Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Promote mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

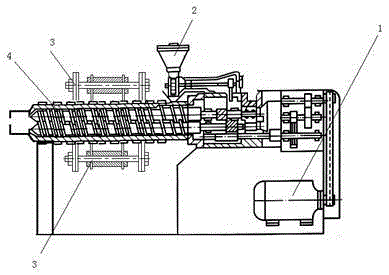

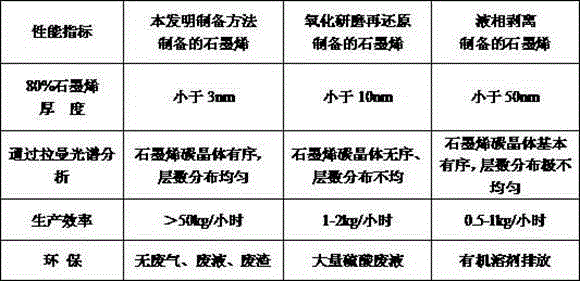

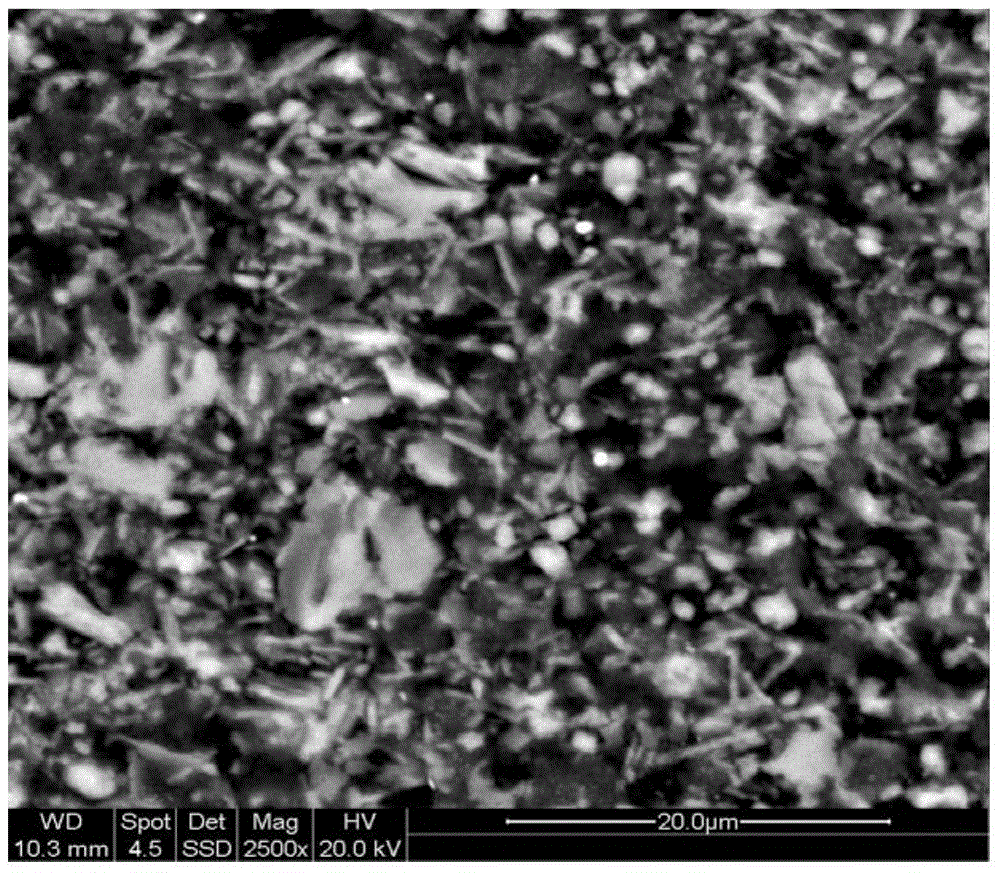

Method for preparing graphene through composite shear stress stripping of vibrating screw extruder

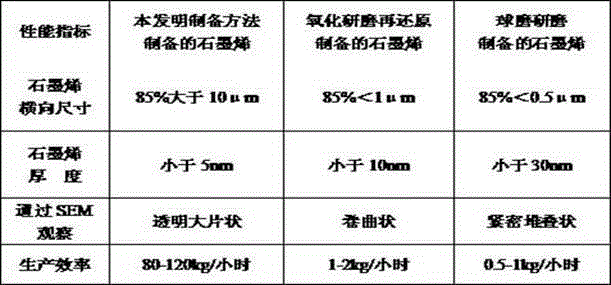

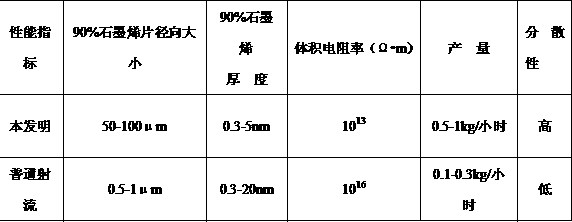

The invention provides a method for preparing graphene through composite shear stress stripping of a vibrating screw extruder, and belongs to the field of graphene materials. According to the method, an electromagnetic, ultrasonic and longitudinal mechanical vibration tensile force field is introduced into the extruder rotating at high speed, the vibration tensile force field periodically changes along with the time to enable the graphite interface to be tensioned, graphite becomes loosened under the action of a stripping agent, the graphite generates powerful shearing stripping through contact interfaces of meshing blocks of the extruder in a tensioned state, thinner graphene with the narrower thickness distribution range is obtained, and then rapid and efficient high-quality graphene preparation under the high-shearing action is achieved. The method has the advantages that the production cost of the high-quality graphene is significantly lowered, the preparation process is green and environmentally friendly, no exhaust gas or waste liquid or waste residue is generated, and scale production of the graphene is promoted.

Owner:ZHEJIANG ZHONGYANG SCREW MFG

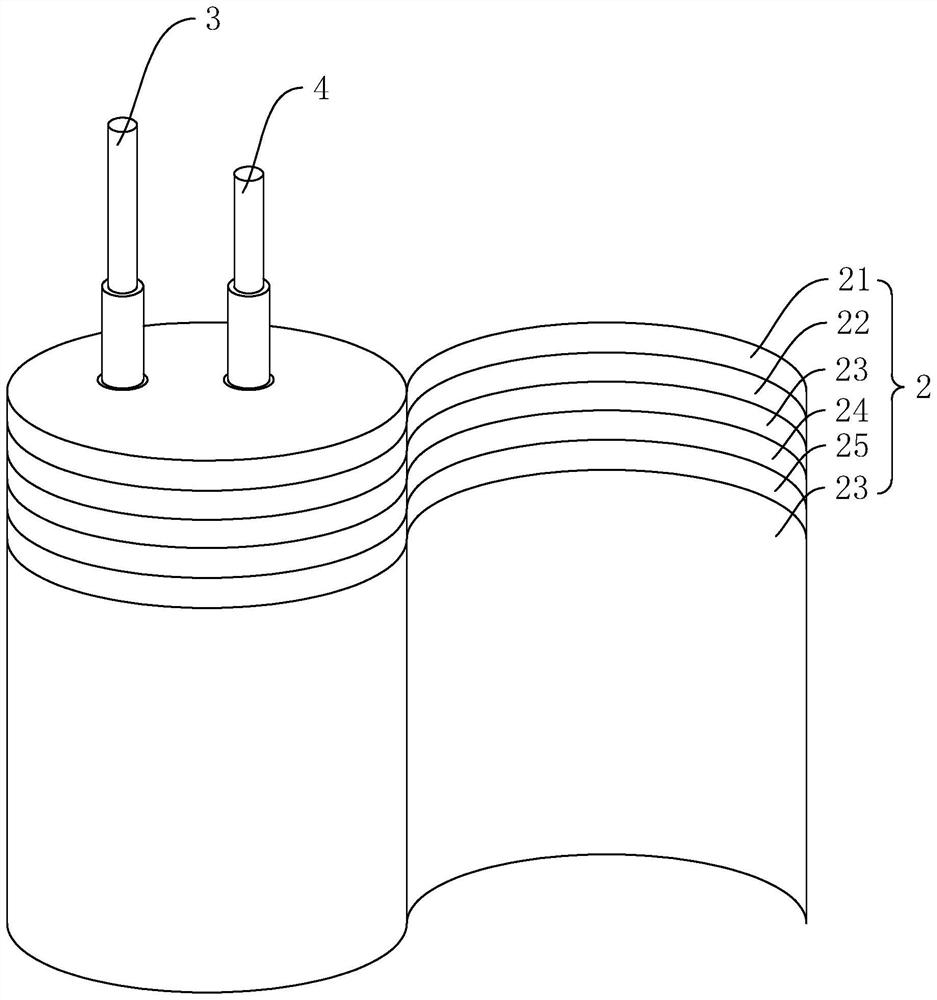

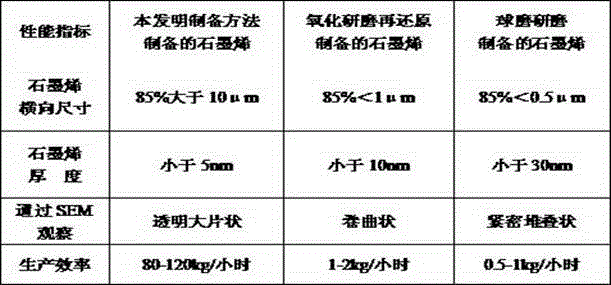

Method for preparing graphene from thermoplastic graphite material

The invention provides a method for preparing graphene from a thermoplastic graphite material, belonging to the field of graphene materials. According to the method, graphite is subjected to thermoplastic treatment, and a hydroxyl-terminated polymer is used for increasing the interlayer spacing of graphite and reducing the interlayer van der Waals force of the graphite, so that the graphite has thermoplastic flowability and flexibility when being processed in a screw extruder, the graphite is thinned through extending by virtue of the shearing stress generated by rotation of a screw, particularly the thinned graphite is sheared and directionally stripped by the screw under the strong shearing action of the screw after a polar high-molecular polymer and the hydroxyl-terminated polymer contained in the thermoplastic graphite are carbonized, and then, the graphene is obtained, so that a graphene layer structure is prevented from being damaged, the crystal lattice integrity of the graphene is better kept, and furthermore high-quality graphene with a large area is obtained. The method for preparing the graphene through carrying out thermoplastic treatment on the graphite and then stripping by using the screw extruder has wider industrial prospects and remarkable market application values and is suitable for large-scale production.

