High-density three-dimensional integrated spiral inductor based on mutual connection of silicon through holes

An integrated spiral, high-density technology, applied in the direction of inductors, fixed inductors, transformer/inductor coils/windings/connections, etc., can solve the problem of increased process cost and difficulty, no improvement in energy storage efficiency, increased size integration and Difficulty in miniaturization and other issues, to achieve the effect of high chip utilization, low cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

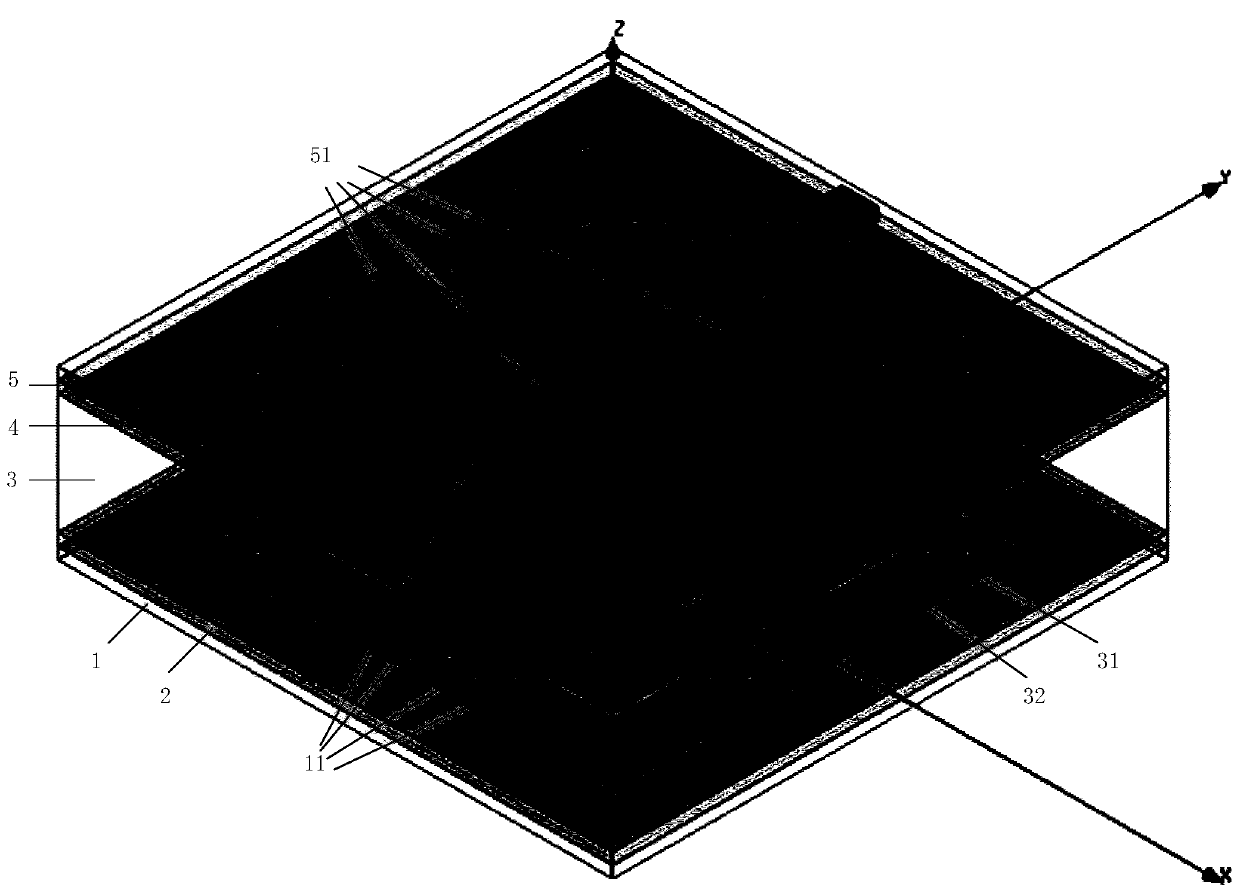

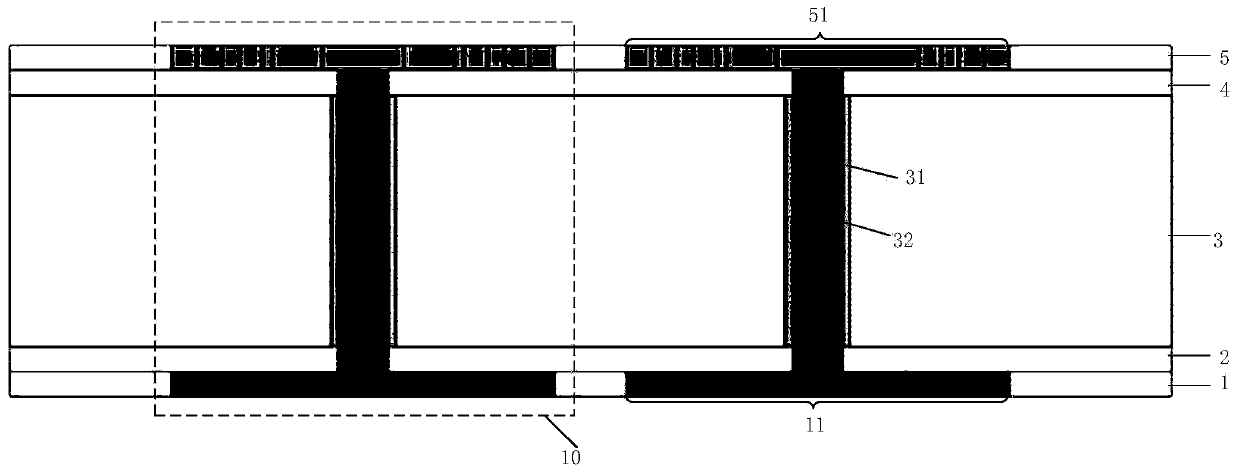

[0036] See figure 1 and figure 2 , figure 1 A schematic structural diagram of a high-density three-dimensional integrated spiral inductor based on through-silicon via interconnection provided by an embodiment of the present invention, figure 2 A cross-sectional view of a high-density three-dimensional integrated spiral inductor based on through-silicon via interconnection provided for an embodiment of the present invention, including: a first metal layer 1 including several first spiral inductors 11; a first dielectric layer 2, Located on the first metal layer 1; the semiconductor substrate 3 is located on the first dielectric layer 2, and a plurality of through holes are arranged in the semiconductor substrate 3, and a dielectric ring 31 and a metal column 32 are arranged in the through holes, and the dielectric ring 31 is located on the Between the metal pillar 32 and the semiconductor substrate 3; the second dielectric layer 4 is located on the semiconductor substrate 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com