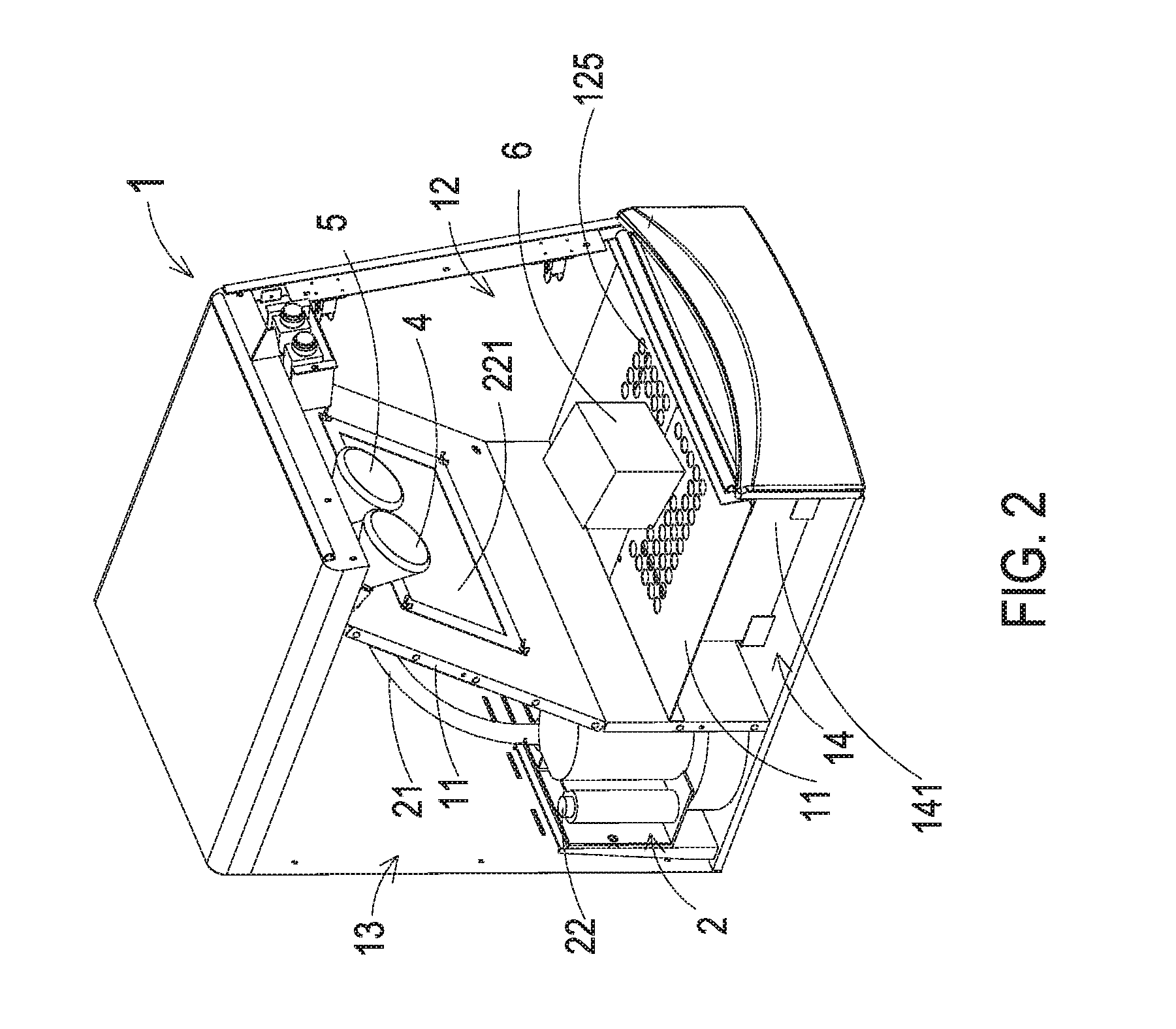

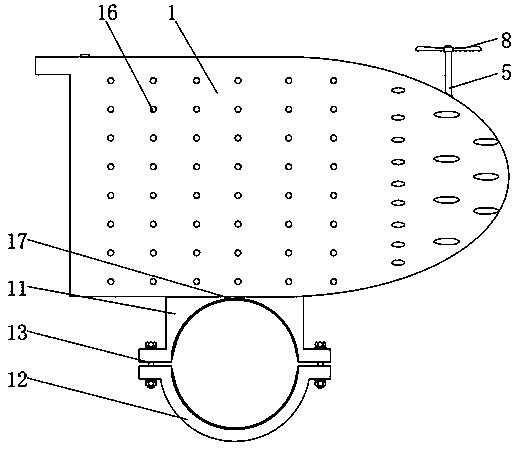

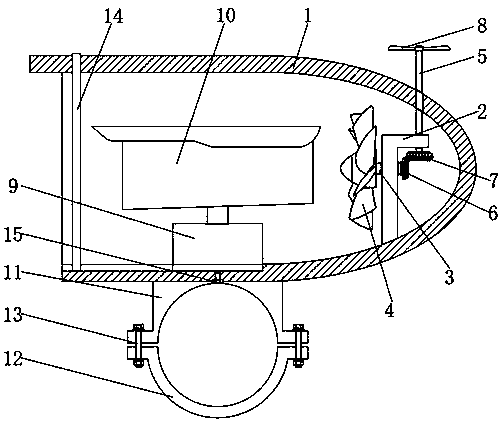

Powder recycling system

InactiveUS20160200053A1Avoid pollutionFacilitate removing excess powderConfectionerySweetmeatsMetallurgyRapid prototyping

A powder recycling system for a three-dimensional rapid prototyping apparatus is provided. The powder recycling system includes a sealed main body, a negative pressure generator, an air pressure generator, a lighting unit and a heater. When an excess powder removing process is performed to remove excess powder from a three-dimensional object, the excess powder is sieved by a screen mesh and collected by a powder collector. Consequently, the excess powder is recycled.

Owner:MICROJET TECH

Static electricity and dust removing apparatus

InactiveUS20090158537A1Improve processing qualityQuality improvementCarpet cleanersFloor cleanersWorking environmentEngineering

This static electricity and dust removing apparatus has a base box (11) provided with an airflow inlet port (16), and a processing head (23) attached to the base box (11) through a support column (21), wherein a processing space (24) is formed between the airflow inlet port (16) and the processing head (23). Air curtains for isolating the processing space (24) from the outside due to air from a spout of an air spout pipe (33) are formed at a front opening portion (29) and right and left side opening portions (28) of the apparatus. Ionized air generated by an ion generator (42) is spouted into the processing space (24), so that the ionized air is sprayed on matters to be processed which are disposed in the processing space (24) and dust is removed from the matters to be processed. Thereby, a static electricity and dust removing operation to the dust adhering to the matters to be processed can be efficiently performed within a short time, and work environment can be prevented from being contaminated due to a leakage of the removed dust.