Owner:魏颖

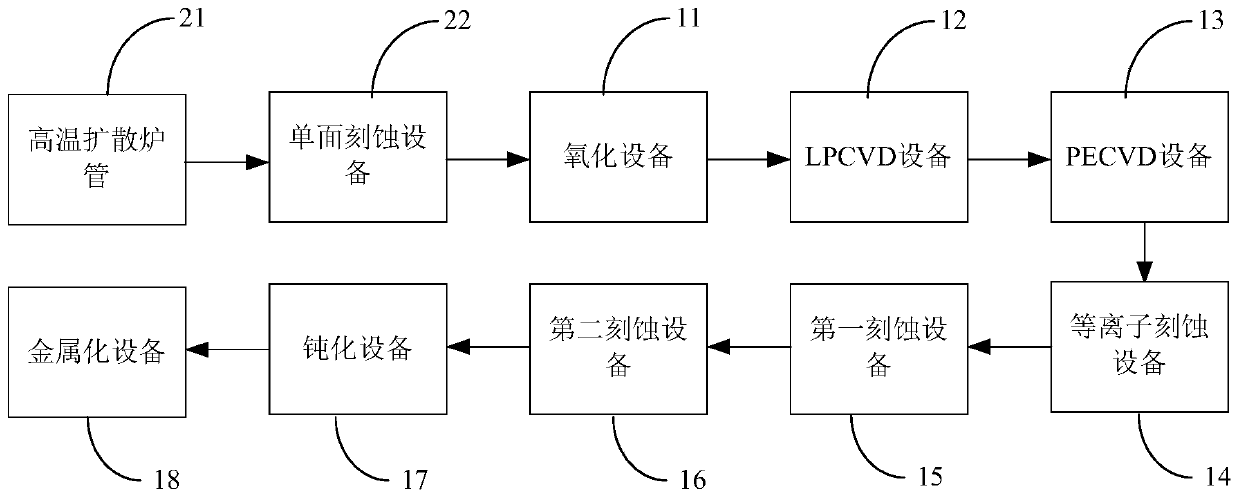

System and method for manufacturing N-type passivation contact battery

PendingCN109962126ASolve the problem of residual edgeSolve residual problemsFinal product manufactureSemiconductor devicesProduction lineMetallurgy

The technical scheme of the invention discloses a system and method for manufacturing an N-type passivation contact battery. The edge isolation technology is combined with PECVD, thereby solving the problem of front polycrystalline silicon thin film edge residue caused by deposition of an n+ polycrystalline silicon layer in an LPCVD method and deposition of a second mask layer in a PECVD method. The technical scheme can be compatible with a production line for conventionally manufacturing a P-type battery, and promotes the mass production promotion of the N-type passivation contact efficient batteries.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

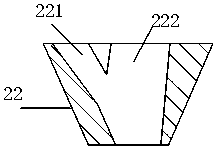

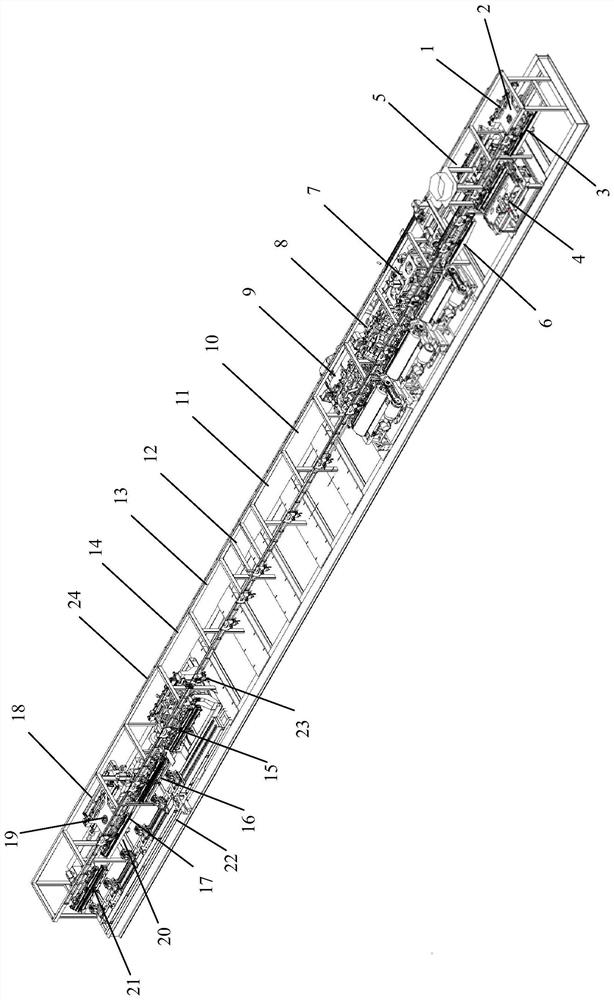

Full-automatic pitting and cutting method and equipment for fruits

PendingCN112120233AEasy to slide outIntact damageFruit stoningCleaning using liquidsTool bitReciprocating motion

The invention relates to a full-automatic pitting and cutting method and equipment for drupe fruits including apricots, plums and the like. The pitting and cutting method comprises the steps of fruitselection, cleaning, airing, peel scratching and pitting and cutting. The pitting and cutting equipment comprises a frame, a conveying mechanism, a feeding mechanism, a peel scratching mechanism, a pit rushing and cutting mechanism, a power mechanism, a discharging device and a self-cleaning device. The conveying mechanism is installed on the frame; a driving motor is controlled by a programmablelogic controller (PLC) to drive a conveying belt consisting of pitting and cutting trays to move forward; materials are borne and conveyed by the pitting and cutting trays to the feeding mechanism forpositioning; the peel scratching mechanism scratches peel; an air cylinder in the pit rushing and cutting mechanism drives a rushing rod and a tool bit to do reciprocating motion to complete pittingand slitting of the materials; and cut pulp slides out of a discharge port under the action of gravity and vibration, so that processing of the materials is completed. The self-cleaning device can clean key components including the rushing rod and the like after the equipment is used. By using the equipment, directional cutting and pitting of the fruits can be realized; processed pulp sections aresmooth and are small in damage; pits are clean; and qualified high-quality raw materials can be provided for follow-up processing.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

