A substation patrol inspection robot with a snow removing tool

A technology for inspection robots and substations, applied in the field of intelligent robots, can solve the problems of robot modification, unable to work normally, easily trapped in extreme environments, etc., and achieve the effect of reducing the turning radius and overcoming the harsh working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

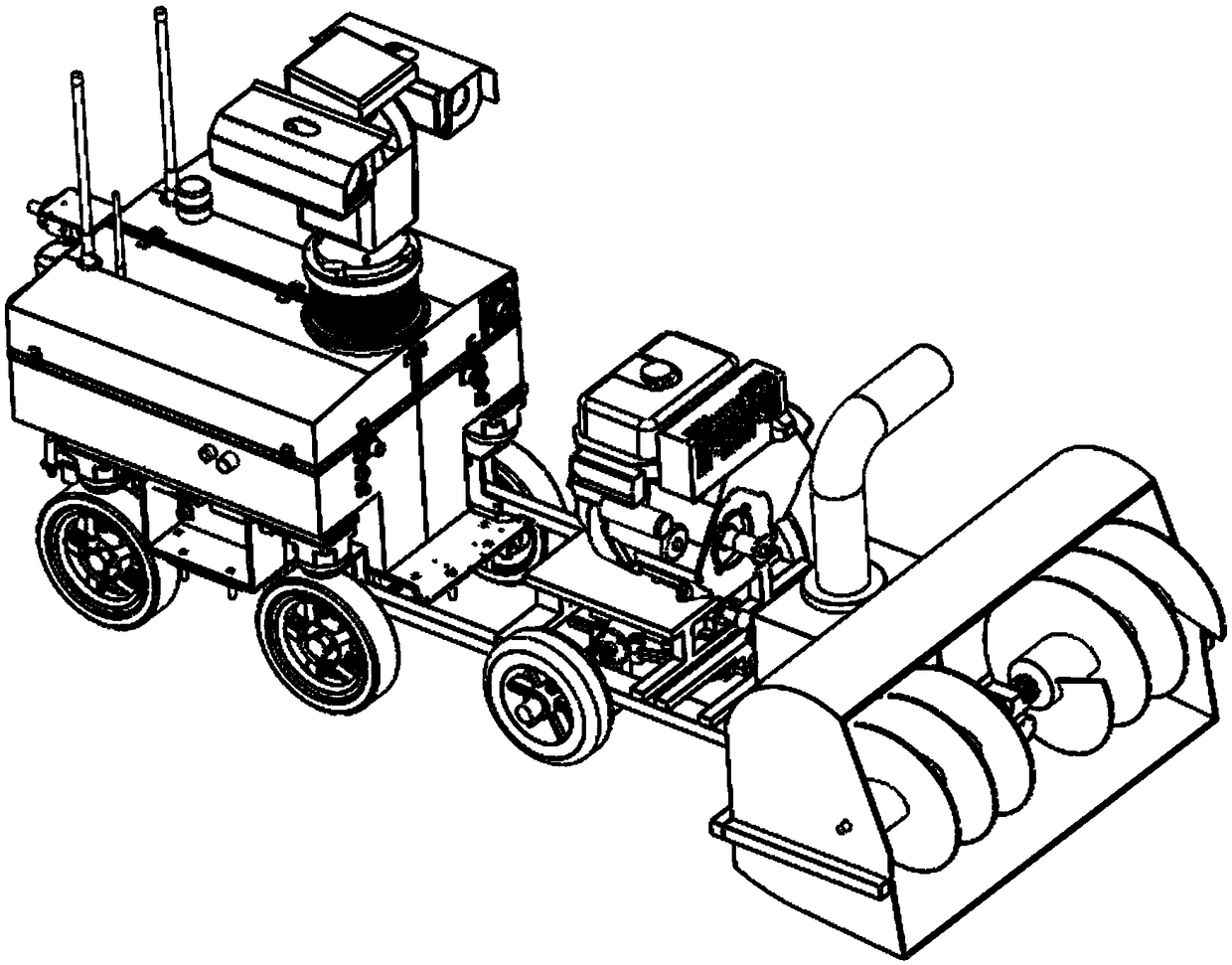

[0058] The substation inspection robot with snow removal tooling of the present invention includes a robot body 8 and a tooling part. The main body of the robot 8 passes through the support 7 and is connected to the front of the snow removal tool. The snow removal tool consists of the auger 1, the snow removal shovel 2, the snow throwing tube 3, the transmission system 4, the motor 5, the wheels 6, the support 7, the robot body 8, and the snow throwing wheel 9.

[0059] The fixed frame includes a bracket 7 and wheels 6. The snow removal mechanism is located at the front end of the bracket. The power unit is fixed at the middle of the bracket. The bottom of the middle of the bracket is equipped with wheels 6. The wheels 6 include driven wheels installed on both sides of the bottom and installed at the front end of the driven wheels. At the same time, the entire snow removal tool is fixed in front of the robot body 8 by the bracket 7.

[0060] Among them, the driven wheels are two w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com