Owner:KOGANEI

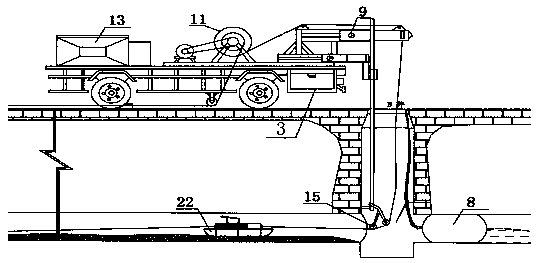

Urban pipe network sludge treatment method and system

ActiveCN109296055AMeet product requirementsMeet the protection requirementsSewer systemsEcological environmentReduction treatment

The invention discloses an urban pipe network sludge treatment method and system. The method comprises the following steps that an inspection well is cleaned, the upstream is plugged, a traction ropepenetrates, pipeline investigation is carried out, and sludge cleaning is carried out. The method also includes the procedures of guide device installation, sludge reduction treatment and dry sludge outward transport. The urban pipe network sludge treatment system comprises a winch system, a shuttle type cable penetrating device, a full-visual-angle pipeline checking device, a digging basket and asludge cleaning and dredging vehicle, and can further comprise a sludge drying treatment vehicle. Equipment of the system is optimized and combined, the application range is wide, safety and effectiveness are achieved, workers do not need to enter a closed severe environment for work, product requirements of human-computer engineering are met, systematization, unitization and high integration areachieved, the cleaning effect is good, and the requirement for protecting modern urban ecological environments is met.

Owner:西北水利水电工程有限责任公司

Disposable Brief

InactiveUS20080262462A1Prevent liquid leakageAvoid contaminationEndoscopesSurgical drapesEndoscopeAnus

A disposable brief for patient use in a colonoscopy procedure is disclosed. The brief comprises at least one back panel with at least one slit constituting an opening, allowing access to an anus of the patient. A fastening means surrounds the opening and is intended for attaching a dispensing assembly used with an endoscopic probe to the brief.

Owner:STRYKER GI

Method of forming spline and keyway for sheet metal rotating member with boss part

InactiveUS7047787B2Reduce weightIncrease productionForging/hammering/pressing machinesWheelsWorking environmentEngineering

An annular excess portion is disposed, a spline forming male mold is passed through a boss of a sheet metal-made rotary member in which a root portion of the boss and a peripheral portion are previously displaced, and the boss is set to a stationary mold with being fitted into a boss fitting hole of a rotary member holding mold. Thereafter, the annular excess portion is clamped between a pressing mold and the stationary mold to be deformed into a flat shape, and the root portion of the boss is squeezed into spline forming grooves to be plastically deformed, thereby forming a boss spline. According to the configuration, increase in thickness os a sheet metal blank is avoided, the strength of the boss is ensured, and weight reduction is achieved. The production efficiency can be remarkably improved, and cutting chips are eliminated, so that adverse influence on the working environment can be avoided.

Owner:KANEMITSU KK

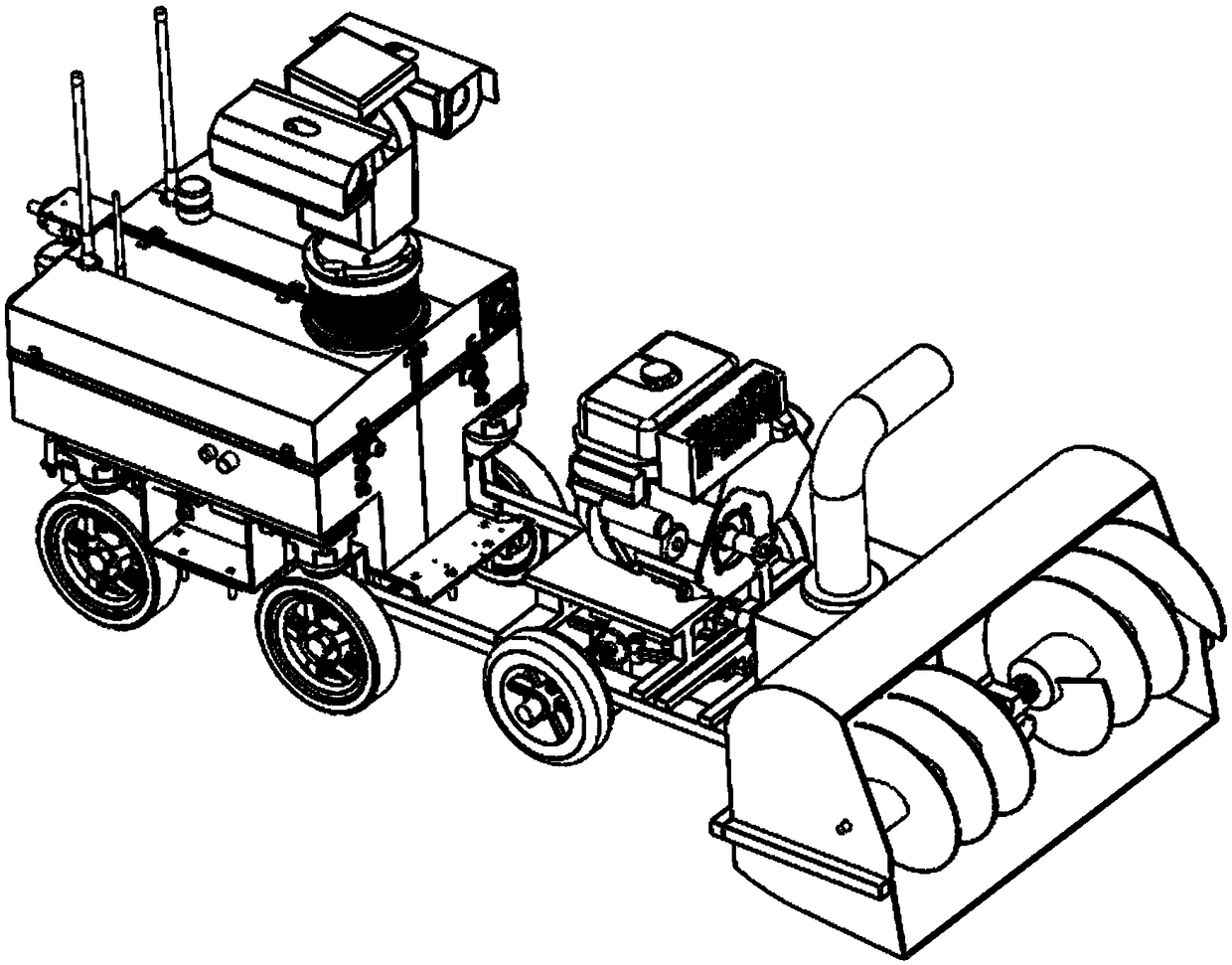

A substation patrol inspection robot with a snow removing tool

InactiveCN109088343ASmall turning radiusOvercome the harsh working environmentSnow cleaningManipulatorPower stationExtreme weather