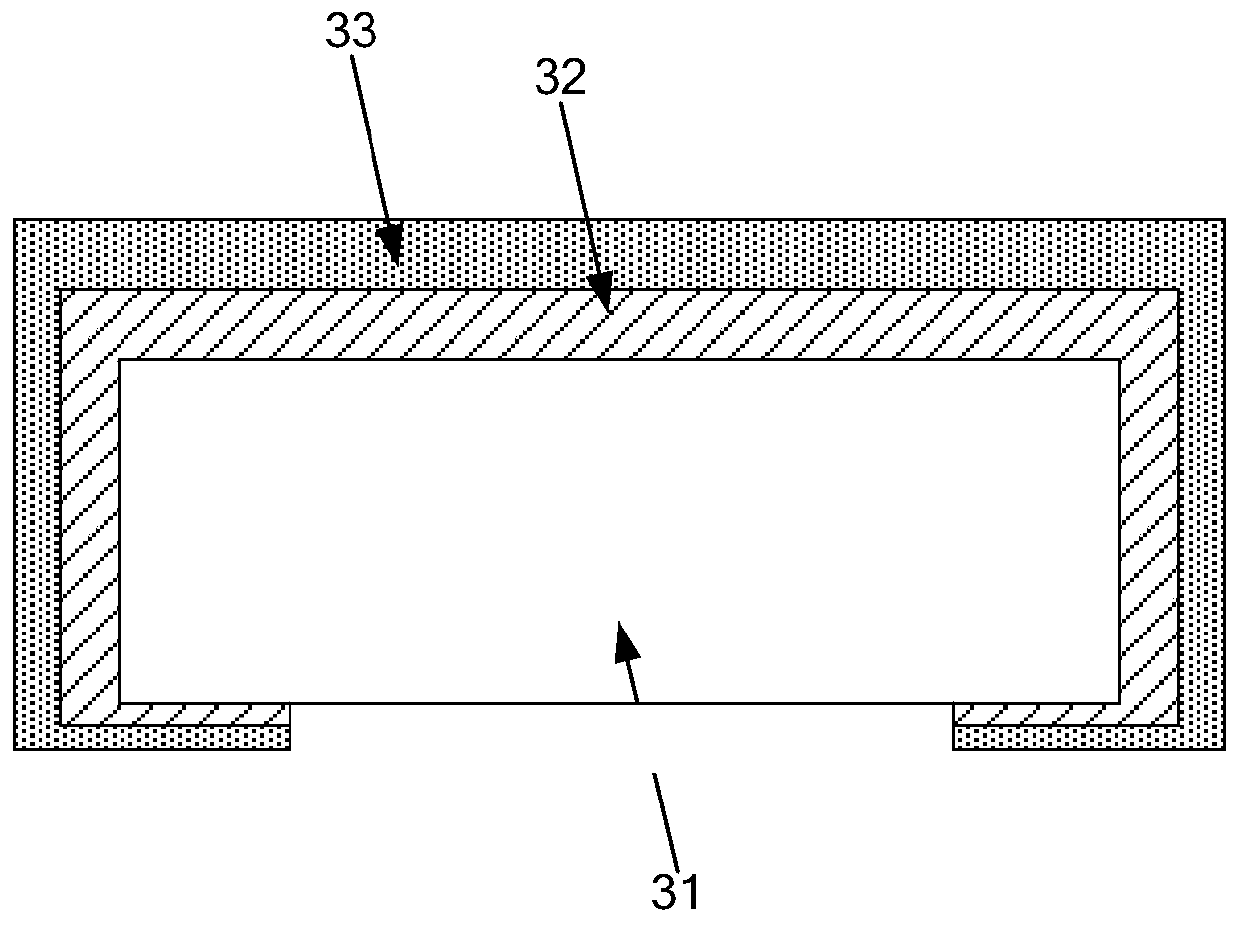

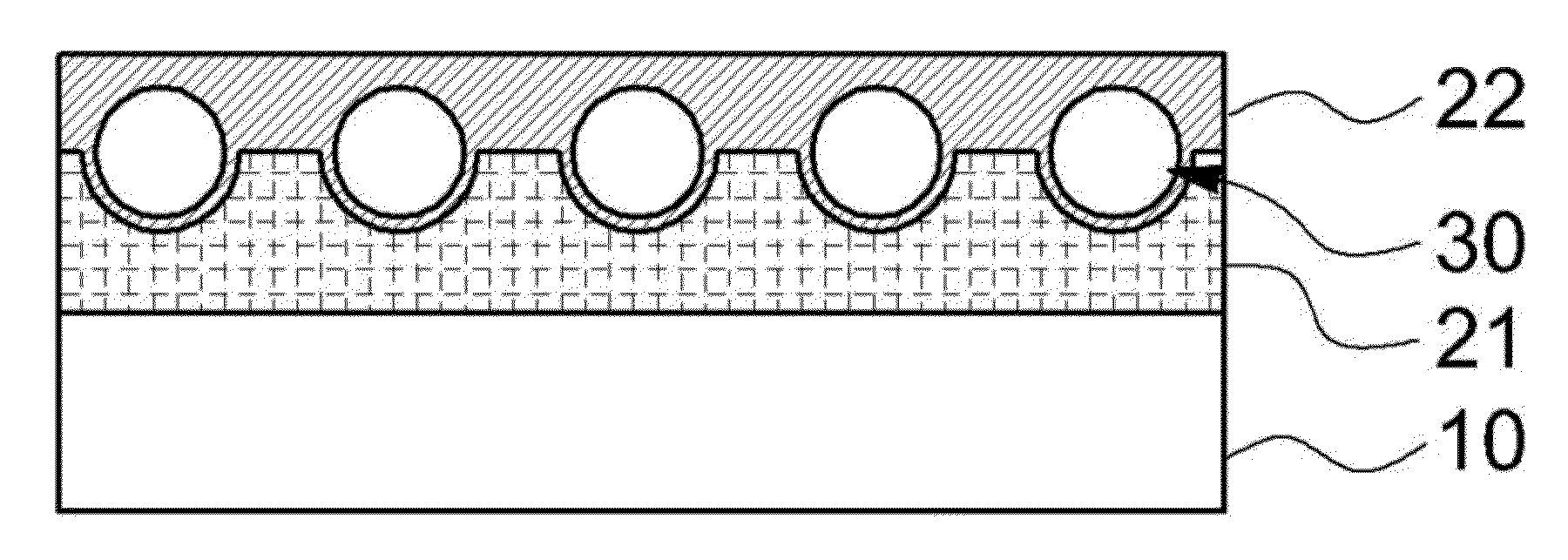

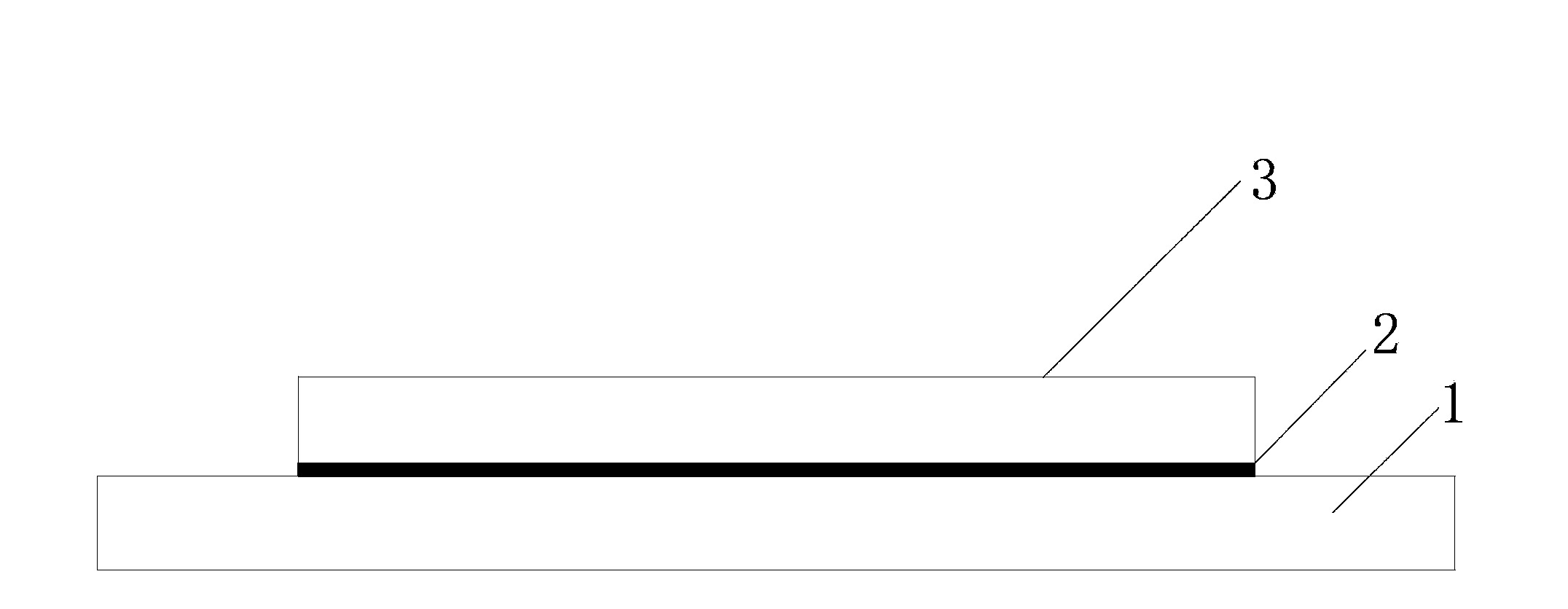

SUBSTRATE FOR AN ORGANIC LIGHT-EMITTING DEVICE AND METHOD FOR MANUFACTURING THE SAME (As Amended)

ActiveUS20130286659A1Light extraction efficiency can be improvedExcellent degree of planarizationFinal product manufactureSolid-state devicesOrganic light emitting deviceLight emitting device

