Special shape follow-up ultrasonic detection device for wall thickness of hollow blade and detection method thereof

A hollow blade, ultrasonic detection technology, applied in measuring devices, devices for fixing grinding wheels, using ultrasonic/sonic/infrasonic waves, etc., can solve problems such as limiting mass production, reduce production costs and time costs, improve productivity, and solve Inaccurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

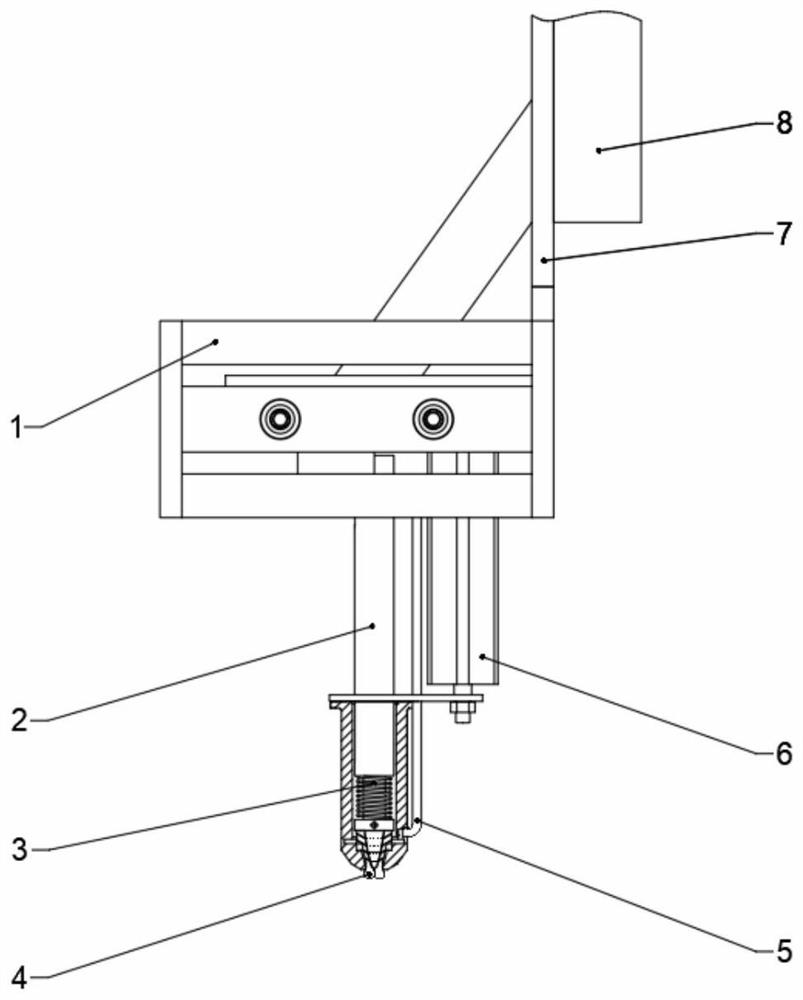

[0040] like Figure 1-7 A hollow blade wall thickness conformal ultrasonic detection device is shown, including a display stand 1, an ultrasonic probe 2, a probe shell 3, a porous flexible body 4, a coupling agent delivery pipe 5, a cylinder 6, an L-shaped connecting block 7, a machine tool grinder Head positioning block 8, probe connecting plate 9 and probe connecting block 10;

[0041] The display frame 1 is connected to one end of the probe connecting plate 9;

[0042] The probe connecting plate 9 is connected with the machine tool grinding head 13 or the grinding head part on the robot through the L-shaped connecting block 7 and the machine tool grinding head positioning block 8;

[0043] The ultrasonic probe 2 is connected to the probe connection block 10;

[0044] The probe shell 3 and the porous flexible body 4 are arranged on the periphery of the ultrasonic probe 2, and the porous flexible body 4 is clamped under the probe shell 3 and covers the front end of the ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com