The invention discloses a substation patrol inspection robot with a snow removing tool. The robot comprises a robot main body and a snow removing tool; the snow removing tool comprises a fixed frame,a snow removing mechanism and a power device, wherein the snow removing mechanism comprises an auger, a snow throwing wheel, a snow shovel and a snow throwing cylinder, and the power device comprisesa transmission system and a motor; the fixed frame comprises a bracket and wheels, the snow removing mechanism is fixed at the front end of the bracket, the power device is fixed at the middle part ofthe bracket, wheels are installed at the bottom of the middle part of the bracket, the wheels include driven wheels installed at both sides of the bottom and universal wheels installed at the front end of the driven wheels, and the whole snow removing tool is fixed at the front of the robot main body by the bracket; after the snow on the ground enters the snow shovel, the snow is thrown into thesnow throwing cylinder through the rotation of the auger and the snow throwing wheel, and finally the snow is discharged through the snow throwing cylinder. The invention enables the power station patrol inspection robot to travel smoothly on the snow covered road surface and finish the snow removing task in extreme weather.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of porous oil-containing lubrication material using UHMWPE as matrix

A preparation method of a porous oil-containing lubrication material using UHMWPE as a matrix comprises the steps that 70-90 parts of the UHMWPE, 1-20 parts of polytetrafluoroethylene and 1-10 parts of a solid lubricant are stirred and mixed; then, the mixed powder is subjected to press forming and sintering treatment; the sintered and formed material is subjected to vacuum oiled immersion.The prepared thermoplastic polyethylene porous oil-containing material having ultra-high molecular weight internally has a rich porous structure, can continuously and stably provide lubricating oil in a working state and has abrasion resistance, impact resistance, chemical corrosion resistance, low temperature resistance and other excellent performances.Oil can be continuously supplied to a mechanical friction pair, and a practical effect is good.

Owner:LUOYANG MOTIPU LUBRICATION MATERIAL CO LTD

Method of forming spline and keyway for sheet metal rotating member with boss part

InactiveUS20050061050A1Forming accuratelyLimited elongationForging/hammering/pressing machinesWheelsWorking environmentEngineering

An annular excess portion is disposed, a spline forming male mold is passed through a boss of a sheet metal-made rotary member in which a root portion of the boss and a peripheral portion are previously displaced, and the boss is set to a stationary mold with being fitted into a boss fitting hole of a rotary member holding mold. Thereafter, the annular excess portion is clamped between a pressing mold and the stationary mold to be deformed into a flat shape, and the root portion of the boss is squeezed into spline forming grooves to be plastically deformed, thereby forming a boss spline. According to the configuration, increase in thickness os a sheet metal blank is avoided, the strength of the boss is ensured, and weight reduction is achieved. The production efficiency can be remarkably improved, and cutting chips are eliminated, so that adverse influence on the working environment can be avoided.

Owner:KANEMITSU KK

Protection device of security equipment

PendingCN111379955AAchieve protectionGuaranteed to workMachine supportsClosed circuit television systemsEquipment useElectrical and Electronics engineering

The invention discloses a protection device of security equipment. The device comprises a fixed shell, one side of the bottom of the inner wall of the fixed shell is fixedly connected with a fixed seat, the center of the fixed seat is rotationally connected with a rotating shaft and a transmission shaft, one end of the rotating shaft is fixedly connected with fan blades, one end, far away from thefan blades, of the rotating shaft is fixedly connected with a first gear, the bottom end of the transmission shaft is fixedly connected with a second gear, the first gear is engaged with the second the gear, the top end of the transmission shaft penetrates through the inner wall of the fixed shell and is fixedly connected with driving blades, the bottom of the inner wall of the fixed shell is connected with a damping fixed seat in a sliding mode, the top of the damping fixed seat is fixedly connected with the security equipment, the bottom of the fixed shell is fixedly connected with the fixed seat, and one side of the fixed shell is provided with a transparent protective sheet. The device relates to the technical field of the security equipment. The protection device of the security equipment solves the problems that a use environment of the security equipment is bad, the security equipment is subject to heavy rains and exposure to the sun, and meanwhile, the security equipment can be damaged manually.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

Mouse with audio output function

InactiveUS20060082552A1Low costUpgraded sound qualityCathode-ray tube indicatorsInput/output processes for data processingOutput deviceSounds device

A mouse with audio output function includes a control circuit, a volume control for adjusting high / low level of audio signals, an ON / OFF switch for supplying or cutting off power output from the control circuit, an amplifying circuit for amplifying audio signals, and a sound output device. A terminal is connected to an audio output on a computer to transmit audio signals from the computer to the amplifying circuit in the mouse. The audio signals amplified at the amplifying circuit are output via the sound device as sound. The mouse can therefore replace conventional sound playing devices and allows a user to enjoy sound from the computer without the need of installing separate speakers. Moreover, the mouse is directly supplied with power from the computer without the need of an external power source to drive the audio output function, and could be conveniently carried along with the user for use at different places.

Owner:SCYTHE TAIWAN

Authorization system and method for intelligent agricultural machine

PendingCN109857101AEnsure safe handlingEnsure reasonablenessDigital data authenticationPosition/course control in two dimensionsRemote controlInteraction interface

The invention provides an authorization system and method for an intelligent agricultural machine. The authorization system for the intelligent agricultural machine comprises a remote control terminal; the remote control terminal is provided with at least one interaction interface, a control module and a communication module; the interaction interface is configured to input instructions; the control module is configured to be capable of receiving inputted control instructions from the interaction interface; the communication module is configured to receive the control instructions from the control module, and send the control instructions to the intelligent agricultural machine; and the control module is further configured to authenticate authentication information received by the controlterminal and send the control instructions inputted through the interaction interface to the communication module when the authentication information passes the authentication, so that the communication module can send the control instructions to the intelligent agricultural machine. Therefore, the safety of the operation of the intelligent agricultural machine can be ensured.