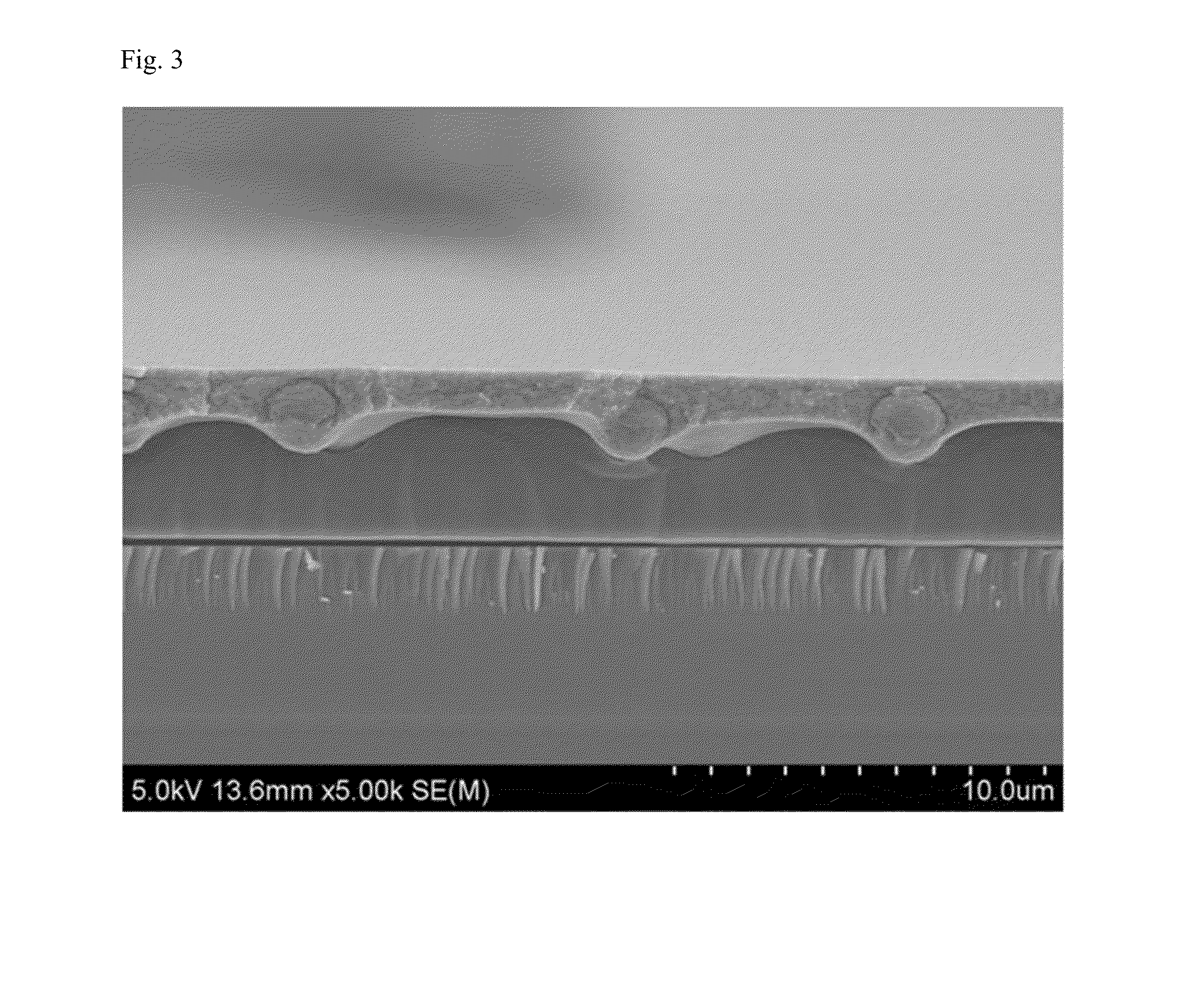

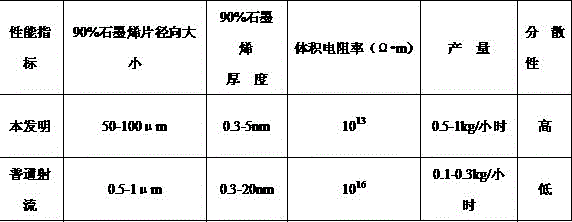

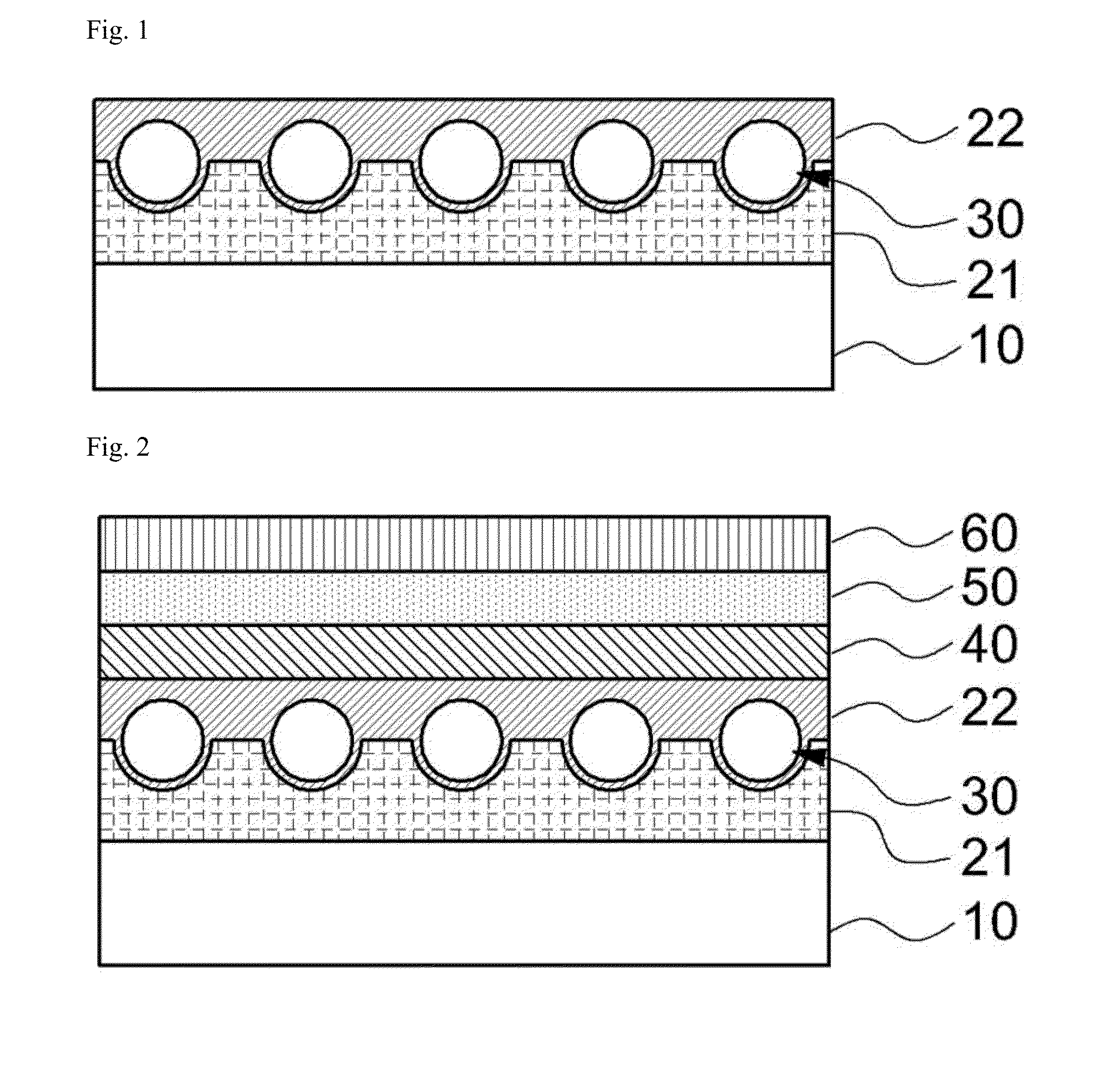

Provided is a substrate for an organic light emitting diode including a base substrate, a high refractive scattering layer formed on the base substrate, and having a scattering particle scattering light in a high refractive material, and an adhesive layer formed between the base substrate and the high refractive scattering layer to laminate the base substrate with the high refractive scattering layer, wherein the high refractive scattering layer has a structure in which the scattering particle is immersed in the high refractive material, an average thickness of the high refractive scattering layer is smaller than an average diameter of the scattering particle, a surface of the high refractive scattering layer laminated with the base substrate by the adhesive layer has unevenness formed by the scattering particle, the opposite surface of the high refractive scattering layer laminated with the base substrate by the adhesive layer has a planarized surface, and a method for manufacturing the same. The substrate may have an excellent degree of planarization and improved light extraction efficiency without degradation in performance of the diode, and low process and material costs and mass-production of the substrate may be easily achieved.

Owner:LG DISPLAY CO LTD

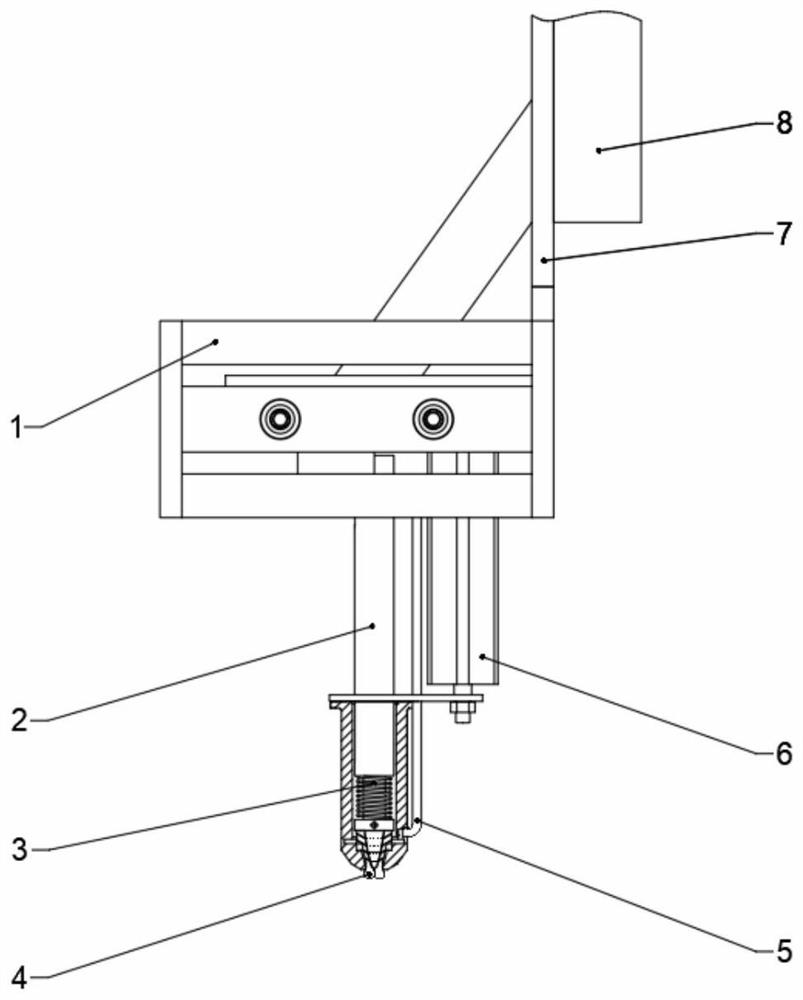

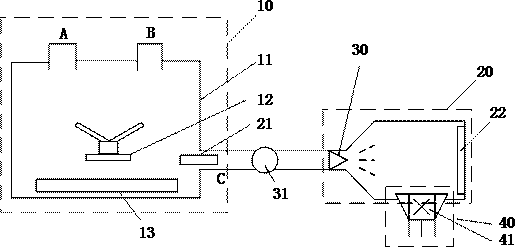

Jet device for continuous preparation of graphene and method thereof

The invention provides a jet device for continuous preparation of graphene and a method thereof. The method includes: mixing a graphite raw material with a medium solution, passing the mixture through a main nozzle for accelerated ejection, impacting and stripping the material with high speed air flow ejected by uniformly distributed convergence nozzles so as to obtain a mixed slurry, finally pumping the mixed slurry into a spray drying chamber by a super high pressure pump, conducting drying treatment to obtain a graphene material, and collecting graphene with a collecting mechanism. The method has low energy consumption, improves the graphene stripping efficiency, employs air flow and liquid flow to strip graphite, and does not introduce grinding medium pollution. The stripped material passes through a homogenizing valve with tiny gap at a high speed, and the generated strong shear force and friction force can homogenize and strip the material. Through further shearing and screening by the homogenizing valve, the graphene stripping efficiency is improved, and at the same time liquid is added in the graphite shear process to serve as the medium, the structure of graphene can be well maintained, thus obtaining high quality graphene, and promoting the mass production of graphene.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Substrate for an organic light-emitting device and method for manufacturing the same

