Tray grabbing mechanism of bread tray collecting machine and bread tray collecting machine

A technology for grabbing mechanisms and pallets, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of inaccurate position correspondence of suction cups, influence on pallet grabbing and recycling, inconvenience, etc., and improve the gripping performance of suction cups , Improving the grasping accuracy and improving the effect of grasping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

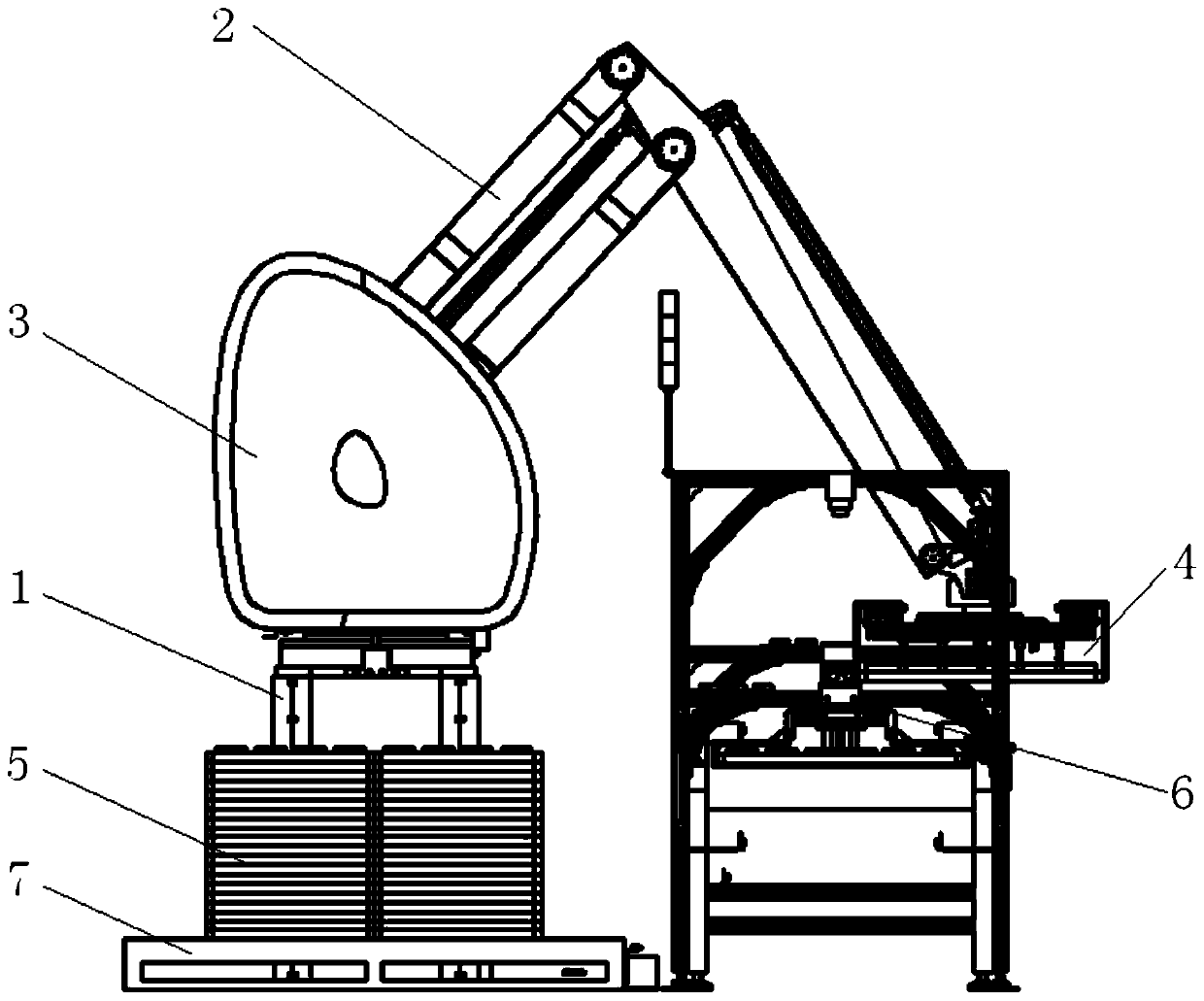

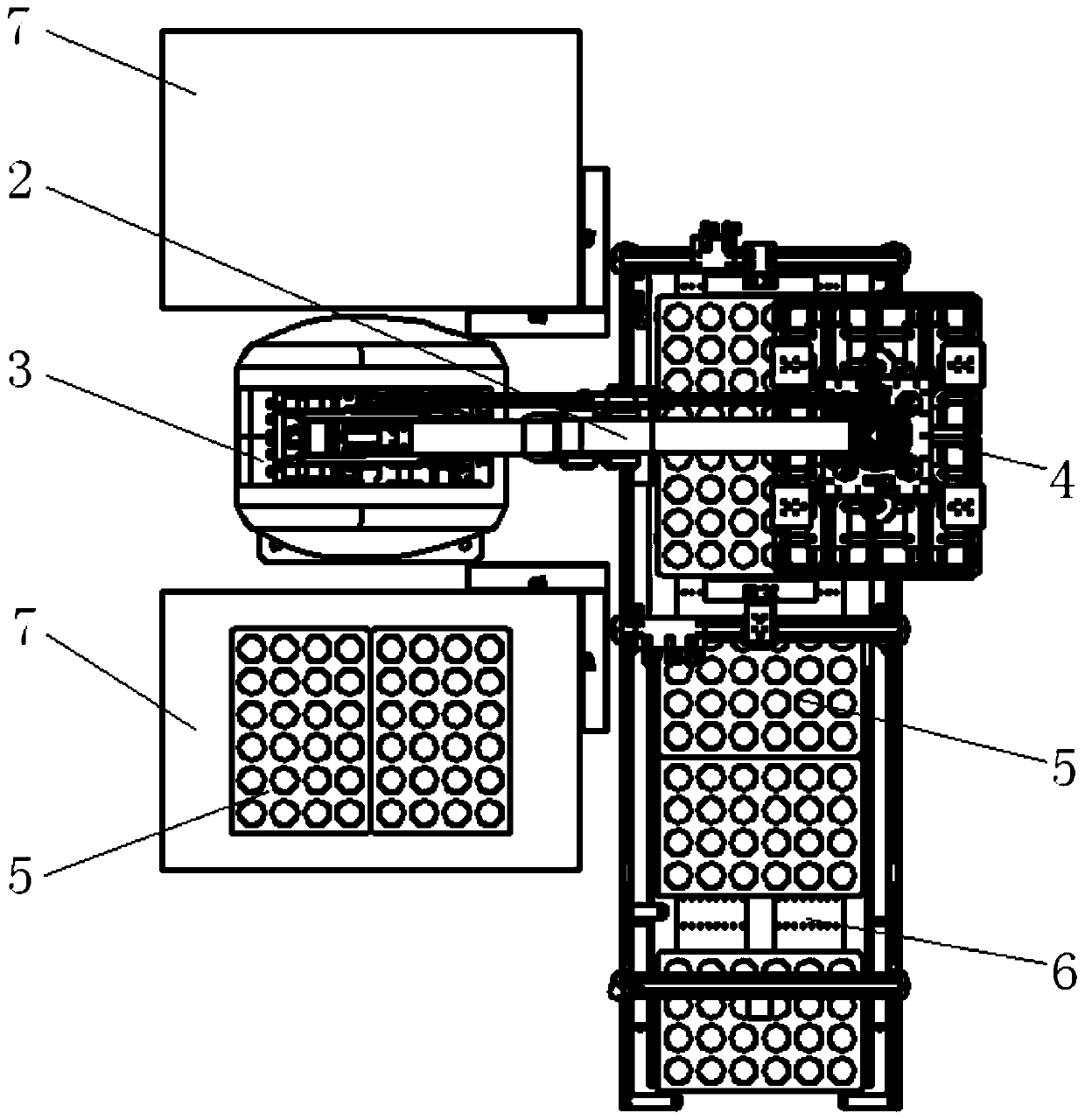

[0030] Refer to attached figure 1 and 2 As shown, the tray grabbing mechanism of the bread closing machine in this embodiment is used to automatically collect the trays conveyed on the tray conveyor belt. on status.