Owner:FJ DYNAMICS TECH CO LTD

Sterilizing device for robot

InactiveCN111298170AAvoid work environmentEasy to recycleDrying gas arrangementsLavatory sanitoryEngineeringElectrical and Electronics engineering

The invention discloses a sterilizing device for a robot in the technical fields of sterilizing devices. The sterilizing device comprises a base station, wherein vertical beams are symmetrically arranged at the left end and the right end of the top end of the base station; the top ends of the vertical beams which are arranged on the two sides of the base station are connected with a cross beam; alifting mechanism is mounted in the middle of the top end of the cross beam; the lower side of the lifting mechanism is connected with a transparent hood; a hanger loop is arranged in the middle of the top end of the transparent hood; the end part of a traction rope of the lifting mechanism is connected with the hanger loop. Sterilization and cleaning processes of the sterilizing device occurs inthe transparent hood, so that surrounding working environments can be prevented from irradiated by water mists, and disinfectant is conveniently and fully recycled; and meanwhile, a hot air drying mechanism is arranged in the transparent hood, so that the drying speed of the robot is quickened. According to the sterilizing device for the robot disclosed by the invention, a rotation mechanism is arranged on the base station, the robot does not need to be moved up and down when being used, and therefore, robots with larger sizes and heavier weight are sterilized more conveniently.

Owner:何海忠

Powder recycling system

InactiveUS10005240B2Avoid work environmentFacilitate removing excess powderAdditive manufacturing apparatusDirt cleaningMetallurgyRapid prototyping

Owner:MICROJET TECH

Original pulp airing vinegar and preparation method thereof

ActiveCN109810870AGive full play to nutritionGive full play to the advantages of fragranceMicroorganism based processesVinegar preparationAmylaseAlcohol

The invention relates to the technical field of vinegar preparation, and particularly discloses an original pulp airing vinegar and a preparation method thereof. The original pulp airing vinegar is prepared from the following raw materials of main materials, auxiliary materials and fermenting agents, wherein the main materials comprise the following components in parts by weight: 700 to 900 partsof rice, 500 to 750 parts of sorghum, 90 to 110 parts of wheat, 80 to 120 parts of millet, and 10 to 30 parts of pea; the auxiliary materials comprise the following components in parts by weight: 1300to 1700 parts of wheat bran, and 1300 to 1700 parts of grain bran; the fermenting agents comprise the following components in parts by weight: 600 to 800 parts of red rice yeast, and 1 to 1.5 parts of alcohol yeast. The original pulp airing vinegar has the advantages that the original pulp airing vinegar is prepared from the red rice yeast; various nutritional primers in the raw materials are fully hydrolyzed by rich glucoamylase and amylase in the red rice yeast, the yield rate of vinegar culture is increased, and the fragrance and nutritional substances of the vinegar are increased.

Owner:河北粟凝香食品有限公司

Green preparation process of 2-methyl-3-methoxybenzoyl chloride

ActiveCN113105323AReduce Methanol ContentReduce CODOrganic compound preparationPreparation from carboxylic acid esters/lactonesBenzoic acidAlkaline water

The invention discloses a green preparation process of 2-methyl-3-methoxybenzoyl chloride. The green preparation process comprises the following steps: heating and hydrolyzing methyl 2-methyl-3-methoxybenzoate in an alkaline aqueous solution, and distilling off generated methanol while a hydrolysis reaction is carried out; adding an organic solvent into hydrolyzed reaction liquid under the condition of heat preservation for dissolving, and adding an acidic aqueous solution for neutralizing; conducting neutralizing, then preserving heat and conducting layering to obtain a water layer and an organic layer, and washing the organic layer with water; heating the washed organic layer for azeotropic water removal; and adding a catalyst into the organic layer after azeotropic dehydration, carrying out heating, dropwise adding an acylating chlorination reagent, and carrying out a heat-preserved reaction to obtain the 2-methyl-3-methoxybenzoyl chloride. In a neutralization process after hydrolysis is completed, the organic solvent is added, and the product 2-methyl-3-methoxybenzoic acid is transferred into the organic solvent and is transferred to a subsequent reaction in a solution state, so water consumption for post-treatment is reduced, and meanwhile, harm to a working environment and the health of workers in the solid dust drying and feeding process is avoided.

Owner:JIANGSU YONGAN CHEM CO LTD

Method for preparing large-sized thin film by mechanically exfoliating graphene nanoplatelets and solar cell

InactiveCN105502376ASimple processLow costPhotovoltaic energy generationSemiconductor devicesIonSolvent

The invention discloses a method for preparing a large-sized thin film by mechanically exfoliating graphene nanoplatelets and a solar cell. The large-sized thin film can be obtained by exfoliating graphite by adopting the shearing force provided by a continuous screw extruder, dispersing the graphite into deionized water, adding a hydrophobic solvent, suspending a substrate material in the hydrophobic solvent, cooling to cure the hydrophobic solvent, taking the substrate out, and removing hydrophobic solvent impurities between and around the graphene and the substrate material. According to the method, a thin graphene layer formed by self-assembly of the graphene at an insoluble liquid / liquid interface is protected by utilizing a cooling curing mode; the thin graphene layer is exfoliated from the dispersion liquid through a physical effect; the working environments of high-temperature environment and high-risk gas are avoided, and the use of a highly toxic organic reagent is avoided, so that the method has a broad market application value.

Owner:魏颖

Preparation method of porous oil-containing lubricating material using uhmwpe as matrix

ActiveCN105695053BProvide continuous and stableImprove the lubrication effectAdditivesChemical corrosionLubrication

A preparation method of a porous oil-containing lubrication material using UHMWPE as a matrix comprises the steps that 70-90 parts of the UHMWPE, 1-20 parts of polytetrafluoroethylene and 1-10 parts of a solid lubricant are stirred and mixed; then, the mixed powder is subjected to press forming and sintering treatment; the sintered and formed material is subjected to vacuum oiled immersion.The prepared thermoplastic polyethylene porous oil-containing material having ultra-high molecular weight internally has a rich porous structure, can continuously and stably provide lubricating oil in a working state and has abrasion resistance, impact resistance, chemical corrosion resistance, low temperature resistance and other excellent performances.Oil can be continuously supplied to a mechanical friction pair, and a practical effect is good.

Owner:LUOYANG MOTIPU LUBRICATION MATERIAL CO LTD

A method for preparing silicene film by mechanical exfoliation and application of silicene film

ActiveCN106554016BPromote mass productionImprove stabilityMaterial nanotechnologySolid-state devicesActive agentSolar battery

The invention discloses a silicene film prepared by mechanical peeling and the application of the obtained silicene film in batteries. The two-dimensional nanomaterials are physically covered on the passivated silicon surface of the metal film. After high-temperature treatment, the silicon element diffuses into the two-dimensional The interface between the nanomaterial and the metal film is lowered to room temperature, and the sample is dispersed in a solvent liquid with a surfactant. Polar molecules are very easy to enter the interface between the metal film and the substrate material, and the metal film and the substrate are increased by ultrasonic stirring. Material friction, peeling two-dimensional nanomaterials and silicene from silicon substrates to obtain silicene films. The present invention utilizes mechanical stripping to peel off the silicene thin layer in the liquid phase through physical action, which protects the physical properties of the silicene material, avoids the working environment of high vacuum and high-risk gas, and avoids highly toxic organic reactants The use of two-dimensional nanomaterials can be used repeatedly, which reduces the cost and has broad market application value in the field of solar cells.