ActiveUS20130284354A1Light extraction efficiency can be improvedExcellent degree of planarizationLamination ancillary operationsFinal product manufactureScattered lightAverage diameter

Provided is a substrate for an organic light emitting diode including a base substrate, a high refractive scattering layer formed on the base substrate, and having a scattering particle scattering light in a high refractive material, and an adhesive layer formed between the base substrate and the high refractive scattering layer to laminate the base substrate with the high refractive scattering layer, wherein the high refractive scattering layer has a structure in which the scattering particle is immersed in the high refractive material, an average thickness of the high refractive scattering layer is smaller than an average diameter of the scattering particle, a surface of the high refractive scattering layer laminated with the base substrate by the adhesive layer has unevenness formed by the scattering particle, the opposite surface of the high refractive scattering layer laminated with the base substrate by the adhesive layer has a planarized surface, and a method for manufacturing the same. The substrate may have an excellent degree of planarization and improved light extraction efficiency without degradation in performance of the diode, and low process and material costs and mass-production of the substrate may be easily achieved.

Owner:LG DISPLAY CO LTD

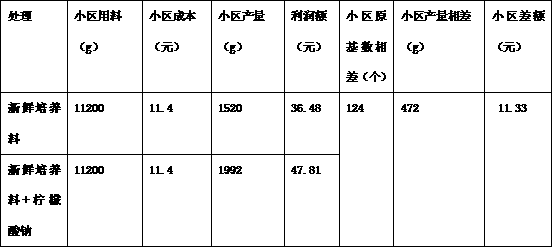

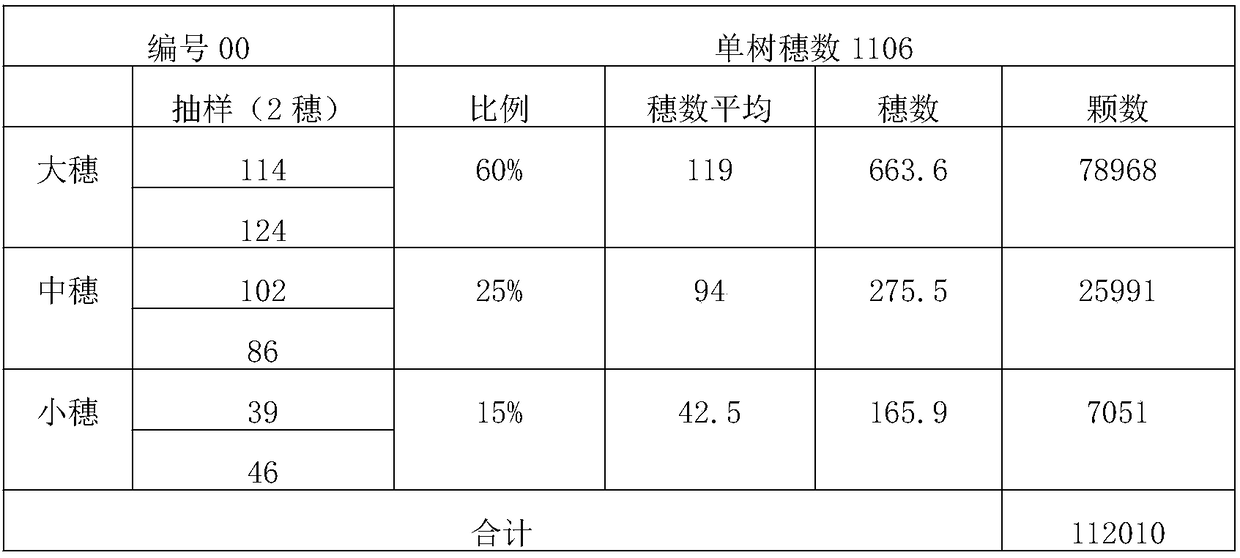

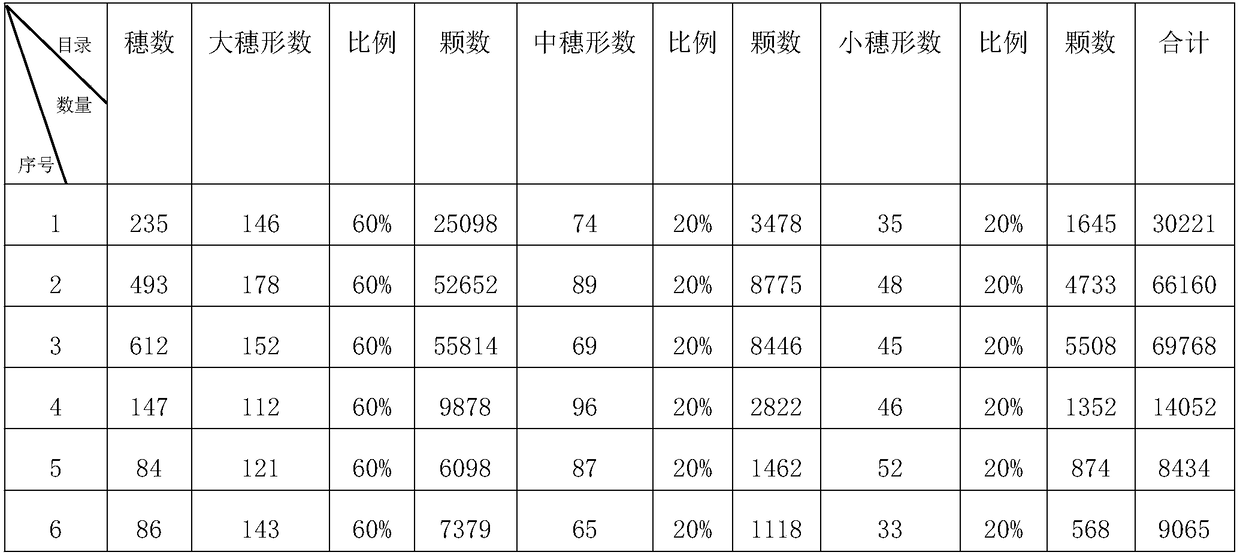

Volvaria volvacea cultivation method capable of promoting volvaria volvacea primordium to be differentiated

The invention relates to a volvaria volvacea cultivation method capable of promoting volvaria volvacea primordium to be differentiated, and in particular relates to a volvaria volvacea cultivation technology. The volvaria volvacea cultivation method comprises the following steps of: (1) soaking raw materials; (2) building and stacking cultivation materials and naturally carrying out stack retting and fermenting; (3) adding 110-120g of sodium citrate into every one hundred kilograms of stirred and wetted cultivation materials (a result is obtained by the trial test), so that the final water content of the cultivation materials is 65%-68%; (4) moving the fermented cultivation materials onto a bed frame, and covering by a thin film; (5) secondly fermenting the cultivation materials, and carrying out pasteurization; (6) inoculating; (7) managing cultivation; and (8) harvesting. The volvaria volvacea cultivation method is simple to use, and has the advantages that the differentiation of the primordium can be promoted, the quantity of the volvaria volvacea primordium can be increased, the number of the effective sporocarp can be increased, the yield per unit area can be improved by 31.05%, the contamination rate is low, the biologicalefficiency is high and the like, thereby being very suitable for the production of the volvaria volvacea, and convenient to practically popularize and use.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