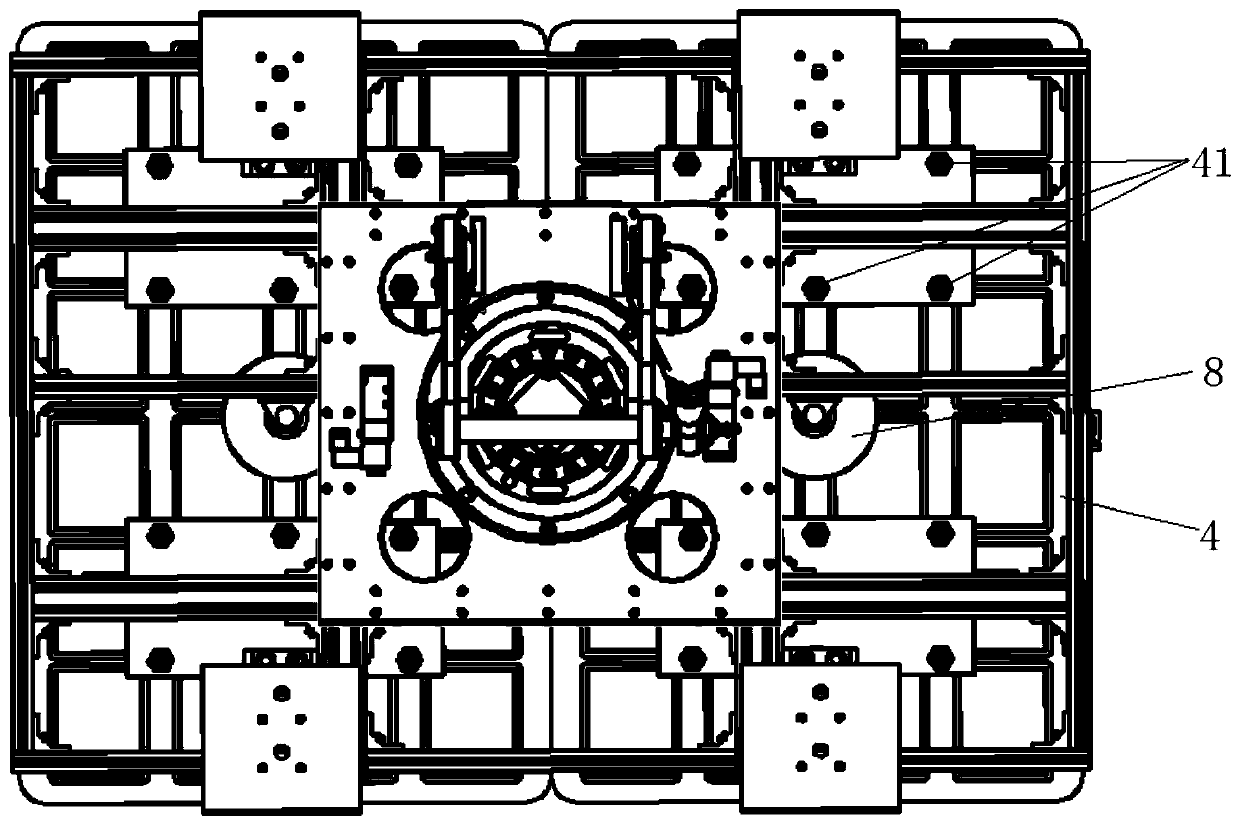

[0031] In order to realize fast and automatic tray collection, the tray grabbing mechanism of the bread closing machine in this embodiment is arranged next to the tray conveyor belt 6, which includes a base 1, a robot arm 2 and its control mechanism 3, and one end of the robot arm 2 is rotatable with the base 1 connected, and the other end is rotatably connected with the upper surface of the grabbing frame 4. The mechanical arm 2 of this embodiment adopts the existing four-link structure mechanical arm, and under the action of the control mechanism 3, it drives the grabbing frame 4 and the pallet 5 it grabs to move, and is used to grab the pallet 5 from the conveyor belt 6 to the On the stacking tray 7, the automatic stacking of pallets is realized.

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com