Owner:日照东润有机硅股份有限公司

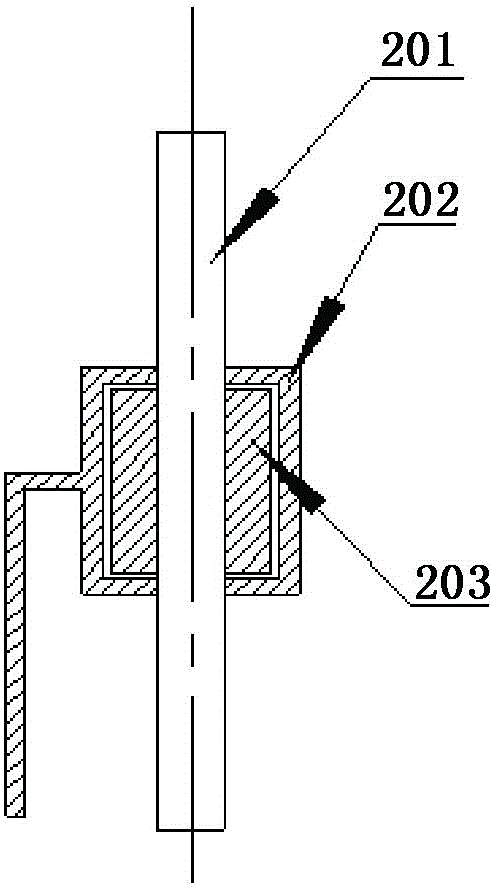

Return-to-zero judgment device and method used in galvanometer scanning rotation process

PendingCN113484849AGuaranteed zero accuracyImprove maintainabilityUsing optical meansElectromagnetic wave reradiationGalvanometerEngineering

The invention discloses a return-to-zero judgment device and method used in a galvanometer scanning rotation process, and belongs to the technical field of environmental monitoring. The return-to-zero judgment device comprises a slewing bearing, a mounting support plate is fixed on an inner ring of the slewing bearing, a driving device, an infrared sensor and a laser sensor are mounted on the mounting support plate, the driving device is connected with an outer ring of the slewing bearing, a stand column A is installed on the outer ring, and a small hole B is formed in the outer ring in the axial direction. According to the invention, multiple sensors are combined and applied to zero-returning positioning of the scanning galvanometer, the outer ring is firstly controlled to rapidly rotate around the inner ring, the infrared sensing technology is utilized to realize large-size positioning and reduce the zero-returning range, then rotation stepping is carried out at a low speed, and the laser detection technology is utilized to realize small-range final rapid zero-returning control.

Owner:合肥中科环境监测技术国家工程实验室有限公司

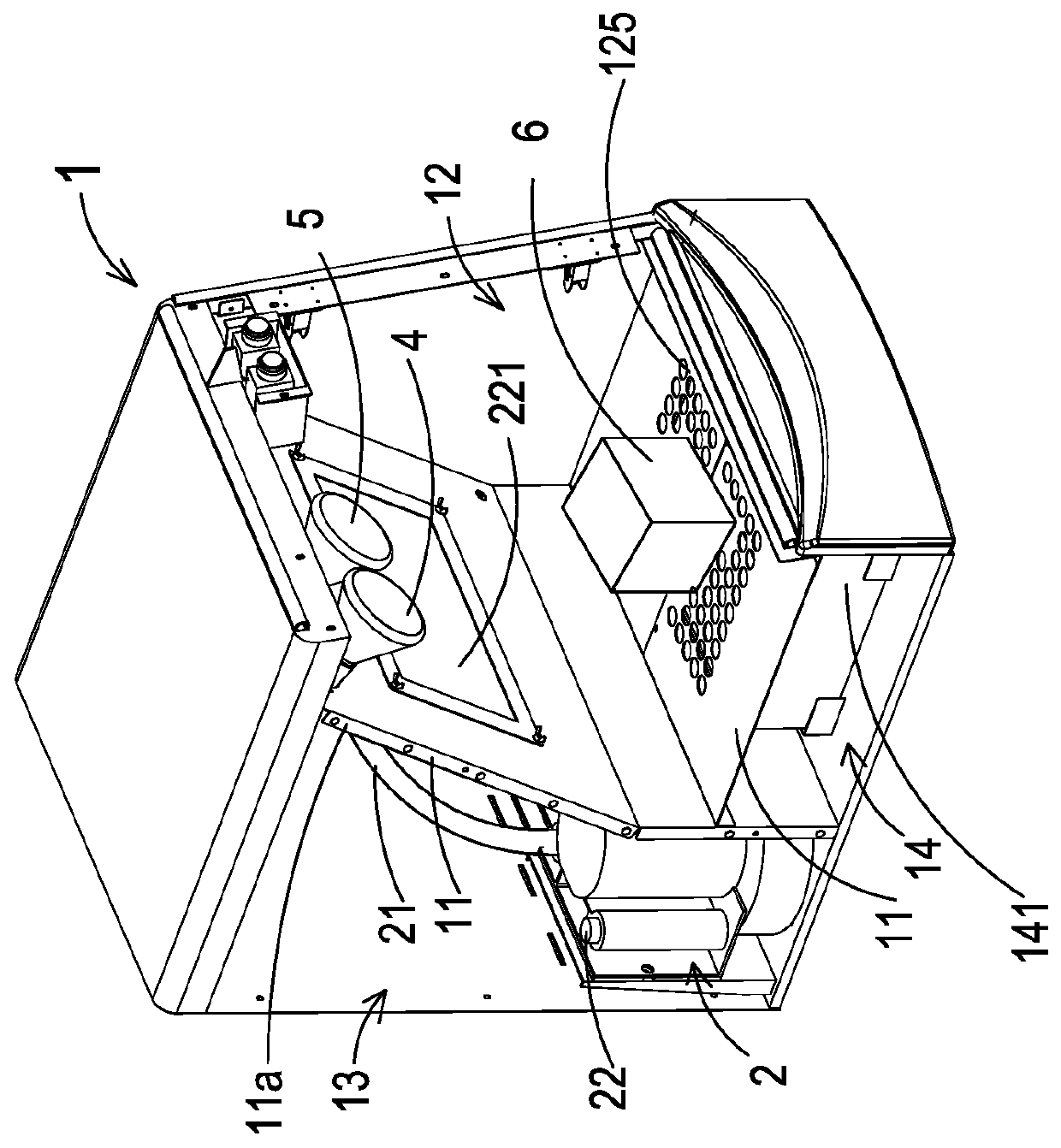

Oven

ActiveUS11054146B2Reduce the temperaturePrevent the personnel around the oven from being burnedDomestic stoves or rangesLighting and heating apparatusEngineeringFood material

The present invention provides an oven including an oven body with an exhaust port and a heat transfer assembly, disposed at a side of the oven body, that includes a top plate and a bottom plate connected by two side plates, and a sealing plate to form an air passage therebetween. The air passage has a first opening near the sealing plate and a second opening away from the sealing plate. The first opening communicates with the exhaust port of the oven body, and the second opening opens to the external of the heat transfer assembly which is arranged so the hot air from the exhaust port may enter the interior of the heat transfer assembly so that the heat energy of the hot air can be absorbed by the top plate and then conducted to the food materials on the top plate to be reused.