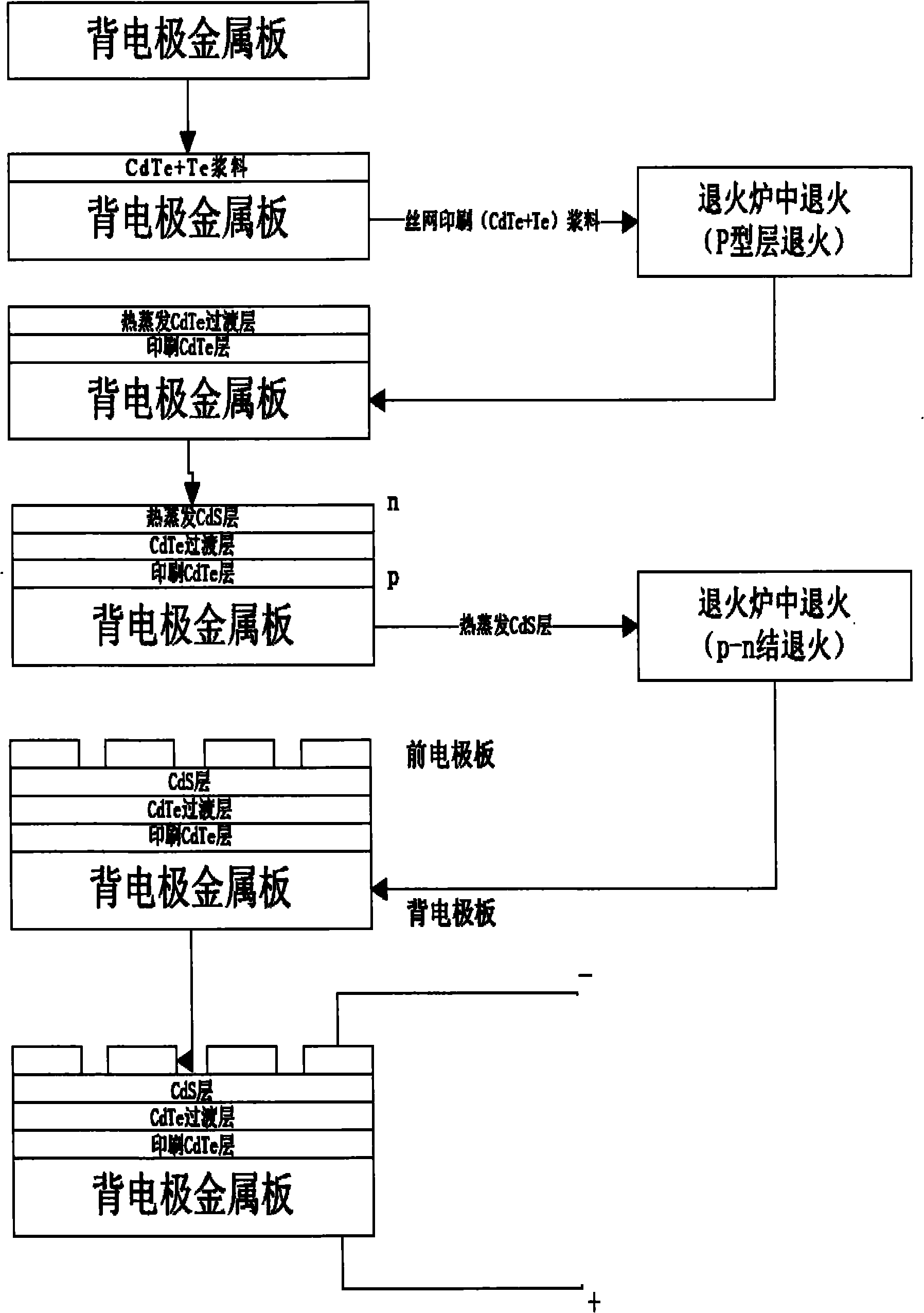

Manufacturing method of cadmium telluride film solar cell

ActiveCN101931031AReduce manufacturing costImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesScreen printingSlurry

The invention discloses a manufacturing method of a cadmium telluride film solar cell, which is characterized by comprising the following steps of: (1) by adopting a copper sheet or a stainless steel sheet as a back electrode of the cadmium telluride film solar cell, coating p (Positve) type cadmium telluride slurry on the metal sheet by a screen printing method to manufacture a p type cadmium telluride film; controlling the annealing temperature of the coated p type layer at 600 DEG C, wherein annealing time is 40 minutes; and then raising the temperature to 850 DEG C and preserving for 1 hour; (2) manufacturing an intermediate transition layer and an n (Negative) type cadmium telluride window layer on the p type cadmium telluride film to form a p-n junction; (3) evaporating or printing a comb-shaped front electrode on the cadmium telluride film of the window layer; and (4) wiring and welding the front and the back electrodes to finish the manufacture of the cadmium telluride film solar cell. The method is simple and convenient as well as easy for scale production, and can promote the scale production, largely reduce the cost and the price of the cadmium telluride film solar cell, and enhance the photovoltaic conversion efficiency of the cell.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

Complete device and method of preparing graphene by jet flow

ActiveCN107265444AFacilitate collision strippingImprove stripping efficiencyGrapheneDispersitySpray nozzle

The invention provides a complete device of preparing graphene by a jet flow. A graphite raw material and a medium solution are intensively mixed, primarily stripped and mixed by a high-mixing stirrer, and accelerated by an acceleration pump to enter a spray drying chamber from a jet nozzle; the materials are collided and stripped in the jet nozzle and ejected to enter the spray drying chamber; the solution is evaporated at the high temperature in the drying chamber; a graphene material is obtained; and finally, a collection mechanism collects the graphene. According to a method, the stripping and dispersion of the graphene are achieved in a one-stop manner; the stripping efficiency of the graphene is improved; a structure of the graphene is kept better, so that the high-quality graphene is obtained; at the same time, the problem of poor dispersity of the graphene is solved; and continuous and mass production of the graphene is promoted.

Owner:天津纳清新材料科技有限公司

Cutting treatment method for increasing polysaccharide content of malus halliana koehne

InactiveCN108419545AImprove physiological activityImprove self-protection performanceVegetative propogationGamma rayGinkgo

The invention belongs to the technical field of seedling cultivation and in particular relates to a cutting treatment method for increasing the polysaccharide content of malus halliana koehne. The cutting treatment method comprises the following specifically steps: (1) shearing branches from a biennial malus halliana koehne seed tree, and pruning the branches as cuttings in the middle ten days ofMarch, placing the cuttings into a freezer for variable-temperature freezing treatment, and taking out the cuttings to obtain pretreated cuttings; and (2) immersing the pretreated cuttings into ginkgoleaf juice, taking out the cuttings, draining water, carrying out irradiation treatment by using 60Co-gamma rays, immersing the cuttings into a treating agent, taking out the cuttings, draining water, and carrying out cuttage, wherein the treating agent is prepared from the following raw materials: soybean protein powder, sodium benzoate, lignosulfonate, fresh purslane, fresh cactus and water. Not only are the rooting and survival rates of the cuttings of the malus halliana koehne effectively increased, but also the polysaccharide content of the malus halliana koehne is greatly increased, andthe nutrition and health care values are increased.

Owner:枞阳县天腾生态农业有限公司

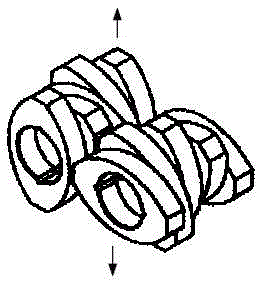

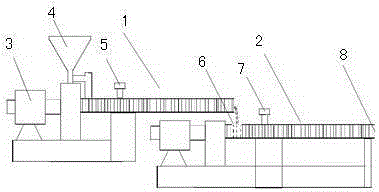

Apparatus and method for preparing graphene composite material through continuous grinding extrusion

The invention provides an apparatus and method for preparing a graphene composite material through continuous grinding extrusion. The method comprises the following steps: adding graphite and a plastic stripping agent to a screw extruder, and carrying out oriented shearing on above raw materials through a feeding mechanism formed by a screw in order to obtain a primary stripping product, conveying the primary stripping product to a stripping mechanism formed by a millstone group, and the primary stripping product undergoes secondary shearing striping through relative rotation of an internal millstone and an external millstone in order to obtain the graphene composite material. The method overcomes the defects of low stripping strength and thick stripping layers of graphene prepared through using screw stripping in the prior art, and the apparatus has the advantages of simple structure, improvement of the shearing strength, realization of continuous production of the graphene composite material, further obtaining of the graphene composite product with thin stripping thickness, avoiding of graphene aggregation, improvement of the quality of graphene, convenience for storage, and promotion of mass production of the graphene product.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Manufacturing method of mullite-boron nitride composite ceramic side sealing plate for thin-strip continuous casting

The invention discloses a manufacturing method of a mullite-boron nitride composite ceramic side sealing plate for thin-strip continuous casting. The manufacturing method comprises the following steps: (1) preparing precursor slurry, namely mixing hexagonal boron nitride powder, silicon dioxide powder and aluminum nitrate powder, then adding a slurry preparing solvent to prepare slurry, fully mixing the slurry uniformly, standing for a certain period of time, and finally washing and filtering the slurry by using distilled water of 100-130 DEG C to obtain a filter residue namely the precursor slurry; (2) preparing a mixed batch, namely mixing the precursor slurry, silicon nitride powder, aluminum nitride powder, titanium boride powder and diboron trioxide to prepare the mixed batch; (3) pretreating the mixed batch; and (4) performing hot pressed sintering. The side sealing plate prepared by the method disclosed by the invention is very high in strength, compactness and breaking strength, low in thermal conductivity and good in thermal shock resistance, so that the service life of the side sealing plate is prolonged, and the problem of continuous casting interruption is avoided; and moreover, the use stability of the ceramic side sealing plate is improved, the production cost of thin-strip continuous casting is reduced, and considerable economic benefits are achieved.

Owner:武汉钢铁有限公司

Method for cultivating piperis dahongpao

The invention discloses a method for cultivating piperis dahongpao. The method includes variety selection, land selection and soil preparation, piperis dahongpao cultivation, seedling strengthening, planting and field management. The method utilizes polar growth characteristics of plants, and combines the demand characteristics of different growth stages of the piperis dahongpao and the occurrencerule of pests and diseases, the control and the supply are combined, the production and demands are balanced, the soil is repaired, the labor is saved by adopting technologies, and convenience and efficiency increase are achieved. Compared with an existing piperis dahongpao planting technology, the yield is increased by 40%, and the picking cost of the piperis dahongpao is reduced by 80%. The method improves the profit of planting of the piperis dahongpao and promotes the large-scale production of the piperis dahongpao; for the biggest problem of the current piperis dahongpao planting technology, a lot of manpower is required for picking; according to the physiological characteristics of the growth of the piperis dahongpao, a planting method of the piperis dahongpao is changed, so that the harvesting of the piperis dahongpao is easier, and a large amount of labor cost can be saved.

