A jet device and method for continuously preparing graphene

A jet device, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of high energy consumption, long production cycle and difficulty in ultra-fine jet crushing, and achieve environmental friendliness, Improved peeling efficiency and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

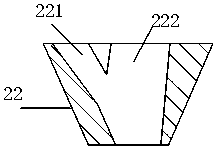

[0036] Such as figure 1 As shown, a jet device for continuous preparation of graphene in the present invention is characterized by comprising: a mixing mechanism 10, consisting of a first body 11, a high-mix agitator 12, and a feed nozzle A arranged on the body And B, the discharge nozzle C; the nozzle crushing mechanism 20 includes a second body 21 connected with the first body, a main nozzle 22, and 4 uniformly distributed converging nozzles 23 with an angle of 60° to the vertical And a high-pressure water jet nozzle 24 arranged at the bottom of the second body to spray into the second body, an ultrasonic probe 25 is arranged at the bottom of the second body, and a homogenization valve 26 is arranged at the end of the nozzle crushing mechanism The gap size of the homogenization valve is 0.5 mm; the spray drying chamber 30 is provided with an acceleration pump 31 between the spray drying chamber 30 and the nozzle crushing mechanism 20, and the spray drying chamber is provided w...

Embodiment 2

[0042] Such as figure 1 As shown, a jet device for continuous preparation of graphene in the present invention is characterized by comprising: a mixing mechanism 10, consisting of a first body 11, a high-mix agitator 12, and a feed nozzle A arranged on the body And B, the discharge nozzle C; the nozzle crushing mechanism 20, including the second body 21 connected with the first body, the main nozzle 22, and 6 uniformly distributed converging nozzles 23 with an angle of 60° to the vertical And a high-pressure water jet nozzle 24 arranged at the bottom of the second body to spray into the second body, an ultrasonic probe 25 is arranged at the bottom of the second body, and a homogenization valve 26 is arranged at the end of the nozzle crushing mechanism , The gap size of the homogenization valve is 0.6 mm; the spray drying chamber 30 is provided with an acceleration pump 31 between the spray drying chamber 30 and the nozzle crushing mechanism 20, and the spray drying chamber is pr...

Embodiment 3

[0048] Such as figure 1 As shown, a jet device for continuous preparation of graphene in the present invention is characterized by comprising: a mixing mechanism 10, consisting of a first body 11, a high-mix agitator 12, and a feed nozzle A arranged on the body And B, the discharge nozzle C; the nozzle crushing mechanism 20 includes a second body 21 connected with the first body, a main nozzle 22, and 8 uniformly distributed converging nozzles 23 with an angle of 70° to the vertical And a high-pressure water jet nozzle 24 arranged at the bottom of the second body to spray into the inside of the second body, two ultrasonic probes 25 are arranged at the bottom of the second body, and two homogenization valves 26 are arranged at the end of the nozzle crushing mechanism , The gap size of the homogenization valve is 1.0 mm; the spray drying chamber 30 is provided with an acceleration pump 31 between the spray drying chamber 30 and the nozzle crushing mechanism 20, and the spray dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com