Owner:GRAND MATE

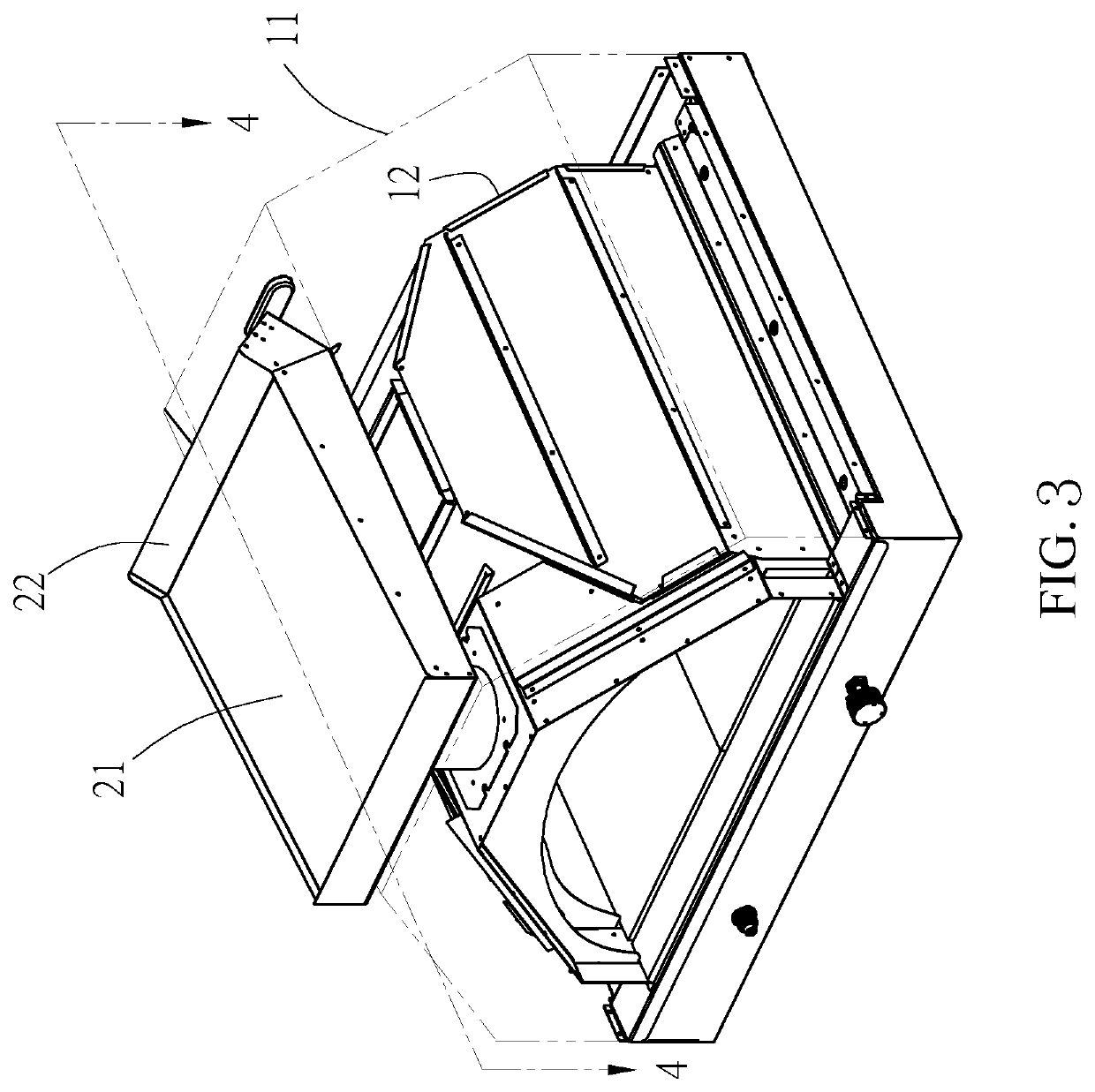

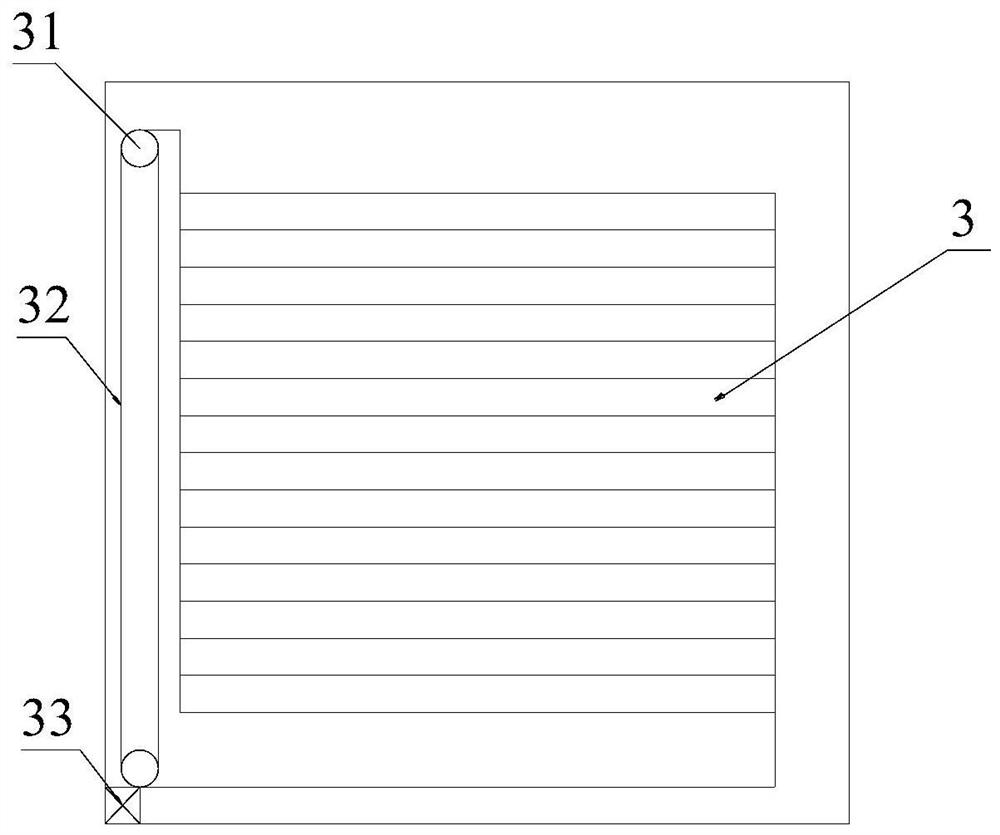

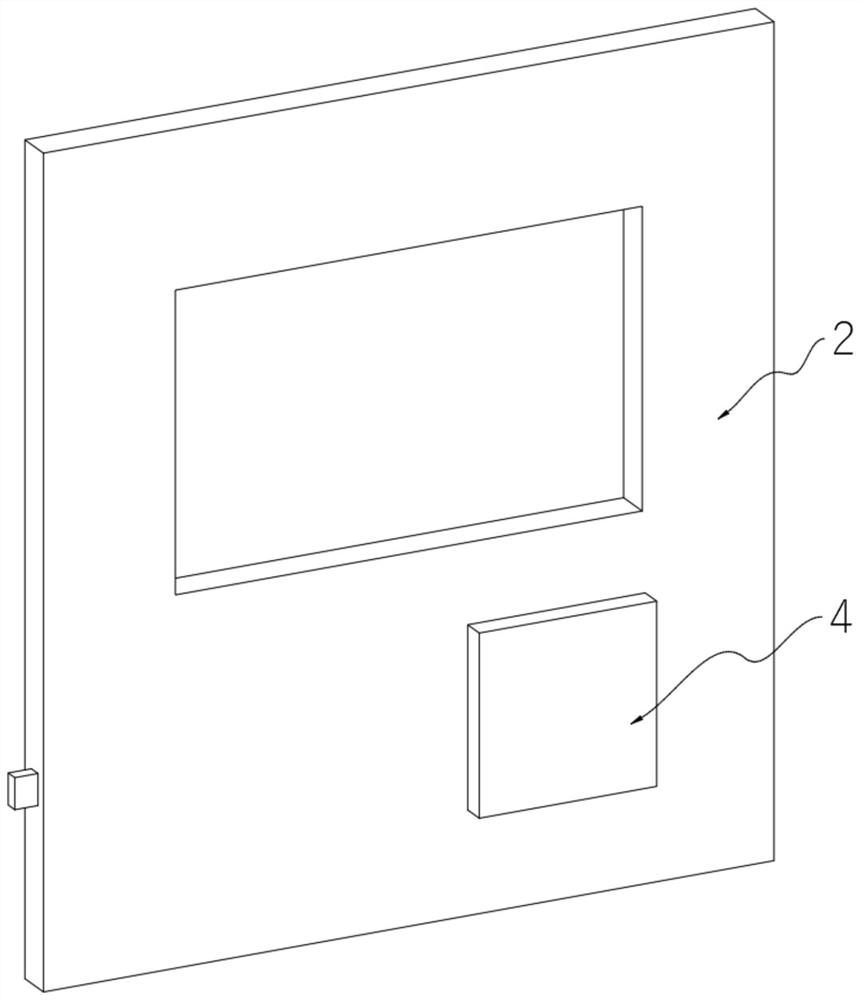

Folded workbench

InactiveCN108926144AAvoid work environmentSimple structureChestsDressing tablesWorking environmentEngineering

The invention provides a folded workbench, which comprises a storage platform, a folded plate, a bracket and supporting legs, wherein the storage platform is connected to the supporting legs; the upper ends of the supporting legs are connected to one end of the folded plate; and the lower ends of the supporting legs are connected to the other end of the folded plate by virtue of the bracket. The workbench can be folded in accordance with users' demands, so that a changeless working environment of normal tables can be overcome. The folded workbench has the characteristics of being simple in structure and capable of saving a space.

Owner:龙海洋

Porous oil-containing lubricating material with polyethylene as matrix and preparation method thereof

ActiveCN105505541BProvide continuous and stableImprove the lubrication effectAdditivesBase-materialsEthyleneLubricant

The invention provides a porous oil-containing lubricating material with polyethylene as a base body. The material is prepared from by 30-94 parts of polyethylene, 5-60 parts of lubricating oil and 1-10 parts of solid lubricant, wherein the average molecular weight of polyethylene is 300,000-10,000,000. A preparation method of the lubricating material includes the steps of material mixing, multiple times of compression moulding, sintering and the like. The porous oil-containing lubricating material prepared through the method is internally provided with a rich porous structure, lubricating oil can be continuously and stably supplied in the work state, and the material integrates excellent