Owner:刘全 +7

Scrub cream for preventing striae gravidarum and preparation method thereof

InactiveCN110123686APromote regenerationImprove newborn stretch marksCosmetic preparationsAntipyreticCentella asiatica extractCellulose

The invention relates to a scrub cream for preventing striae gravidarum and a preparation method thereof. The scrub cream is mainly prepared by Centella asiatica extract, opuntia streptacantha stem extract, palmitoyl pentapeptide-4, palmitoyl tetrapeptide-7, carnosine, copper tripeptide-1 and mixed cellulose scrub particles. The preparation method includes: pre-dispersing sodium hyaluronate and Carbomer into glycerin and part of butanediol to obtain a first mixture; evenly mixing the rest of butanediol, p-hydroxy phenyl ethyl ketone and hexanediol for dissolving to obtain a second mixture; homogenizing and stirring the first mixture and purified water; adding the second mixture, and stirring; adding the Centella asiatica extract, opuntia streptacantha stem extract, palmitoyl pentapeptide-4, palmitoyl tetrapeptide-7, carnosine and copper tripeptide-1, and stirring; adding sodium hydroxide, regulating pH, adding the cellulose scrub particles, and stirring to obtain the scrub cream. The striae gravidarum can be gently massaged with the scrub scream to remove epidermis cutin and allow substances such as polypeptides to be absorbed by the epidermis.

Owner:GUANGZHOU KEEN BIOTECH CO LTD

High-survival-rate cultivation method for tilia europaea

InactiveCN108307910AEasy to managePromote mass productionSewage/sludge fertilisersCultivating equipmentsTilia × europaeaPlant cultivation

The invention provides a high-survival-rate cultivation method for tilia europaea, and relates to the technical field of plant cultivation. The high-survival-rate cultivation method comprises the following steps: seed treatment, seeding land treatment, seeding, seedling transplanting, and post management after transplanting. The high-survival-rate cultivation method for the tilia europaea providedby the invention not only has simple management, saves labor and time, but also facilitates viewing application, and promotes large-scale production of tilia europaea roadside landscape trees.

Owner:WUHU OUBIAO AGRI DEV

Method for improving seedling lifting and transportation efficiency

InactiveCN109006149AStrong root developmentEasy to manageCultivating equipmentsForestryFertilizerWoven fabric

The invention provides a method for improving the seedling lifting and transportation efficiency, and belongs to the technical field of garden planting. The problems that in the existing seedling transplanting process, seedling lifting is slow, and the efficiency is low are solved; when seedlings are planted, according to the sizes of the seedlings, a proper root control bag is selected, a water-retaining agent, rooting powder and fertilizer are added, and the seedlings are planted in a non-woven fabric root control bag; the exterior of the root control bag is surrounded by root control devices to be protected; multiple planting pits with the depth being 1 / 3 of the height of the root control devices are dug in a nursery, the root control devices and the seedling are put into the planting pits, and the surroundings are filled with soil; after the seedlings are planted, the seedlings are subjected to fertilization and watering maintenance by adopting drip irrigation facilities; after theseedlings grow to need seedling lifting and transportation, the seedlings and the root control devices are taken out of the planting pits together; in the transportation process, the root control devices are taken down to be used next time, the root control bag and the seedlings are subjected car loading together, and a protection cover is additionally installed outside the root control bag. According to the method, seedling lifting is easy, and transportation is facilitated.

Owner:山西东创林业科技股份有限公司

Rapid determination method for current efficiency of Mg-Mn sacrificial anode material

InactiveCN113186534AQuick judgment of current efficiencyPromote mass productionMetallurgyHigh potential

The invention discloses a rapid determination method for current efficiency of a Mg-Mn sacrificial anode material, relates to a method for judging the current efficiency of a Mg sacrificial anode material, and aims to solve the technical problem that an existing method for judging the current efficiency of the Mg-Mn sacrificial anode material is slow. According to the method for rapidly detecting whether the current efficiency of the Mg-Mn sacrificial anode material is qualified or not, the current efficiency of the anode material is rapidly judged through a simple soaking test according to the macroscopic soaking corrosion morphology, the production efficiency is improved, and batch production of the high-potential Mg-Mn sacrificial anode material is promoted. According to the method, whether the current efficiency of the sacrificial anode material is qualified or not can be rapidly judged, and the error between the current efficiency result and the current efficiency result of a GB / T24488-2009 detection method is within + / -2%.

Owner:山西银光华盛镁业股份有限公司

Curing Process of Piezoelectric Ceramic Buzzer

ActiveCN102729577BFast curingEven by forceLamination ancillary operationsLaminationScreen printingPiezoelectric resonance

The present invention relates to a curing process for a piezoelectric ceramics buzzing sheet in a buzzer. According to the curing process, a metal sheet is placed on a sheet suction mold, the sheet suction mold adsorbs the metal sheet, and silk-screen printing is adopted to print an anaerobic glue onto the upper surface of the metal sheet; a piezoelectric resonance sheet is placed on the metal sheet, and is bonded on the metal sheet through the anaerobic glue; the metal sheet and the piezoelectric resonance sheet bonded on the metal sheet are removed from the sheet suction mold, and are packaged by adopting a vacuum package bag; the vacuum package bag filled with the metal sheet and the piezoelectric resonance sheet is placed in ultra-high hydrostatic hydraulic equipment to carry out pressing curing, wherein the pressure of ultra-high hydrostatic hydraulic pressure is more than or equal to 120 MPa, and a pressure keeping time is 3-5 minutes; and the vacuum package bag is removed from the ultra-high hydrostatic hydraulic equipment, and is unpacked, the metal sheet and the piezoelectric resonance sheet are firmly bonded, and the curing process is completed. According to the present invention, the force applying on the product is uniform, the bonding force is stable and reliable, the curing time is short, the production efficiency is improved, the product is not deformed, and the frequency consistency is good.

Owner:BESTAR HLDG

A method for preparing silicene film by mechanical exfoliation and application of silicene film

ActiveCN106554016BPromote mass productionImprove stabilityMaterial nanotechnologySolid-state devicesActive agentSolar battery

The invention discloses a silicene film prepared by mechanical peeling and the application of the obtained silicene film in batteries. The two-dimensional nanomaterials are physically covered on the passivated silicon surface of the metal film. After high-temperature treatment, the silicon element diffuses into the two-dimensional The interface between the nanomaterial and the metal film is lowered to room temperature, and the sample is dispersed in a solvent liquid with a surfactant. Polar molecules are very easy to enter the interface between the metal film and the substrate material, and the metal film and the substrate are increased by ultrasonic stirring. Material friction, peeling two-dimensional nanomaterials and silicene from silicon substrates to obtain silicene films. The present invention utilizes mechanical stripping to peel off the silicene thin layer in the liquid phase through physical action, which protects the physical properties of the silicene material, avoids the working environment of high vacuum and high-risk gas, and avoids highly toxic organic reactants The use of two-dimensional nanomaterials can be used repeatedly, which reduces the cost and has broad market application value in the field of solar cells.

Owner:日照东润有机硅股份有限公司

A jet device and method for continuously preparing graphene

Owner:CHENDU NEW KELI CHEM SCI CO LTD

A method for preparing graphene by composite shear stress exfoliation using vibrating screw extruder

The invention provides a method for preparing graphene through composite shear stress stripping of a vibrating screw extruder, and belongs to the field of graphene materials. According to the method, an electromagnetic, ultrasonic and longitudinal mechanical vibration tensile force field is introduced into the extruder rotating at high speed, the vibration tensile force field periodically changes along with the time to enable the graphite interface to be tensioned, graphite becomes loosened under the action of a stripping agent, the graphite generates powerful shearing stripping through contact interfaces of meshing blocks of the extruder in a tensioned state, thinner graphene with the narrower thickness distribution range is obtained, and then rapid and efficient high-quality graphene preparation under the high-shearing action is achieved. The method has the advantages that the production cost of the high-quality graphene is significantly lowered, the preparation process is green and environmentally friendly, no exhaust gas or waste liquid or waste residue is generated, and scale production of the graphene is promoted.

