Bolt pre-processing assembly

A bolt and assembly technology, which is applied in the field of bolt pre-processing assembly, can solve the problems of high hidden dangers in operation safety, high labor intensity of staff, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below through specific examples.

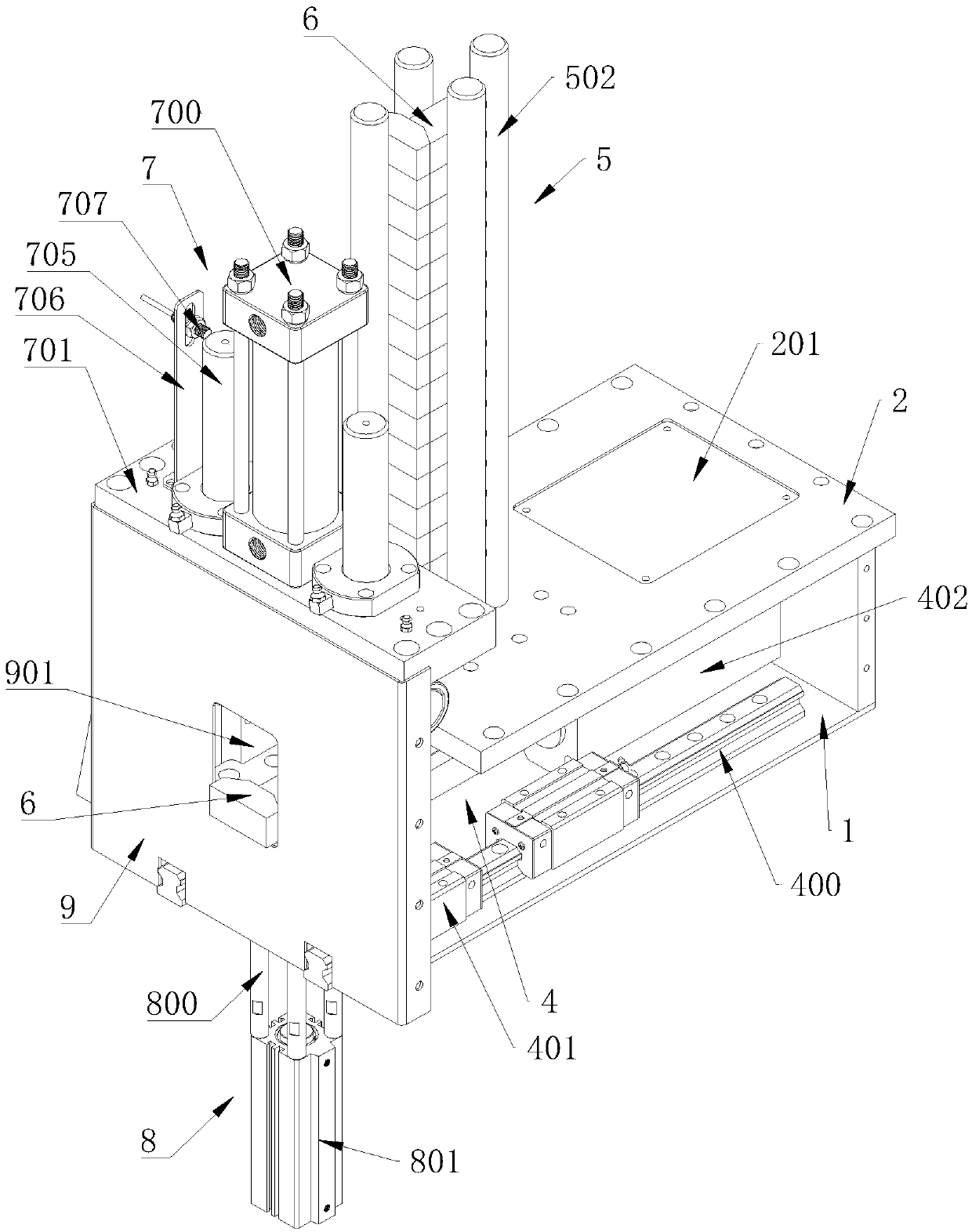

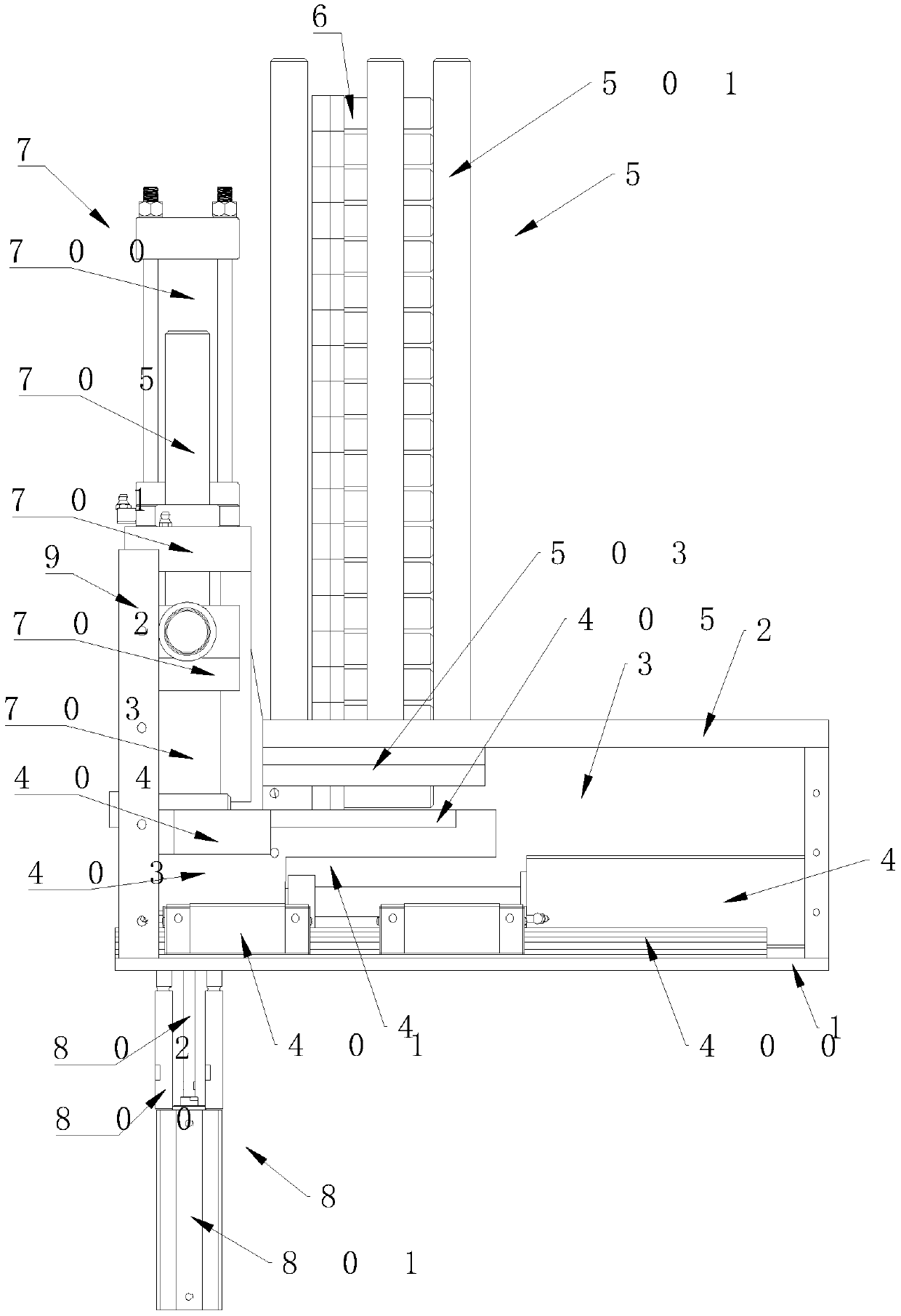

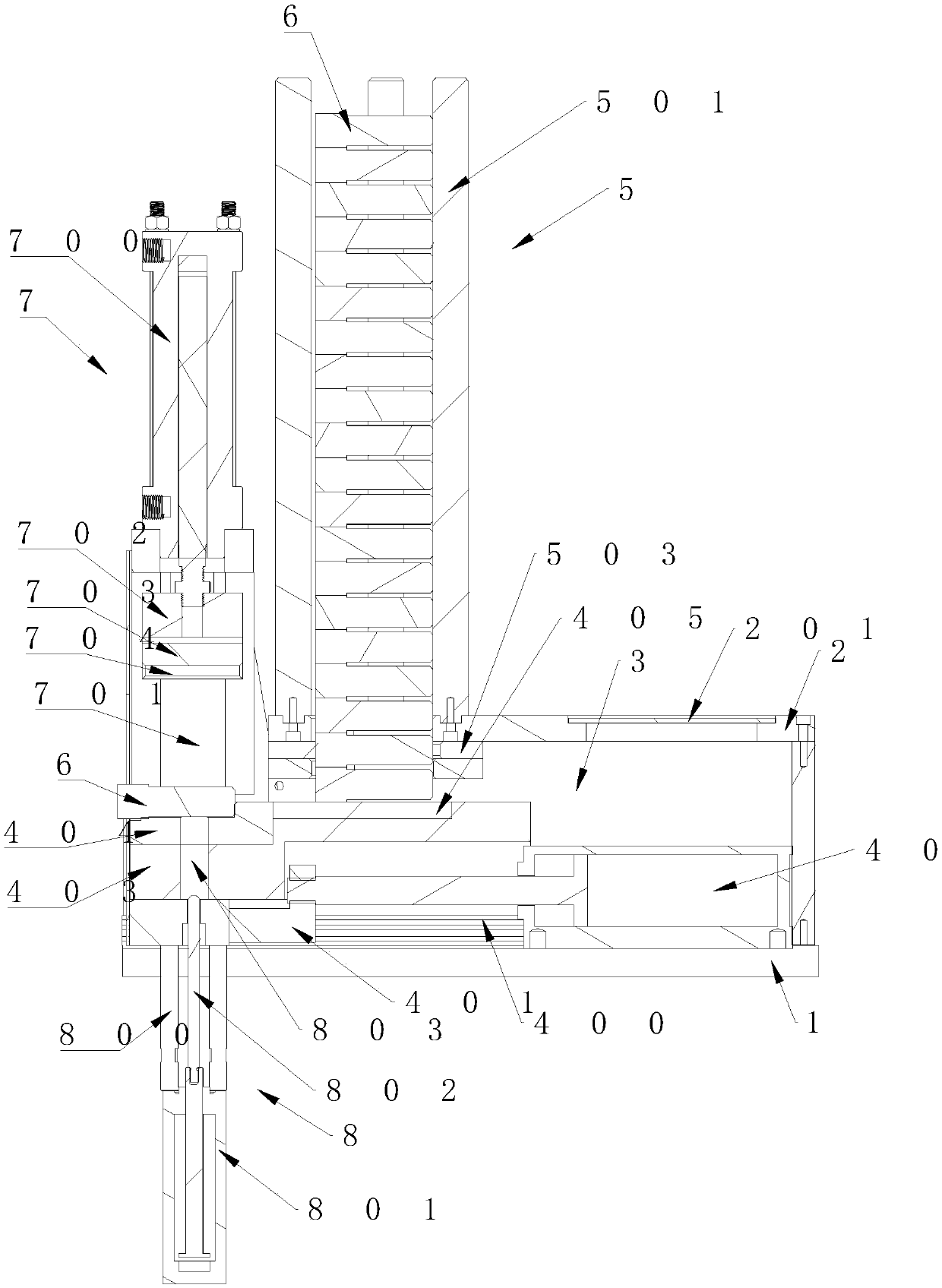

[0041] Such as Figure 1 to Figure 4 Commonly shown, a bolt pre-processing assembly includes an installation body 1, a support body 2 is provided on the installation body 1, and an installation cavity 3 is provided between the support body 2 and the installation body 1, and is located in the installation cavity A pusher mechanism 4 is slidingly installed on the installation body 1 inside 3; a bolt guide mechanism 5 communicating with the installation cavity 3 is provided on the support body 2; a clamping mechanism is provided on the installation body 1 at one end of the support body 2 7. The clamping mechanism 7 is arranged on the pushing direction of the pushing mechanism 4; the pushing mechanism 4 is provided with a pushing mechanism 8 for pushing the bolts pushed by the pushing mechanism 4, and the pushing mechanism 8 and The clamping mechanism 7 is distributed on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com