performance such as abrasion resistance, impact resistance, chemical corrosion resistance and low temperature resistance. Oil can be supplied to a chemical friction pair continuously, the lubricating material can be refilled with oil and continuously used, and the practical effect is good.

Owner:LUOYANG MOTIPU LUBRICATION MATERIAL CO LTD

Biological odor removal device for kitchen garbage

InactiveCN109316950AAvoid work environmentExquisite structureGas treatmentDispersed particle separationWater dischargeEngineering

The invention provides a biological odor removal device for kitchen garbage, and relates to the field of kitchen garbage treatment. The invention provides the biological odor removal device for kitchen garbage with the advantages of ingenious structure, use convenience, high treatment efficiency, good odor filtering and removal effect and good gas purification effect. The biological odor removal device comprises a box body, wherein a water pump, a spraying cabin and a grid plate are arranged in the box body; an air inlet pipe, an exhaust pipe and a water discharging pipe communicated with thespraying cabin are also arranged on the box body; the grid plate is detachably connected with the middle part of the spraying cabin and is used for bearing and carrying a culture medium; the air inletpipe is communicated with the lower part of the grid plate; the exhaust pipe is communicated with the top of the spraying cabin; the water discharging pipe is communicated with the bottom of the spraying cabin; the top of the spraying cabin is also fixedly connected with a spray head communicated with the water pump. The biological odor removal device integrally has the characteristics of ingenious structure, use convenience, high treatment efficiency, good odor filtering and removal effect and good gas purification effect.