Owner:ZHEJIANG ZHONGYANG SCREW MFG

Special shape follow-up ultrasonic detection device for wall thickness of hollow blade and detection method thereof

PendingCN113983974AAchieve clamping positioningEfficient sprayingGrinding wheel securing apparatusUsing subsonic/sonic/ultrasonic vibration meansEngineeringUltrasonic testing

The invention discloses a special shape follow-up ultrasonic detectiondevice for the wall thickness of a hollow blade and a detection method thereof. A display frame is connected to one end of a probe connecting plate; the probe connecting plate is connected with a grinding head part on a machine tool or a robot through an L-shaped connecting block and a machine tool grinding head positioning block; an ultrasonic probe is connected to the probe connecting block; a probe shell and a porous flexible body are arranged on the periphery of the ultrasonic probe; relative movement between the ultrasonic probe and the probe shell is realized through an air cylinder; and a spring is arranged between a cavity of the ultrasonic probe and a probe needle, one end of a coupling agent conveying pipe is connected into a coupling agent container, the other end of the coupling agent conveying pipe is connected with the probe shell, a coupling agent is stored in the coupling agent conveying pipe, and the space between the probe and a blade is filled with the coupling agent through a porous flexible body. The production cost and the time cost of a hollow blade can be effectively reduced, the development of the hollow blade process is further promoted, and the batch production of a hollow blade is promoted.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION +1

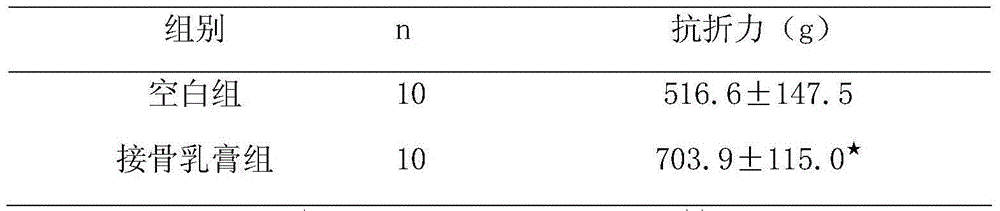

Active extract for promoting fracture healing and application of active extract

InactiveCN104857495AAccelerate hematoma organization and absorptionPromote local blood circulationSkeletal disorderPlant ingredientsOsseous CellBlood circulation

The invention discloses an active extract for promoting fracture healing and application of the active extract. The active extract is prepared from the following raw traditional Chinese medicinal materials by weight: 18 to 30 parts of henry clematis root, 40 to 60 parts of rhizoma zingiberis, 18 to 30 parts of beautiful millettia root, 20 to 30 parts of jakaranda and 1 to 2 parts of asafoetida. The active extract can be used for accelerating local hematoma organization and absorption of a fracture, improving local blood circulation, promoting osteoblast multiplication, and accelerating osteotylus filling and bone trabeculation, thereby significantly accelerating fracture healing.

Owner:强红枫

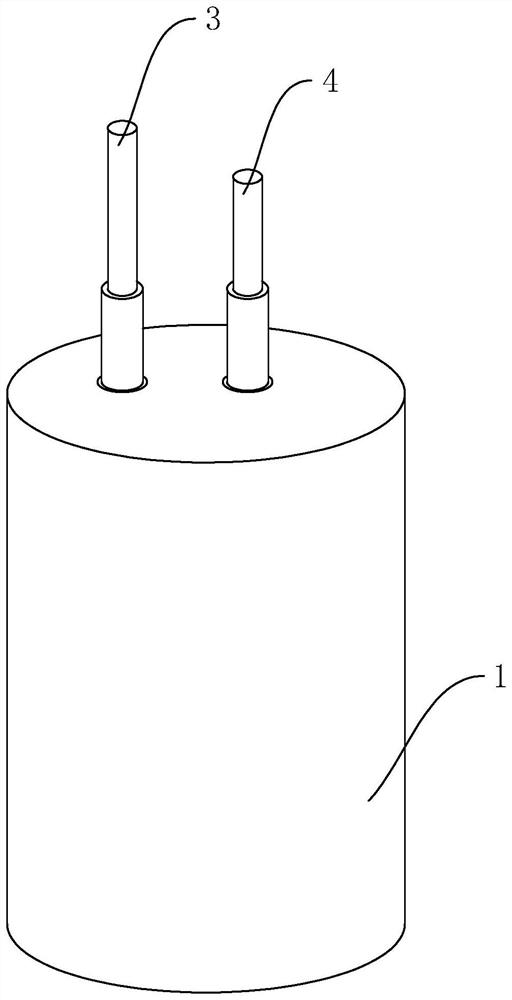

Electrode slurry for paper-based supercapacitor, paper-based electrode, preparation method and application

ActiveCN114284075ALarge specific surface areaHigh bonding strengthHybrid capacitor electrodesHybrid/EDL manufactureFiberSupercapacitor

The invention relates to the field of paper-based supercapacitors, and particularly discloses electrode slurry for a paper-based supercapacitor, a paper-based electrode, a preparation method and application. The electrode slurry is composed of a solvent and a solute dissolved in the solvent, and the weight of the solvent is 1.5-2 times that of the solute; the solute comprises the following components in percentage by weight: 85%-95% of an active electrode material, 0.5%-4.5% of a binder, 0.1%-5% of a proppant and 0.1%-8% of a conductive agent; the paper-based electrode comprises a paper substrate, the surface of the paper substrate is coated with the electrode slurry, the paper substrate is made of a long-fiber non-woven paper material, and the thickness of the paper substrate is 50-80 microns. The adhesive force between the electrode slurry and a paper substrate is good, the bonding strength is high, the electrode slurry is not prone to falling off, the electrode slurry is suitable for large-scale production of winding type super capacitors, the prepared paper-based electrode is excellent in conductivity, the surface of the paper-based electrode is provided with a plurality of micropore structures, and the super capacitor has a higher capacity value.

Owner:SHENZHEN JIANGHAO ELECTRON

Chinese medicine extract with function of reducing blood-sugar and preparing method

InactiveCN100361674CNo toxicityNo pollution in the processMetabolism disorderCarbohydrate active ingredientsAlkaloidIon-exchange resin

The present invention relates to a Chinese medicine extract with action of reducing blood sugar. It is composed of polysaccharides, flavones and alkaloids obtained by separating and extracting mulberry leaf, mulberry twig and mulberry root bark. Their contents respectively are 24-27%, 53-61% and 15-20%. Said invention also provides the concrete steps of the above-mentioned separation and extraction process.

Owner:原爱红 +1

Automatic production detection system and method for grinding and polishing machine

ActiveCN112809494AShorten working timeShorten production timePolishing machinesSpherical surface grinding machinesControl systemProcess engineering

The invention discloses an automatic production detection system and method for a grinding and polishing machine. The system comprises a powder feeding heating unit, a feeding and discharging unit, a cooling unit, an AB face grinding and polishing unit and a switching system which are sequentially arranged and connected with a control system, each station is provided with a conveying mechanism and a detection device, and each detection device is connected to the control system. Full-automatic conveying, machining and detecting of products are achieved through the control system, the products are machined from a feeding device of the feeding and discharging unit through each station till a discharging device completes operation, and meanwhile a control method of the system is further introduced. The system has the advantages of being convenient to operate, safe, reliable, high in working efficiency and good in product quality.

Owner:抚州市晟邦科技有限公司

A kind of method that prepares graphene by thermal plasticization graphite material

The invention provides a method for preparing graphene from a thermoplastic graphite material, belonging to the field of graphene materials. According to the method, graphite is subjected to thermoplastic treatment, and a hydroxyl-terminated polymer is used for increasing the interlayer spacing of graphite and reducing the interlayer van der Waals force of the graphite, so that the graphite has thermoplastic flowability and flexibility when being processed in a screw extruder, the graphite is thinned through extending by virtue of the shearing stress generated by rotation of a screw, particularly the thinned graphite is sheared and directionally stripped by the screw under the strong shearing action of the screw after a polar high-molecular polymer and the hydroxyl-terminated polymer contained in the thermoplastic graphite are carbonized, and then, the graphene is obtained, so that a graphene layer structure is prevented from being damaged, the crystal lattice integrity of the graphene is better kept, and furthermore high-quality graphene with a large area is obtained. The method for preparing the graphene through carrying out thermoplastic treatment on the graphite and then stripping by using the screw extruder has wider industrial prospects and remarkable market application values and is suitable for large-scale production.

Owner:魏颖

A kind of complete device and method for preparing graphene using jet

ActiveCN107265444BFacilitate collision strippingImprove stripping efficiencyGrapheneDispersityGraphite

The invention provides a complete device of preparing graphene by a jet flow. A graphite raw material and a medium solution are intensively mixed, primarily stripped and mixed by a high-mixing stirrer, and accelerated by an acceleration pump to enter a spray drying chamber from a jet nozzle; the materials are collided and stripped in the jet nozzle and ejected to enter the spray drying chamber; the solution is evaporated at the high temperature in the drying chamber; a graphene material is obtained; and finally, a collection mechanism collects the graphene. According to a method, the stripping and dispersion of the graphene are achieved in a one-stop manner; the stripping efficiency of the graphene is improved; a structure of the graphene is kept better, so that the high-quality graphene is obtained; at the same time, the problem of poor dispersity of the graphene is solved; and continuous and mass production of the graphene is promoted.

Owner:天津纳清新材料科技有限公司

Manufacturing method of mullite-boron nitride composite ceramic side sealing plate for thin strip continuous casting

The invention discloses a manufacturing method of a mullite-boron nitride composite ceramic side sealing plate for thin-strip continuous casting. The manufacturing method comprises the following steps: (1) preparing precursor slurry, namely mixing hexagonal boron nitride powder, silicon dioxide powder and aluminum nitrate powder, then adding a slurry preparing solvent to prepare slurry, fully mixing the slurry uniformly, standing for a certain period of time, and finally washing and filtering the slurry by using distilled water of 100-130 DEG C to obtain a filter residue namely the precursor slurry; (2) preparing a mixed batch, namely mixing the precursor slurry, silicon nitride powder, aluminum nitride powder, titanium boride powder and diboron trioxide to prepare the mixed batch; (3) pretreating the mixed batch; and (4) performing hot pressed sintering. The side sealing plate prepared by the method disclosed by the invention is very high in strength, compactness and breaking strength, low in thermal conductivity and good in thermal shock resistance, so that the service life of the side sealing plate is prolonged, and the problem of continuous casting interruption is avoided; and moreover, the use stability of the ceramic side sealing plate is improved, the production cost of thin-strip continuous casting is reduced, and considerable economic benefits are achieved.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com