Owner:江苏中科金汇生态科技有限公司

A special ventilation window for self-cleaning operating room

ActiveCN110454056BPrevent proliferationImprove cleanlinessVentilation arrangementPower-operated mechanismFixed bearingWindow shutter

The invention belongs to the technical field of ventilation windows, and in particular relates to a special ventilation window for a self-cleaning operating room. The ventilation window includes a cavity formed between the shell and the shell. The shell is divided into a front shell and a rear shell. A glass window is arranged in the cavity between the front shell and the rear shell. The glass window is circular, and the glass A fixed bearing is arranged at the center of the window circle, and the glass window is composed of several fan-shaped glass sheets; the fan-shaped glass sheets are fixedly connected with the fixed bearing, and the fixed bearing is driven by a rotating motor; cleaning brushes are arranged on both sides of the glass window; Sliding guide rails for moving the cleaning brush are provided perpendicular to the direction of the cleaning brush; louvers are respectively provided on the front and rear sides of the self-cleaning brush; micro-fans are also provided in the front shell and the shell. The special ventilation window for the operating room has a simple structure and good ventilation effect. The dust and bacteria adsorbed on the ventilation window are regularly and automatically cleaned, and the self-cleaning performance is good and the cleaning degree is high.

Owner:青岛市第九人民医院

Bulging liner plate and gap control method and system

InactiveCN110227720AImprove efficiencyAvoid work environmentMetal rolling stand detailsMass flow control deviceEngineeringRolling mill

The invention relates to a bulging liner plate and a gap control method and system, and belongs to the field of rolling mill control. The bulging liner plate comprises a first plate and a second plate, wherein the first plate is provided with a first matching surface, the second plate is provided with a second matching surface, one of the first plate and the second plate or both the first plate and the second plate are provided with fluid channels, the first matching surface and the second matching surface are arranged facing each other to form a closed containing cavity, the containing cavitycommunicates with the fluid channels, and the first plate is constructed to be bulged under driving of fluid in the containing cavity through the first matching surface. The bulging liner plate in the embodiment can be used for filling a gap between a rolling mill stand column surface and a roll bearing chock.

Owner:TAIYUAN UNIV OF TECH +1

Multifunctional safe electricity utilization monitoring equipment based on Internet of Things and NFC technology

PendingCN113993355AEnsure regular inspection of safety electricity monitoring equipmentAvoid work environmentDispersed particle filtrationParticular environment based servicesEmbedded systemInternet of Things

The invention relates to the technical field of power utilization monitoring equipment, and concretely relates to multifunctional safe power utilization monitoring equipment based on the Internet of Things and the NFC technology. The equipment comprises a box body, a box door is hinged to the front side of the box body, an NFC reader-writer is embedded in the position, close to the lower left corner, of the front side of the box door, Internet of Things connecting equipment is arranged at the position, right behind the NFC reader-writer, of the rear side of the box door, a power utilization monitoring instrument is arranged on the upper middle portion in the box body, and fans are arranged at the bottom of the inner wall of the box body and close to the two ends. According to the multifunctional safe electricity utilization monitoring equipment based on the Internet of Things and the NFC technology, an NFC identification tag carried by an inspector can be identified through the NFC reader-writer and the Internet of Things connection equipment, so that a manager obtains information of the inspector in real time, and it is ensured that the inspector regularly inspects the safe electricity utilization monitoring equipment; and the fans can dissipate heat of the power utilization monitoring instrument, so that the power utilization monitoring instrument is prevented from being in a high-temperature working environment.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO JIMO POWER SUPPLY CO

A kind of mefenamic acid and its synthesis process

ActiveCN106380414BHigh yieldHigh bulk densityOrganic compound preparationAmino-carboxyl compound preparationSodium acetateSodium bicarbonate

The invention discloses a mefenamic acid. The mefenamic acid is prepared by the following steps: taking o-chlorobenzoic acid and 2,3-dimethylaniline as the reactants and weakly alkaline salt as the acid binding agent, and then carrying out C-N condensation reactions in the presence of a copper catalyst. The invention also provides a synthesis technology of mefenamic acid. The synthesis technology comprises the following steps: adding 2,3-dimethylaniline, strongly acidic cation exchange resin, o-chlorobenzoic acid, sodium bicarbonate, a copper catalyst, sodium acetate, and sodium ethyl benzene sulfonate into a condensation reaction tank to synthesize a first reaction liquid; then sequentially adding o-chlorobenzoic acid, sodium bicarbonate, and a copper catalyst into the first reaction liquid, dropwise adding liquid alkali to synthesize a second reaction liquid, adjusting the pH value of the second reaction liquid to obtain a condensation liquid, and finally subjecting the condensation liquid to filtering, decoloring, and purification to obtain mefenamic acid. The provided mefenamic acid synthesis technology has the advantages of few byproducts, high yield, safety, environment-friendliness, energy saving, improved efficiency, and simple operation.

Owner:西安利君精华药业有限责任公司

Urban pipe network sludge treatment method and system

ActiveCN109296055BMeet production requirementsMeet the protection requirementsSewer systemsSludgeTreatment Vehicle

The invention discloses a method and a system for treating sludge in an urban pipe network. The method comprises the following steps: inspection well cleaning→blocking upstream→passing a traction rope→pipeline survey→silt cleaning, which also includes installing a guide device, sludge reduction treatment, drying Silt removal process, a sludge treatment system for urban pipe network, including hoisting system, shuttle cable passer, full-view pipeline surveyor, digging basket and sludge dredging vehicle, and may also include sludge drying treatment vehicle, The optimized combination of system equipment has a wide range of applications, is safe and effective, and does not require personnel to enter a closed and harsh environment for operation. It meets the product requirements of ergonomics and realizes systematization, unitization, and high integration. The cleaning effect is better and meets the needs of modern cities. Ecological environment protection requirements.

Owner:西北水利水电工程有限责任公司

A phosphogypsum treatment device and method based on sodium sulfate electrolysis

ActiveCN111364055BFlexible disassembly and assemblySimple structureCellsCalcium/strontium/barium oxides/hydroxidesElectrolysisLime sulfur

The invention discloses a phosphogypsum treatment device and method based on sodium sulfate electrolysis, belonging to the technical field of electrochemical engineering technology application. Including electrolysis unit and reaction unit, sulfuric acid storage tank, acid circulation pump, acid three-way valve and sodium sulfate electrolyzer are connected sequentially, and sulfuric acid storage tank is directly connected with sodium sulfate electrolyzer; sodium sulfate storage tank, alkali circulation pump, alkali three The through valve is connected to the sodium sulfate electrolyzer in sequence, and the sodium sulfate storage tank is directly connected to the sodium sulfate electrolyzer; the alkali three-way valve is connected to the phosphogypsum reactor, and the phosphogypsum reactor, slag discharge pump, filter, filtrate storage tank and The return pump is connected in turn, and the return pump is connected with the sodium sulfate storage tank. In the treatment method of the present invention, sodium sulfate is electrolyzed to generate caustic soda and sulfuric acid, and caustic soda reacts with phosphogypsum to generate slaked lime. The sulfuric acid is returned to the production line of the phosphate fertilizer plant, and the sodium sulfate solution is recycled to recycle calcium and sulfur elements. The device is compact, the structure is simple, the operation is stable, the resource recovery rate is high, there is no secondary pollution, and zero pollution emission is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com